Content Menu

● Understanding Powder Supply Systems

>> Key Applications Across Industries

● H2: Essential Features of a Modern Powder Supply System

>> H3: 1. Efficient Storage and Feeding Solutions

>> H3: 2. Advanced Conveying Technologies

>> H3: 3. Dust Control and Containment

>> H3: 4. Automation and Process Integration

>> H3: 5. Hygiene and Cleanability

>> H3: 6. Flexibility and Modular Design

>> H3: 7. Precise Control and Monitoring

>> H3: 8. Material Compatibility and Product Protection

>> H3: 9. Safety Features

>> H3: 10. Energy Efficiency and Sustainability

● H2: Comparing Powder Supply System Technologies

● H2: Key Performance Indicators for System Selection

● H2: Real-World Benefits of Advanced Powder Supply Systems

● H2: Frequently Asked Questions

>> Q1: What is the difference between pneumatic and mechanical powder conveying?

>> Q2: How can I ensure my powder supply system is safe for combustible dusts?

>> Q3: What maintenance is required for a powder supply system?

>> Q4: How do I select the right system for my powder's characteristics?

>> Q5: Can powder supply systems be integrated with existing factory automation?

>> Q6: What features help minimize cross-contamination during color or material changeovers?

>> Q7: Are there solutions for handling highly hygroscopic or heat-sensitive powders?

● Citations:

Selecting the right powder supply system is crucial for industries such as pharmaceuticals, food processing, chemicals, and manufacturing. The efficiency, safety, and reliability of powder handling directly impact product quality, operational costs, and workplace safety. This comprehensive guide explores the top features to consider when investing in a powder supply system, ensuring optimal performance and long-term value.

Understanding Powder Supply Systems

Powder supply systems are engineered solutions designed to store, convey, and deliver powdered or granular materials throughout a production process. Their core function is to move materials efficiently and safely between different stages of manufacturing, minimizing human intervention and reducing contamination risks.

Key Applications Across Industries

- Pharmaceuticals: Charging granulators, dryers, blenders, and tableting machines.

- Food Processing: Transferring dry ingredients between milling, mixing, coating, and packaging.

- Chemicals: Safe transfer of hazardous or sensitive powders.

- Manufacturing: Feeding powder coating lines, additive manufacturing, and more.

