Content Menu

● Introduction to Powder Coating

>> What is Semi-Automated Powder Coating?

>> What is Fully Automated Powder Coating?

● Key Differences Between Semi-Automated and Fully Automated Powder Coating

>> Level of Human Intervention

>> Production Capacity and Speed

>> Cost Considerations

>> Precision and Consistency

>> Flexibility and Customization

● Components and Workflow Differences

>> Semi-Automated Powder Coating System Components

>> Fully Automated Powder Coating System Components

● Advantages and Disadvantages

>> Semi-Automated Powder Coating

>>> Advantages

>>> Disadvantages

>> Fully Automated Powder Coating

>>> Advantages

>>> Disadvantages

● Ideal Applications for Both Systems

>> When to Choose Semi-Automated Powder Coating

>> When to Choose Fully Automated Powder Coating

● Comparing Environmental Impact

● Cost Implications Over Time

● Maintenance and Downtime Differences

● Conclusion

● Frequently Asked Questions

Powder coating is a popular finishing process used in many industries due to its durability, environmental friendliness, and aesthetic appeal. Understanding the distinction between semi-automated and fully automated powder coating systems is essential for businesses looking to optimize their coating operations. This article explores the differences, advantages, disadvantages, and suitable applications of both types of systems.

Introduction to Powder Coating

Powder coating is a finishing technique where a dry powder, composed of pigment and resin, is applied electrostatically to a substrate and then cured under heat. Unlike traditional liquid paint, powder coating forms a tough, consistent, and environmentally safe finish without the use of solvents.

What is Semi-Automated Powder Coating?

