Content Menu

Working Principle of Electrostatic Powder Coating

The working principle of electrostatic powder coating is almost identical to that of traditional electrostatic spraying using liquid coatings. The key difference lies in the fact that powder coating involves the dispersion of powder particles, rather than atomization. Using an electrostatic powder spray gun, the coating material is dispersed while the powder particles are negatively charged. These charged particles are then directed by airflow (or other forces such as centrifugal force) and attracted to the grounded object due to electrostatic forces. Upon heating, the particles melt and cure to form a solid film. Electrostatic powder coating is currently the dominant method in the field of industrial coating applications.

Definition of Electrostatic Powder Coating

Electrostatic powder coating, commonly referred to as “electrostatic spraying,” utilizes a spraying device equipped with an atomizing nozzle and a discharge electrode to micronize the coating material and apply a charge. An electric field is created between the electrode and the object to be coated, enabling electrostatic attraction for coating adhesion.

Main Characteristics

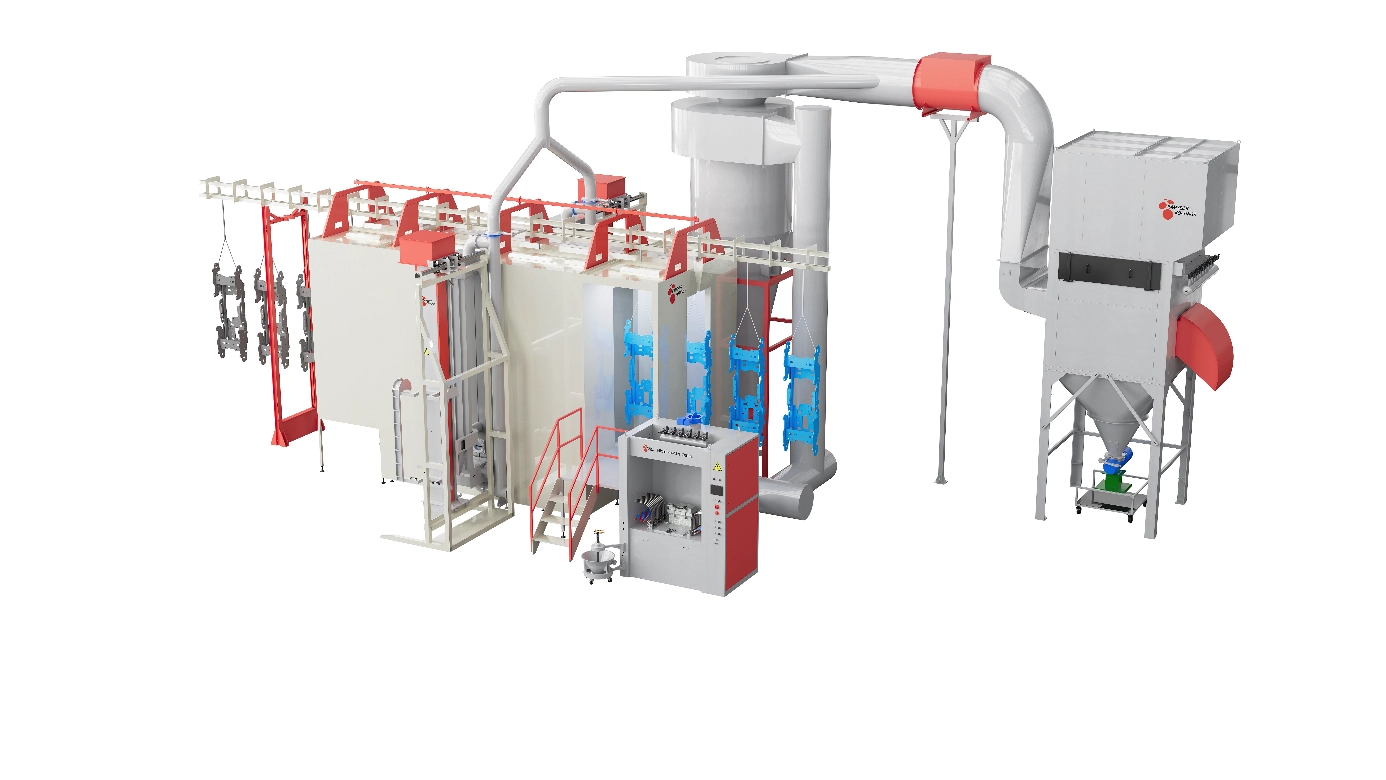

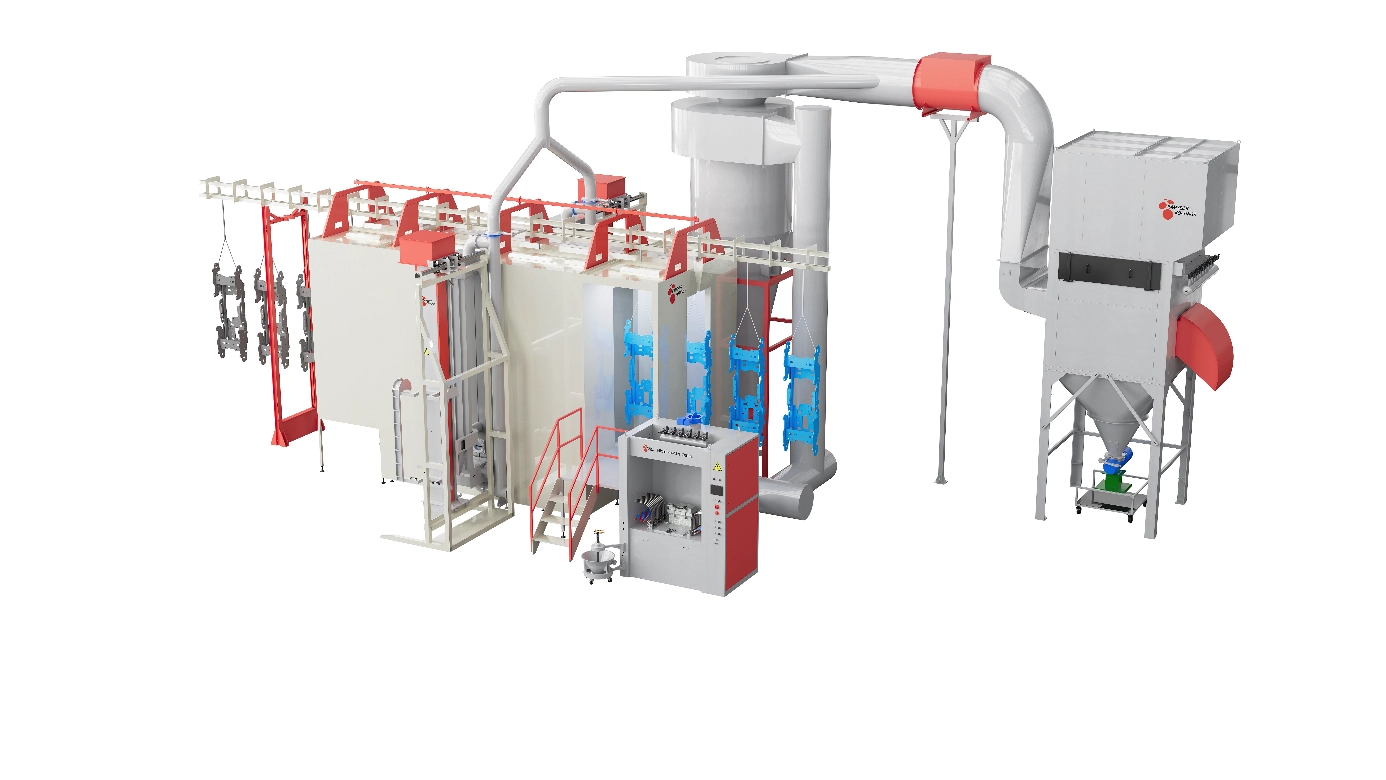

Spraying methods can be manual, automatic, or a combination of both.

The coating material is 100% solid powder, and overspray can be recovered, with a recycling rate of up to 98%.

