Content Menu

● Understanding Powder Supply Systems

>> What Is a Powder Supply System?

>> Key Features of an Effective Powder Supply System

● Major Industrial Applications of Powder Supply Systems

>> Powder Coating Industry

>>> Automotive and Heavy-Duty Equipment

>>> Building and Construction

>>> Consumer Products and Furniture

>> Powder Metallurgy and Additive Manufacturing

>> Pharmaceuticals and Nutraceuticals

>> Food and Beverage Industry

>> Chemicals and Catalysts

● Technological Innovations in Powder Supply Systems

>> Electrostatic Spray Deposition (ESD)

>> Mobile and Remote Monitoring Applications

>> Automation and Integration

● Benefits of Using Powder Supply Systems in Various Applications

● Challenges and Considerations

● Conclusion

● Frequently Asked Questions

Powder supply systems are critical components in various industrial processes where powders are used as raw materials or coatings. These systems ensure the efficient handling, delivery, and application of powders, which can significantly impact product quality, production efficiency, and operational costs. This article explores the best applications for powder supply systems across different industries, highlighting their roles, benefits, and technological advancements.

Understanding Powder Supply Systems

What Is a Powder Supply System?

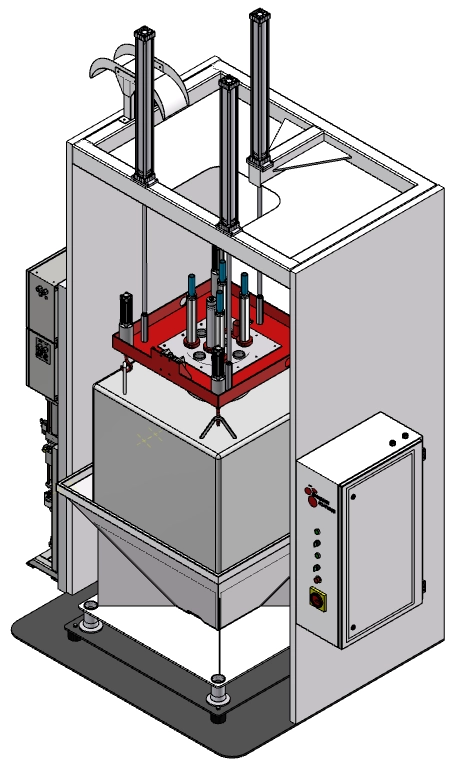

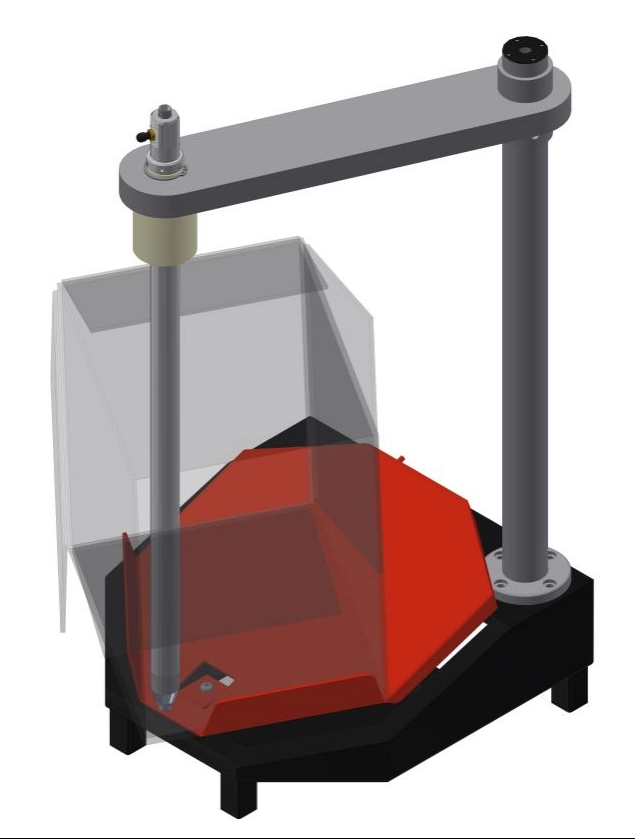

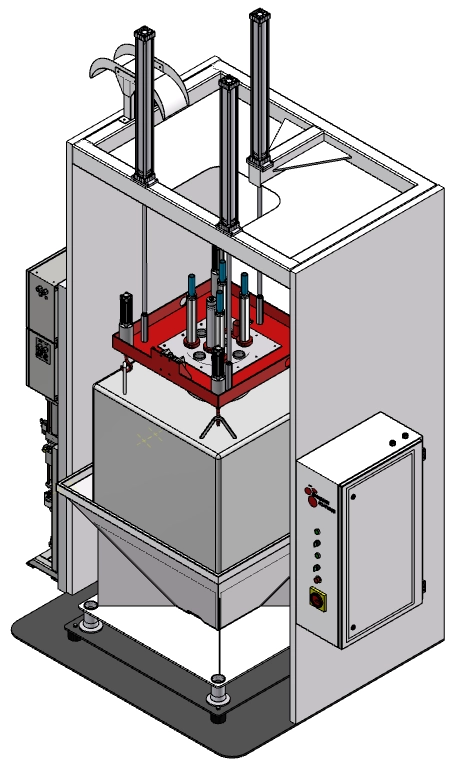

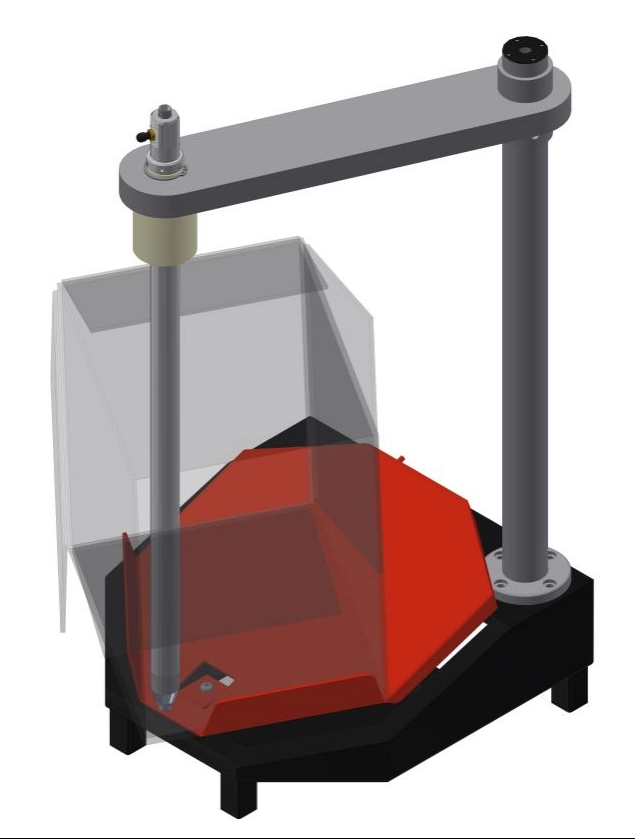