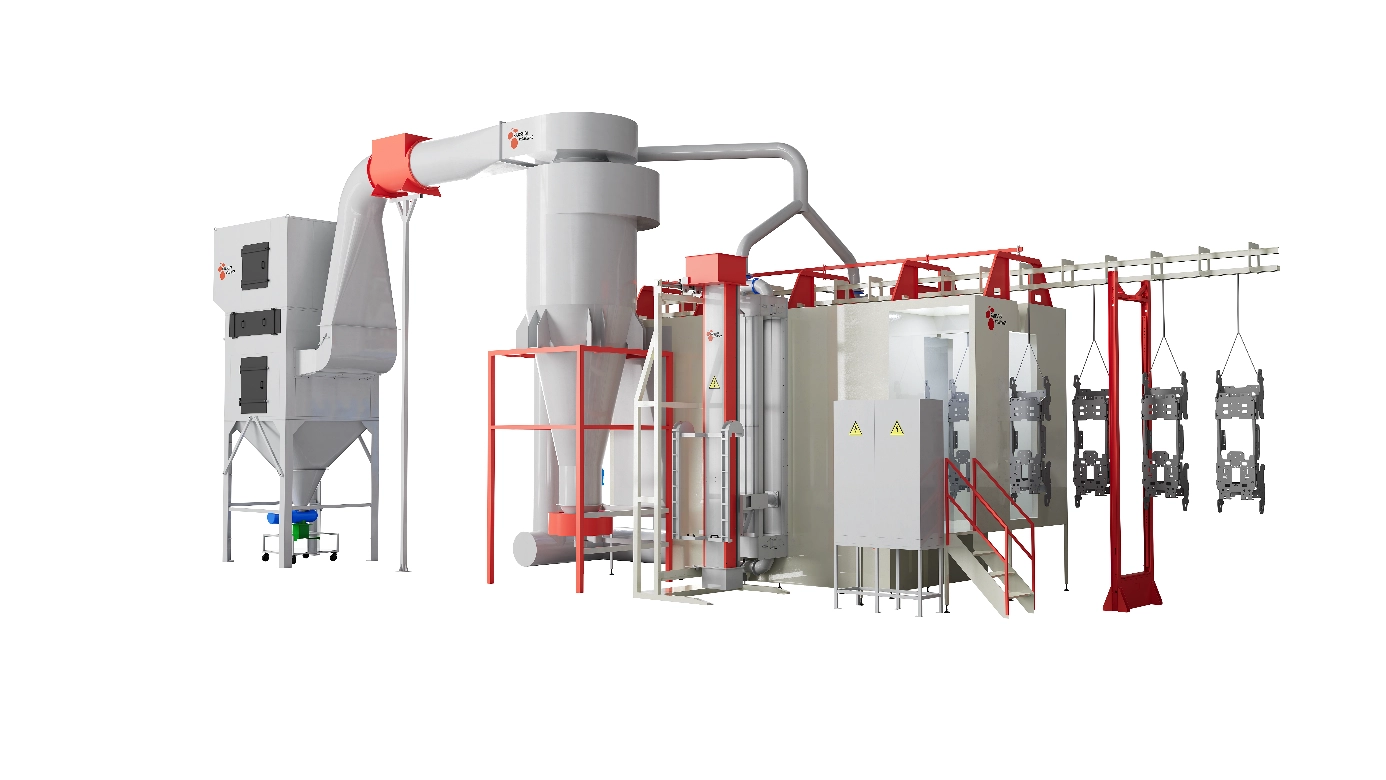

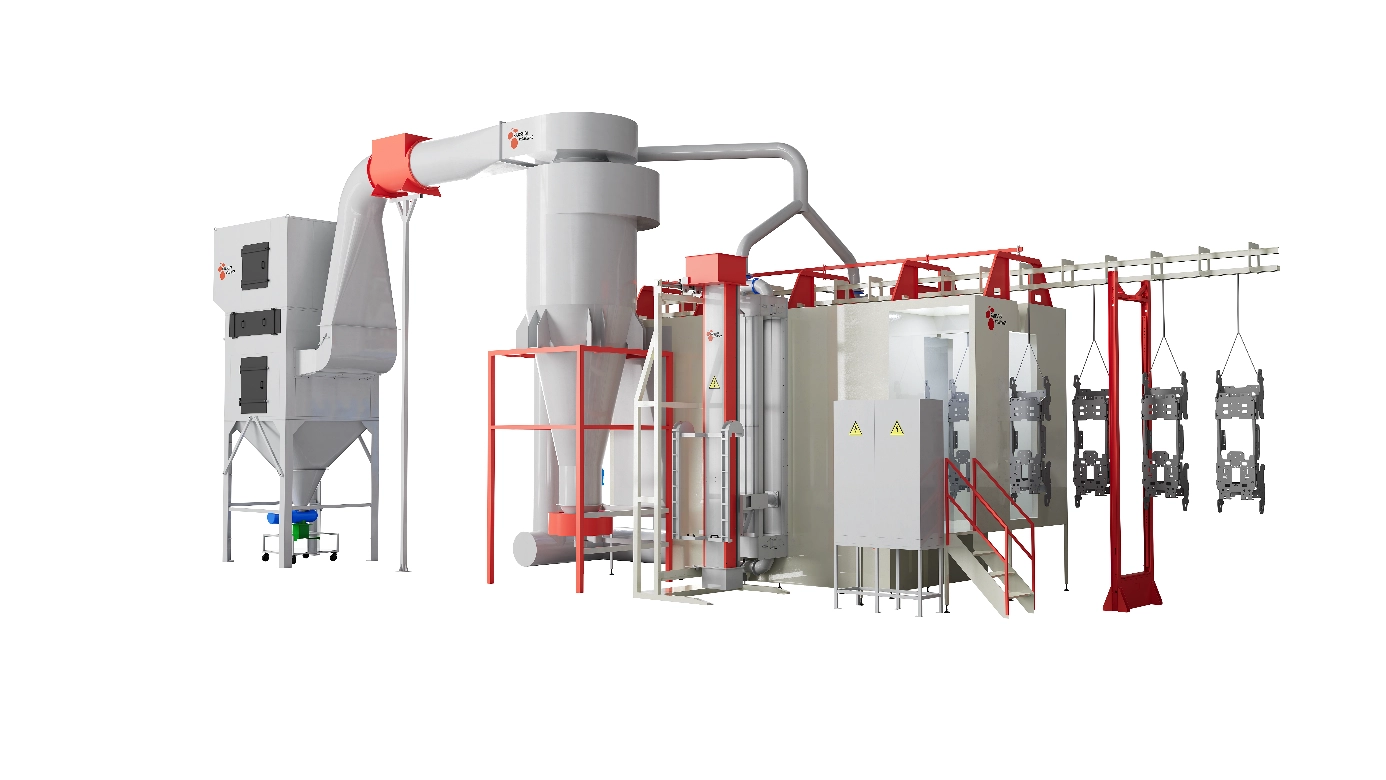

Semi-automated powder coating systems combine manual operation with mechanized processes. Operators typically load and unload parts manually while key steps like powder application and curing are performed using automated equipment. This approach balances human control with automation, making it flexible for various production needs.

