Content Menu

● Understanding Powder Supply Systems

>> Key Functions of Powder Supply Systems

● Top Powder Supply System Technologies

>> Pneumatic Conveying Systems

>>> Vacuum Conveying

>>> Pressure Conveying

>>> Advantages of Pneumatic Conveying

>> Screw Conveyors

>>> Key Features

>> Intermediate Bulk Containers (IBCs) and Cone Valve Technology

>>> Cone Valve Technology

>>> Advantages

>> Automated Sieving and Preparation Stations

>>> Key Benefits

>> Bulk Powder Handling Automation

>>> Benefits of Automation

● Leading Industrial Powder Supply System Providers

>> TRUMPF

>> Matcon

>> AZO

>> Powder Process-Solutions

>> ProChem and KnitCon Solutions

● How to Choose the Right Powder Supply System

>> Powder Characteristics

>> Process Requirements

>> Facility Constraints

>> Cost and ROI

● Applications of Powder Supply Systems

● Future Trends in Powder Supply Systems

● Frequently Asked Questions

>> 1. What are the main advantages of automated powder supply systems?

>> 2. How do pneumatic conveying systems differ from screw conveyors?

>> 3. What is cone valve technology, and why is it important?

>> 4. How can powder supply systems help with allergen control in food processing?

>> 5. What should be considered when integrating a powder supply system into an existing production line?

● Citations:

Powder supply systems are the backbone of modern industrial manufacturing, ensuring the seamless transfer, storage, and dosing of powders across a wide range of sectors, from pharmaceuticals and food to chemicals and additive manufacturing. As industries strive for higher productivity, automation, and quality control, the choice of powder supply system becomes a critical factor in operational success. This article explores the leading powder supply systems for industrial use, examining their technologies, advantages, and applications.

Understanding Powder Supply Systems

Powder supply systems encompass a variety of equipment and technologies designed to handle bulk powders efficiently, safely, and hygienically. These systems automate the movement, storage, and dosing of powders, reducing manual labor, minimizing contamination risks, and enhancing process consistency.

Key Functions of Powder Supply Systems

- Conveying: Transporting powders between processing steps.

- Storage: Holding powders in silos, hoppers, or intermediate bulk containers (IBCs).

- Dosing and Feeding: Delivering precise quantities for mixing, packaging, or processing.

- Sieving and Preparation: Ensuring powder quality by removing contaminants and achieving desired particle sizes.

- Automation and Control: Integrating with production lines for real-time monitoring and process optimization.

Top Powder Supply System Technologies

Pneumatic Conveying Systems

Pneumatic conveying uses air or inert gases to move powders through pipelines. There are two main types: vacuum and pressure systems.

Vacuum Conveying

Vacuum conveyors draw powders from containers or silos and transport them to the destination under negative pressure. This method is ideal for enclosed, dust-free transfer and is widely used in food, pharmaceutical, and chemical industries. Modern vacuum systems can handle up to 10,000 lbs (4,500 kg) of powder per hour, making them suitable for high-throughput production lines. They also facilitate automated refill of packaging machines, minimizing manual intervention and reducing contamination risks.

Pressure Conveying

Pressure systems push powders through pipelines using positive air pressure. They are often used for longer distances or when higher transfer rates are required.

Advantages of Pneumatic Conveying

- Enclosed system minimizes dust and contamination.

- Supports automation and integration with process controls.

- Flexible routing, allowing powders to be delivered to multiple destinations.

- Suitable for a wide range of powder types and bulk densities.

Screw Conveyors

Screw conveyors use a rotating helical screw blade within a tube or trough to move powders. They are known for their simplicity, reliability, and ability to handle a wide variety of powders, including those prone to bridging or rat-holing.

Key Features

- Continuous operation, supporting batch and continuous processes.

- Customizable for different inclinations, lengths, and capacities.

- Minimal maintenance and robust construction.

- Suitable for both horizontal and inclined conveying.

Intermediate Bulk Containers (IBCs) and Cone Valve Technology

IBCs are precision-engineered containers, often made of stainless steel, used to store, blend, and transport powders between manufacturing steps. Advanced IBCs feature patented cone valve technology, which overcomes common powder flow problems such as bridging, rat-holing, and segregation.

