Content Menu

● Understanding Swinger Powder Supply and Management Systems

>> What Is a Powder Supply and Management System?

>> Key Components of Swinger Powder Supply Systems

● Benefits of Using Swinger Powder Supply and Management Systems

>> Enhanced Efficiency and Throughput

>> Superior Coating Quality

>> Reduced Powder Waste and Environmental Impact

>> Flexibility and Customization

● Operating Principles and Workflow

>> Powder Preparation and Storage

>> Powder Conveyance

>> Spray Application with Swinger Mechanism

>> Color Change Process

>> Overspray Recovery and Recycling

● Installation and Integration Considerations

>> System Configuration and Layout

>> Integration with Coating Booths and Automation

>> Maintenance and Operator Training

● Challenges and Solutions

>> Powder Fluidity Issues

>> Color Cross-Contamination

>> System Downtime and Troubleshooting

● Future Trends in Swinger Powder Supply Systems

● Frequently Asked Questions (FAQs)

Powder coating is a widely-used finishing process in many industries due to its durability, environmental friendliness, and aesthetic appeal. Among the various powder coating technologies, swinger powder supply and management systems play a vital role in ensuring efficient, consistent, and high-quality coating performance. This article provides an in-depth overview of swinger powder supply and management systems, outlining their components, operation principles, benefits, challenges, and tips for optimal use. The goal is to equip manufacturers, engineers, and users with essential knowledge on how these systems contribute to superior powder coating results and streamlined production workflows.

