Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Does a Vibrating Sieve Work?

● The Role of Vibrating Sieves in Coating Lines

>> Importance of Powder Quality

>> Enhancing Automation

● Benefits of Using Vibrating Sieves

>> Improved Efficiency

>> Consistent Product Quality

>> Reduced Waste

>> Versatility

● Types of Vibrating Sieves

>> Circular Vibrating Sieves

>> Linear Vibrating Sieves

>> Ultrasonic Vibrating Sieves

● Implementing Vibrating Sieves in Coating Lines

>> Integration with Existing Systems

>> Maintenance and Care

● Challenges and Solutions

>> Common Challenges

>> Solutions

● Future Trends in Vibrating Sieves

>> Technological Advancements

>> Sustainability Considerations

● Conclusion

>> Frequently Asked Questions

In the modern manufacturing landscape, automation plays a crucial role in enhancing efficiency, consistency, and quality. One of the key components in automated processes, particularly in coating lines, is the vibrating sieve. This article explores the significance of vibrating sieves in powder handling, their operational principles, benefits, and their impact on automation in coating lines.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

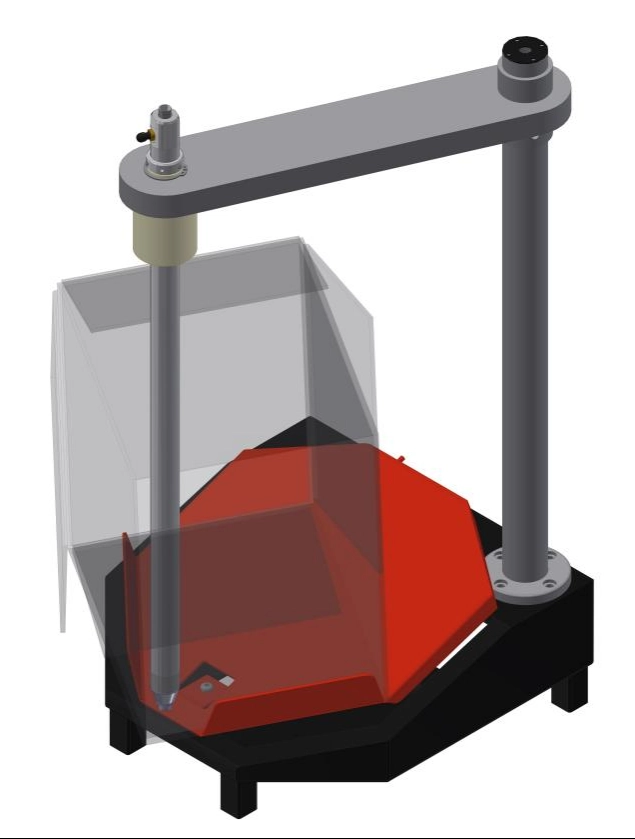

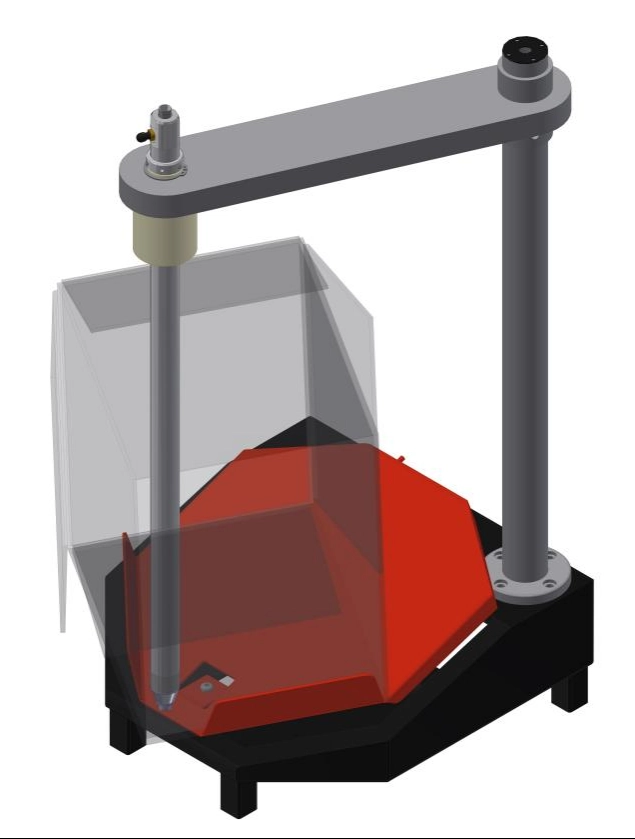

A vibrating sieve is a mechanical device used to separate materials based on size. It employs vibration to facilitate the movement of powder through a mesh screen, allowing smaller particles to pass through while larger ones are retained. This process is essential in various industries, including food processing, pharmaceuticals, and coatings.

How Does a Vibrating Sieve Work?

