Content Menu

● Understanding the Powder Supply System

● Store Powders in Controlled Environments

● Use Original, Sealed Packaging

● Monitor Humidity and Temperature Regularly

● Rotate Inventory Using FIFO Method

● Regular Cleaning of Powder Handling Equipment

● Inspect and Replace Worn Parts

● Maintain Filters and Airflow Systems

● Check Seals and Prevent Air Leaks

● Verify Air-Bleed Systems and Control Settings

● Grounding and Static Control

● Conduct Small-Scale Tests Before Full Application

● Prepare Substrates Properly

● Maintain Clean Booths and Work Areas

● Use Dry, Oil-Free Compressed Air

● Protect Powder from Sunlight and Contaminants

● Ensure Worker Safety

● Powder Clumping and Hardening

● Equipment Clogging

● Inconsistent Powder Flow

● Related Questions and Answers

Maintaining a powder supply system is critical for ensuring consistent product quality, operational efficiency, and minimizing downtime in industries such as powder coating, pharmaceuticals, food processing, and chemical manufacturing. A well-maintained powder supply system not only preserves the integrity of the powder material but also extends the life of the equipment involved in handling and applying powders. This article explores the best practices for maintaining a powder supply system, covering storage, equipment upkeep, environmental control, and operational procedures.

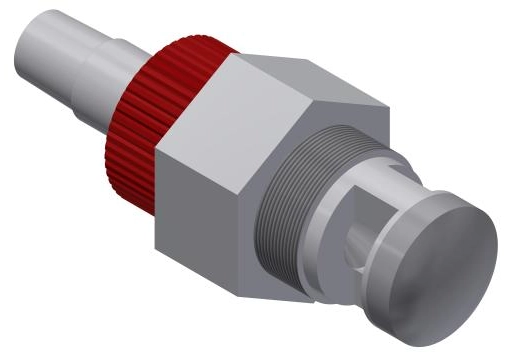

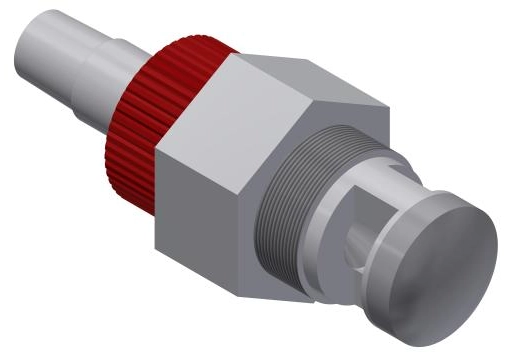

Understanding the Powder Supply System

Before diving into maintenance practices, it is important to understand the components of a typical powder supply system. Such systems generally include powder storage units, transfer mechanisms (such as vacuum conveyors or pneumatic conveyors), feeding and dosing equipment, and application or processing machinery. Each component plays a vital role in ensuring the powder remains free-flowing, uncontaminated, and ready for use.

Store Powders in Controlled Environments

Powders are sensitive to environmental conditions, especially humidity and temperature. Storing powders in a climate-controlled room is essential to prevent moisture absorption, which can cause powders to clump, harden, or degrade. Maintaining a stable temperature and low humidity environment helps preserve powder quality over time.

Use Original, Sealed Packaging

When powders are not in use, keeping them in their original sealed packaging prevents contamination and exposure to air and moisture. If powders are transferred to secondary containers, these should be airtight and clean to avoid contamination.

Monitor Humidity and Temperature Regularly

Using humidity gauges and temperature sensors to continuously monitor storage conditions allows early detection of unfavorable changes. In areas prone to high humidity, employing dehumidifiers can help maintain the ideal environment.

Rotate Inventory Using FIFO Method

Applying a First In, First Out (FIFO) inventory management system ensures older powders are used before newer stock, reducing the risk of using expired or degraded materials. Proper labeling and organized storage facilitate effective inventory rotation.

# Equipment Maintenance and Cleaning

Regular Cleaning of Powder Handling Equipment

Powder feed hoppers, spray guns, nozzles, and transfer lines should be cleaned frequently to prevent powder buildup and clogging. Residual powder can cause blockages, reduce flow efficiency, and affect the quality of powder application.

Inspect and Replace Worn Parts

Regular inspection of hoses, seals, filters, and gaskets is necessary to detect wear or damage. Replacing these parts promptly prevents leaks, air loss, and contamination, which can compromise system performance.

Maintain Filters and Airflow Systems

Filters are central to powder transfer systems, especially in vacuum conveying setups. Blocked or dirty filters reduce airflow and throughput. Cartridge-type filters can be vacuumed clean, while fabric-type filter bags may require washing. Ensuring filters are clean and functioning optimally maintains efficient powder flow.