Understanding Swinger Powder Supply and Management Systems

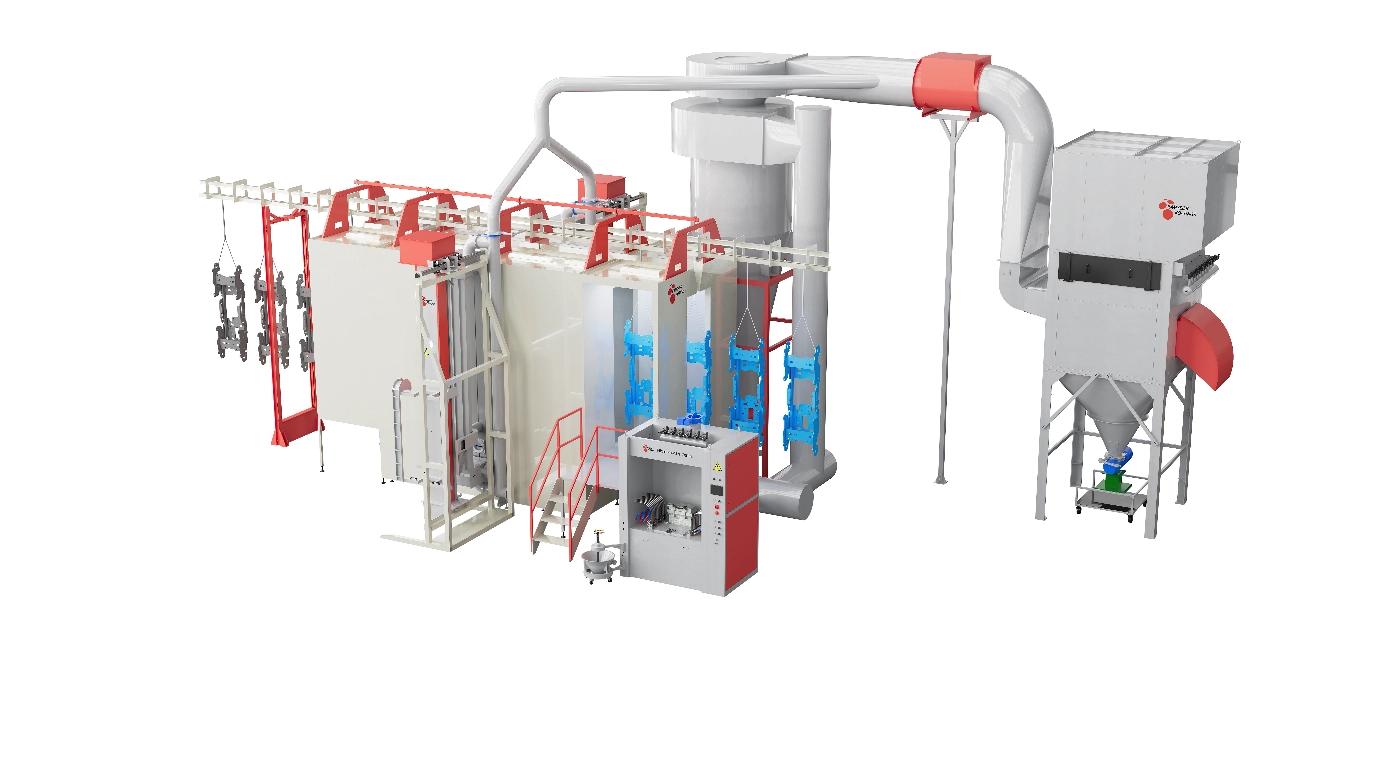

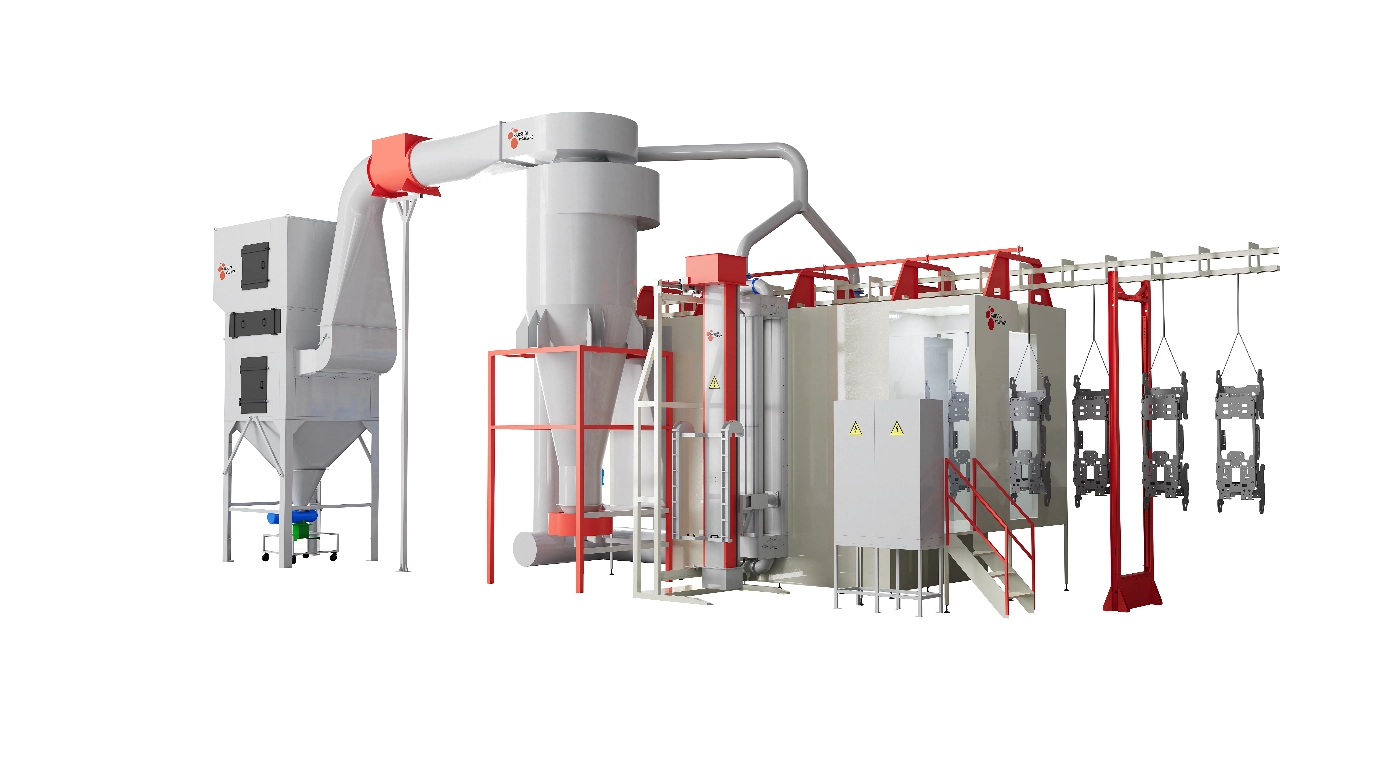

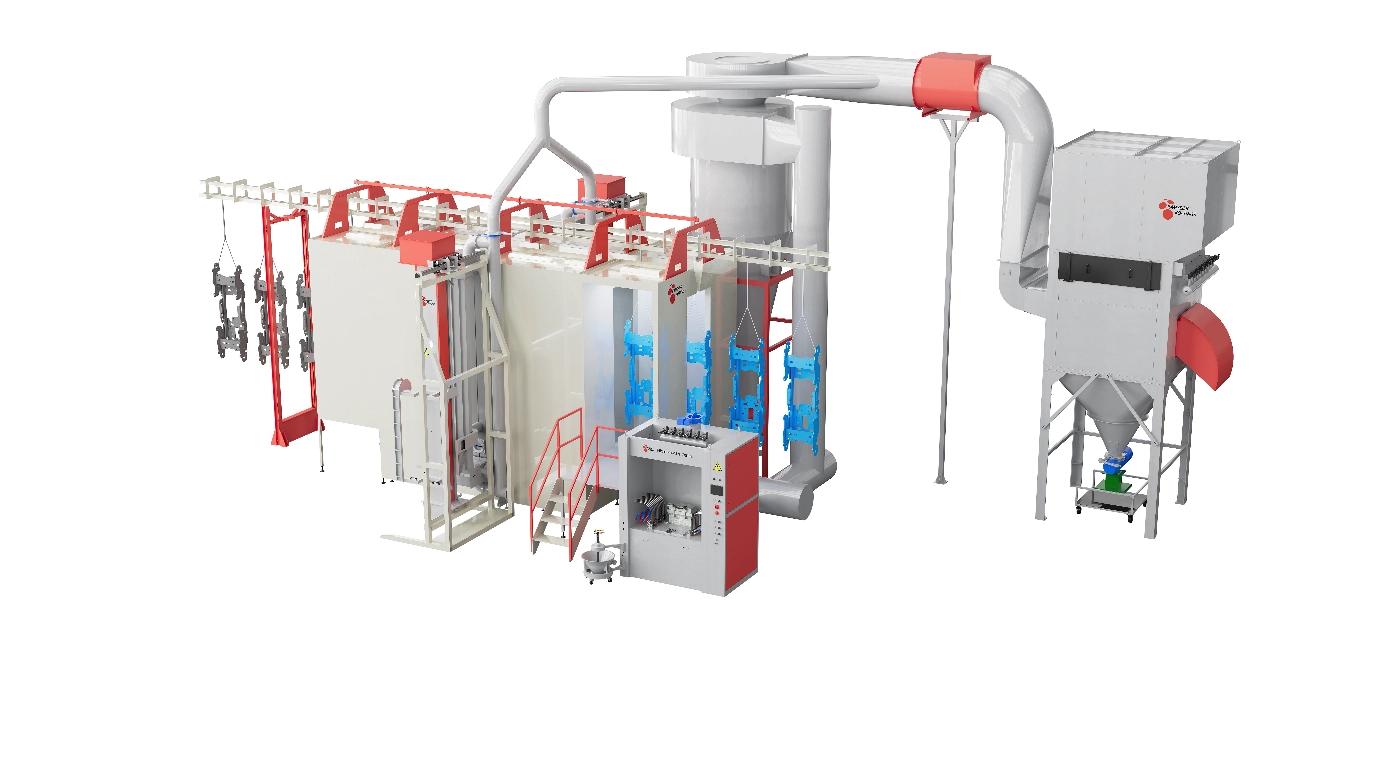

