Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Do Vibrating Sieves Work?

● Key Features of High-Quality Vibrating Sieves

● Top Vibrating Sieve Brands

>> 1. Russell Finex

>> 2. Galaxy Sivtek

>> 3. Schenck Process

>> 4. Dahan Machinery

>> 5. Palamatic Process

● Applications of Vibrating Sieves

● Benefits of Using Vibrating Sieves

>> Improved Product Quality

>> Increased Efficiency

>> Versatility

>> Customization

● Maintenance Tips for Vibrating Sieves

● Conclusion

>> Frequently Asked Questions

In the world of industrial processing, vibrating sieves play a crucial role in ensuring the quality and consistency of powdered materials. These machines are designed to separate particles based on size, making them essential in various industries, including food, pharmaceuticals, chemicals, and more. This article explores the best vibrating sieve brands for high-volume powder processing, highlighting their features, benefits, and applications.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

A vibrating sieve is a mechanical device that uses vibration to separate materials based on their size. It consists of a screen or mesh that allows smaller particles to pass through while retaining larger ones. The vibration helps to move the materials across the screen, enhancing the separation process.

How Do Vibrating Sieves Work?

Vibrating sieves operate by generating a three-dimensional motion that causes the material to move across the screen. This motion can be adjusted to optimize the separation process, depending on the material being processed. The design of the sieve, including the mesh size and the angle of inclination, can also affect its efficiency.

Key Features of High-Quality Vibrating Sieves

When selecting a vibrating sieve for high-volume powder processing, consider the following features:

- Material Construction: High-quality sieves are typically made from stainless steel or other durable materials that resist corrosion and wear.

- Screening Capacity: The ability to handle large volumes of material efficiently is crucial for high-volume applications.

- Adjustable Vibration: The ability to adjust the vibration frequency and amplitude allows for better control over the separation process.

- Ease of Cleaning: A design that facilitates easy cleaning is essential to maintain hygiene, especially in food and pharmaceutical applications.

- Customization Options: Many manufacturers offer customizable solutions to meet specific processing needs.

Top Vibrating Sieve Brands

1. Russell Finex

Russell Finex is a leading manufacturer of industrial sieving and filtration solutions. Their products are known for their high efficiency and reliability. The Russell Compact Sieve® is particularly popular for its ability to improve product quality by removing contamination from powders and liquid slurries. This sieve is designed for easy cleaning and maintenance, making it ideal for industries with strict hygiene standards.

2. Galaxy Sivtek

Galaxy Sivtek has established itself as a trusted name in the vibrating sieve industry. Their sieves are designed to achieve high-quality separation and are widely used in various sectors, including food, pharmaceuticals, and chemicals. The Sivtek Separator is known for its robust construction and high screening capacity, making it suitable for high-volume applications.

3. Schenck Process

Schenck Process offers a range of vibrating sieves that are engineered for precision and efficiency. Their products are designed to handle a variety of materials, from fine powders to coarse granules. The Schenck Process Vibratory Sieve is particularly noted for its ability to provide accurate separation while minimizing downtime.

4. Dahan Machinery

Dahan Machinery specializes in industrial vibrating sieves that cater to diverse applications. Their products are known for their high capacity and customizable features. The Dahan Industrial Vibrating Sieve can handle up to 10 tons per hour, making it an excellent choice for high-volume processing.

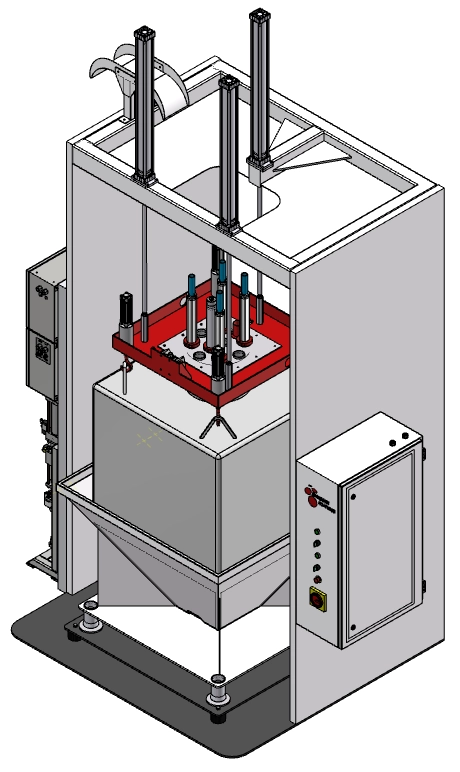

5. Palamatic Process

Palamatic Process is recognized for its innovative approach to bulk handling and sieving equipment. Their GSC Vibrating Screens are designed for high-capacity safety sieving, ensuring that powders are free from contamination. These screens are easy to clean and maintain, making them suitable for industries with stringent quality requirements.

Applications of Vibrating Sieves

Vibrating sieves are used in a wide range of applications, including:

- Food Processing: Ensuring that food powders are free from contaminants and meet quality standards.

- Pharmaceuticals: Screening active ingredients and excipients to ensure uniformity and quality.

- Chemical Industry: Separating fine powders and granules to maintain product consistency.

- Recycling: Sorting materials based on size to enhance recycling processes.

Benefits of Using Vibrating Sieves

Improved Product Quality

By effectively removing oversized particles and contaminants, vibrating sieves help improve the overall quality of the final product. This is particularly important in industries where product purity is critical.

Increased Efficiency

Vibrating sieves can process large volumes of material quickly, reducing the time required for screening and separation. This efficiency can lead to increased productivity and lower operational costs.

Versatility

Vibrating sieves can be used for a variety of materials, including powders, granules, and liquids. This versatility makes them suitable for multiple applications across different industries.

Customization

Many manufacturers offer customizable solutions, allowing businesses to tailor the sieve to their specific processing needs. This can include adjustments to the screen size, vibration frequency, and overall design.

Maintenance Tips for Vibrating Sieves

To ensure optimal performance and longevity of vibrating sieves, consider the following maintenance tips:

- Regular Cleaning: Keep the sieve clean to prevent contamination and ensure efficient operation.

- Check for Wear: Regularly inspect the screens and other components for signs of wear and replace them as needed.

- Monitor Vibration Levels: Ensure that the vibration levels are within the recommended range to maintain effective separation.

- Lubricate Moving Parts: Regular lubrication of moving parts can help reduce wear and extend the life of the equipment.

Conclusion

Choosing the right vibrating sieve is essential for high-volume powder processing. Brands like Russell Finex, Galaxy Sivtek, Schenck Process, Dahan Machinery, and Palamatic Process offer reliable and efficient solutions tailored to various industrial needs. By understanding the features, benefits, and applications of these machines, businesses can enhance their processing capabilities and ensure product quality.

Frequently Asked Questions

1. What is the main function of a vibrating sieve?

- The main function of a vibrating sieve is to separate materials based on size, allowing smaller particles to pass through while retaining larger ones.

2. How do I choose the right vibrating sieve for my application?

- Consider factors such as material type, screening capacity, ease of cleaning, and customization options when selecting a vibrating sieve.

3. What industries commonly use vibrating sieves?

- Vibrating sieves are commonly used in food processing, pharmaceuticals, chemicals, and recycling industries.

4. How often should I clean my vibrating sieve?

- It is recommended to clean the vibrating sieve regularly, especially in industries with strict hygiene standards, such as food and pharmaceuticals.

5. Can vibrating sieves be customized?

- Yes, many manufacturers offer customizable solutions to meet specific processing needs, including adjustments to screen size and vibration settings.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.