Cone Valve Technology

A cone valve at the outlet of the IBC ensures mass flow by lifting a cone to create an annular gap for powder discharge. This action breaks up compacted powder, ensuring consistent flow and preventing blockages.

Advantages

- Enables decoupling of processing stages for flexible manufacturing.

- Dust-tight, hygienic, and easy to clean.

- Reduces cross-contamination risks.

- Supports automated filling, blending, and discharge operations.

Automated Sieving and Preparation Stations

Sieving stations are integrated systems that automatically sieve powders to remove contaminants and achieve uniform particle size. They often include features such as ultrasonic cleaning, vacuum conveyors, and HEPA filtration for operator safety and environmental protection.

Key Benefits

- High throughput with consistent powder quality.

- Automated operation reduces labor and error.

- Optional inert gas environments for sensitive powders.

- Modular design for integration with multiple machines.

Bulk Powder Handling Automation

Automation in powder handling spans from ingredient unloading and conveying to mixing, weighing, and packaging. Leading providers offer customized solutions that address industry-specific challenges, such as allergen segregation, dust control, and regulatory compliance.

Benefits of Automation

- Improved quality control through consistent, accurate dosing.

- Enhanced worker safety by reducing manual handling.

- Increased productivity and throughput.

- Better inventory management and reduced product loss.

Leading Industrial Powder Supply System Providers

TRUMPF

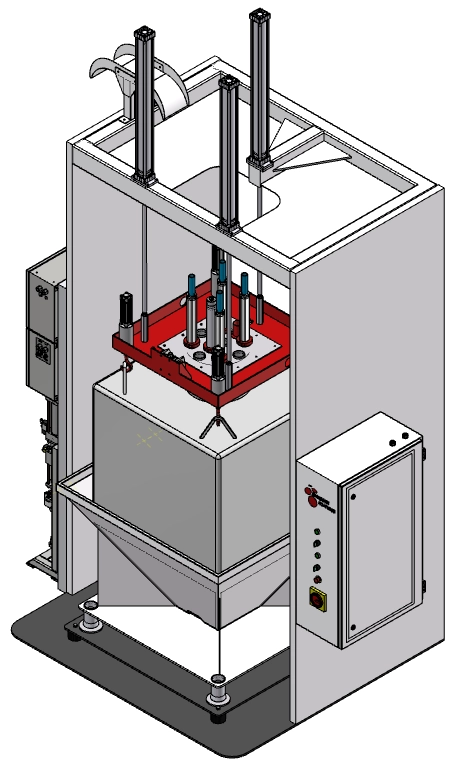

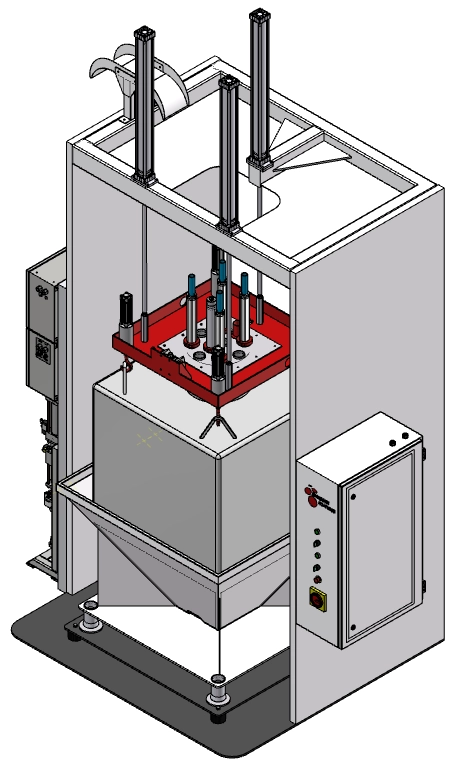

TRUMPF offers modular powder management systems for additive manufacturing, including powder removal, sieving, storage silos, and preparation stations. Their closed powder circuits ensure clean, safe environments, while high automation levels support parallel operation of multiple machines. Features such as inert gas handling and automated weighing make them ideal for high-quality, high-volume production.

Matcon

Matcon specializes in IBC-based powder handling systems with patented cone valve technology. Their solutions address common flow issues, enable flexible batch processing, and support stringent hygiene and safety standards. Matcon's systems are widely used in pharmaceuticals, food, and specialty chemicals.

