Content Menu

● Understanding Manual Spray Booths

>> Types of Manual Spray Booths

● Key Features That Ensure High-Quality Finishes

>> Effective Ventilation and Airflow

>> Advanced Filtration Systems

>> Superior Lighting and Visibility

>> User-Friendly Controls

>> Safety Features

>> Booth Enclosure and Construction

>> Powder Containment and Overspray Capture

>> Optimal Temperature and Humidity Control

● Enhancing Finish Quality with Manual Spray Booths

>> Preparation and Setup

>> Spraying Technique

>> Inspection and Touch-Up

>> Drying and Curing

● Maintenance for Consistent High-Quality Results

● Customization and Flexibility

● Compliance and Environmental Considerations

● Cost Efficiency and Long-Term Value

● Frequently Asked Questions

● Citations:

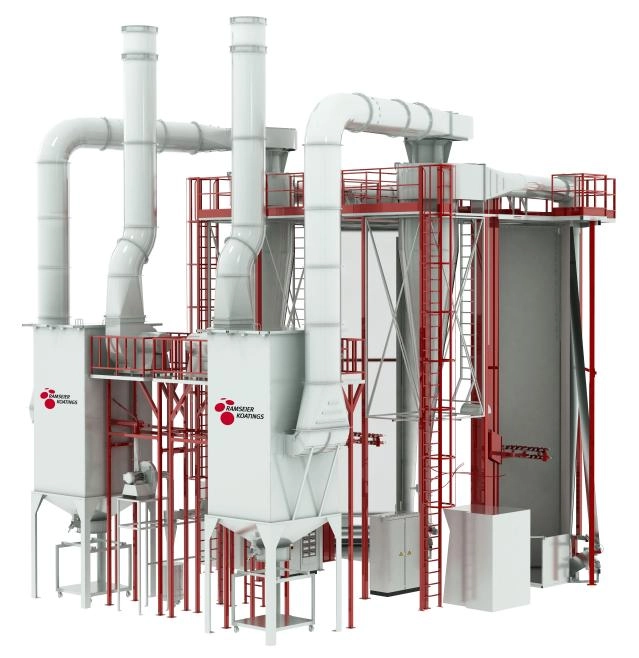

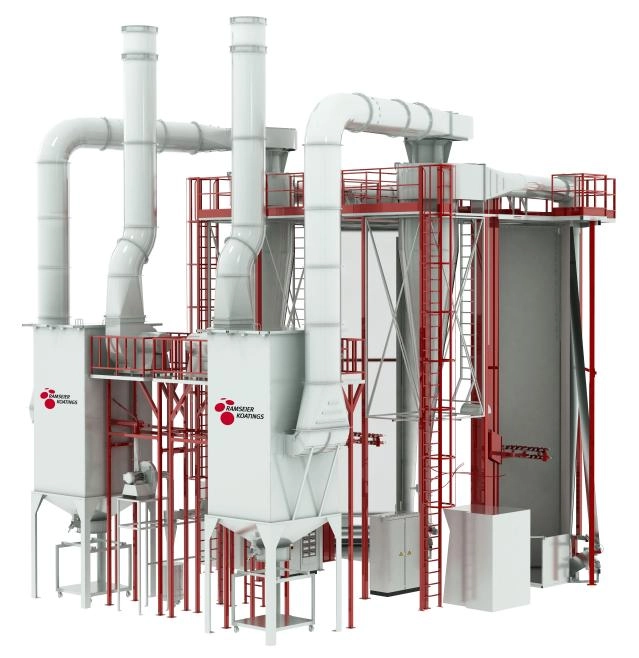

Manual spray booths are essential in industries where precision, finish quality, and safety are paramount. Whether used for automotive refinishing, woodworking, metal fabrication, or custom manufacturing, these booths provide controlled environments that enable operators to achieve flawless finishes. This article explores the best features of manual spray booths that contribute to high-quality results, covering booth types, airflow systems, lighting, filtration, safety, maintenance, and more.

