Content Menu

● Understanding the Role of a Powder Hopper

>> Why Powder Hoppers Are Essential in High-Volume Production

● Critical Design Features for High-Volume Production Hoppers

>> Size and Capacity

>> Material Compatibility and Construction

>> Flow Control Mechanisms

● Integration with Production Line Equipment

>> Automated Feeding Compatibility

>> Ease of Cleaning and Maintenance

● Operational Advantages of High-Performance Powder Hoppers

>> Increased Production Efficiency

>> Improved Product Consistency

>> Reduced Waste and Spillage

>> Enhanced Worker Safety

● Maintenance Considerations for Long-Term Performance

>> Routine Inspection and Cleaning

>> Replacement of Wear Parts

>> Documentation and Training

● Challenges in Powder Hopper Selection for High-Volume Operations

>> Handling Difficult Powders

>> Space Limitations

>> Budget Constraints

● Innovations in Powder Hopper Technology

>> Smart Sensors and IoT Integration

>> Modular and Flexible Design

>> Advanced Material Coatings

● Conclusion

>> Frequently Asked Questions

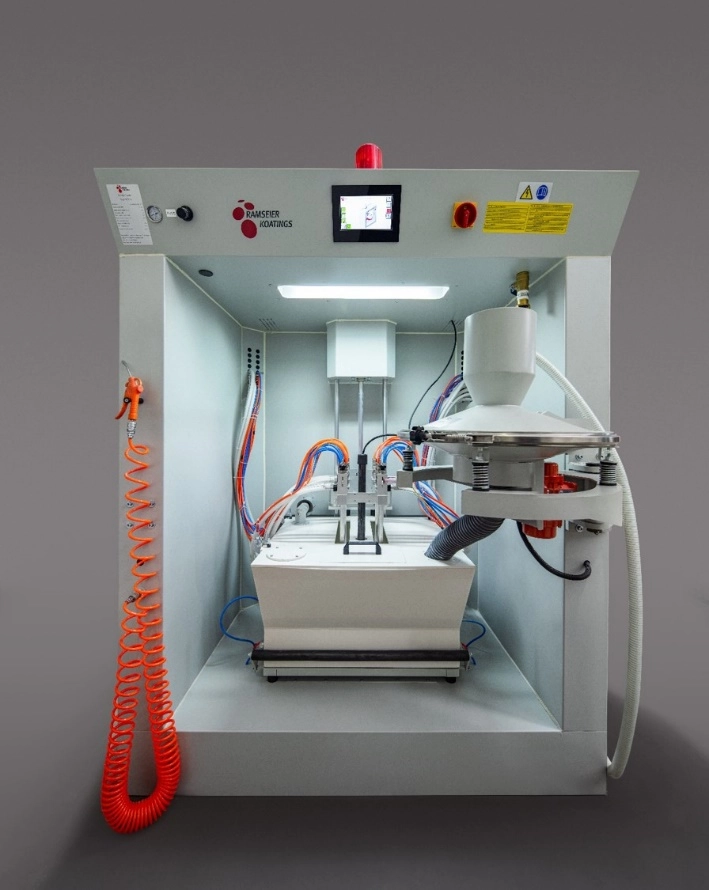

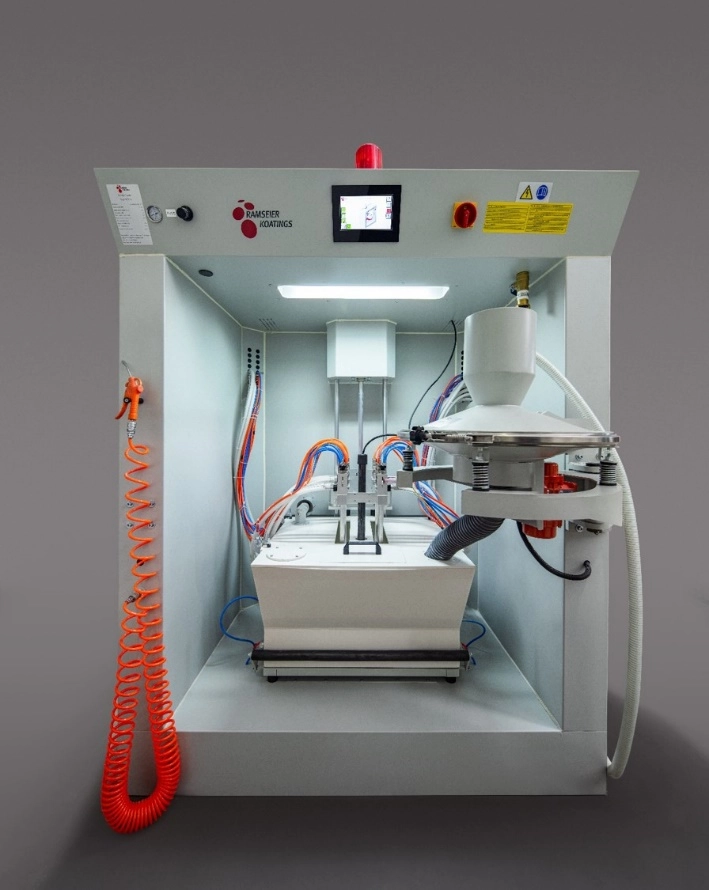

In high-volume production environments, the efficiency and reliability of equipment are crucial for maintaining product quality and meeting demanding output goals. A powder hopper, as a key component in many manufacturing processes such as pharmaceuticals, food processing, and chemical production, must be carefully designed and selected to suit these rigorous conditions. This article explores what makes a powder hopper suitable for high-volume production by addressing key features, design considerations, operational benefits, and maintenance aspects.