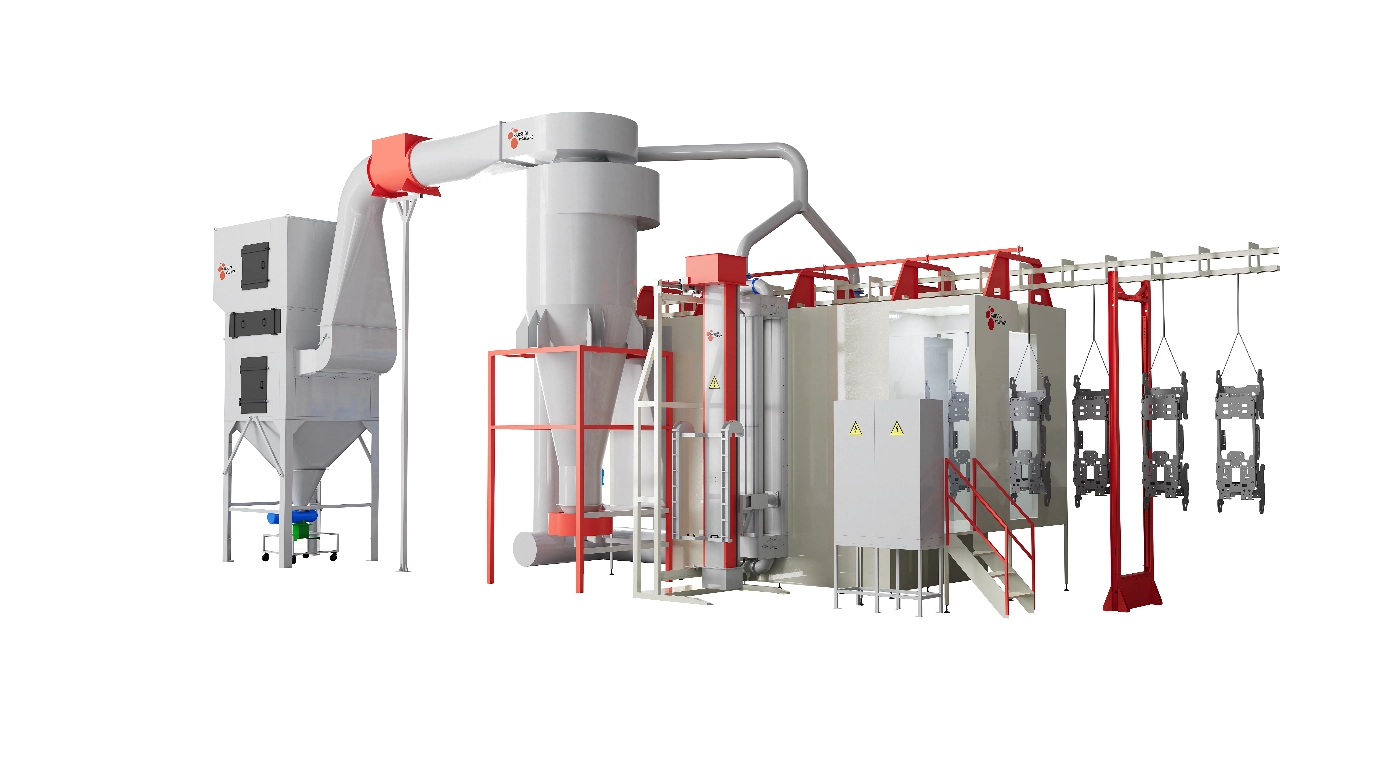

Swinger powder coating systems differ from conventional powder coating methods by incorporating a distinctive swinging mechanism that moves parts through the spray zone. The "swinger" device typically rotates or swings parts to ensure even and complete coverage of powder across all surfaces. This mechanical action reduces the need for manual repositioning and improves efficiency.