What is Fully Automated Powder Coating?

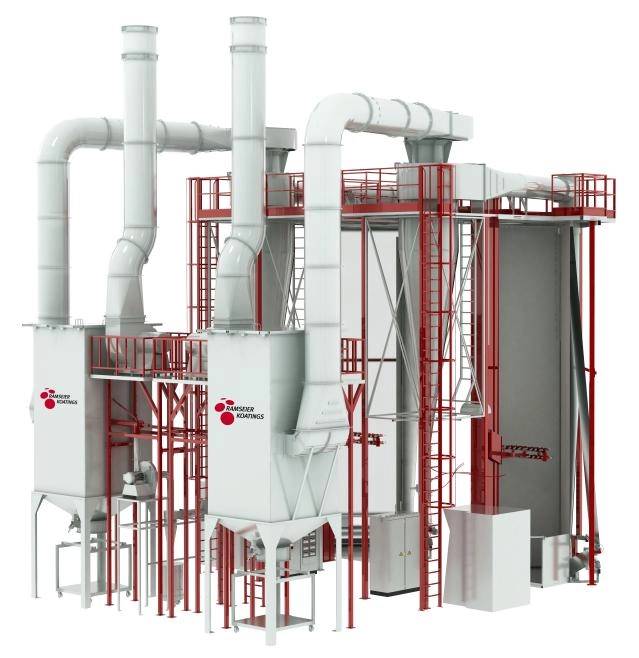

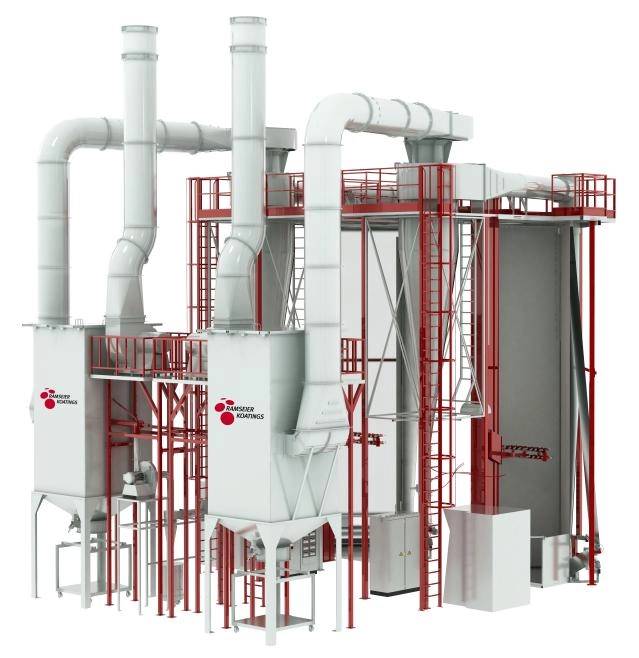

Fully automated powder coating systems integrate every stage of the coating process—from part loading, powder application, curing, to unloading—into a seamless, machine-controlled workflow. Human intervention is minimized, focusing mainly on monitoring and maintenance. These systems are designed for high volume and consistent quality output.

Key Differences Between Semi-Automated and Fully Automated Powder Coating

Understanding the main differences helps in deciding which system suits your production goals and budget.

Level of Human Intervention

- Semi-Automated: Requires operator involvement in loading/unloading and sometimes in programming the equipment.

- Fully Automated: Operates with minimal human intervention, often within tightly controlled production lines.

Production Capacity and Speed

- Semi-Automated: Suitable for medium to small production volumes with moderate speed.

- Fully Automated: Designed for large-scale, high-speed production lines requiring continuous operation.

Cost Considerations

- Semi-Automated: Lower initial investment, making it ideal for startups or businesses with budget constraints.