Understanding the Role of a Powder Hopper

A powder hopper is a container used to store and feed powdered materials into processing machinery. Its primary function is to facilitate a continuous and controlled flow of powder, which is vital in automated or semi-automated production lines.

Why Powder Hoppers Are Essential in High-Volume Production

In high-volume settings, the demand for uninterrupted and consistent material feeding is critical. Any disruption or inconsistency in powder feeding can cause production delays, wastage, or compromised product quality. Hence, the hopper must be able to:

- Hold large quantities of powder for extended processing periods without frequent refilling.

- Maintain consistent material flow to feeding or dosing systems.

- Handle varying powder characteristics such as granularity, flowability, and moisture content.

Critical Design Features for High-Volume Production Hoppers

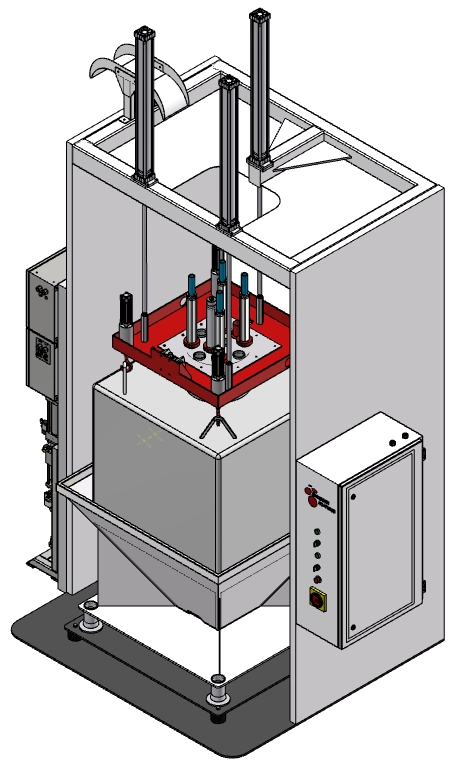

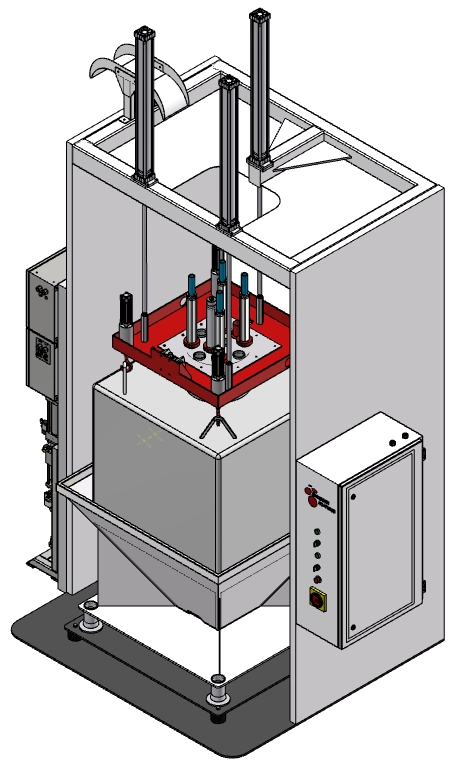

The design of a powder hopper directly impacts its suitability for high-volume production. Several features must be considered to optimize performance.

Size and Capacity

High-volume production lines require hoppers with sufficiently large capacity to minimize downtime caused by refilling. However, the size must balance with the physical space constraints and the ease of handling.