AZO

AZO is known for its advanced pneumatic vacuum conveying systems and automated material feeding solutions. Their DosiBox® and other innovations streamline the handling of bulk goods and minor components, supporting efficient, contamination-free processing.

Powder Process-Solutions

With decades of experience, Powder Process-Solutions provides custom pneumatic conveying and bulk powder handling equipment, particularly for the food, dairy, and infant nutrition sectors. Their systems emphasize hygiene, efficiency, and regulatory compliance.

ProChem and KnitCon Solutions

These companies offer comprehensive powder handling solutions, including unloading, conveying, mixing, and packaging. Their focus on automation, quality, and after-sales support makes them reliable partners for industrial powder processing.

How to Choose the Right Powder Supply System

Selecting the optimal powder supply system depends on several factors:

Powder Characteristics

- Particle size, shape, and flowability.

- Bulk density and moisture content.

- Sensitivity to contamination or degradation.

Process Requirements

- Throughput and batch size.

- Degree of automation and integration with existing systems.

- Hygiene and regulatory standards.

Facility Constraints

- Available space and layout.

- Distance and elevation between process steps.

- Environmental controls (e.g., dust, temperature, humidity).

Cost and ROI

- Initial investment versus long-term operational savings.

- Maintenance and support requirements.

- Scalability for future expansion.

Applications of Powder Supply Systems

Powder supply systems are essential in:

- Pharmaceuticals: Ensuring precise dosing, containment, and hygiene.

- Food and Beverage: Managing allergens, preventing cross-contamination, and maintaining product quality.

- Additive Manufacturing: Handling metal powders under inert conditions for 3D printing.

- Chemicals: Safe transfer and blending of hazardous or reactive powders.

- Cosmetics: Homogeneous mixing and dust-free packaging of fine powders.

Future Trends in Powder Supply Systems

- Increased Automation: Greater use of robotics, sensors, and AI for process optimization.

- Smart Monitoring: Real-time tracking of powder flow, inventory, and quality parameters.

- Sustainability: Energy-efficient designs, waste reduction, and improved material recovery.

- Enhanced Safety: Advanced containment, explosion protection, and ergonomic designs.

Frequently Asked Questions

1. What are the main advantages of automated powder supply systems?

Automated powder supply systems improve productivity, ensure consistent product quality, reduce contamination risks, and enhance worker safety by minimizing manual handling.

2. How do pneumatic conveying systems differ from screw conveyors?

Pneumatic conveying uses air or inert gases to move powders through pipes, offering flexible routing and dust-free transfer, while screw conveyors use a rotating screw to move powders, providing robust and continuous operation for a wide range of materials.

3. What is cone valve technology, and why is it important?

Cone valve technology, used in advanced IBCs, prevents common powder flow problems such as bridging and rat-holing by mechanically breaking up compacted powders, ensuring consistent and controlled discharge.

4. How can powder supply systems help with allergen control in food processing?

Enclosed, automated powder supply systems prevent cross-contamination by segregating allergen-containing powders and reducing the risk of manual handling errors.

5. What should be considered when integrating a powder supply system into an existing production line?

Consider powder characteristics, process requirements, facility constraints, hygiene and safety standards, and the level of automation required to ensure seamless integration and optimal performance.

---

Citations:

[1] https://www.trumpf.com/en_US/products/machines-systems/additive-production-systems/truprint-periphery/

[2] https://www.pneumaticconveyingsolutions.com/blog/powder-conveying-methods/

[3] https://www.matconibc.com/powder-handling-systems

[4] https://www.plantengineering.com/five-bulk-powder-handling-automation-benefits-for-manufacturers-operators/

[5] https://ensun.io/search/powder-handling

[6] https://datacentremagazine.com/top10/top-10-power-distribution-unit-companies

[7] https://www.c3controls.com/products/industrial-power-supplies/

[8] https://www.matconibc.com/industrial-mixing-for-manufacturers-of-powder-based-products

[9] https://www.nordson.com/en/divisions/industrial-coating-systems

[10] https://www.pekoprecision.com/blog/industrial-power-supply-manufacturers-latest-advances/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.