Content Menu

● Understanding Powder Hoppers: Purpose and Types

>> What Is a Powder Hopper?

>> Common Types of Powder Hoppers

● How the Right Powder Hopper Saves Time

>> Reducing Downtime with Consistent Flow

>> Streamlining Material Handling and Transfer

>> Minimizing Cleaning and Maintenance Time

● How the Right Powder Hopper Saves Cost

>> Minimizing Waste and Product Loss

>> Enhancing Product Quality and Reducing Defects

>> Lowering Energy and Labor Costs

>> Extending Equipment Lifespan

● Key Factors to Consider When Choosing a Powder Hopper

>> Powder Characteristics

>> Hopper Design Features

>> Integration and Automation Capability

>> Regulatory and Safety Requirements

● Common Challenges and How the Right Hopper Helps Overcome Them

>> Bridging and Rat-holing

>> Dust Control

>> Handling Variable Powder Properties

● Case Studies: Real-World Benefits of Correct Powder Hopper Choices

>> Pharmaceutical Manufacturing

>> Food Processing Industry

>> Chemical Production

● Tips for Maintaining Your Powder Hopper for Longevity

>> Regular Inspection and Cleaning

>> Monitor Powder Quality

>> Replace Worn Components Promptly

>> Train Operators Thoroughly

● Conclusion

● Frequently Asked Questions

In many industrial and manufacturing processes, powder handling is a critical operation that requires efficiency, precision, and reliability. A powder hopper, an essential component in the storage, dispensing, and feeding of powdered materials, plays a significant role in these processes. Selecting the right powder hopper can lead to substantial time and cost savings by optimizing workflow, reducing waste, and improving product quality. This article delves into the importance of choosing the correct powder hopper, exploring its impact on manufacturing efficiency, common challenges, and practical considerations to help industries make informed decisions.

Understanding Powder Hoppers: Purpose and Types

What Is a Powder Hopper?