- Large capacity reduces refill frequency, supporting continuous production.

- Modular hopper designs allow flexibility in capacity according to production scaling.

Material Compatibility and Construction

The hopper material must be compatible with the powder being handled to avoid contamination or corrosion.

- Stainless steel is widely preferred for its durability, corrosion resistance, and ease of cleaning.

- Food-grade or pharmaceutical-grade materials ensure compliance with industry standards.

Flow Control Mechanisms

To maintain a smooth and consistent powder flow, flow control features are essential.

- Vibrators and agitators break up powder clumps and prevent bridging.

- Flow aids such as air fluidization systems can improve powder mobility.

- Steep hopper walls and optimized outlet design prevent material buildup.

Integration with Production Line Equipment

For high-volume production, the hopper must seamlessly integrate with other machines and systems.

Automated Feeding Compatibility

Integration with automated dosing, filling, or mixing equipment ensures consistent and accurate powder dispensing.

- Sensors to monitor powder levels trigger refill alerts or automated feed.

- Communication interfaces with production line control systems enhance process automation.

Ease of Cleaning and Maintenance

Frequent cleaning is often required in production environments to avoid cross-contamination and maintain product quality.

- Easy disassembly or access points allow for quick cleaning.

- Smooth interior surfaces prevent powder adherence and facilitate washdown.

Operational Advantages of High-Performance Powder Hoppers

Selecting the right powder hopper contributes to several operational benefits that support productivity and product quality.

Increased Production Efficiency

A hopper designed for high-volume production minimizes downtime by enabling longer processing runs without interruption.

Improved Product Consistency

Consistent powder flow and feeding reduce variation in product formulation and ensure uniformity.

Reduced Waste and Spillage

Effective powder handling decreases powder waste caused by blockages, spillage, or segregation.

Enhanced Worker Safety

Automated feeding systems and enclosed hopper designs reduce operator exposure to dust and improve workplace safety.

Maintenance Considerations for Long-Term Performance

Maintaining powder hoppers in optimal condition is vital for sustaining production output and avoiding unexpected breakdowns.

Routine Inspection and Cleaning

Scheduled checks detect wear, corrosion, or malfunction in flow control equipment early.

Replacement of Wear Parts

Components such as agitators, seals, and sensors require monitoring and replacement to maintain hopper efficiency.

Documentation and Training

Proper documentation of maintenance procedures and staff training ensure consistent upkeep.

Challenges in Powder Hopper Selection for High-Volume Operations

Selecting the right hopper also involves overcoming challenges related to material variability and operational constraints.

Handling Difficult Powders

Certain powders may be cohesive, hygroscopic, or abrasive, requiring specialized hopper design and material handling strategies.

Space Limitations

Production floors may restrict hopper size and layout flexibility, necessitating custom solutions.

Budget Constraints

Balancing the cost of advanced hopper technology with production benefits is a key consideration.

Innovations in Powder Hopper Technology

Advancements in hopper technology continually improve suitability for high-volume production.

Smart Sensors and IoT Integration

Real-time monitoring of powder flow, level, and hopper condition through connected devices enhances process control.

Modular and Flexible Design

Hoppers with adjustable features allow manufacturers to adapt to different powders and production volumes easily.

Advanced Material Coatings

Special coatings reduce powder sticking and facilitate cleaning, improving operational efficiency.

Conclusion

A powder hopper suitable for high-volume production is characterized by its large capacity, durable construction, effective flow control, ease of integration with automated systems, and manageable maintenance requirements. Selecting the right hopper significantly boosts production efficiency, product consistency, and worker safety while reducing waste and downtime.

Frequently Asked Questions

Q1: What materials are best for powder hoppers in pharmaceutical production?

A1: Stainless steel with pharmaceutical-grade finishing is preferred for its durability, corrosion resistance, and compliance with sanitary standards.

Q2: How can powder bridging inside a hopper be prevented?

A2: Using vibrators, agitators, air fluidization, and hopper design features like steep walls can prevent bridging and ensure smooth powder flow.

Q3: What are common flow control mechanisms used in powder hoppers?

A3: Vibrators, agitators, flow aids such as air fluidization systems, and optimized outlet shapes are typical flow control mechanisms.

Q4: How important is hopper integration with automated production lines?

A4: It is critical for consistent dosing, reducing manual intervention, and maintaining high production efficiency and product quality.

Q5: What maintenance practices ensure long-term hopper performance?

A5: Regular inspection, cleaning, timely replacement of wear parts, and proper staff training are essential for long-term reliable operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.