Content Menu

● Understanding Powder Coating and Quality Challenges

>> What is Powder Coating?

>> Challenges in Achieving Consistent Powder Coating Quality

● The Role of Automation in Powder Coating

>> Precision and Repeatability

>> Increased Production Efficiency

>> Waste Reduction and Environmental Benefits

● Key Automated Technologies Enhancing Powder Coating Consistency

>> Robotic Powder Spray Systems

>> Automated Booths and Powders Recovery Systems

>> Integrated Curing Ovens with Temperature Control

>> Quality Monitoring and Feedback Systems

● Benefits of Automation for Powder Coating Quality

>> Enhanced Product Consistency

>> Improved Surface Durability

>> Cost Savings and Resource Efficiency

>> Worker Safety and Ergonomics

● Implementation Considerations and Challenges

>> Initial Investment Costs

>> Integration with Existing Production Lines

>> Maintenance and Technical Expertise

● Future Trends in Powder Coating Automation

>> Artificial Intelligence and Machine Learning

>> IoT-Enabled Smart Powder Coating

>> Sustainable Practices

● FAQs

Powder coating is a widely used finishing process that provides a durable, high-quality, and aesthetically pleasing surface on various materials. Despite its popularity, achieving consistent and superior powder coating quality remains a challenging task for manufacturers and finishers. Automation has emerged as a critical factor in ensuring this consistency, offering precision, repeatability, and efficiency that manual processes often cannot match.

This comprehensive article explores why automation is essential to maintaining consistency in powder coating quality, discussing the technological advancements, benefits, challenges, and practical applications of automation in powder coating lines. It also addresses frequently asked questions to provide deeper insights into the topic.

Understanding Powder Coating and Quality Challenges

What is Powder Coating?

Powder coating is a finishing technique where powdered paint is electrostatically applied to a substrate and then cured under heat to form a hard, protective layer. The process is favored for its environmental benefits, reduced waste, and ability to produce a uniform finish on metals and other materials.

Challenges in Achieving Consistent Powder Coating Quality

Manual powder coating processes often face several challenges due to human error and variability:

- Uneven coating thickness

- Overspray waste and contamination

- Inconsistent curing temperatures

- Variability in material handling and surface preparation

- Reduced throughput and efficiency

These challenges can impact the final appearance and durability of the coating, leading to costly rework or product rejection.

The Role of Automation in Powder Coating

Automation in powder coating involves using robotic arms, computerized control systems, automated spray guns, and conveyor systems to control every aspect of the process with precision.

Precision and Repeatability

Automated systems are designed to replicate the exact same coating technique across thousands of parts without deviation. This reduces variability caused by human operators and ensures each piece receives an even layer of powder.

- Robotic spray systems can be programmed for specific angles, distances, and speeds.

- Automated powder delivery systems regulate the amount of coating applied precisely.

- Conveyor speeds and curing ovens are controlled to maintain uniform heating profiles.

Increased Production Efficiency

Automation enables high throughput by streamlining workflow and minimizing downtime.

- Continuous movement of parts through conveyor systems.

- Synchronization of coating and curing processes.

- Reduced need for manual labor and associated delays.

Waste Reduction and Environmental Benefits

Automated powder coating reduces overspray and material waste through fine-tuned control of spray parameters and recycling systems.

- Less overspray means fewer pollutants and lower disposal costs.

- Precise application reduces powder consumption and cost.

Key Automated Technologies Enhancing Powder Coating Consistency

Robotic Powder Spray Systems

Robotic arms equipped with electrostatic powder spray guns offer unparalleled accuracy and flexibility. These systems can be programmed to handle complex shapes and ensure full coverage with minimal manual intervention.

