Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Does a Vibrating Sieve Work?

● Key Specifications of Vibrating Sieves

>> 1. Sieve Diameter

>> 2. Number of Decks

>> 3. Mesh Size

>> 4. Capacity

>> 5. Vibration Frequency and Amplitude

>> 6. Material Construction

>> 7. Noise Level

>> 8. Anti-Blinding Features

● Applications of Vibrating Sieves

>> 1. Food Industry

>> 2. Pharmaceuticals

>> 3. Chemical Processing

>> 4. Mining and Minerals

>> 5. Recycling

● Choosing the Right Vibrating Sieve

● Maintenance of Vibrating Sieves

>> Common Maintenance Practices

● Conclusion

>> Frequently Asked Questions

Vibrating sieves are essential equipment in various industries, particularly for the processing of powders. They are designed to separate materials based on size, ensuring that the final product meets specific quality standards. This article delves into the key specifications of vibrating sieves, their operational principles, and their applications across different sectors.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

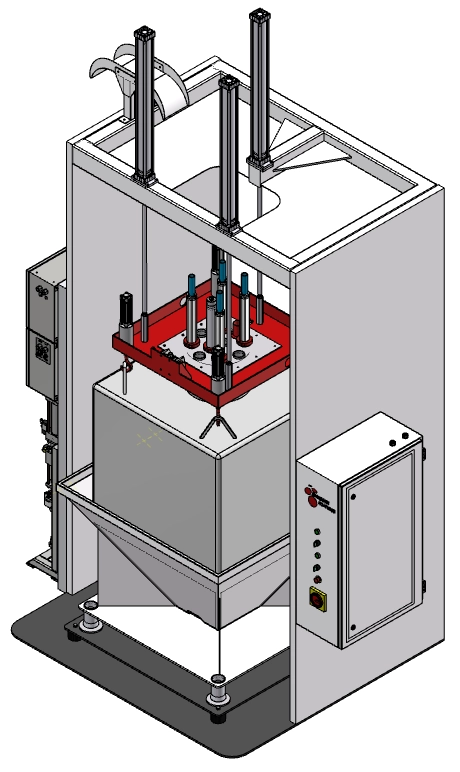

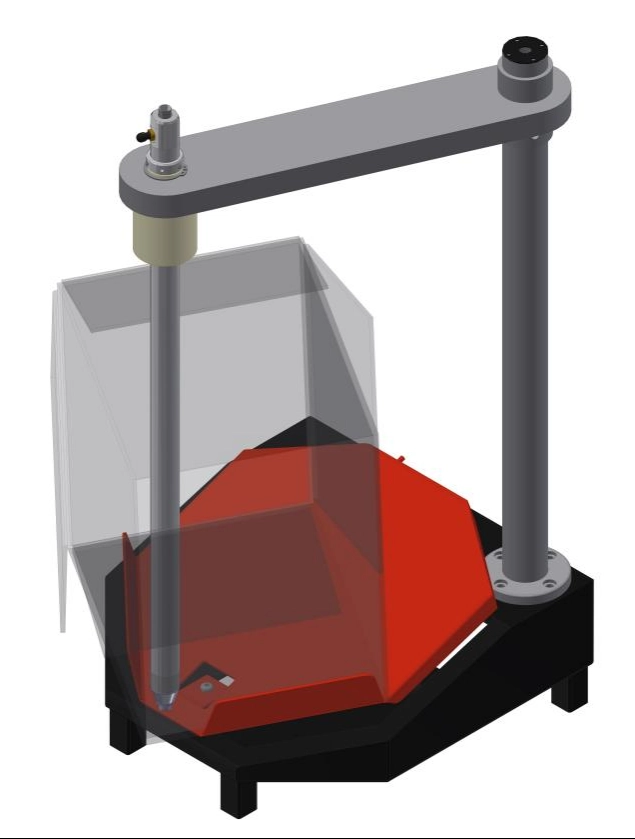

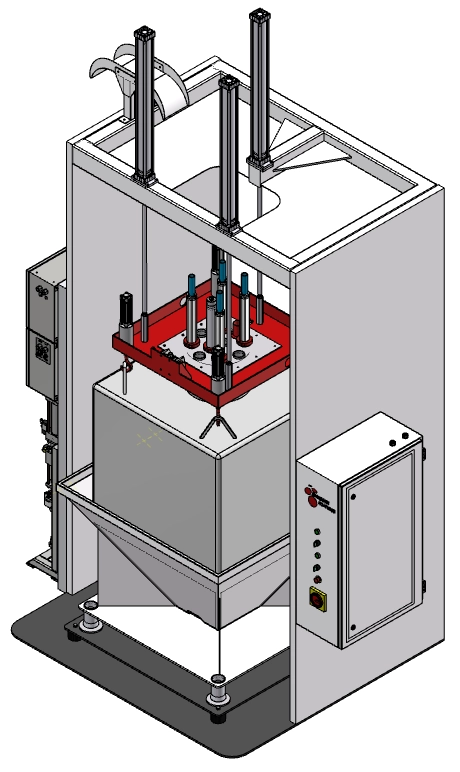

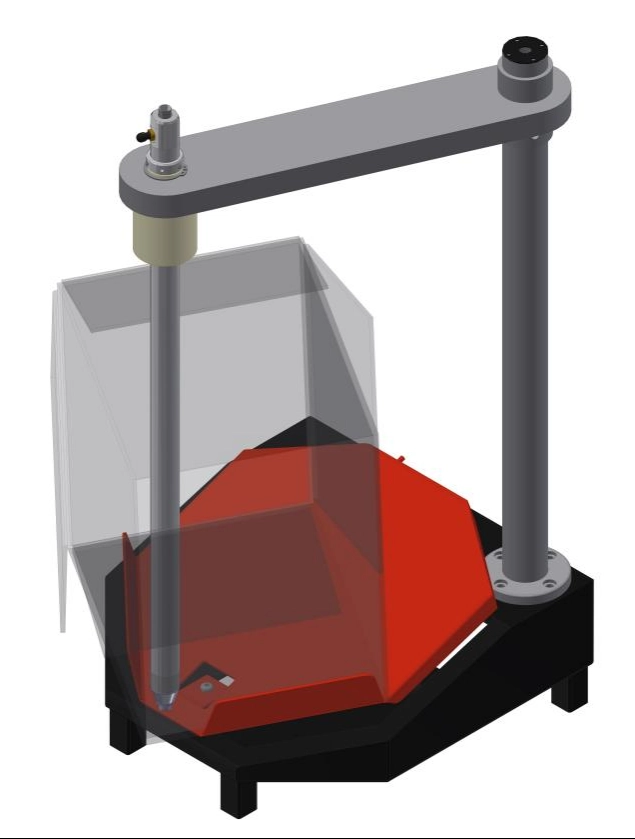

A vibrating sieve is a mechanical device that uses vibration to separate materials based on their size. It consists of a screen or mesh that allows smaller particles to pass through while retaining larger ones. The vibration helps to keep the material moving, preventing blockages and ensuring efficient separation.

How Does a Vibrating Sieve Work?

The operation of a vibrating sieve is based on the principle of vibration. A motor generates vibrations that are transmitted to the sieve. This motion causes the material on the screen to move in a controlled manner, allowing particles to pass through the mesh openings. The design of the sieve, including the mesh size and the angle of inclination, can be adjusted to optimize performance for different materials.

Key Specifications of Vibrating Sieves

When selecting a vibrating sieve for powder processing, several key specifications should be considered:

1. Sieve Diameter

The diameter of the sieve is a crucial specification that affects its capacity and efficiency. Common diameters range from 400 mm to 1500 mm. Larger diameters can handle higher volumes of material, making them suitable for industrial applications.

2. Number of Decks

Vibrating sieves can have multiple decks, typically ranging from one to four. Each deck can be fitted with different mesh sizes, allowing for the separation of materials into various grades simultaneously. This feature is particularly beneficial in industries where precise particle size distribution is required.

3. Mesh Size

The mesh size determines the smallest particle that can pass through the sieve. Mesh sizes can vary widely, from as fine as 20 microns to as coarse as several millimeters. The choice of mesh size depends on the specific application and the characteristics of the powder being processed.