A powder supply system is designed to transport, meter, and deliver powder materials in a controlled manner to a process or application point. It typically includes components such as powder feeders, pumps, fluidizing units, conveyors, and application guns or nozzles. The system must maintain consistent powder flow and prevent contamination or clumping to ensure optimal performance.

Key Features of an Effective Powder Supply System

- Uniform and consistent powder delivery rate

- Capability to handle various powder types and particle sizes

- Integration with application equipment such as spray guns or coating booths

- Automation and control for precision and repeatability

- Ease of maintenance and cleaning to prevent downtime

Major Industrial Applications of Powder Supply Systems

Powder Coating Industry

Powder coating is one of the most prominent applications of powder supply systems. It involves applying a dry powder to a surface, which is then cured to form a durable and uniform coating.

Automotive and Heavy-Duty Equipment

In automotive manufacturing, powder supply systems deliver coatings for parts and accessories, ensuring corrosion protection and aesthetic finishes. Heavy-duty equipment manufacturers rely on these systems for durable coatings that withstand harsh environments. The systems support high throughput and automated application lines, meeting stringent OEM specifications.

Building and Construction

Powder coatings are widely used in architectural applications for metal extrusions, panels, and fixtures. The powder supply system ensures consistent coverage and color uniformity, meeting industry standards for durability and corrosion resistance.