- Fully Automated: Higher upfront costs due to advanced robotics and conveyor systems but offers long-term savings with efficiency.

Precision and Consistency

- Semi-Automated: Quality may vary with operator skill; slightly less uniform coating.

- Fully Automated: High precision and consistent finish due to programmable controls.

Flexibility and Customization

- Semi-Automated: More adaptable for varied part sizes, shapes, and batch sizes.

- Fully Automated: Best suited for standardized parts and high repeatability.

Components and Workflow Differences

Semi-Automated Powder Coating System Components

- Manual or semi-manual loading station

- Automatic or manual powder spray guns

- Curing oven with conveyor or pass-through design

- Control panel for managing spray and curing parameters

Fully Automated Powder Coating System Components

- Robotic or conveyor loading and unloading units

- Robotic powder spray applicators with 3D movement capabilities

- Automated curing ovens integrated into a continuous conveyor line

- Centralized control system with software for programming and monitoring

Advantages and Disadvantages

Semi-Automated Powder Coating

Advantages

- Lower equipment cost and complexity

- Easier to operate and maintain for small teams

- Greater flexibility for custom or low-volume jobs

- Ability to manually adjust process during operation

Disadvantages

- Operator dependence can affect consistency

- Slower cycle time compared to fully automated systems

- Less efficient for high-volume production

Fully Automated Powder Coating

Advantages

- High throughput and productivity

- Consistent quality and finish with minimal variation

- Reduced labor costs over time

- Enhanced safety due to reduced human contact with materials and ovens

Disadvantages

- Higher initial capital expenditure

- Requires expert maintenance and technical support

- Less flexible for custom or variable batch jobs

Ideal Applications for Both Systems

When to Choose Semi-Automated Powder Coating

- Small to medium-sized production batches

- Businesses with budget constraints or limited space

- Custom or prototype parts requiring frequent process adjustments

- Operations where operator skill adds value in quality control

When to Choose Fully Automated Powder Coating

- Large-scale manufacturing with standardized parts

- Continuous production lines demanding high speed and precision

- Automated plants aiming to reduce labor and improve safety

- Companies requiring tight production schedules and consistent coatings

Comparing Environmental Impact

Both semi-automated and fully automated powder coating systems provide environmental benefits over liquid paints, including zero volatile organic compounds (VOCs) and reduced waste due to overspray recovery.

- Semi-automated systems may have slightly higher powder waste as manual control can lead to less precise application.

- Fully automated systems optimize powder usage through precise robotics, minimizing waste and improving material efficiency.

Cost Implications Over Time

- Semi-automated systems involve more labor costs and potential rework costs but have lower upfront investment.

- Fully automated systems demand higher startup costs but reduce labor and improve throughput, potentially offering better ROI for large production volumes.

Maintenance and Downtime Differences

- Semi-automated equipment is generally simpler, easier to troubleshoot, and requires fewer specialized technicians.

- Fully automated lines have complex electronics and robotics, requiring scheduled maintenance and skilled technicians, but benefit from predictive maintenance through monitoring software.

Conclusion

Choosing between semi-automated and fully automated powder coating depends largely on your production volume, budget, product complexity, and quality requirements. Semi-automated systems offer flexibility and lower investment ideal for smaller operations, while fully automated setups provide unparalleled efficiency and consistency needed for large-scale manufacturing.

Frequently Asked Questions

Q1: Can a semi-automated powder coating system be upgraded to full automation?

A1: Yes, many semi-automated systems are designed to be modular and can be gradually upgraded with automated components like robotic arms and conveyors.

Q2: Which system provides a better finish quality?

A2: Fully automated systems typically provide a more consistent and precise finish due to robotic application and controlled environments.

Q3: Are there significant safety differences between these systems?

A3: Fully automated systems tend to improve safety by minimizing operator exposure to powders and ovens, though semi-automated systems require proper safety training.

Q4: How much space is needed for a fully automated powder coating line?

A4: Fully automated lines require more floor space due to conveyors, robotic arms, and curing ovens integrated into a continuous workflow.

Q5: What types of industries benefit most from fully automated powder coating?

A5: Large industries such as automotive, appliances, and metal furniture manufacturers benefit most from fully automated systems due to their volume and quality consistency needs.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.