Content Menu

● Introduction

● The Evolution of Powder Coating Technology

>> Historical Context

>> Ramseier Koatings' Role in Innovation

● Key Features of Ramseier Koatings' Systems

>> Advanced Automation

>> Smart Control Systems

>> Customization Options

● Benefits of Using Ramseier Koatings' Systems

>> Increased Efficiency

>> Cost Savings

>> Enhanced Quality Control

● Commitment to Sustainability

>> Eco-Friendly Practices

>> Energy Efficiency

● Customer Support and Service

>> Comprehensive Training Programs

>> Ongoing Support

● Case Studies of Success

>> Automotive Industry

>> Consumer Goods

● Future Trends in Powder Coating Automation

>> Integration of IoT

>> Continued Innovation

● Conclusion

>> Frequently Asked Questions

Introduction

In the rapidly evolving world of manufacturing, the demand for efficient and high-quality coating solutions has never been greater. Among the leaders in this field is Ramseier Koatings, a company renowned for its innovative powder coating automation systems. This article explores the key factors that contribute to Ramseier Koatings' reputation as a top manufacturer in the industry, examining their technology, customer service, and commitment to sustainability.

The Evolution of Powder Coating Technology

Historical Context

Powder coating has transformed from a niche application to a mainstream finishing process in various industries, including automotive, aerospace, and consumer goods. Initially, powder coating was limited by manual application methods, which often resulted in inconsistencies and inefficiencies. However, advancements in technology have paved the way for automated systems that enhance precision and reduce waste.

Ramseier Koatings' Role in Innovation

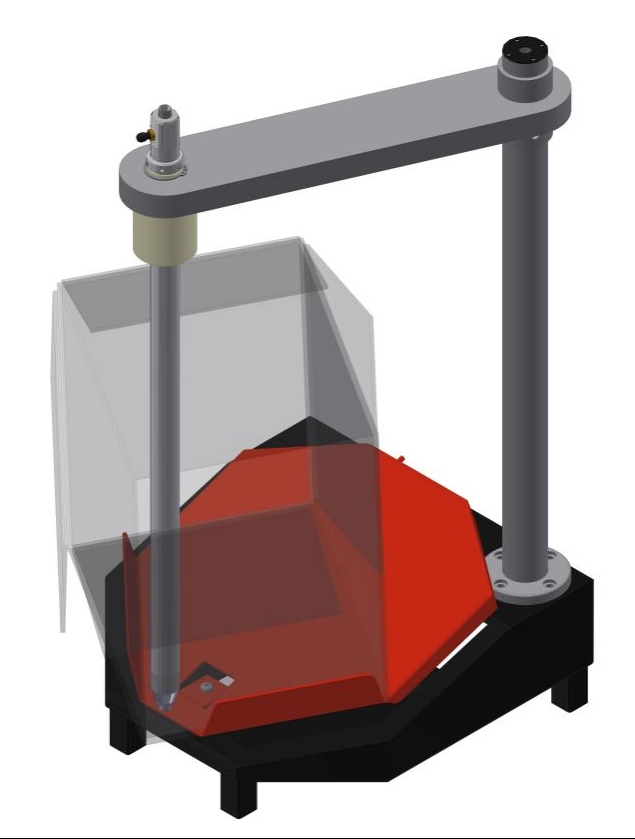

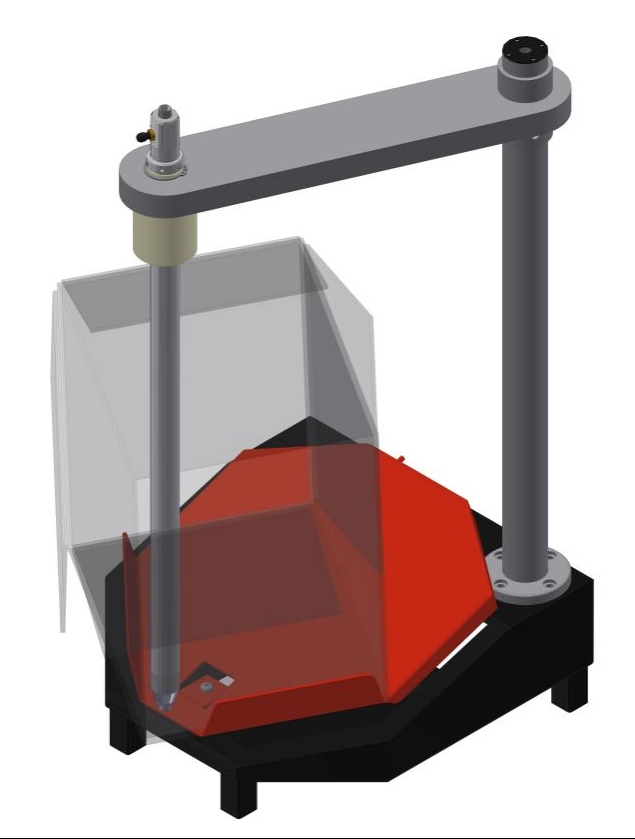

Ramseier Koatings has been at the forefront of this transformation, integrating cutting-edge technology into their powder coating systems. Their commitment to research and development has led to the creation of advanced electrostatic spray guns and automated application systems that ensure uniform coverage and high-quality finishes.

