Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Do Vibrating Sieves Work?

● The Importance of Powder Purity

>> Why is Powder Purity Essential?

>> Contaminant Removal

● Enhancing Powder Consistency

>> The Role of Particle Size Distribution

>> Improving Flowability

● Applications of Vibrating Sieves

>> Pharmaceutical Industry

>> Food Processing

>> Chemical Manufacturing

● Benefits of Using Vibrating Sieves

>> Enhanced Product Quality

>> Increased Efficiency

>> Versatility Across Industries

>> Cost-Effectiveness

● Conclusion

>> Frequently Asked Questions

In various industries, the purity and consistency of powdered materials are crucial for product quality and performance. Vibrating sieves play a significant role in achieving these standards by effectively separating particles based on size and removing contaminants. This article explores the mechanisms by which vibrating sieves enhance powder purity and consistency, their applications across different sectors, and the benefits they provide.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

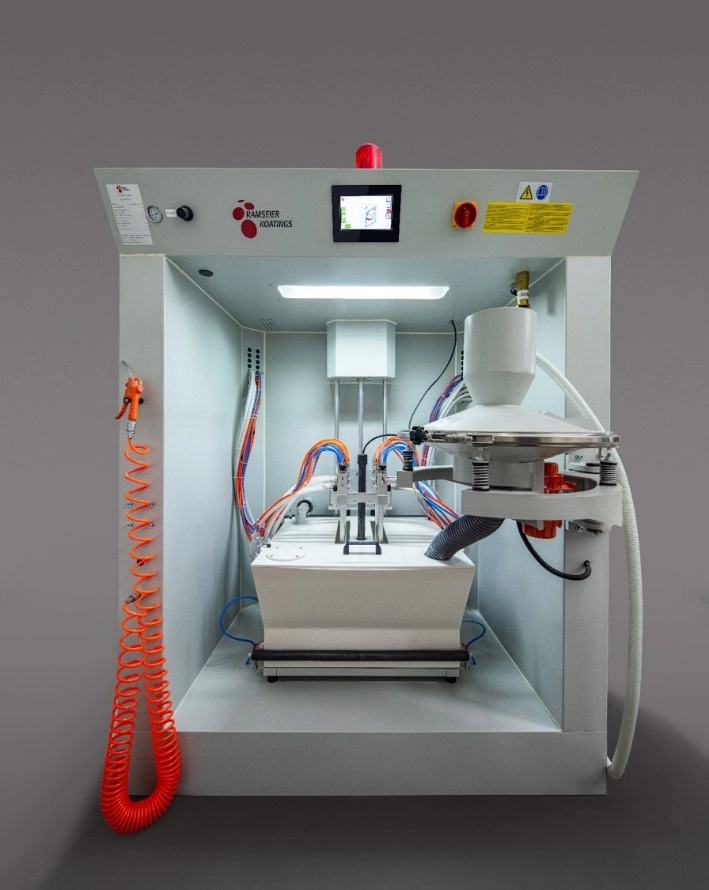

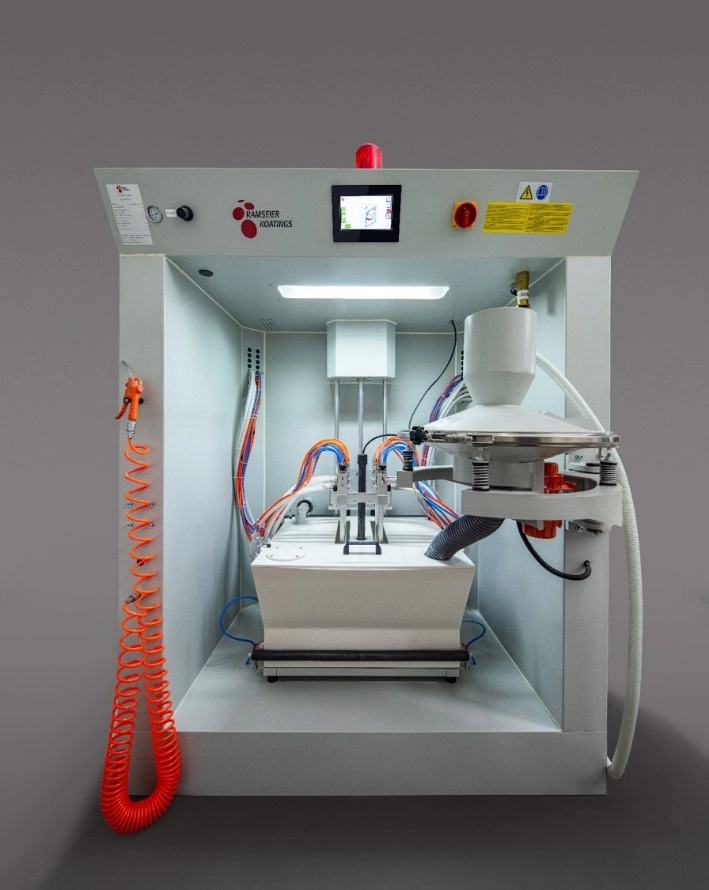

A vibrating sieve is a mechanical device that utilizes vibration to separate materials based on their size. It consists of a screen or mesh that allows smaller particles to pass through while retaining larger ones. This separation process is essential in industries where the quality of powders directly impacts the final product.