H2: Essential Features of a Modern Powder Supply System

H3: 1. Efficient Storage and Feeding Solutions

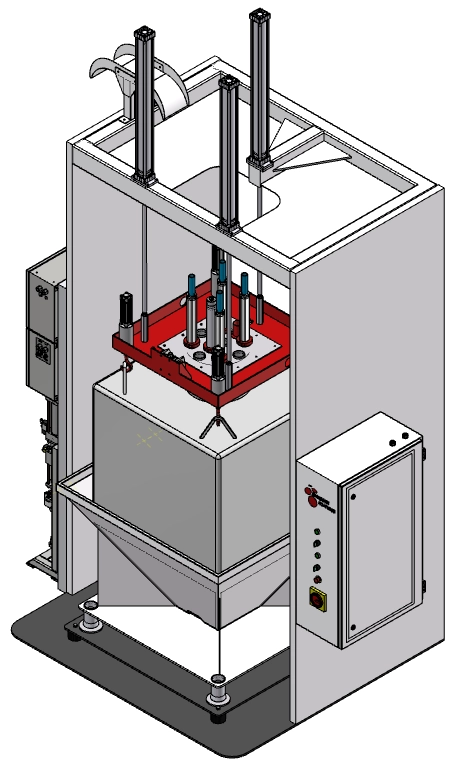

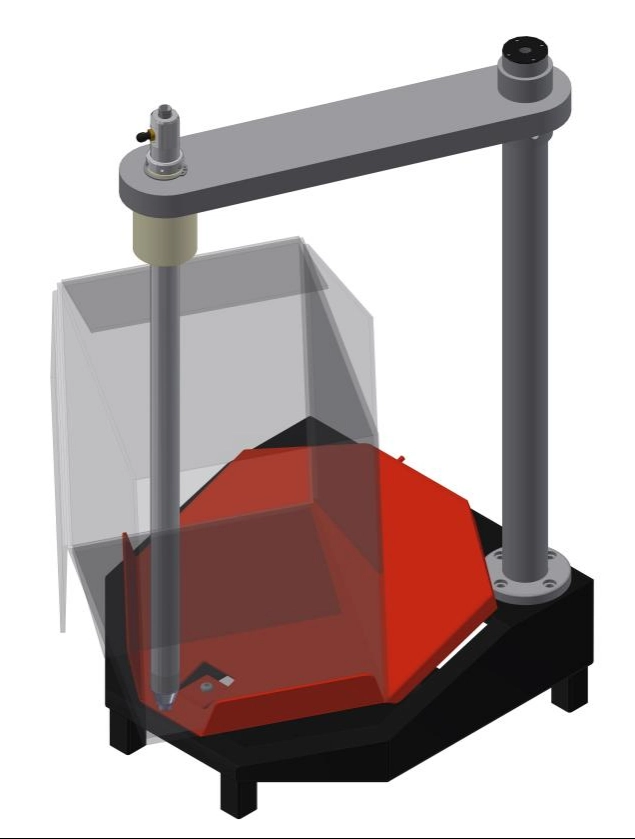

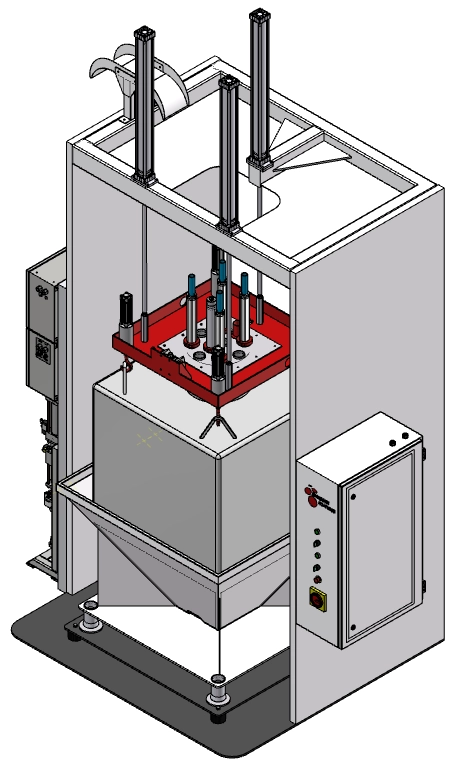

A robust powder supply system starts with well-designed storage and feeding equipment. Silos and hoppers are fundamental for bulk storage, providing controlled dispensing and minimizing clogging. Material unloading stations equipped with dust collectors and integrated sieving systems ensure clean, safe, and contaminant-free handling. The design should facilitate smooth flow, easy cleaning, and minimal operator intervention.

H3: 2. Advanced Conveying Technologies

The method of conveying powder is a critical determinant of system performance. Two primary technologies are prevalent:

- Pneumatic Conveyors: Utilize air pressure or vacuum to transport powders through pipelines, ensuring dust-free, hygienic, and enclosed transfer. These systems are ideal for high-throughput, automated environments and for materials that require protection from contamination or moisture.

- Mechanical Conveyors: Include screw conveyors, belt conveyors, and tube chain conveyors. These are suitable for short distances, heavy-duty applications, or when gentle handling is required to prevent product degradation.

The choice depends on the powder characteristics, required transfer rate, and specific process needs.

H3: 3. Dust Control and Containment

Effective dust management is non-negotiable in modern powder handling. Fugitive dust can pose health hazards, contaminate products, and increase the risk of combustible dust explosions. Look for systems with:

- Enclosed transfer lines and sealed joints.

- Integrated dust collection at unloading and transfer points.

- Bag dump stations with built-in dust extraction.

- Automated cleaning cycles to prevent buildup.

These features not only protect workers and products but also help comply with safety regulations and minimize housekeeping costs.

H3: 4. Automation and Process Integration

Automation transforms powder handling from a labor-intensive task to a streamlined, error-resistant process. Key automation features include:

- Programmable controls for recipe management and batch tracking.

- Automated weighing and dosing systems for precise ingredient delivery.

- Touchscreen interfaces for intuitive operation and reduced training requirements.

- Real-time monitoring and alarms for powder levels, flow rates, and system status.

Automated systems reduce manual handling, minimize operator error, and support consistent product quality, especially in high-volume or multi-shift operations.