Key Features of Ramseier Koatings' Systems

Advanced Automation

One of the standout features of Ramseier Koatings' systems is their advanced automation capabilities. By utilizing robotics and programmable logic controllers (PLCs), these systems can operate with minimal human intervention. This not only increases efficiency but also significantly reduces the likelihood of human error, leading to more consistent results.

Smart Control Systems

Ramseier Koatings has developed smart control systems that allow for real-time monitoring and adjustments during the coating process. These systems utilize sensors to track various parameters, such as temperature and humidity, ensuring optimal conditions for powder application. This level of control is crucial for maintaining quality standards and minimizing defects.

Customization Options

Understanding that different industries have unique requirements, Ramseier Koatings offers customizable solutions tailored to specific applications. Whether it's adjusting the spray pattern for intricate parts or modifying the curing process for different materials, their systems can be adapted to meet diverse customer needs.

Benefits of Using Ramseier Koatings' Systems

Increased Efficiency

The automation of powder coating processes leads to significant efficiency gains. With systems designed to operate continuously, manufacturers can achieve higher throughput without compromising quality. This is particularly beneficial in high-demand environments where production speed is critical.

Cost Savings

Investing in Ramseier Koatings' automation systems can lead to substantial cost savings over time. By reducing powder waste through efficient application and reclaiming unused powder, companies can lower their material costs. Additionally, the reduction in labor requirements due to automation translates to lower operational expenses.

Enhanced Quality Control

Quality control is paramount in manufacturing, and Ramseier Koatings' systems excel in this area. The integration of smart technology allows for immediate feedback and adjustments, ensuring that any deviations from desired specifications are corrected in real-time. This proactive approach minimizes defects and enhances overall product quality.

Commitment to Sustainability

Eco-Friendly Practices

In today's environmentally conscious market, sustainability is a key consideration for manufacturers. Ramseier Koatings is committed to reducing its environmental impact through various initiatives. Their powder coating processes are inherently more sustainable than traditional liquid coatings, as they produce less waste and do not require solvents.

Energy Efficiency

The company also focuses on energy efficiency in its systems. By optimizing curing processes and utilizing energy-efficient components, Ramseier Koatings helps manufacturers reduce their carbon footprint while maintaining high production standards.

Customer Support and Service

Comprehensive Training Programs

Ramseier Koatings understands that the successful implementation of their systems relies on proper training. They offer comprehensive training programs for operators and maintenance personnel, ensuring that users are well-equipped to maximize the capabilities of their equipment.

Ongoing Support

Beyond initial training, Ramseier Koatings provides ongoing support to its customers. Their dedicated service team is available to assist with troubleshooting, maintenance, and upgrades, ensuring that systems remain operational and efficient throughout their lifecycle.

Case Studies of Success

Automotive Industry

In the automotive sector, Ramseier Koatings has partnered with several manufacturers to enhance their coating processes. By implementing automated systems, these companies have reported significant improvements in coating consistency and reductions in production downtime.

Consumer Goods

Similarly, in the consumer goods industry, companies utilizing Ramseier Koatings' technology have experienced increased customer satisfaction due to the superior quality of their finished products. The ability to customize coatings for various applications has also allowed these manufacturers to differentiate themselves in a competitive market.

Future Trends in Powder Coating Automation

Integration of IoT

As technology continues to advance, the integration of the Internet of Things (IoT) into powder coating systems is becoming increasingly prevalent. Ramseier Koatings is exploring ways to incorporate IoT capabilities into their systems, allowing for even greater connectivity and data analysis.

Continued Innovation

The future of powder coating automation is bright, with ongoing innovations expected to further enhance efficiency and quality. Ramseier Koatings is committed to staying at the forefront of these developments, ensuring that their customers benefit from the latest advancements in technology.

Conclusion

Ramseier Koatings has established itself as a top manufacturer of powder coating automation systems through its commitment to innovation, quality, and customer service. By leveraging advanced technology and sustainable practices, the company not only meets the demands of modern manufacturing but also sets new standards for the industry. As they continue to evolve and adapt to changing market needs, Ramseier Koatings remains a trusted partner for manufacturers seeking to enhance their coating processes.

Frequently Asked Questions

1. What types of industries benefit from Ramseier Koatings' systems?

- Ramseier Koatings serves various industries, including automotive, aerospace, and consumer goods, providing tailored solutions for each sector.

2. How does automation improve powder coating processes?

- Automation enhances efficiency, reduces human error, and ensures consistent quality by utilizing robotics and smart control systems.

3. What are the environmental benefits of powder coating?

- Powder coating produces less waste and does not require solvents, making it a more sustainable option compared to traditional liquid coatings.

4. Can Ramseier Koatings' systems be customized?

- Yes, Ramseier Koatings offers customizable solutions to meet the specific needs of different applications and industries.

5. What support does Ramseier Koatings provide after installation?

- They offer comprehensive training programs and ongoing support to ensure that customers can effectively operate and maintain their systems.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.