Content Menu

● Introduction

● Understanding Powder Particle Size

>> What is Powder Particle Size?

>> Importance of Consistent Particle Size

● The Mechanism of Vibrating Sieves

>> How Vibrating Sieves Work

>> Types of Vibrating Sieves

● Applications of Vibrating Sieves

>> Pharmaceutical Industry

>> Food Processing

>> Chemical Manufacturing

● Benefits of Using Vibrating Sieves

>> Enhanced Efficiency

>> Improved Product Quality

>> Reduced Waste

>> Versatility

● Challenges and Considerations

>> Maintenance and Calibration

>> Material Characteristics

>> Cost Considerations

● Future Trends in Vibrating Sieve Technology

>> Automation and Smart Technology

>> Eco-Friendly Designs

>> Advanced Materials

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of a vibrating sieve?

>> 2. How does particle size affect product quality?

>> 3. What types of materials can be processed with vibrating sieves?

>> 4. How often should vibrating sieves be maintained?

>> 5. What are the future trends in vibrating sieve technology?

Introduction

In various industries, from pharmaceuticals to food processing, the consistency of powder particle size is crucial for product quality and performance. One of the most effective tools for achieving this consistency is the vibrating sieve. This article explores the role of vibrating sieves in ensuring uniform powder particle size, discussing their mechanisms, applications, and benefits.

Understanding Powder Particle Size

What is Powder Particle Size?

Powder particle size refers to the dimensions of individual particles within a powder. It is a critical parameter that influences the behavior of powders in various applications, including flowability, solubility, and reactivity. The size distribution of particles can significantly affect the performance of the final product.

Importance of Consistent Particle Size

Consistent particle size is essential for several reasons:

- Quality Control: Uniform particle size ensures that products meet specific quality standards, which is particularly important in regulated industries like pharmaceuticals.

- Performance: In applications such as drug formulation, the efficacy of a product can depend on the particle size of its components.

- Processing Efficiency: Consistent particle sizes improve the efficiency of mixing, blending, and other processing operations.

The Mechanism of Vibrating Sieves

How Vibrating Sieves Work

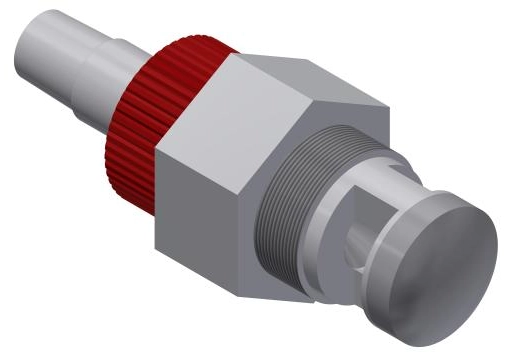

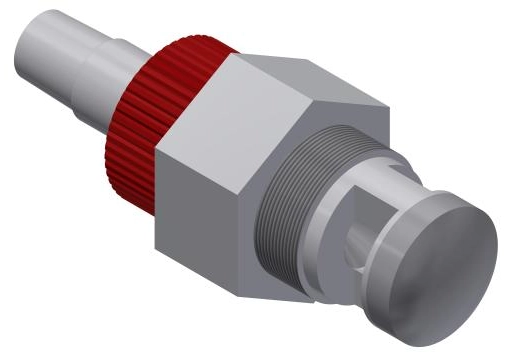

Vibrating sieves operate on the principle of mechanical vibration. They consist of a mesh screen that separates particles based on size. When the sieve vibrates, it creates a dynamic motion that allows smaller particles to pass through the mesh while larger particles remain on top.

Types of Vibrating Sieves

There are several types of vibrating sieves, each designed for specific applications:

- Linear Vibrating Sieves: These are commonly used for dry materials and operate in a straight line, providing efficient separation.

- Circular Vibrating Sieves: These sieves use a circular motion to separate particles and are effective for both dry and wet materials.

