Content Menu

>> Assessing Production Line Compatibility

>> Selecting the Right Automated Spray Booth System

>>> Types of Automated Spray Booths

>>> Critical Components for Integration

>> Steps for Seamless Integration

>>> 1. Retrofitting Existing Infrastructure

>>> 2. Optimizing Spray Parameters

>>> 3. Implementing Real-Time Monitoring

>>> 4. Training Workforce for Hybrid Operations

>> Addressing Common Integration Challenges

>> Case Studies in Successful Integration

>> Maintenance and Long-Term Performance

>> Frequently Asked Questions

>> Citations:

Integrating automated spray booth systems into existing production lines requires strategic planning, technical adaptation, and a thorough understanding of operational requirements. These systems enhance efficiency, reduce waste, and improve workplace safety, but their successful implementation depends on aligning booth design with production workflows, optimizing automation levels, and ensuring seamless compatibility with existing infrastructure. Below, we explore actionable strategies for achieving this integration while addressing common challenges.

Assessing Production Line Compatibility

Before selecting an automated spray booth, evaluate your production environment's unique demands. Key considerations include:

Production Volume and Speed

High-volume, repetitive tasks benefit most from synchronous or continuous spray booths, which maintain consistent output with minimal downtime. For smaller batches or variable product sizes, non-synchronous or single-station systems offer greater flexibility.

Product Dimensions and Geometry

Customizable booth designs accommodate parts of varying shapes and sizes. Motorized conveyor systems, overhead rails, or robotic arms ensure precise positioning during spraying, reducing overspray and improving coating consistency.

Existing Workflow Gaps

Identify bottlenecks in manual processes, such as prolonged drying times or frequent changeovers. Automated systems with integrated curing ovens or quick-adjust settings can streamline these stages.

Selecting the Right Automated Spray Booth System

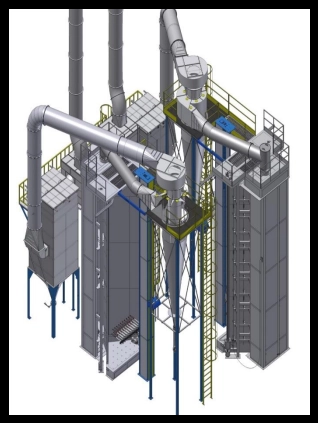

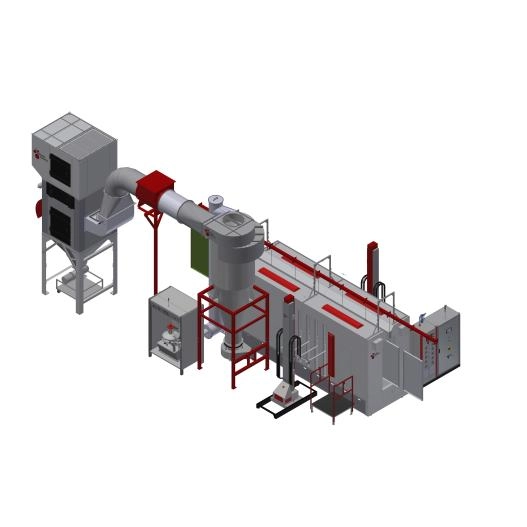

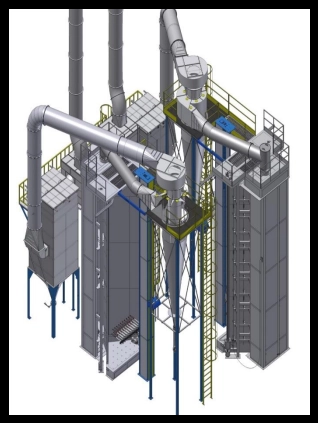

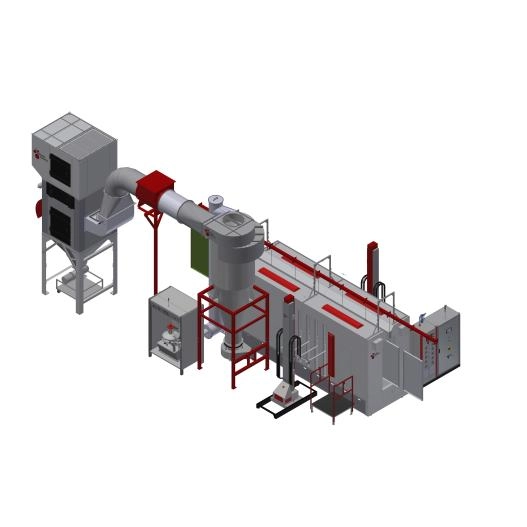

Types of Automated Spray Booths

- Synchronous Systems: Ideal for high-volume, uniform production lines (e.g., automotive parts).

- Non-Synchronous Systems: Suit mixed-product environments with frequent adjustments.