What Is a Powder Supply and Management System?

A powder supply and management system refers to the arrangement and equipment responsible for storing, conveying, dosing, and supplying coating powders to the spray guns in a controlled manner. The system manages fresh powder supply, reclaiming overspray powder, and batch color changes while minimizing contamination and downtime.

Key Components of Swinger Powder Supply Systems

- Powder Containers: These store the powder in fluid tanks or boxes. They often include specialized covers and fluidizing units that help maintain powder flowability.

- Injectors: Devices that convey powder from storage tanks to spray guns. Typical swinger systems include multiple injectors (20-34 or more) to supply several spray guns simultaneously.

- Powder Conveying Lines: Tubes or pipes connecting injectors to spray guns, sometimes featuring cleaning and air blowing mechanisms to ensure fast color change without powder mixing.

- Control Units: Touchscreen or digital panels that allow operators to manage powder flow rates, color changes, and system diagnostics.

- Sieving and Filtering: Ultrasonic screens and vibrating tables remove debris and prepare powder for consistent delivery.

- Fresh Powder Supply Modules: Units such as the IP5000 that enable automatic and continuous replenishment of fresh powder during operation.

Benefits of Using Swinger Powder Supply and Management Systems

Enhanced Efficiency and Throughput

Swinger systems allow for smooth and continuous powder delivery to multiple spray guns, supporting high-volume production lines. With automated fresh powder supply and fast color change features, they minimize downtime and help maintain steady coating cycles.

Superior Coating Quality

The swinging mechanism ensures all part surfaces receive uniform powder coverage, reducing defects such as uneven thickness or bare spots. Sieving and filtration improve powder purity, and fluidizing and vibrating auxiliaries maintain consistent powder flow and application.

Reduced Powder Waste and Environmental Impact

Many swinger systems incorporate overspray recovery and dust control to contain excess powder within the working area. This containment not only reduces environmental contamination but also allows reclaiming valuable powder, improving cost efficiency.

Flexibility and Customization

Swinger powder management centers are available in different configurations with varying injector counts and accessories, making them adaptable to diverse production needs, from small custom jobs to large automated lines.

Operating Principles and Workflow

Powder Preparation and Storage

Powder coatings are first loaded into fluid tanks or boxes designed to keep the powder aerated and free-flowing using fluidizing plates or vibrating tables. Covers prevent powder leakage and contamination.

Powder Conveyance

Injectors pull powder from storage containers and propel it through supply lines to the spray guns. Some systems deliver powder directly from the box or container, while others use intermediate fluid tanks.

Spray Application with Swinger Mechanism

Parts mounted on swinger devices rotate or swing through spray booths. This motion exposes all surfaces to the powder spray uniformly. The swinging speed and angle can be adjusted to optimize coverage.

Color Change Process

When switching powder colors, advanced swinger systems use automated blowing out and wiping of supply tubes to prevent cross-contamination. Menu-guided controls streamline the color change procedure, reducing downtime.

Overspray Recovery and Recycling

Excess powder not adhering to parts is collected by recovery units (integrated filters or dust collectors). Reclaimed powder is screened and sieved for reuse, ensuring minimal waste.

Installation and Integration Considerations

System Configuration and Layout

Planning a swinger powder supply system requires assessing production volume, part size, color change frequency, and space availability. The number of injectors and accessories like vibrating tables, ultrasonic screens, and fresh powder supply units should be selected accordingly.

Integration with Coating Booths and Automation

Swinger powder systems can be integrated with automated powder coating booths, conveyor systems, and robotic handling for fully automated paint lines. External touchscreens or networked control systems allow remote monitoring and operation.