- Ultrasonic Vibrating Sieves: These incorporate ultrasonic technology to enhance the separation of fine particles, preventing clogging and ensuring a more consistent output.

Applications of Vibrating Sieves

Pharmaceutical Industry

In the pharmaceutical industry, the uniformity of powder particle size is critical for drug formulation. Vibrating sieves are used to ensure that active pharmaceutical ingredients (APIs) and excipients are of the correct size, which affects the dissolution rate and bioavailability of the drug.

Food Processing

In food processing, vibrating sieves are employed to ensure that ingredients such as flour, sugar, and spices are of consistent particle size. This consistency is vital for maintaining product quality and ensuring even mixing and baking.

Chemical Manufacturing

Chemical manufacturers use vibrating sieves to separate and classify powders, ensuring that the final products meet specific size requirements. This is particularly important in industries where particle size can affect chemical reactivity and product stability.

Benefits of Using Vibrating Sieves

Enhanced Efficiency

Vibrating sieves improve processing efficiency by quickly and effectively separating particles. This speed is crucial in high-volume production environments where time is of the essence.

Improved Product Quality

By ensuring consistent particle size, vibrating sieves contribute to higher product quality. This is particularly important in industries where product performance is directly linked to particle size.

Reduced Waste

Vibrating sieves help minimize waste by ensuring that only particles of the desired size are processed. This reduces the need for reprocessing and enhances overall production efficiency.

Versatility

Vibrating sieves are versatile and can be used for a wide range of materials, including powders, granules, and even liquids. This adaptability makes them a valuable tool in various industries.

Challenges and Considerations

Maintenance and Calibration

While vibrating sieves are effective, they require regular maintenance and calibration to ensure optimal performance. Operators must monitor the condition of the mesh and the vibration mechanism to prevent issues that could affect particle size consistency.

Material Characteristics

The characteristics of the material being processed can impact the effectiveness of vibrating sieves. Factors such as moisture content, particle shape, and density can influence how well the sieve performs.

Cost Considerations

Investing in high-quality vibrating sieves can be costly. However, the long-term benefits in terms of efficiency and product quality often outweigh the initial investment.

Future Trends in Vibrating Sieve Technology

Automation and Smart Technology

The future of vibrating sieve technology lies in automation and smart technology. Integrating sensors and data analytics can enhance the monitoring and control of particle size, leading to even greater consistency and efficiency.

Eco-Friendly Designs

As industries move towards sustainability, there is a growing demand for eco-friendly vibrating sieve designs. Innovations that reduce energy consumption and waste will likely become more prevalent.

Advanced Materials

The development of advanced materials for sieve construction can improve durability and performance. These materials can withstand harsher processing conditions and extend the lifespan of the equipment.

Conclusion

Vibrating sieves play a crucial role in ensuring consistent powder particle size across various industries. Their ability to enhance efficiency, improve product quality, and reduce waste makes them an invaluable tool in modern manufacturing processes. As technology continues to evolve, vibrating sieves will likely become even more sophisticated, further enhancing their effectiveness in maintaining particle size consistency.

Frequently Asked Questions

1. What is the primary function of a vibrating sieve?

The primary function of a vibrating sieve is to separate particles based on size, ensuring that only particles of the desired size pass through the mesh screen.

2. How does particle size affect product quality?

Particle size can influence various properties of a product, including flowability, solubility, and reactivity, which are critical for performance in applications like pharmaceuticals and food processing.

3. What types of materials can be processed with vibrating sieves?

Vibrating sieves can process a wide range of materials, including powders, granules, and liquids, making them versatile for various industrial applications.

4. How often should vibrating sieves be maintained?

Regular maintenance is essential for optimal performance. Operators should inspect the mesh and vibration mechanism frequently and perform calibration as needed.

5. What are the future trends in vibrating sieve technology?

Future trends include automation, eco-friendly designs, and the use of advanced materials to enhance performance and sustainability in vibrating sieve technology.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.