Understanding Manual Spray Booths

Manual spray booths are enclosures designed to contain the application of paints, coatings, or powders. Unlike automated booths, manual booths require an operator to handle the spray gun and control the application process. Their versatility makes them ideal for custom jobs, prototypes, and small to medium production runs.

Types of Manual Spray Booths

- Crossdraft Booths: Air flows horizontally from one end to the other, providing straightforward construction and cost-effectiveness. Best suited for smaller parts or workshops where space is limited.

- Downdraft Booths: Air is drawn from the ceiling and exhausted through the floor, offering superior control over overspray and contaminants. Ideal for large vehicles or high-quality finishes.

- Semi-Downdraft Booths: Combine features of crossdraft and downdraft designs, balancing performance and affordability.

- Side Downdraft Booths: Air enters from the ceiling and exits through side walls, ensuring even coverage and effective contaminant removal.

Each booth type offers unique advantages depending on the application, space, and finish requirements.

Key Features That Ensure High-Quality Finishes

Effective Ventilation and Airflow

Proper ventilation is the cornerstone of any high-quality spray booth. A well-designed airflow system removes overspray, fumes, and airborne contaminants, preventing them from settling on freshly coated surfaces. Balanced airflow, whether horizontal, vertical, or side-to-side, ensures even paint distribution and minimizes imperfections. Advanced booths allow operators to adjust airflow rates for optimal results, regardless of the coating type or environmental conditions.

Advanced Filtration Systems

Filtration is critical for both finish quality and operator safety. Multi-stage filters capture dust, particulates, and volatile organic compounds (VOCs) before they can contaminate the workpiece or escape into the workplace. High-efficiency filters not only protect the finish but also extend equipment life and maintain regulatory compliance. Some booths feature visual gauges or manometers to indicate when filters need replacing, ensuring consistent performance.

Superior Lighting and Visibility

High-quality lighting is essential for manual spraying. Proper illumination allows operators to see subtle defects, achieve even coverage, and avoid costly mistakes. Modern booths use a combination of overhead and side-mounted fixtures, often with color-corrected bulbs, to simulate natural daylight. Protective covers and easy-clean designs prevent overspray buildup on lights, maintaining visibility over time.

User-Friendly Controls

Manual spray booths are equipped with intuitive control panels that manage airflow, lighting, temperature, and safety systems. These controls allow operators to adjust settings quickly, ensuring optimal conditions for each job. Advanced models may include programmable timers, digital displays, and integrated alarms for filter maintenance or airflow issues.

Safety Features

Safety is paramount in any spray environment. Manual spray booths incorporate features such as:

- Explosion-proof lighting and electrical components

- Fire suppression systems

- Emergency shut-off switches

- Interlocked doors to prevent operation when open

- Proper grounding to prevent static discharge

These safeguards protect both operators and facilities, reducing the risk of accidents and ensuring compliance with safety regulations.

Booth Enclosure and Construction

A robust booth enclosure prevents overspray from escaping, maintains a clean working environment, and shields the operator from external contaminants. High-quality booths use durable materials like galvanized steel and feature smooth, easy-to-clean surfaces. Sealed joints and caulked gaps further reduce dust intrusion and maintain positive pressure within the booth.

Powder Containment and Overspray Capture

For powder coating, manual booths are designed to contain powder particles and capture overspray efficiently. This not only protects the operator but also reduces material waste and environmental impact. Integrated extraction systems and multiple filters ensure that airborne particles are removed before they can settle on surfaces or escape into the workspace.

Optimal Temperature and Humidity Control

Consistent temperature and humidity levels are vital for achieving flawless finishes. Some manual booths feature integrated air makeup units or heaters to maintain stable conditions, reducing drying times and minimizing defects like runs or orange peel. Proper environmental control also improves adhesion and durability of the final coating.

Enhancing Finish Quality with Manual Spray Booths

Preparation and Setup

- Ensure the booth is clean, with all filters and ventilation systems functioning properly.

- Position workpieces centrally to maximize airflow coverage.

- Mask areas not to be coated, avoiding blockage of ventilation grates.