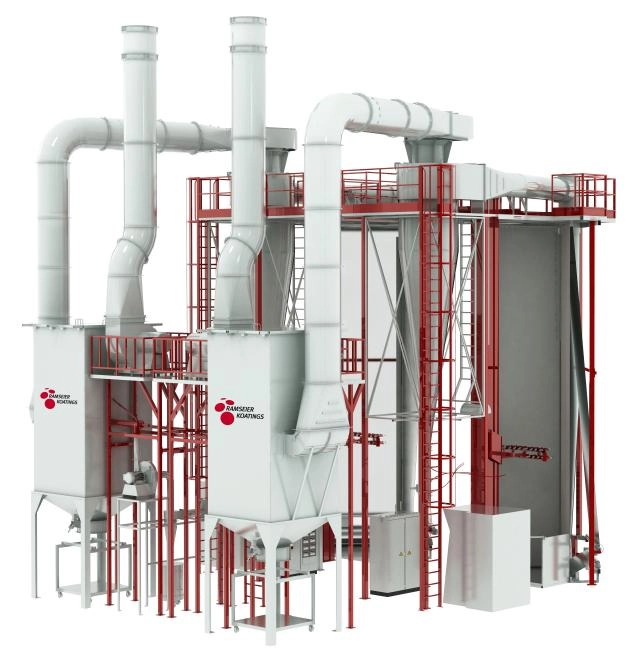

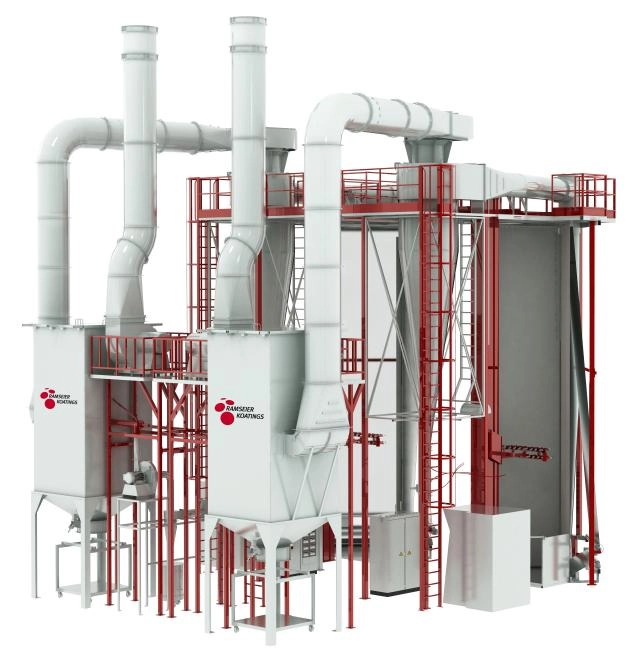

High automation with suspended conveyor systems.

The resulting coating has fewer pores, excellent corrosion resistance, and can be applied in a single thick layer.

The electrostatic powder coating process emerged in the 1960s, primarily used for coating metal surfaces. By the late 1990s, advancements in powder coatings and spraying equipment enabled its application to non-metallic surfaces.

Electrostatic Powder Coating Process

The use of electrostatic powder coating significantly reduces environmental pollution. As this method does not involve volatile substances such as organic solvents or water, it greatly reduces the risk of operational accidents. Unlike traditional paints, which release many harmful substances, electrostatic powder coating dramatically enhances safety while lowering costs.

Besides saving energy and reducing material consumption, electrostatic powder coating also greatly improves economic efficiency. The coating efficiency can reach nearly 100% without the need for solvents, significantly reducing the quantity of raw materials used. This method is fully mechanized, saving labor costs and enabling high-speed, large-scale operations.

Prior to coating, it is essential to clean the surface thoroughly to remove dust and rust, ensuring longer service life. Key surface treatment steps include: degreasing, phosphating, derusting, and passivation. These steps enhance surface adhesion and are typically performed through immersion, spraying, or waterfall-type processes.

After surface treatment, the object can be coated using a high-performance powder spraying machine designed for efficient powder recovery. Collected powder can be sieved and reused. After spraying, the item undergoes curing, usually at around 160°C, which ensures optimal powder concentration and uniform distribution.

Key Features of Electrostatic Powder Coating

Since powder coating technology entered the finishing industry, its share in general industrial coatings has steadily increased due to its unique advantages:

1. Environmental Protection

As environmental regulations increasingly restrict volatile organic compounds (VOCs), the coating industry has sought more eco-friendly alternatives. Electrostatic powder coating has proven to be one of the cleanest coating technologies available.

Powder coatings use no organic solvents or volatile substances, significantly reducing solvent-related pollution and safety hazards such as operator poisoning or fire risk. Since its introduction, no major safety incidents have been attributed to powder coatings.

As powder coating is a 100% solid formulation, it allows for full automation. Overspray can be easily recovered and reused, leading to a nearly 100% utilization rate, lowering waste disposal costs and minimizing environmental impact.

2. Economic Benefits

In traditional solvent-based coatings, only 60–65% of the material forms the final film. In contrast, powder coatings can achieve nearly 100% efficiency, and unused powder can be recycled. This technology enables cost-effective and efficient operations.

If any defects occur before baking, they can be removed using an air gun and re-sprayed without affecting the finish, reducing rework rates. The high level of automation also reduces labor requirements, and minimal training is needed for operators.

Since powder coatings contain no solvents, material consumption is reduced, packaging is minimized, and storage space is saved.

3. Energy Savings

Without volatile solvents, powder coatings reduce energy waste due to evaporation. Compared to liquid coatings, this method lowers energy costs significantly.

A single application can yield a thick film without the need for priming or multiple coats, making the process faster and more efficient. The equipment does not require dwell time, saving space. The curing time is also shorter than with liquid coatings, reducing fuel consumption and increasing production efficiency.

4. Excellent Film Properties

Once powder is sprayed onto a properly pre-treated MDF (medium-density fiberboard) surface and baked, it forms a high-quality film with excellent performance.

Common powder coatings exhibit long-lasting characteristics, including wear resistance, impact resistance, adhesion, toughness, corrosion resistance, and chemical resistance. For outdoor use, additional advantages include high weather resistance and anti-pollution properties.

Powder coatings can achieve thick coatings (50–300μm) in one application without sagging or dripping, unlike liquid coatings.

5. Electrostatic Powder Coating Process Flow

Using electrostatic powder coating equipment (electrostatic spray machines), powder coating is applied to the surface of a workpiece. Under the influence of static electricity, the powder adheres evenly to the surface, forming a powder layer. This powder layer is then melted and cured through high-temperature baking, resulting in a solid, decorative, and protective finish depending on the type of powder used.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.