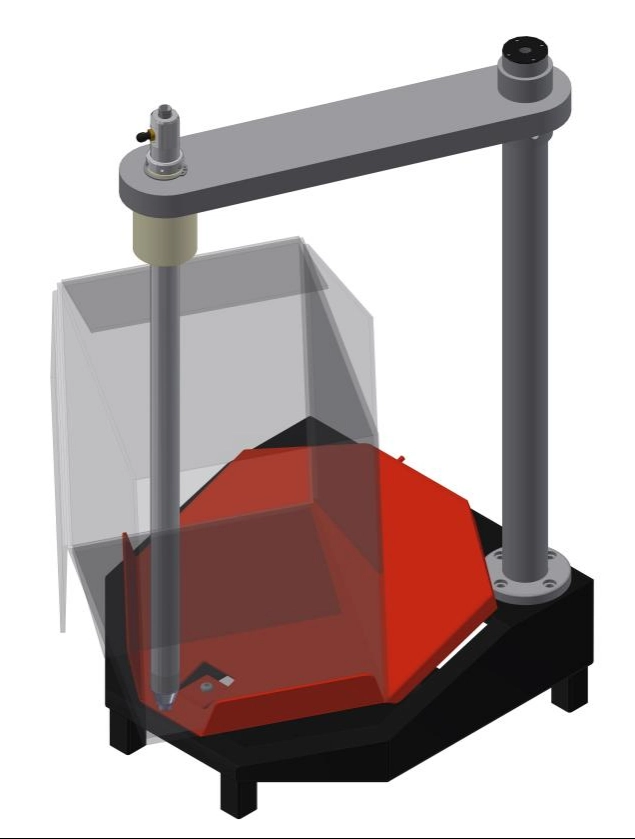

H3: 5. Hygiene and Cleanability

Industries like pharmaceuticals and food processing demand the highest hygiene standards. Powder supply systems must be designed for easy cleaning and fast changeovers:

- Tool-free disassembly and smooth, crevice-free surfaces.

- Automated cleaning-in-place (CIP) or high-pressure cleaning options.

- Integrated sieving to remove contaminants and oversize particles.

- Quick color or material change features for flexible production lines.

Such features minimize downtime, prevent cross-contamination, and support regulatory compliance.

H3: 6. Flexibility and Modular Design

Production requirements can change rapidly. A modular powder supply system allows for:

- Easy expansion or reconfiguration as needs evolve.

- Compatibility with various powder types and packaging formats.

- Integration with existing plant equipment and control systems.

Flexible systems protect your investment by adapting to new products, increased capacity, or process changes.

H3: 7. Precise Control and Monitoring

Consistent powder delivery is vital for quality control. Look for features such as:

- Gravimetric (loss-in-weight) or volumetric feeders for accurate dosing.

- Level sensors with visual/audible alarms to maintain optimal powder supply.

- Real-time data logging for process validation and troubleshooting.

- Discharge-on-demand capability for immediate, responsive powder delivery.

These controls ensure that powders are delivered in the correct quantity and at the right time, supporting repeatable, high-quality production.

H3: 8. Material Compatibility and Product Protection

The system must be compatible with the specific powders being handled. Considerations include:

- Bulk density and flowability: Systems should accommodate powders from free-flowing to cohesive or sticky.

- Particle size distribution: Fine powders may require special handling to prevent dusting or clogging.

- Sensitivity: Heat-sensitive, hygroscopic, or oxidizable powders may need inert gas blanketing, temperature control, or moisture barriers.

- Abrasiveness: Highly abrasive powders require wear-resistant materials and components.

Selecting the right system ensures product integrity and reduces maintenance costs.

H3: 9. Safety Features

Safety is paramount in powder handling. Essential features include:

- Explosion-proof components and grounding for combustible dusts.

- Interlocks and emergency stop functions.

- Enclosed systems to prevent operator exposure to allergens, toxins, or carcinogens.

- Compliance with industry standards (e.g., NFPA, OSHA).

A well-designed system protects both personnel and assets.

H3: 10. Energy Efficiency and Sustainability

Modern powder supply systems are designed for minimal energy consumption and waste:

- Optimized conveying velocities to reduce power use and equipment wear.

- Efficient dust collection and powder recovery to minimize losses.

- Ability to handle bulk containers, reducing packaging waste and ingredient costs.

Energy-efficient systems lower operational costs and support sustainability goals.