Spraying Technique

- Adjust spray gun settings according to the coating material and desired finish.

- Apply thin, even coats, allowing proper drying between layers.

- Maintain a consistent distance and angle to the workpiece for uniform coverage.

Inspection and Touch-Up

- Use the booth's superior lighting to inspect for defects or missed spots.

- Perform touch-ups as needed, taking advantage of the controlled environment.

Drying and Curing

- Allow adequate drying time within the booth, utilizing temperature and airflow controls.

- For powder coating, transfer parts to a curing oven as specified by the coating manufacturer.

Maintenance for Consistent High-Quality Results

Routine maintenance is essential to preserve booth performance and finish quality:

- Daily: Sweep floors, inspect filters, and check for visible blockages.

- Weekly: Clean booth walls, floors, and light covers to prevent overspray buildup.

- Monthly: Inspect fans, electrical systems, and safety devices.

- As Needed: Replace filters, clean ventilation ducts, and recalibrate control systems.

Using peelable coatings on booth walls and floors can simplify cleaning and protect surfaces from overspray accumulation.

Customization and Flexibility

Manual spray booths can be tailored to specific industry needs, from automotive refinishing to furniture manufacturing. Custom features may include specialized racks, adjustable lighting, variable airflow controls, and size modifications to accommodate unique workpieces. This flexibility makes manual booths a preferred choice for businesses requiring adaptability and high-quality output.

Compliance and Environmental Considerations

Investing in a quality manual spray booth ensures compliance with occupational safety and environmental regulations. Proper containment of hazardous materials, efficient filtration, and safe disposal of waste contribute to a healthier workplace and reduced environmental impact. Adherence to standards such as OSHA, NFPA, and EPA guidelines is not only a legal requirement but also a mark of professionalism and responsibility.

Cost Efficiency and Long-Term Value

While the initial investment in a manual spray booth may be significant, the long-term benefits include reduced material waste, fewer reworks, extended equipment lifespan, and minimized downtime. Well-maintained booths can last for decades, providing consistent, high-quality finishes that enhance product value and customer satisfaction.

Frequently Asked Questions

1. What is the difference between crossdraft and downdraft manual spray booths?

Crossdraft booths move air horizontally, making them cost-effective and easy to install, but they may allow more contaminants onto the workpiece. Downdraft booths pull air vertically from ceiling to floor, offering better control of overspray and superior finish quality, especially for larger items.

2. How often should I replace the filters in my manual spray booth?

Filter replacement depends on usage and the type of coatings applied. Many booths feature gauges or manometers to indicate when filters are clogged. As a rule of thumb, inspect filters daily and replace them as soon as airflow is compromised or visible saturation occurs.

3. Why is lighting so important in a manual spray booth?

Good lighting enables operators to see defects, ensure even coverage, and avoid costly mistakes. It also improves safety and efficiency, allowing for thorough inspections and touch-ups before curing.

4. Can manual spray booths be used for both wet and powder coatings?

Yes, but the booth design and filtration system must be appropriate for the type of coating. Powder booths require specialized filters and containment systems to handle fine particles, while wet booths focus on VOC and overspray control.

5. How do I maintain a manual spray booth for optimal performance?

Regular cleaning, filter replacement, inspection of ventilation and safety systems, and use of protective coatings on booth surfaces are key. Following the manufacturer's maintenance schedule ensures consistent performance and extends booth life.

Citations:

[1] https://www.ramseierkoatings.com/what-are-the-top-features-to-look-for-in-a-manual-spray-booth-system.html

[2] https://www.hppneumatics.com/spray-booth-benefits/

[3] https://www.alibaba.com/showroom/manual-paint-spray-booth.html

[4] https://ems-powdercoating.com/manual-powder-coating-booth/

[5] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[6] https://marathonspraybooths.com/industrial-spray-booth-maintenance-guide/

[7] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/a-complete-guide-to-keeping-a-paint-booth-clean

[8] https://www.codinter.com/en/spray-booths-a-complete-guide/

[9] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[10] https://www.spraysystems.com/case-studies/

