Content Menu

● Understanding Vibrating Sieves

>> What Are Vibrating Sieves?

>> How Do They Work?

● Safety Risks Associated with Vibrating Sieves

>> Dust Exposure

>> Mechanical Hazards

>> Contamination Risks

● Essential Safety Measures

>> Personal Protective Equipment (PPE)

>>> Importance of PPE

>>> Training on PPE Usage

>> Equipment Maintenance

>>> Regular Inspections

>>> Cleaning Protocols

>> Dust Control Measures

>>> Enclosed Systems

>>> Local Exhaust Ventilation

>> Emergency Procedures

>>> Establishing Protocols

>>> Regular Drills

>> Operator Training

>>> Comprehensive Training Programs

>>> Continuous Education

● Design Considerations for Safety

>> Choosing the Right Equipment

>> Compliance with Safety Standards

● Conclusion

>> Frequently Asked Questions

Vibrating sieves are essential equipment in various industries, particularly in powder handling processes. They are used to separate materials based on size, ensuring that only the desired particle sizes pass through. However, the operation of vibrating sieves comes with inherent risks, including dust exposure, mechanical hazards, and potential contamination. This article explores the safety measures that should be considered when using vibrating sieves in powder handling.

Understanding Vibrating Sieves

What Are Vibrating Sieves?

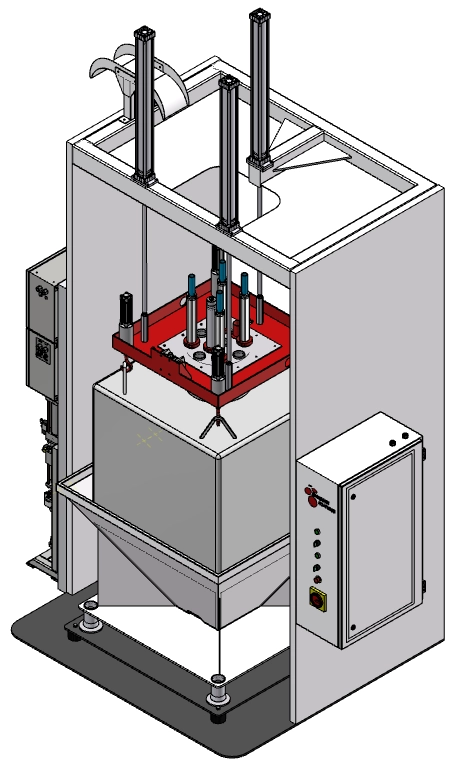

Vibrating sieves are mechanical devices that use vibration to separate particles of different sizes. They consist of a screen or mesh that allows smaller particles to pass through while retaining larger ones. These machines are widely used in industries such as food processing, pharmaceuticals, chemicals, and mining.

How Do They Work?

The operation of a vibrating sieve involves the application of mechanical vibrations to the screen. This vibration causes the material on the screen to move, allowing smaller particles to fall through the mesh while larger particles remain on top. The efficiency of this process depends on several factors, including the frequency and amplitude of the vibrations, the type of material being processed, and the design of the sieve.

Safety Risks Associated with Vibrating Sieves

Dust Exposure

One of the primary safety concerns when operating vibrating sieves is dust exposure. Fine powders can create airborne dust that poses health risks to operators. Prolonged exposure to certain powders can lead to respiratory issues and other health problems.

Mechanical Hazards

Vibrating sieves have moving parts that can pose mechanical hazards. Operators may be at risk of injury from moving components, especially if safety guards are not in place or if proper operating procedures are not followed.

Contamination Risks

In industries such as food and pharmaceuticals, contamination is a significant concern. If not properly maintained, vibrating sieves can become contaminated with residual materials from previous batches, leading to product quality issues.

Essential Safety Measures

Personal Protective Equipment (PPE)

Importance of PPE

Wearing appropriate personal protective equipment is crucial for operators working with vibrating sieves. PPE can include:

- Dust Masks: To protect against inhalation of fine particles.

- Safety Goggles: To shield the eyes from flying debris.

- Gloves: To protect hands from sharp edges and contaminants.

Training on PPE Usage

It is essential to train operators on the correct use of PPE. Regular reminders and checks can help ensure compliance and enhance safety.

Equipment Maintenance

Regular Inspections

Conducting regular inspections of vibrating sieves is vital for identifying potential issues before they lead to accidents. Operators should check for:

- Wear and tear on screens and frames.

- Loose or damaged components.

- Proper functioning of safety guards.

Cleaning Protocols

Establishing cleaning protocols is essential to prevent contamination. Operators should be trained to clean the equipment thoroughly after each use, ensuring that no residual materials remain.

Dust Control Measures

Enclosed Systems

Implementing enclosed systems can significantly reduce dust exposure. Enclosures prevent dust from escaping into the work environment, protecting operators and maintaining air quality.

Local Exhaust Ventilation

Installing local exhaust ventilation systems can help capture airborne dust at the source. This system draws dust away from the operator's breathing zone, minimizing exposure.

Emergency Procedures

Establishing Protocols

Developing clear emergency procedures is crucial for responding to accidents or equipment failures. These protocols should include:

- Steps to take in case of a dust explosion.

- Procedures for dealing with equipment malfunctions.

- Emergency contact information for quick access.

Regular Drills

Conducting regular emergency drills can help ensure that all operators are familiar with the procedures and can respond effectively in an emergency.

Operator Training

Comprehensive Training Programs

Providing comprehensive training for operators is essential for safe operation. Training should cover:

- Proper operating procedures for vibrating sieves.

- Safety protocols and the importance of PPE.

- Emergency response procedures.

Continuous Education

Ongoing education and training sessions can help keep operators updated on the latest safety practices and technologies.

Design Considerations for Safety

Choosing the Right Equipment

When selecting vibrating sieves, consider equipment designed with safety features. Look for:

- Dust-tight designs: To minimize dust exposure.

- Safety guards: To protect operators from moving parts.

- User-friendly controls: To reduce the risk of operator error.

Compliance with Safety Standards

Ensure that the vibrating sieves comply with relevant safety standards and regulations. This compliance can help mitigate risks and ensure a safer working environment.

Conclusion

Vibrating sieves play a crucial role in powder handling across various industries. However, their operation comes with risks that must be managed through effective safety measures. By implementing proper PPE, maintaining equipment, controlling dust, establishing emergency procedures, and providing comprehensive training, organizations can create a safer working environment for their operators.

Frequently Asked Questions

1. What types of PPE should be used when operating vibrating sieves?

- Operators should wear dust masks, safety goggles, and gloves to protect against dust exposure and mechanical hazards.

2. How often should vibrating sieves be inspected?

- Regular inspections should be conducted at least once a week, or more frequently if the equipment is used heavily.

3. What are the risks of dust exposure in powder handling?

- Dust exposure can lead to respiratory issues, skin irritation, and other health problems, depending on the material being handled.

4. What should be included in emergency procedures for vibrating sieves?

- Emergency procedures should include steps for responding to dust explosions, equipment malfunctions, and contact information for emergency services.

5. How can dust control be improved in powder handling?

- Implementing enclosed systems and local exhaust ventilation can significantly reduce dust exposure and improve air quality.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.