H2: Comparing Powder Supply System Technologies

| Feature | Pneumatic Conveying | Mechanical Conveying | Gravity-Based Systems |

| Dust Containment | Excellent | Good | Good |

| Automation Potential | High | Moderate | Low |

| Suitable for Long Distances | Yes | Limited | No |

| Gentle Handling | Moderate | Excellent | Excellent |

| Maintenance Requirements | Moderate | Higher (moving parts) | Low |

| Flexibility | High | Moderate | Low |

| Initial Investment | Higher | Moderate | Low |

H2: Key Performance Indicators for System Selection

When evaluating powder supply systems, consider these KPIs:

- Throughput Rate: Can the system meet your required transfer speeds?

- Accuracy: How precisely does it dose or weigh powders?

- Downtime: How quickly can the system be cleaned or changed over?

- Operator Safety: Does it minimize manual handling and exposure?

- Product Integrity: Is the powder protected from contamination and degradation?

- Scalability: Can the system grow with your production needs?

H2: Real-World Benefits of Advanced Powder Supply Systems

Implementing a state-of-the-art powder supply system delivers tangible advantages:

- Improved Workplace Safety: Reduces risk of injury and exposure to hazardous dusts.

- Enhanced Product Quality: Prevents contamination and ensures consistent ingredient delivery.

- Increased Productivity: Automation supports higher throughput and less downtime.

- Lower Operational Costs: Minimizes product loss, labor, and maintenance expenses.

- Regulatory Compliance: Supports adherence to safety and hygiene standards.

H2: Frequently Asked Questions

Q1: What is the difference between pneumatic and mechanical powder conveying?

A: Pneumatic systems use air or vacuum to move powders through sealed pipelines, offering excellent dust containment and automation potential. Mechanical systems use physical components like screws or belts, providing gentle handling for fragile materials but may generate more maintenance due to moving parts.

Q2: How can I ensure my powder supply system is safe for combustible dusts?

A: Choose systems with explosion-proof components, proper grounding, enclosed transfer lines, and integrated dust collection. Ensure compliance with NFPA and OSHA standards, and conduct regular risk assessments.

Q3: What maintenance is required for a powder supply system?

A: Maintenance needs vary by technology. Pneumatic systems require periodic inspection of filters, seals, and valves. Mechanical systems need regular lubrication and inspection of moving parts. Automated cleaning features can reduce manual maintenance.

Q4: How do I select the right system for my powder's characteristics?

A: Assess your powder's bulk density, flowability, particle size, sensitivity, and abrasiveness. Consult with system suppliers to match these properties to appropriate conveying and storage solutions.

Q5: Can powder supply systems be integrated with existing factory automation?

A: Yes, modern systems offer modular designs and programmable controls that can interface with plant-wide automation, MES, and ERP systems for seamless process integration.

Q6: What features help minimize cross-contamination during color or material changeovers?

A: Look for tool-free disassembly, automated cleaning cycles, smooth internal surfaces, and fast-change hoppers or feed lines. Systems with integrated sieving and purge functions further reduce contamination risk.

Q7: Are there solutions for handling highly hygroscopic or heat-sensitive powders?

A: Yes, specialized systems offer inert gas blanketing, temperature control, and moisture barriers to protect sensitive powders during transfer and storage.

Citations:

[1] https://indpro.com/blog/powder-handling-systems-equipment-a-comprehensive-guide/

[2] https://www.plantengineering.com/five-bulk-powder-handling-automation-benefits-for-manufacturers-operators/

[3] https://www.pcimag.com/articles/102796-powder-management-system

[4] https://www.ddpsinc.com/blog/choosing-the-right-powder-transfer-system-a-guide-to-key-performance-indicators

[5] https://www.wagner-group.com/fileadmin/industrie/wagner-usa/brochures/WAGNER_BR_PowderCoatingSystems_EN.pdf

[6] https://www.linkedin.com/pulse/applications-benefits-powder-transfer-system-chemiplantindia-qrbpf

[7] https://www.bolair.ca/blog/choose-right-powder-coating-system/

[8] https://ampp.org/technical-research/what-is-corrosion/types-of-powder-coatings-systems

[9] https://www.ipco.com/en-us/solutions/powder-coating-production-systems

[10] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating

---

来自 Perplexity 的回答: pplx.ai/share

.

.