[11] https://globalfinishing.com/2020/06/05/how-to-maximize-your-paint-booth-cycles/

[12] https://www.spraysystems.com/spray-booth-lighting-a-guide-to-finish-quality-safety-and-operational-costs/

[13] https://pfsspraybooths.com/deciding-on-the-right-spray-booth-for-your-business

[14] https://www.powderspraymachine.com/spray-booth-function-and-classification/

[15] https://jmcautomotiveequipment.com/blog/the-benefits-of-using-a-portable-paint-booth/

[16] https://www.spraysystems.com/spray-booth-lighting-a-guide-to-finish-quality-safety-and-operational-costs/

[17] https://www.colo-group.com/closed-powder-coating-booth-15241932163728183.html

[18] https://www.rohnerspraybooths.com/blog/choosing-the-right-spray-booth

[19] https://www.powderspraymachine.com/adding-manual-conveyor-lines-to-paint-booths/

[20] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[21] https://wflitone.en.made-in-china.com/product/KJbUWdwVyjci/China-Manual-Powder-Coating-Paint-Spray-Booth-System.html

[22] https://www.ramseierkoatings.com/what-makes-a-manual-spray-booth-the-best-choice-for-precision-painting.html

[23] https://www.ramseierkoatings.com/what-are-the-top-advantages-of-manual-spray-booths-in-custom-painting-projects.html

[24] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[25] https://pfsspraybooths.com/how-do-paint-booth-control-panels-work-a-complete-guide

[26] https://woodweb.com/cgi-bin/forums/finishing.pl?read=852919

[27] https://masterflo-uk.com/essential-guide-to-spray-booth-safety-regulations-best-practices-and-maintenance/

[28] https://www.reddit.com/r/minipainting/comments/197lvr8/airbrush_booth_not_working/

[29] https://www.finishsystems.com/blogs/news/what-maintenance-do-you-recommend-for-our-spray-booth

[30] https://globalfinishing.com/2011/02/24/paint-booth-faqs-part-1/

[31] https://cakesafe.com/products/SPRAY-BOOTH-FAQS-c145403013

[32] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/common-paint-booth-problems-and-how-to-fix-them

[33] https://globalfinishing.com/wp-content/uploads/2023/11/Dry_Filter_Booths_Service_and_Maintenance_Manual.pdf

[34] https://community.ceramicartsdaily.org/topic/1697-spray-booth-help/

[35] https://gsbindustries.com/faqs/

[36] https://www.garmatspraybooths.com/tips-from-garmat/how-to-fix-the-most-common-paint-booth-issues/

[37] https://www.usius.com/essential-questions-to-ask-your-paint-booth-supplier/

[38] https://www.reddit.com/r/airbrush/comments/147rs99/recommendation_for_spray_booth/

[39] https://p2infohouse.org/ref/30/29081.pdf

[40] https://envirocare.org/case-studies/spray-booth-emissions-monitoring-in-leeds/

[41] https://pfsspraybooths.com/common-spray-booth-mistakes-and-how-to-avoid-them

[42] https://www.ultrimaxstore.com/blogs/news/best-practice-for-spray-booth-maintenance

[43] https://www.finewoodworking.com/forum/spray-booth-setup

[44] https://www.paintbooth.com/things-need-for-paint-booth/

[45] https://relyonusa.com/five-essential-tips-paint-booth-maintenance/

[46] https://www.blastone.com/case-studies/

[47] https://www.ramseierkoatings.com/what-are-the-best-practices-for-maintaining-a-manual-spray-booth-system.html

[48] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[49] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[50] https://www.youtube.com/watch?v=r0n0vtVtv28

[51] https://www.duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers

[52] https://www.paint-booths.com/FAQS.html

[53] https://forum.finescale.com/t/spray-booth-question/250541

[54] https://www.youtube.com/watch?v=IQodfZvcX7Y

[55] https://marathonspraybooths.com/industrial-spray-booth-maintenance-guide/

[56] https://www.ecotechsystems.net/choosing-the-right-paint-booth-for-you

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.