Maintenance and Operator Training

Proper system maintenance, including cleaning injectors and sieving units regularly, ensures consistent powder flow and prevents blockages. Operators should be trained on system controls, safety procedures, and troubleshooting.

Challenges and Solutions

Powder Fluidity Issues

Powders with poor flow properties may cause blockages or inconsistent feed. Using fluidizing units and vibrating tables helps maintain powder fluidity for reliable conveying.

Color Cross-Contamination

Automated blowing and wiping of supply lines greatly reduce color mixing during changes, but operators must still follow strict procedures to maintain purity.

System Downtime and Troubleshooting

Regularly scheduled maintenance and predictive diagnostics integrated into control software help prevent unexpected downtime. Quick injector replacement and modular design minimize repair time.

Future Trends in Swinger Powder Supply Systems

- Smart Powder Management: Integration of IoT sensors and AI-driven controls to optimize powder usage, monitor equipment health, and predict maintenance needs.

- Eco-Friendly Enhancements: Increased focus on reducing emissions, improving powder recycling, and developing biodegradable powder coatings.

- Higher Throughput Designs: Advances in injector technology and swing mechanisms allow faster coating cycles for mass production.

- User Interface Improvements: More intuitive touchscreens, voice control, and remote diagnostics simplify operator control.

Frequently Asked Questions (FAQs)

Q1: What industries commonly use swinger powder supply and management systems?

A1: These systems are widely used in automotive, appliance manufacturing, metal furniture, and industrial equipment sectors where high-quality powder coating is required.

Q2: How does the swinger mechanism improve coating quality?

A2: By rotating or swinging parts through the powder spray, it ensures even coating coverage over complex geometries and hidden surfaces that are difficult to reach manually.

Q3: Can swinger powder systems handle multiple colors efficiently?

A3: Yes, with features like automated tube cleaning and menu-controlled color changes, swinger systems enable quick and contamination-free switching between powder colors.

Q4: What maintenance is needed to keep the swinger powder system running smoothly?

A4: Regular cleaning of injectors, sieves, and powder supply lines, checking fluidizing units for optimal powder flow, and routine calibration of control systems are essential.

Q5: Are swinger powder supply systems suitable for small production runs?

A5: While they excel in high-volume settings, modular swinger systems can be configured for flexible production, including smaller batch sizes, with options for manual or automatic powder supply.

[1] https://www.wagner-group.com/fileadmin/industrie/wagner-usa/brochures/WAGNER_BR_PXM_03-2019_EN.pdf

[2] https://www.scribd.com/document/720575171/%E9%9B%85%E6%80%9DIELTS%E4%B8%BB%E9%A1%8C%E9%96%B1%E8%AE%80%E6%B3%95

[3] https://indpro.com/blog/powder-handling-systems-equipment-a-comprehensive-guide/

[4] https://cloud.tencent.com/developer/article/1408145

[5] https://www.ddpsinc.com/powder-handling-systems

[6] https://m.51jiaoxi.com/doc-12207502.html

[7] https://www.ramseierkoatings.com/how-to-choose-the-right-swinger-powder-coating-system-for-your-production-line.html

[8] https://www.cnblogs.com/best/p/6589908.html

[9] https://www.ramseierkoatings.com/best-swinger-powder-coating-machines-for-high-performance-finishing.html

[10] https://ia800600.us.archive.org/5/items/ittushu-2470/%E6%B8%85%E5%8D%8E%E5%A4%A7%E5%AD%A6%E5%9B%BE%E4%B9%A6%E9%A6%86-%E6%88%98%E7%96%AB%E7%89%88/H_%E8%AF%AD%E8%A8%80%E3%80%81%E6%96%87%E5%AD%97/12133_%E5%9B%BD%E9%99%85%E4%BA%A4%E6%B5%81%E8%8B%B1%E8%AF%AD%E9%98%85%E8%AF%BB%E8%BF%9B%E9%98%B6%E6%95%99%E7%A8%8B_text.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.