4. Capacity

The capacity of a vibrating sieve is usually measured in tons per hour (TPH). This specification indicates how much material the sieve can process within a given time frame. For instance, some industrial vibrating sieves can handle capacities ranging from 100 kg/h to over 10 tons/h, depending on the model and configuration.

5. Vibration Frequency and Amplitude

The frequency and amplitude of the vibrations are critical for effective separation. Most vibrating sieves operate at frequencies between 1500 to 3000 RPM. The amplitude can also be adjusted to suit different materials, with higher amplitudes typically used for larger particles.

6. Material Construction

The construction material of the sieve affects its durability and suitability for different applications. Common materials include stainless steel (304 or 316L) and carbon steel. Stainless steel is preferred for food and pharmaceutical applications due to its corrosion resistance and ease of cleaning.

7. Noise Level

Noise generated during operation is an important consideration, especially in environments where noise regulations are strict. Many modern vibrating sieves are designed to operate at noise levels below 80 dB, making them suitable for use in various settings.

8. Anti-Blinding Features

To enhance efficiency, many vibrating sieves are equipped with anti-blinding devices. These can include bouncing balls, ultrasonic cleaning systems, or specially designed mesh that reduces the likelihood of particles clogging the openings.

Applications of Vibrating Sieves

Vibrating sieves are used in a wide range of industries, including:

1. Food Industry

In the food industry, vibrating sieves are used to ensure the quality of products by removing impurities and ensuring uniform particle size. They are commonly used for flour, sugar, and spice processing.

2. Pharmaceuticals

Pharmaceutical companies utilize vibrating sieves to ensure that powders meet strict quality standards. The ability to separate fine particles is crucial for the production of tablets and capsules.

3. Chemical Processing

In chemical processing, vibrating sieves are used to separate raw materials and finished products. They help in the classification of powders and granules, ensuring that the final product meets specifications.

4. Mining and Minerals

Vibrating sieves play a vital role in the mining industry, where they are used to separate valuable minerals from waste material. They help in the efficient processing of ores and other materials.

5. Recycling

In recycling operations, vibrating sieves are used to separate different materials, such as metals, plastics, and glass. This separation is essential for effective recycling and waste management.

Choosing the Right Vibrating Sieve

When selecting a vibrating sieve, it is essential to consider the specific requirements of your application. Factors such as the type of material, desired particle size, and production capacity should guide your choice. Additionally, consulting with manufacturers or suppliers can provide valuable insights into the best options available.

Maintenance of Vibrating Sieves

Proper maintenance is crucial for the longevity and efficiency of vibrating sieves. Regular cleaning, inspection of the mesh, and checking the motor and vibration settings can help prevent issues and ensure optimal performance.

Common Maintenance Practices

- Regular Cleaning: Ensure that the sieve is cleaned after each use to prevent contamination and buildup of materials.

- Inspection: Regularly check the mesh for wear and tear, replacing it as necessary to maintain efficiency.

- Motor Maintenance: Inspect the motor and vibration components to ensure they are functioning correctly and replace any worn parts.

Conclusion

Vibrating sieves are indispensable tools in the processing of powders across various industries. Understanding their key specifications, including sieve diameter, mesh size, capacity, and construction material, is essential for selecting the right equipment for your needs. By considering these factors and maintaining the equipment properly, businesses can enhance their operational efficiency and product quality.

Frequently Asked Questions

1. What is the typical lifespan of a vibrating sieve?

- The lifespan of a vibrating sieve can vary based on usage and maintenance but typically ranges from 5 to 10 years.

2. Can vibrating sieves be used for wet materials?

- Yes, many vibrating sieves are designed to handle both dry and wet materials, making them versatile for various applications.

3. What industries commonly use vibrating sieves?

- Vibrating sieves are widely used in the food, pharmaceutical, chemical, mining, and recycling industries.

4. How do I determine the right mesh size for my application?

- The right mesh size depends on the specific material and the desired particle size. Testing with different mesh sizes can help identify the best option.

5. Are there energy-efficient options for vibrating sieves?

- Yes, many modern vibrating sieves are designed to be energy-efficient, utilizing optimized motors and vibration settings to reduce power consumption.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.