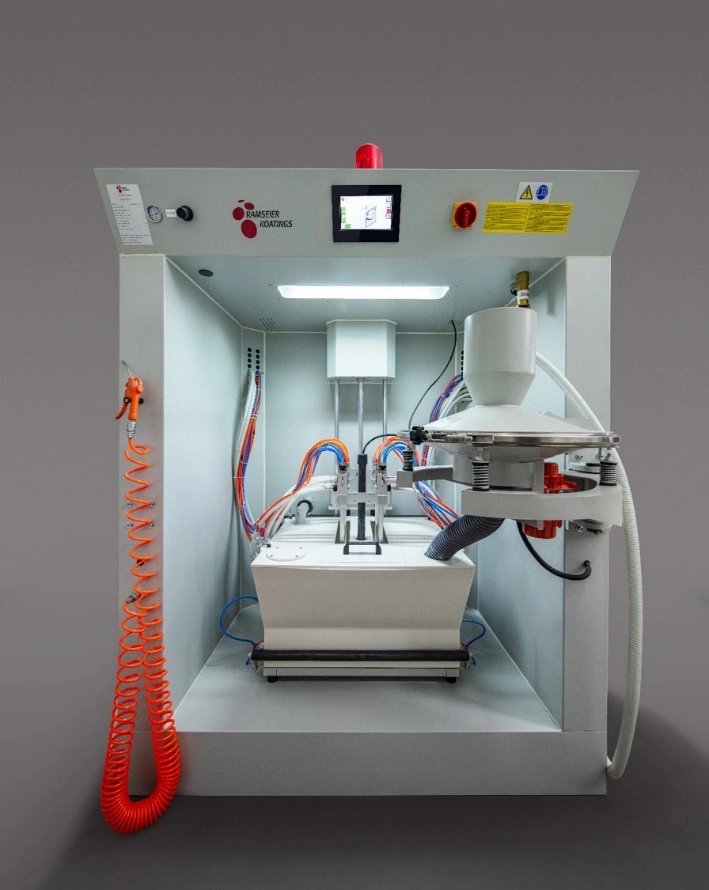

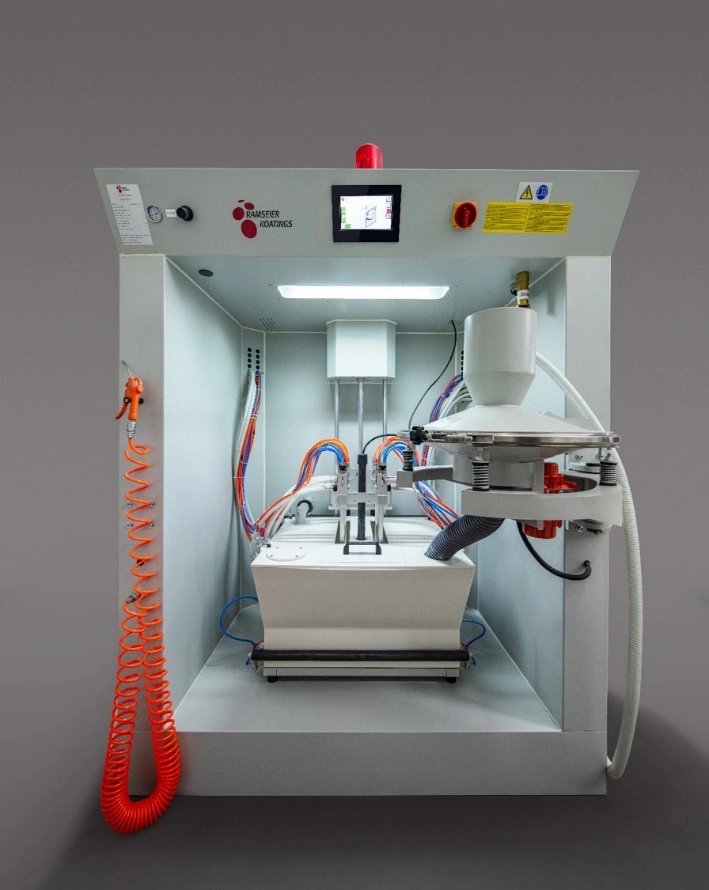

A powder hopper is a container designed to hold and dispense powdered materials in a controlled manner. It serves as an intermediary storage unit between the bulk powder supply and the processing or packaging machinery. The hopper's design ensures consistent flow, prevents material clumping or bridging, and maintains the quality of the powder during transfer.

Common Types of Powder Hoppers

- Gravity-fed hoppers: Use gravity to facilitate powder movement, ideal for free-flowing powders but may have issues with sticky or cohesive powders.

- Pneumatic hoppers: Employ air pressure to move powders, suitable for delicate or fine powders requiring gentle handling.

- Vacuum hoppers: Utilize vacuum pressure for powder transfer, often used when contamination control or dust suppression is vital.

- Vibratory hoppers: Incorporate vibration to prevent powder compaction and ensure steady flow, helpful for powders prone to bridging.

Each type offers unique advantages depending on powder characteristics, production speed, and environmental conditions.

How the Right Powder Hopper Saves Time

Reducing Downtime with Consistent Flow

One of the primary ways the right powder hopper saves time is by ensuring a consistent and uninterrupted powder flow. An appropriately designed hopper prevents common issues such as bridging (where powder forms a bridge over the hopper opening) or rat-holing (channeling of powder inside the hopper), which can cause blockages. These interruptions may halt production lines, requiring labor-intensive clearing and cleaning processes.

Streamlining Material Handling and Transfer

Choosing a hopper that matches the specific powder properties and production process allows smoother material handling. For example, a vibratory hopper can continuously break up compacted powder, enabling faster discharge rates. Likewise, pneumatic or vacuum hoppers facilitate quick transfer over longer distances without manual intervention, reducing transfer time and labor requirements.

Minimizing Cleaning and Maintenance Time

Powder hoppers made of materials that resist powder adhesion or corrosion simplify cleaning routines. Custom surface coatings or polished finishes reduce residue buildup, thereby reducing downtime between production batches. Additionally, hoppers with easy-access doors or modular components accelerate maintenance, allowing work to be done without lengthy disassembly.

How the Right Powder Hopper Saves Cost

Minimizing Waste and Product Loss

Inaccurate powder dispensing and inconsistent flow often lead to powder spillage or leftover residues inside hoppers. A properly sized and designed hopper reduces powder waste by ensuring accurate dosing and complete discharge. Precision in powder handling translates directly into cost savings as raw materials are expensive, and waste reduction improves overall material utilization.

Enhancing Product Quality and Reducing Defects

Incorrect flow can cause segregation of powder components or inconsistent mix ratios, compromising product quality. By maintaining a steady and uniform powder flow, the right hopper improves the homogeneity of the blends and downstream processes. Higher product quality diminishes the costs related to rejects, reworks, and customer returns.

Lowering Energy and Labor Costs

Efficient hoppers cut down the need for manual handling and reduce energy consumption by preventing blockages and system inefficiencies. Vibratory or pneumatic systems can optimize energy use compared to brute force mechanical feeders. Additionally, labor cost reductions occur due to less intervention needed to clear jams, refill hoppers, or perform maintenance frequently.

Extending Equipment Lifespan

Hoppers that reduce stress on connected machinery (e.g., feeders, conveyors) contribute to longer operational life of the entire production line. Fewer breakdowns and less wear and tear mean savings in repair, replacement, and production downtime costs.