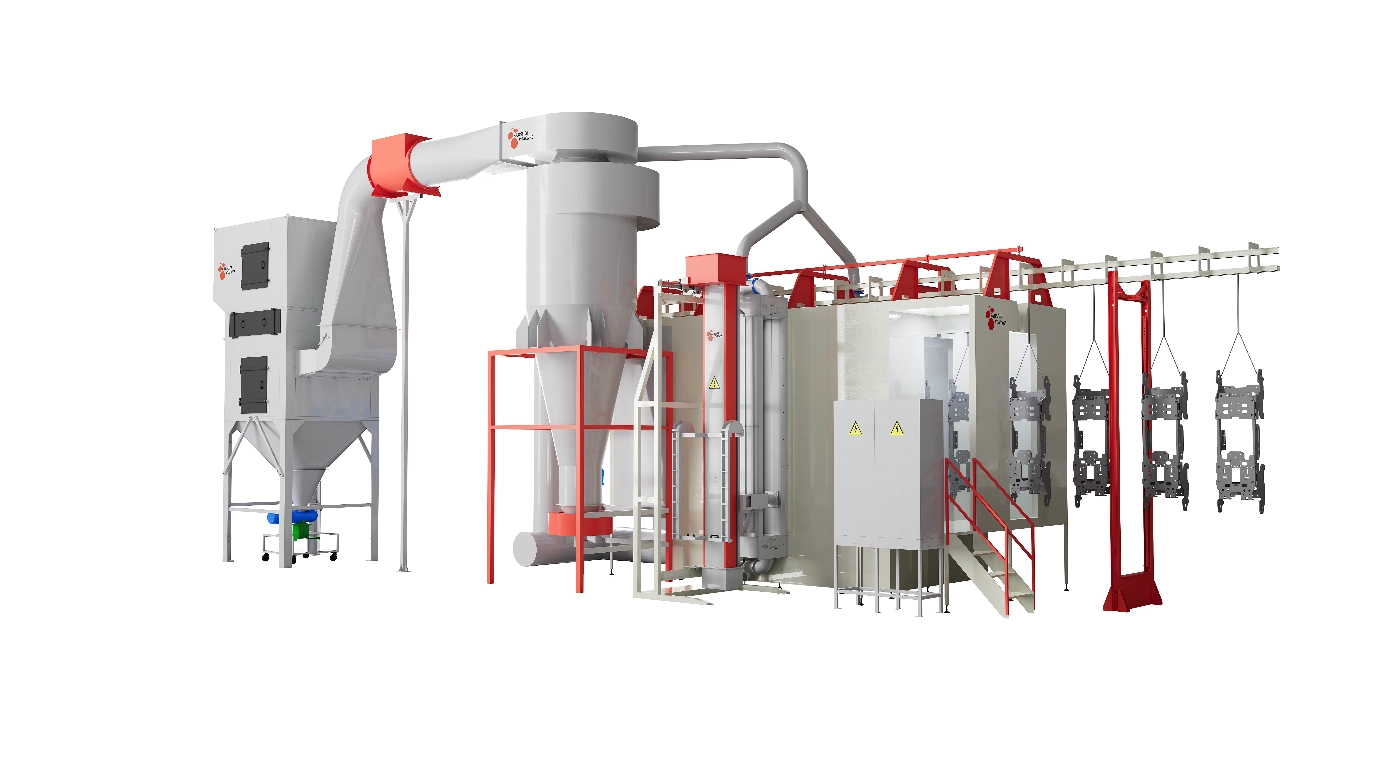

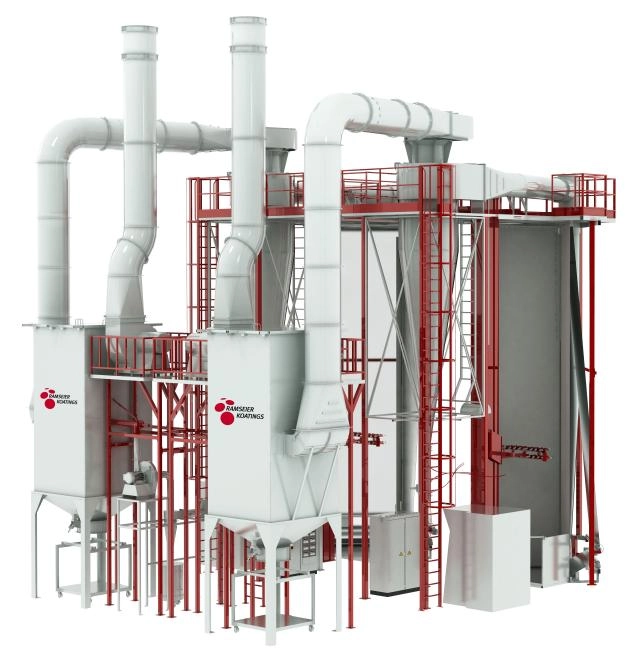

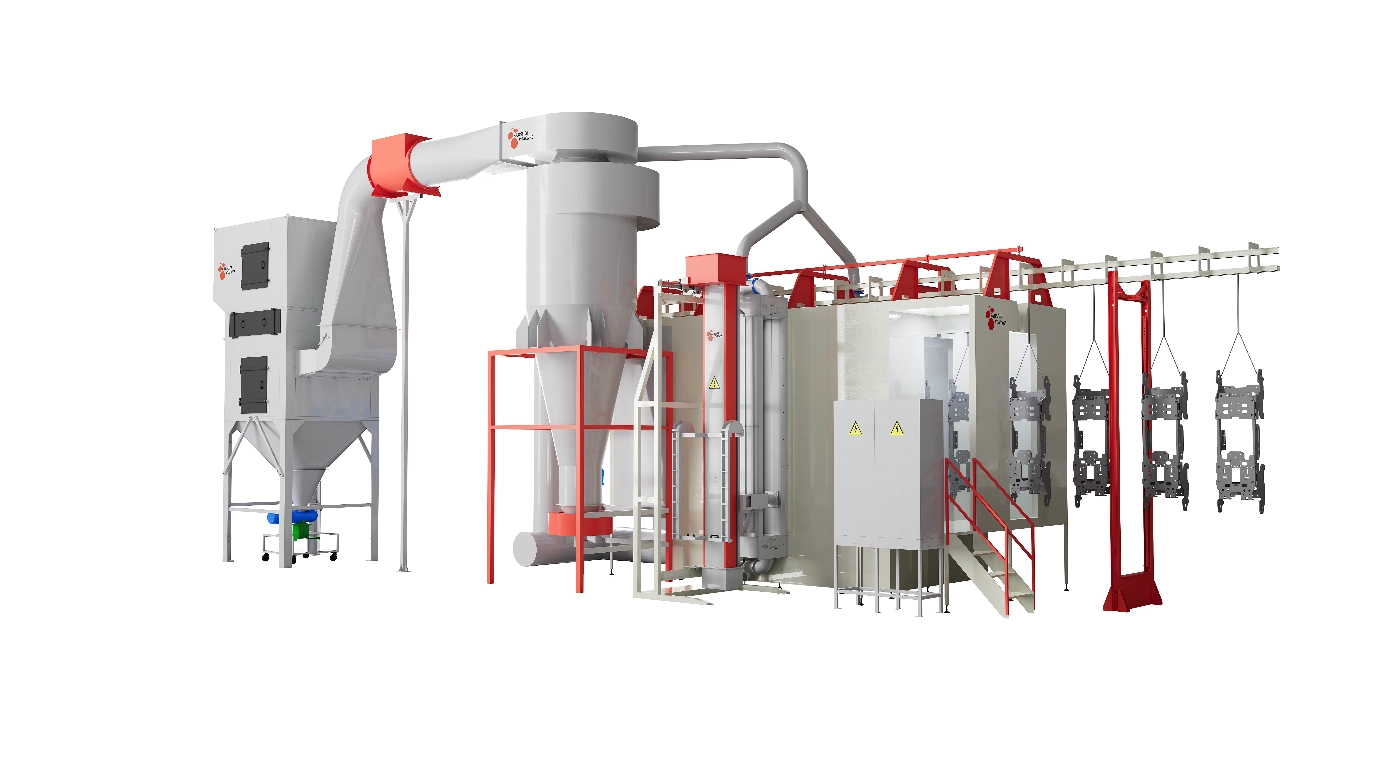

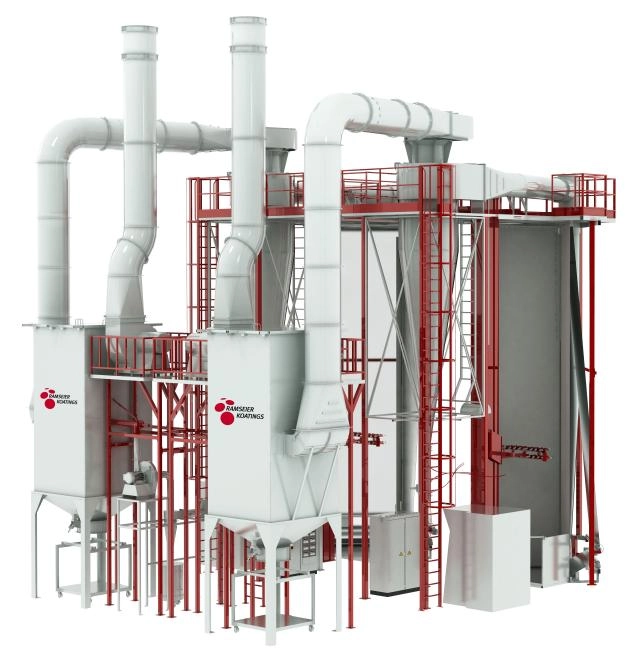

Automated Booths and Powders Recovery Systems

Enclosed automated booths help control environmental factors such as humidity and temperature, enhancing coating adhesion. Automated powder recovery systems capture and recycle unused powder, maintaining consistent material quality.

Integrated Curing Ovens with Temperature Control

Automated ovens with precise temperature monitoring and control ensure that coatings cure uniformly, preventing defects like orange peel texture or undercured powder.

Quality Monitoring and Feedback Systems

Modern automation includes real-time monitoring technologies that inspect coating thickness, coverage, and curing status. Feedback loops allow the system to adjust parameters on the fly to maintain ideal conditions.

Benefits of Automation for Powder Coating Quality

Enhanced Product Consistency

Automation eliminates operator variability, resulting in uniform coating thickness and finish quality on every product.

Improved Surface Durability

Consistent curing and layer application enhance adhesion and resistance to wear, chemicals, and corrosion.