- Single-Station Units: Cost-effective for small-scale operations requiring partial automation.

- Continuous Conveyor Systems: Maximize throughput for industries like appliance manufacturing.

Critical Components for Integration

- Robotic Paint Applicators: FANUC robots, for example, enable high-speed, precision spraying with programmable paths.

- Centralized Control Panels: Monitor airflow, temperature, and safety protocols in real time.

- Water Wall Filtration: Reduces overspray contamination and meets environmental standards.

Steps for Seamless Integration

1. Retrofitting Existing Infrastructure

Modify conveyor systems or part hangers to align with the booth's loading mechanisms. For example, retrofitting motorized rails ensures smooth transitions between spraying and drying zones.

2. Optimizing Spray Parameters

Use programmable logic controllers (PLCs) to standardize fluid pressure, nozzle distance, and coating thickness. This minimizes material waste and ensures uniform finishes.

3. Implementing Real-Time Monitoring

Advanced sensors track air quality, filter efficiency, and equipment performance. Alerts for maintenance needs or deviations prevent unplanned downtime.

4. Training Workforce for Hybrid Operations

Transition operators to supervisory roles focused on system oversight, quality checks, and troubleshooting. Cross-training ensures adaptability during technical disruptions.

Addressing Common Integration Challenges

Material Waste

Automated systems reduce overspray by 30–50% compared to manual methods. Flow meters and recirculation systems further optimize adhesive or paint usage.

High Labor Costs

Robotic arms and automated changeovers cut labor expenses by 40–60%. Digitally stored settings enable rapid transitions between product variants.

Safety and Compliance

Enclosed ventilation, fire suppression systems, and PPE protocols mitigate exposure to hazardous fumes. Compliance with OSHA and NFPA standards is non-negotiable.

Case Studies in Successful Integration

Automotive Parts Manufacturer

A mid-sized manufacturer integrated a continuous conveyor system with FANUC robots, reducing cycle times by 25% and coating defects by 18%. Real-time diagnostics slashed maintenance costs by 30%.

Furniture Production Facility

By retrofitting a single-station booth with programmable spray guns, the company achieved 95% consistency in finish quality while accommodating custom designs.

Maintenance and Long-Term Performance

Preventive Maintenance Strategies

- Schedule filter replacements based on usage data.

- Calibrate sensors and robots quarterly.

- Update software for adaptive learning algorithms.

Data-Driven Optimization

Historical performance reports identify trends, such as peak efficiency periods or recurring malfunctions. This informs future upgrades or process adjustments.

Frequently Asked Questions

Q1: How do I choose between batch and continuous spray systems?

Batch systems suit low-volume, diverse production lines, while continuous systems excel in high-volume environments. Assess throughput goals and product variability.

Q2: Can automated booths handle irregularly shaped parts?

Yes. Customizable robotic arms and adjustable conveyors adapt to complex geometries.

Q3: What is the ROI timeline for automation?

Most operations recoup costs within 12–18 months through reduced waste, labor savings, and higher output.

Q4: How do I ensure compatibility with older machinery?

Retrofitting connectors, updating PLCs, and modular booth designs bridge technological gaps.

Q5: Are automated systems compliant with environmental regulations?

Advanced filtration and closed-loop recycling systems meet EPA and ISO standards for emissions and waste.

Citations:

[1] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[2] https://pfsspraybooths.com/how-do-paint-booth-control-panels-work-a-complete-guide

[3] https://truflowspraybooths.com.au/production-line-booths-curing-ovens.htm

[4] https://arnoldmachine.com/resources/adhesive-spraying-equipment-problems-and-solutions/

[5] https://automatedsolutions.com.au/automated-spray-booth/

[6] https://www.sprayboothshop.com/blog/spray-booth-monitoring/

[7] https://www.rohnerspraybooths.com/blog/integrating-automation-into-your-finishing-process

[8] https://www.asminternational.org/tss/wp-content/uploads/sites/38/files/content/safety5.pdf

[9] https://spraytech.com/f-a-q/

[10] https://360zolutions.com/need-spraybooth-questions-to-answer/

[11] https://www.spraysystems.com/key-decisions-for-powder-coatings-batch-or-automated-spray-to-waste-or-reclaim/

[12] https://marathonspraybooths.com/faq/

[13] https://arnoldmachine.com/expertise/coating-systems/

[14] https://www.rohnerspraybooths.com/blog/benefits-of-custom-paint-booth

[15] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P100P6SY.TXT

[16] https://www.accudraftpaintbooths.com/faqs/

[17] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/why-you-should-automate-your-paint-booth.html

[18] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[19] https://pfsspraybooths.com/breathing-easy-how-airflow-transforms-paint-booth-efficiency

[20] https://www.warrenforensics.com/wp-content/uploads/2013/11/Recirculation-Paint-Spray-Booths.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.