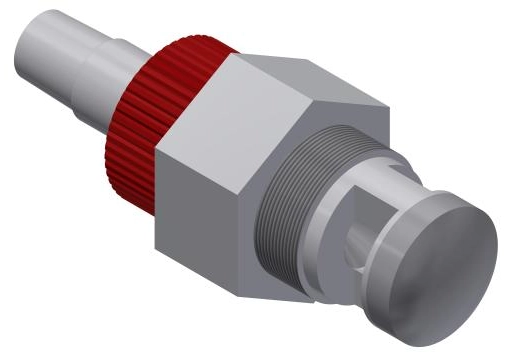

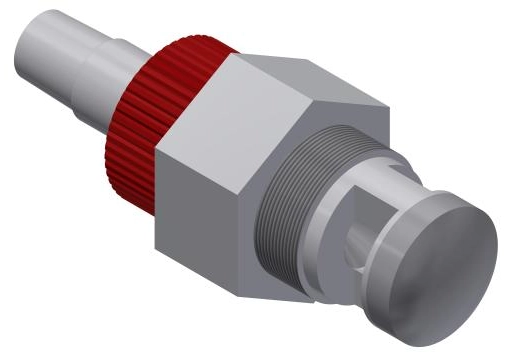

The operation of a vibrating sieve is relatively straightforward. The sieve consists of a screen or mesh that is mounted on a frame. An electric motor generates vibrations, causing the sieve to oscillate. As the powder is fed onto the sieve, the vibrations help to stratify the particles, allowing finer materials to pass through the mesh while coarser particles remain on top. This separation process is crucial for ensuring the quality and consistency of the final product.

The Role of Vibrating Sieves in Coating Lines

Importance of Powder Quality

In coating applications, the quality of the powder is paramount. Contaminants or oversized particles can lead to defects in the coating process, affecting adhesion, finish, and overall performance. Vibrating sieves help maintain powder quality by removing impurities and ensuring uniform particle size distribution.

Enhancing Automation

The integration of vibrating sieves into coating lines significantly enhances automation. By automating the sieving process, manufacturers can reduce manual labor, minimize human error, and increase throughput. This automation is particularly beneficial in high-volume production environments where consistency and speed are critical.

Benefits of Using Vibrating Sieves

Improved Efficiency

Vibrating sieves improve operational efficiency by streamlining the powder handling process. The continuous flow of material through the sieve allows for uninterrupted production, reducing downtime associated with manual sieving.

Consistent Product Quality

By ensuring that only properly sized particles are used in the coating process, vibrating sieves contribute to consistent product quality. This consistency is vital for meeting customer expectations and regulatory standards.

Reduced Waste

The use of vibrating sieves minimizes waste by ensuring that only the desired particle sizes are used in production. This not only conserves materials but also reduces costs associated with rework and scrap.

Versatility

Vibrating sieves are versatile and can be used for various types of powders, including those used in coatings, pharmaceuticals, and food products. This adaptability makes them an essential tool in many manufacturing processes.

Types of Vibrating Sieves

Circular Vibrating Sieves

Circular vibrating sieves are the most common type used in industrial applications. They feature a circular motion that effectively stratifies materials. These sieves are ideal for applications requiring high throughput and efficient separation.

Linear Vibrating Sieves

Linear vibrating sieves operate with a linear motion, which is effective for separating materials with a high degree of accuracy. They are often used in applications where precise particle size control is necessary.

Ultrasonic Vibrating Sieves

Ultrasonic vibrating sieves utilize ultrasonic waves to enhance the sieving process. This technology is particularly effective for fine powders that tend to clump together, ensuring a more efficient separation.

Implementing Vibrating Sieves in Coating Lines

Integration with Existing Systems

Integrating vibrating sieves into existing coating lines requires careful planning. Manufacturers must consider factors such as the size of the sieve, the type of powder being processed, and the overall layout of the production line. Proper integration ensures that the sieving process complements other automated systems, enhancing overall efficiency.

Maintenance and Care

Regular maintenance of vibrating sieves is essential to ensure optimal performance. This includes routine cleaning, inspection of the mesh for wear and tear, and checking the motor and vibration settings. Proper maintenance extends the lifespan of the equipment and ensures consistent product quality.

Challenges and Solutions

Common Challenges

While vibrating sieves offer numerous benefits, they are not without challenges. Common issues include mesh clogging, inadequate vibration, and wear and tear on components. These challenges can impact the efficiency and effectiveness of the sieving process.

Solutions

To address these challenges, manufacturers can implement several strategies. Regular maintenance schedules can help prevent issues related to wear and tear. Additionally, using the appropriate mesh size for the specific powder can reduce clogging and improve flow rates. Investing in high-quality vibrating sieves with adjustable vibration settings can also enhance performance.

Future Trends in Vibrating Sieves

Technological Advancements

The future of vibrating sieves is likely to be shaped by technological advancements. Innovations such as smart sensors and IoT integration can provide real-time monitoring of the sieving process, allowing for immediate adjustments and improved efficiency.

Sustainability Considerations

As industries move towards more sustainable practices, vibrating sieves will play a role in reducing waste and improving resource efficiency. By ensuring that only the necessary materials are used in production, manufacturers can contribute to more sustainable operations.

Conclusion

Vibrating sieves are a vital component in the automation of coating lines, enhancing efficiency, consistency, and product quality. Their ability to separate powders effectively makes them indispensable in various industries. As technology continues to evolve, the role of vibrating sieves will only become more significant, driving innovation and sustainability in manufacturing processes.

Frequently Asked Questions

1. What types of materials can be processed with vibrating sieves?

- Vibrating sieves can process a wide range of materials, including powders used in coatings, pharmaceuticals, and food products.

2. How often should vibrating sieves be maintained?

- Regular maintenance should be performed based on usage, but a general guideline is to inspect and clean the sieves at least once a month.

3. What are the signs of a clogged sieve?

- Signs of a clogged sieve include reduced flow rates, inconsistent product quality, and visible buildup of material on the mesh.

4. Can vibrating sieves be integrated with other automated systems?

- Yes, vibrating sieves can be integrated with various automated systems, enhancing overall production efficiency.

5. What advancements are expected in vibrating sieve technology?

- Future advancements may include smart sensors for real-time monitoring and IoT integration for improved process control.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.