Cost Savings and Resource Efficiency

Reduced powder waste, less rework, and faster cycles decrease overall manufacturing costs.

Worker Safety and Ergonomics

Automation reduces worker exposure to powder particles and repetitive motions, improving workplace safety and comfort.

Implementation Considerations and Challenges

Initial Investment Costs

Setting up automated powder coating can require significant upfront investment in equipment and personnel training.

Integration with Existing Production Lines

Retrofitting automation into older systems requires careful planning to avoid disruptions.

Maintenance and Technical Expertise

Robotic and computerized systems require regular maintenance and skilled technicians for optimal operation.

Future Trends in Powder Coating Automation

Artificial Intelligence and Machine Learning

AI-enabled systems will predict maintenance needs, optimize coating parameters, and enhance quality control.

IoT-Enabled Smart Powder Coating

Connected devices will allow remote monitoring, diagnostics, and process control for better efficiency.

Sustainable Practices

Innovations in automation will continue driving powder coating toward lower environmental impact and higher material recycling rates.

FAQs

1. How does automation improve powder coating consistency?

Automation minimizes human error by precisely controlling spray parameters, conveyor speed, and curing temperature, ensuring uniform application and finish on every item.

2. Can automation reduce powder waste in coating processes?

Yes, automated powder delivery and recovery systems optimize the amount of powder used and capture overspray, significantly reducing waste.

3. What are the main challenges when adopting automation in powder coating?

High initial investment, integration with existing systems, and need for technical expertise are the primary challenges faced by manufacturers.

4. Does automation impact worker safety?

Automation enhances worker safety by reducing exposure to powder particles and limiting repetitive manual tasks, promoting a healthier working environment.

5. Are automated powder coating systems suitable for all product types?

While suitable for many applications, heavily customized or irregular parts may require specialized robotic programming or manual touch-ups alongside automation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.