Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> Importance of Maintenance

● Key Maintenance Tips

>> 1. Regular Cleaning

>>> Daily Cleaning

>>> Deep Cleaning

>> 2. Lubrication

>> 3. Regular Inspections

>>> Key Components to Inspect

>> 4. Avoid Overloading

>> 5. Proper Storage

>> 6. Training Operators

>> 7. Record Keeping

>> 8. Follow Manufacturer Guidelines

● Conclusion

● Frequently Asked Questions

>> 1. How often should I clean my vibrating sieve?

>> 2. What should I do if the mesh is damaged?

>> 3. How can I ensure the longevity of my vibrating sieve?

>> 4. What are the signs that my vibrating sieve needs maintenance?

>> 5. Can I operate a vibrating sieve without proper training?

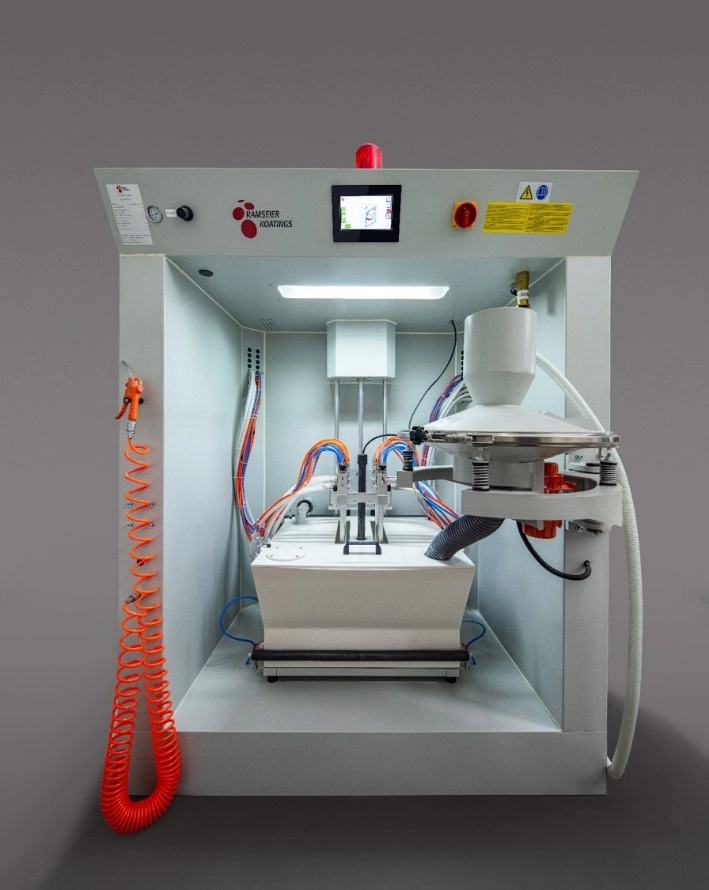

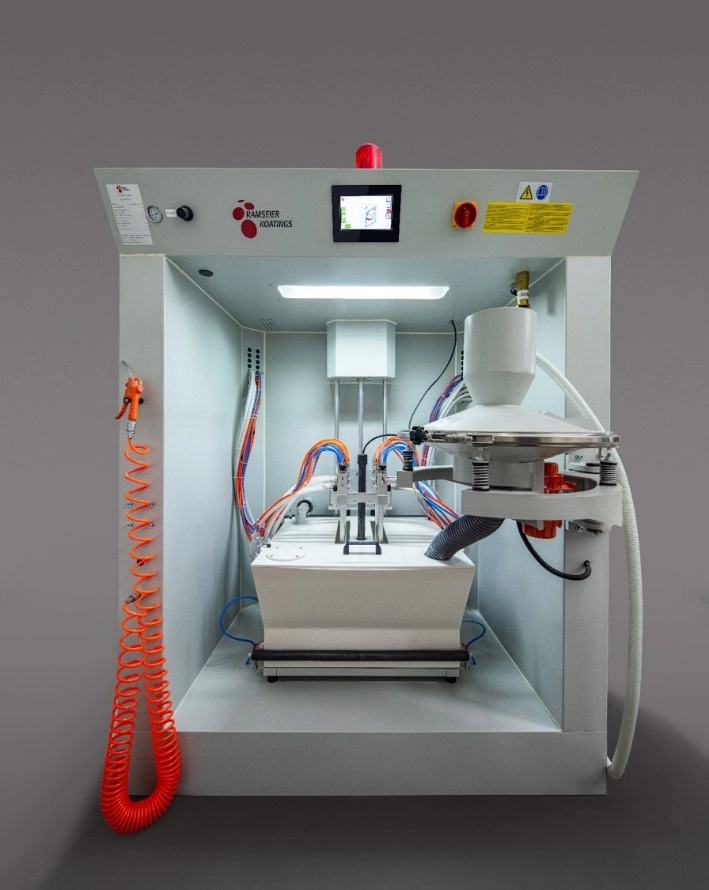

Vibrating sieves are essential equipment in various industries, including food processing, pharmaceuticals, and mining. They are designed to separate materials based on size, ensuring that only the desired particles pass through. However, like any machinery, vibrating sieves require proper maintenance to ensure their longevity and optimal performance. This article outlines the best maintenance tips to prolong your vibrating sieve's lifespan.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

A vibrating sieve is a mechanical device that uses vibration to separate materials. It consists of a screen mesh that vibrates to allow smaller particles to pass through while larger particles remain on top. The efficiency of a vibrating sieve depends on its design, the materials being processed, and how well it is maintained.