Consumer Products and Furniture

Powder coatings provide a preferred finishing solution for metal furniture and consumer goods due to their durability, wear resistance, and colorfastness. Powder supply systems enable efficient application on complex shapes and surfaces, enhancing product appeal and longevity.

Powder Metallurgy and Additive Manufacturing

Powder supply systems are integral to powder metallurgy processes, where metal powders are fed into sintering or additive manufacturing equipment. Precise powder delivery ensures consistent part quality and mechanical properties.

Pharmaceuticals and Nutraceuticals

In pharmaceutical manufacturing, powder supply systems handle active ingredients and excipients for tablet production and other dosage forms. Accurate metering and contamination control are critical for product safety and efficacy.

Food and Beverage Industry

Powders such as flavorings, thickeners, and emulsifiers are supplied through powder systems in food processing. The systems maintain hygiene standards and prevent cross-contamination while ensuring consistent ingredient dosing.

Chemicals and Catalysts

Specialty chemicals and catalysts in powder form require controlled supply for synthesis and reaction processes. Powder supply systems optimize feed rates and reduce material waste.

Technological Innovations in Powder Supply Systems

Electrostatic Spray Deposition (ESD)

ESD is a leading powder coating application method where powder particles are electrostatically charged and sprayed onto grounded surfaces. Powder supply systems integrated with ESD technology provide uniform and efficient coating with minimal overspray.

Mobile and Remote Monitoring Applications

Advanced powder supply systems now incorporate mobile apps and remote monitoring technologies. These applications allow operators to track powder usage, system performance, and maintenance needs in real time. For example, apps can calculate powder coverage, cost per unit area, and optimize line speeds to reduce waste and improve productivity.

Automation and Integration

Modern powder supply systems are designed for seamless integration with automated production lines. Features include programmable logic controllers (PLCs), sensors, and feedback loops to maintain consistent powder flow and adapt to changing production demands.

Benefits of Using Powder Supply Systems in Various Applications

- Enhanced product quality through uniform powder application

- Increased operational efficiency and reduced material waste

- Improved environmental compliance by minimizing overspray and emissions

- Greater flexibility to handle diverse powder materials and formulations

- Reduced labor costs due to automation and remote monitoring

Challenges and Considerations

While powder supply systems offer many advantages, they also present challenges such as powder clogging, system wear, and the need for precise calibration. Selecting the right system depends on factors like powder characteristics, application requirements, and production volume.

Conclusion

Powder supply systems are indispensable in industries ranging from automotive and construction to pharmaceuticals and food processing. Their ability to deliver powders consistently and efficiently enhances product quality and operational performance. Advances in technology, including electrostatic application and digital monitoring, continue to expand their capabilities and applications.

Frequently Asked Questions

Q1: What industries benefit most from powder supply systems?

A1: Key industries include automotive, heavy-duty equipment, building and construction, consumer products, pharmaceuticals, food and beverage, chemicals, and additive manufacturing.

Q2: How does electrostatic spray deposition improve powder coating?

A2: It charges powder particles electrostatically, allowing them to adhere uniformly to surfaces, reducing waste and improving coating quality.

Q3: Can powder supply systems handle different types of powders?

A3: Yes, modern systems can handle a wide range of powders with varying particle sizes and properties, provided they are properly configured.

Q4: What role do mobile apps play in powder supply systems?

A4: Mobile apps facilitate real-time monitoring, data analysis, cost calculation, and remote management of powder supply equipment.

Q5: What are common challenges when using powder supply systems?

A5: Challenges include powder flow consistency, system maintenance, preventing contamination, and adapting to different powder characteristics.

[1] https://www.wagner-group.com/us/industry/products/powder-coating/applying/

[2] https://www.tiger-coatings.com/us-en/blog/powder-coating-process

[3] https://www.pfonline.com/cdn/cms/uploadedFiles/About-powder-coating.pdf

[4] https://www.ppg.com/en-US/industrial-powder/about-powder/powder-application

[5] https://met3dp.com/powder-manufacturing-applications/

[6] https://www.gemu.cn/static/uploads/editor/files/20200511/1589177189554633.pdf

[7] https://www.powdercoatedtough.com/News/ID/906/Mobile-Apps-for-Powder-Coating

[8] https://docs.redhat.com/zh_hans/documentation/Red_Hat_Enterprise_Linux/7/html-single/System_Administrators_Guide/index

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.