Check Seals and Prevent Air Leaks

Seals and gaskets must be in perfect condition and properly fitted to avoid air leaks that can disrupt powder transfer. Removing residual powder from sealing surfaces helps maintain airtight connections.

Verify Air-Bleed Systems and Control Settings

Air-bleed systems allow controlled introduction of air to assist powder flow. These systems should be checked regularly for proper operation. Additionally, control sequences such as convey duration, discharge times, and filter cleaning cycles must be optimized and monitored to ensure peak performance.

Grounding and Static Control

Static electricity buildup can cause powder to cling to equipment surfaces, leading to blockages and uneven application. Using embedded-wire flexible hoses and ensuring proper grounding at all points in the system prevents static accumulation. Periodic testing with a multimeter confirms continuous grounding.

Conduct Small-Scale Tests Before Full Application

Before applying powder on a large scale, perform test sprays on sample panels to check powder fluidization, spray consistency, and adhesion. This practice helps identify potential issues early and allows adjustments to application parameters.

Prepare Substrates Properly

The surface to be coated or processed must be clean, dry, and free of oils or contaminants. Proper substrate preparation ensures optimal powder adhesion and finish quality.

Maintain Clean Booths and Work Areas

Powder coating booths and surrounding areas should be cleaned regularly to remove residual powders. This prevents cross-contamination between colors or batches and maintains a safe working environment.

Use Dry, Oil-Free Compressed Air

Compressed air used for cleaning or powder conveyance must be dry and free of oil to avoid contaminating the powder and affecting its performance.

Protect Powder from Sunlight and Contaminants

Exposure to sunlight and airborne contaminants can degrade powder quality. Store powders away from direct light and in clean environments to minimize these risks.

Ensure Worker Safety

Operators should use appropriate personal protective equipment (PPE) such as masks, gloves, and eye protection to avoid inhaling powder particles or skin contact. Proper ventilation in powder handling areas also reduces health risks.

Powder Clumping and Hardening

If powders show signs of clumping or hardening, lightly shaking or rolling the sealed liner may help detect the problem. Mild agglomeration can sometimes be corrected by sieving or fluidizing the powder with dry compressed air. However, if the powder has absorbed significant moisture and hardened, it may need to be discarded.

Equipment Clogging

Frequent cleaning of spray nozzles and powder feed components prevents clogging. If clogging occurs, inspect for damaged parts or contamination and replace or clean as necessary.

Inconsistent Powder Flow

Check for air leaks, filter blockages, and proper grounding to resolve inconsistent powder flow issues. Adjust control sequences and air-bleed systems as needed to optimize performance.

Maintaining a powder supply system requires diligent attention to storage conditions, equipment cleanliness, and operational procedures. By controlling environmental factors such as humidity and temperature, regularly cleaning and inspecting equipment, and following proper handling protocols, operators can ensure powder quality and system efficiency. Additionally, safety measures protect workers and maintain a clean, productive workspace. Implementing these best practices leads to consistent, high-quality powder application and prolonged equipment life.

Related Questions and Answers

Q1: How often should powder coating equipment be cleaned?

A1: Powder coating equipment such as feed hoppers, spray guns, and nozzles should be cleaned frequently, ideally after each use or at least daily, to prevent buildup and clogging.

Q2: What is the ideal environment for storing powder coatings?

A2: Powders should be stored in a climate-controlled room with low humidity and stable temperature, away from sunlight and contaminants.

Q3: How can static electricity be controlled in a powder supply system?

A3: Using embedded-wire hoses and ensuring proper grounding throughout the system prevents static buildup. Regular testing with a multimeter confirms grounding effectiveness.

Q4: What should be done if powder has absorbed moisture and hardened?

A4: If the powder is significantly hardened due to moisture, it is usually no longer usable and should be discarded to avoid quality issues.

Q5: Why is the FIFO method important in powder inventory management?

A5: FIFO ensures older powders are used first, preventing the use of expired or degraded materials and reducing waste.

[1] https://www.tiger-coatings.com/us-en/blog/powder-coating-storage

[2] https://hmft.com/blogs/news/how-to-properly-maintain-and-troubleshoot-powder-coating-equipment

[3] https://resources.forrestpaint.com/powder-coating-best-practices

[4] https://www.lanecoatings.com/powder-coating-care-maintenance/

[5] https://www.hanningfield.com/optimising-powder-transfer-system/

[6] https://www.gemu.cn/static/uploads/editor/files/20200511/1589177189554633.pdf

[7] https://tncoating.com/blog/powder-coating-parts/

[8] http://www.tup.tsinghua.edu.cn/upload/books/yz/084548-01.txt

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.