How Do Vibrating Sieves Work?

Vibrating sieves operate by creating controlled vibrations that move materials across the screen. The vibration causes particles to stratify, allowing smaller particles to fall through the mesh while larger particles are pushed forward. This efficient separation process is crucial in industries where purity and particle size are critical.

The Importance of Powder Purity

Why is Powder Purity Essential?

Powder purity is vital in many applications, particularly in pharmaceuticals, food processing, and chemical manufacturing. Impurities can lead to product defects, reduced efficacy, and safety concerns. For instance, in pharmaceuticals, the presence of contaminants can affect drug potency and safety, making it essential to ensure that active ingredients are free from foreign particles.

Contaminant Removal

Vibrating sieves are designed to remove contaminants such as metal shavings, dust, and lumps from powders. This function is especially critical in sensitive applications like pharmaceuticals and food processing, where even minor impurities can compromise product quality. By effectively filtering out these contaminants, vibrating sieves help maintain the integrity of the final product.

Enhancing Powder Consistency

The Role of Particle Size Distribution

Consistency in powder characteristics, such as particle size distribution, is crucial for ensuring uniformity in product performance. Inconsistent particle sizes can lead to variations in flowability, mixing, and compaction, which can ultimately affect the quality of the final product. Vibrating sieves help achieve a uniform particle size by efficiently separating powders into defined size ranges, eliminating oversized or undersized particles.

Improving Flowability

Flowability is a critical property in powder processing, influencing how materials behave during mixing, transport, and compaction. Vibrating sieves enhance flowability by breaking up agglomerates and ensuring that particles remain loose and free-flowing. This is particularly important in industries like food and pharmaceuticals, where consistent material flow is essential for efficient production processes.

Applications of Vibrating Sieves

Pharmaceutical Industry

In the pharmaceutical industry, vibrating sieves are used to ensure the purity and consistency of powders used in drug manufacturing. By removing oversized particles and contaminants, these sieves play a critical role in maintaining the efficacy of pharmaceutical products. The ability to achieve a uniform particle size is essential for accurate dosing and effective drug formulation.

Food Processing

The food industry relies heavily on vibrating sieves to maintain product quality. They are used to remove contaminants from flour, sugar, and other powdered ingredients, ensuring that the final products meet safety and quality standards. Consistent particle size and purity are crucial in food processing, as they directly impact texture, flavor, and overall product quality.

Chemical Manufacturing

In chemical manufacturing, vibrating sieves are employed to ensure the purity of raw materials and finished products. The ability to separate particles based on size helps maintain consistency in chemical formulations, which is essential for achieving desired reactions and product characteristics.

Benefits of Using Vibrating Sieves

Enhanced Product Quality

One of the primary benefits of using vibrating sieves is the enhancement of product quality. By ensuring that powders are free from contaminants and have a consistent particle size, manufacturers can produce higher-quality products that meet industry standards and customer expectations.

Increased Efficiency

Vibrating sieves improve operational efficiency by streamlining the sifting process. They help prevent clogging and ensure smooth material flow, reducing downtime and increasing productivity. This efficiency is particularly beneficial in high-volume production environments where maintaining consistent output is crucial.

Versatility Across Industries

Vibrating sieves are versatile and can be adapted to various applications across different industries. Whether in pharmaceuticals, food processing, or chemical manufacturing, these machines can handle a wide range of materials and requirements, making them an essential tool for quality control.

Cost-Effectiveness

Investing in vibrating sieves can lead to significant cost savings in the long run. By improving product quality and consistency, manufacturers can reduce waste, minimize rework, and enhance customer satisfaction. Additionally, the efficiency gains achieved through the use of vibrating sieves can lead to lower operational costs.

Conclusion

Vibrating sieves are indispensable tools in ensuring the purity and consistency of powdered materials across various industries. By effectively removing contaminants and achieving uniform particle sizes, these machines play a crucial role in maintaining product quality and enhancing operational efficiency. As industries continue to prioritize quality control, the importance of vibrating sieves will only grow.

Frequently Asked Questions

1. What types of materials can vibrating sieves process?

- Vibrating sieves can process a wide range of materials, including powders, granules, and liquids across various industries such as pharmaceuticals, food processing, and chemicals.

2. How do vibrating sieves improve powder flowability?

- By breaking up agglomerates and ensuring that particles remain loose and free-flowing, vibrating sieves enhance the flowability of powders, which is crucial for efficient processing.

3. What is the impact of particle size distribution on product quality?

- Consistent particle size distribution is essential for uniformity in product performance. Variations in particle size can lead to inconsistencies in flowability, mixing, and compaction.

4. Why is contaminant removal important in powder processing?

- Contaminants can compromise product quality and safety, making it essential to ensure that powders are free from foreign particles, especially in sensitive applications like pharmaceuticals and food processing.

5. What are the cost benefits of using vibrating sieves?

- Vibrating sieves can lead to cost savings by improving product quality, reducing waste, minimizing rework, and enhancing operational efficiency, ultimately lowering overall production costs.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.