Key Factors to Consider When Choosing a Powder Hopper

Powder Characteristics

- Particle size and distribution: Fine powders may require smooth, non-adhesive surfaces and vibration to avoid clumping.

- Flowability: Powders that easily form bridges or rat-holes need special hopper shapes or aeration.

- Moisture content: High moisture can lead to caking, demanding heated or ventilated hoppers.

- Chemical properties: Corrosive powders need corrosion-resistant materials to prolong hopper life.

Hopper Design Features

- Shape: Conical or wedge shapes help gravity flow for powders that bridge easily.

- Material: Stainless steel, aluminum, or coated metals suit different powders and hygiene requirements.

- Capacity: Size should balance the frequency of filling with the space available.

- Discharge mechanism: Valves, rotary feeders, or augers can control flow rate precisely.

Integration and Automation Capability

- Compatibility with existing machinery and control systems allows automation, reducing manual errors and improving efficiency.

- Sensors to monitor material levels and flow conditions enable timely interventions.

Regulatory and Safety Requirements

- Food, pharmaceutical, or chemical industries often require sanitary designs that meet specific standards.

- Dust control and explosion-proof designs may be necessary to ensure workplace safety.

Common Challenges and How the Right Hopper Helps Overcome Them

Bridging and Rat-holing

Bridging occurs when powders form a dome or arch obstructing the outlet. Rat-holing happens when powder flows only through a narrow channel, leaving unused powder stuck to the hopper walls. Choosing a hopper with the right geometry, surface finish, and vibration or aeration can break these blockages before they halt production.

Dust Control

Powder dust can pose health risks and cause product loss. Hoppers with sealed designs, dust extraction ports, or integrated filter systems reduce airborne dust, improving operator safety and workplace cleanliness.

Handling Variable Powder Properties

Inconsistencies in powder batches, such as moisture variation or particle size changes, can affect flow behavior. Flexible hopper designs with adjustable agitation or aeration allow operators to adapt to changing powder properties, maintaining stable process performance.

Case Studies: Real-World Benefits of Correct Powder Hopper Choices

Pharmaceutical Manufacturing

A pharmaceutical company replaced gravity-fed hoppers with vacuum-assisted hoppers featuring polished stainless steel interiors. This change reduced product residue by 30%, minimized cleaning times, and ensured consistent powder flow critical for dosage accuracy. The result was improved batch consistency and significant labor savings.

Food Processing Industry

A food manufacturer handling sticky sugar powders switched to vibratory hoppers that prevented bridging and allowed continuous flow. The upgrade resulted in a reduction of production stoppages by 40% and lowered material waste. Additionally, hygiene standards improved due to easier hopper cleaning.

Chemical Production

In a chemical plant, the introduction of corrosion-resistant, heated hoppers prevented powder caking caused by moisture exposure. It eliminated frequent hopper clogging and enhanced transfer efficiency, saving costs related to lost production hours and maintenance.

Tips for Maintaining Your Powder Hopper for Longevity

Regular Inspection and Cleaning

Schedule inspections to identify wear or buildup early. Clean using appropriate methods to avoid powder residue accumulation, which affects flow.

Monitor Powder Quality

Keep an eye on moisture levels and particle size consistency to ensure stable hopper performance.

Replace Worn Components Promptly

Seals, valves, and agitators should be replaced as needed to maintain reliability.

Train Operators Thoroughly

Knowledgeable operators can recognize signs of hopper inefficiency and take corrective actions, reducing downtime.

Conclusion

Choosing the right powder hopper is more than just a purchasing decision—it is a strategic move that affects time efficiency and cost-effectiveness in any powder handling process. By understanding powder characteristics, hopper design, and operational requirements, manufacturers can select equipment that minimizes downtime, reduces waste, ensures product quality, and cuts operational costs. Investing in the correct powder hopper ultimately leads to smoother operations, better product outcomes, and improved profitability.

Frequently Asked Questions

Q1: How does powder hopper design impact production speed?

A1: The design determines powder flow consistency. Proper hopper shape and discharge mechanisms prevent blockages, keeping production lines running smoothly and quickly.

Q2: What materials are best for powder hoppers handling corrosive powders?

A2: Stainless steel or specially coated metals are preferred, as they resist corrosion and maintain hopper longevity.

Q3: Can powder hoppers handle multiple types of powders simultaneously?

A3: Some hoppers can be adjusted with features like variable vibration or aeration to accommodate different powder properties, but typically one hopper is optimized for a specific powder type.

Q4: How do powder hoppers contribute to product quality?

A4: They ensure uniform powder flow and reduce segregation, resulting in consistent blends and better final product quality.

Q5: What maintenance is essential for prolonging hopper life?

A5: Regular inspection, cleaning, monitoring of powder quality, timely replacement of components, and operator training are crucial for long-term performance.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.