Importance of Maintenance

Regular maintenance is crucial for vibrating sieves to function effectively. Neglecting maintenance can lead to decreased performance, increased wear and tear, and ultimately, costly repairs or replacements. By following a structured maintenance routine, you can enhance the sieve's efficiency and extend its operational life.

Key Maintenance Tips

1. Regular Cleaning

Daily Cleaning

After each use, it is essential to clean the vibrating sieve thoroughly. Residual materials can accumulate on the screen and in the machine's components, leading to blockages and reduced efficiency. Use a soft brush or cloth to remove any leftover particles from the screen and body of the sieve.

Deep Cleaning

In addition to daily cleaning, a more thorough cleaning should be performed weekly or monthly, depending on usage. This involves disassembling the sieve according to the manufacturer's instructions and cleaning all components with a mild detergent and water. Ensure that no residue remains, as this can affect the sieve's performance.

2. Lubrication

Proper lubrication of moving parts is vital for the smooth operation of a vibrating sieve. Bearings, motors, and other mechanical components should be lubricated regularly to minimize friction and prevent premature wear. Always use the lubricant recommended by the manufacturer and follow the specified lubrication intervals.

3. Regular Inspections

Conducting regular inspections is a proactive approach to maintenance. Check for signs of wear, loose connections, and potential damage to critical parts such as the screen mesh, motors, and bearings. Create a checklist for weekly or monthly inspections to ensure that all essential components are covered.

Key Components to Inspect

- Screen Mesh: Look for irregularities such as dents or tears that could affect screening quality.

- Motors: Ensure that motors are functioning correctly and that there are no unusual noises or vibrations.

- Bearings: Check for signs of wear and ensure they are properly lubricated.

4. Avoid Overloading

Overloading the vibrating sieve is one of the main causes of decreased performance and lifespan. Ensure that the sieve is not subjected to loads beyond its specified capacity. Overloading can lead to excessive wear on the screen and other components, resulting in costly repairs.

5. Proper Storage

When not in use, store the vibrating sieve in a clean, dry environment. Protect it from dust, moisture, and extreme temperatures, which can cause damage over time. If the sieve is to be stored for an extended period, consider covering it with a protective tarp or plastic to prevent dust accumulation.

6. Training Operators

Proper training for operators is essential to ensure that the vibrating sieve is used correctly. Operators should be familiar with the machine's functions, maintenance requirements, and safety protocols. Regular training sessions can help reinforce best practices and reduce the risk of misuse.

7. Record Keeping

Maintain a log of all maintenance activities, including inspections, repairs, and cleaning. This documentation can help track the sieve's performance over time and identify patterns that may indicate underlying issues. Regularly reviewing this log can assist in planning future maintenance and addressing potential problems before they escalate.

8. Follow Manufacturer Guidelines

Always refer to the manufacturer's guidelines for specific maintenance recommendations. Each vibrating sieve may have unique requirements based on its design and intended use. Adhering to these guidelines will help ensure optimal performance and longevity.

Conclusion

Maintaining a vibrating sieve is essential for ensuring its longevity and efficiency. By following these maintenance tips—regular cleaning, lubrication, inspections, avoiding overloads, proper storage, training operators, record keeping, and adhering to manufacturer guidelines—you can significantly extend the lifespan of your vibrating sieve. Investing time and resources into maintenance will pay off in the long run by reducing downtime and repair costs.

Frequently Asked Questions

1. How often should I clean my vibrating sieve?

It is recommended to clean the sieve after each use and perform a more thorough cleaning weekly or monthly, depending on usage.

2. What should I do if the mesh is damaged?

If the mesh is damaged, it should be replaced immediately to maintain screening quality.

3. How can I ensure the longevity of my vibrating sieve?

Regular maintenance, including cleaning, lubrication, and inspections, can significantly extend the lifespan of your sieve.

4. What are the signs that my vibrating sieve needs maintenance?

Signs include unusual noises, decreased performance, visible wear on components, and frequent blockages.

5. Can I operate a vibrating sieve without proper training?

No, operating a vibrating sieve without proper training can lead to misuse, which may cause damage to the equipment and pose safety risks.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.