Content Menu

● Introduction

● What is an Automatic Spray Booth System?

>> H2: Definition and Core Components

>> H3: Key Features of Automatic Spray Booth Systems

● Types of Automatic Spray Booth Systems

>> H2: Common Configurations

>> H3: Synchronous Spray Booths

>> H3: Non-Synchronous Spray Booths

>> H3: Single Station Spray Booths

>> H3: Continuous Spray Booths

● Advantages of Partnering with an Automatic Spray Booth Systems Company

>> H2: Enhanced Consistency and Quality

>> H2: Increased Production Efficiency

>> H2: Cost and Resource Savings

>> H2: Safety and Environmental Compliance

● Applications of Automatic Spray Booth Systems

>> H2: Industries Benefiting from Automatic Spray Booth Systems

>> H3: OEM Services for Global Brands

● Technological Innovations in Automatic Spray Booth Systems

>> H2: Sensor and AI Integration

>> H2: Advanced Filtration and Paint Abatement

● Why Choose Us as Your Automatic Spray Booth Systems Company?

>> H2: Comprehensive OEM and ODM Services

>> H2: Commitment to Quality and Innovation

>> H2: Global Reach and Support

● Frequently Asked Questions (FAQs)

Introduction

In the modern manufacturing landscape, the demand for precision, efficiency, and environmental compliance has propelled the rise of automatic spray booth systems. As a leading Chinese manufacturer, supplier, and OEM partner for automatic spray booth systems companies worldwide, we provide cutting-edge solutions tailored to the needs of brand owners, wholesalers, and production enterprises. This comprehensive article explores the technology, benefits, types, and applications of automatic spray booth systems, demonstrating why partnering with a trusted automatic spray booth systems company is essential for competitive advantage.

What is an Automatic Spray Booth System?

H2: Definition and Core Components

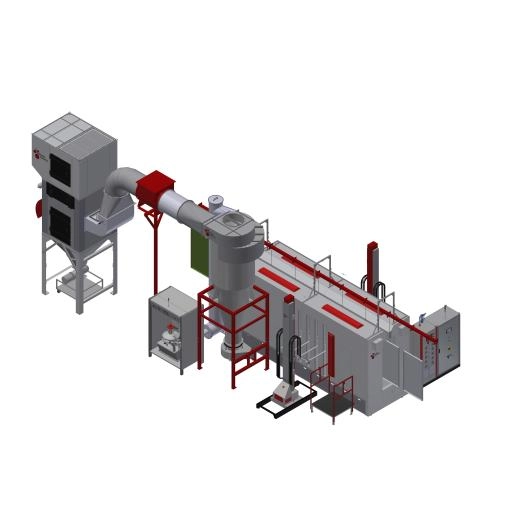

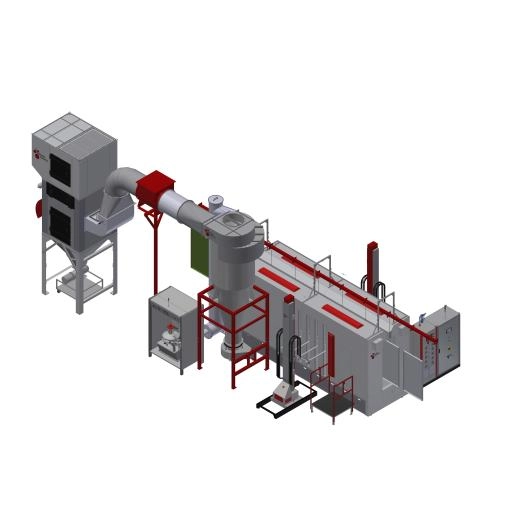

An automatic spray booth system is a specialized enclosed environment designed to apply coatings such as paint or varnish to products using automated technology. These systems typically include robotic spray applicators, conveyor mechanisms, ventilation and filtration units, and control software to ensure precision and safety throughout the coating process.

H3: Key Features of Automatic Spray Booth Systems

- Automation and Robotics: Replace manual labor with programmed robotic arms for consistent spray patterns.

- Controlled Environment: Maintain optimal temperature, humidity, and airflow to ensure finish quality.

- Safety Systems: Include ventilation and filtration to minimize hazardous fumes and overspray.

- Integration Capability: Seamlessly connect with production lines for continuous operation.

Types of Automatic Spray Booth Systems

H2: Common Configurations

H3: Synchronous Spray Booths

Designed for high-volume, repetitive production, synchronous booths operate with minimal intervention, ensuring rapid and consistent coating applications.

H3: Non-Synchronous Spray Booths

These booths offer compartmentalized operation, allowing flexibility and reduced downtime for adjustments, suitable for varied production demands.

H3: Single Station Spray Booths

Single station systems range from partially to fully automated units, often incorporating robotic components. They are cost-effective and practical for smaller-scale operations.

H3: Continuous Spray Booths

Continuous booths feature conveyor systems that keep parts moving steadily through the spray process, ideal for extremely high-volume manufacturing despite higher installation costs.

Advantages of Partnering with an Automatic Spray Booth Systems Company

H2: Enhanced Consistency and Quality

Automatic spray booth systems guarantee uniform coating application, eliminating defects such as runs, drips, or uneven layers that are common in manual spraying. Robotics and sensor-driven adjustments ensure every product meets exacting quality standards.

H2: Increased Production Efficiency

The integration of conveyor systems and automated spray technology accelerates throughput. Continuous and synchronous booths maintain steady production rates, significantly reducing cycle times and labor requirements.

H2: Cost and Resource Savings

Automatic spray booths improve transfer efficiency—the proportion of paint adhering to the product versus paint lost as overspray. This efficiency reduces material waste and lowers operational costs, delivering a rapid return on investment.

H2: Safety and Environmental Compliance

By automating the spray process, worker exposure to hazardous fumes and chemicals is minimized. Advanced filtration and ventilation systems ensure compliance with environmental regulations, safeguarding both workers and the environment.

Applications of Automatic Spray Booth Systems

H2: Industries Benefiting from Automatic Spray Booth Systems

- Automotive Manufacturing: High-volume painting of car bodies and parts.

- Consumer Electronics: Precise coating of delicate components.

- Furniture Production: Uniform finishing of wood and metal furniture.

- Industrial Equipment: Protective coatings for machinery and tools.

H3: OEM Services for Global Brands

As a China-based automatic spray booth systems company, we specialize in providing OEM manufacturing and design services to international brands, wholesalers, and producers. Our expertise ensures customized solutions that meet diverse production requirements and quality standards.

Technological Innovations in Automatic Spray Booth Systems

H2: Sensor and AI Integration

Modern automatic spray booths utilize sensors and AI to monitor spray patterns and adjust parameters in real-time, optimizing finish quality and reducing defects.

H2: Advanced Filtration and Paint Abatement

Innovative four-stage paint abatement systems, including water curtain and dry filter technologies, effectively capture paint particles and fumes, ensuring clean emissions and compliance with strict environmental laws.

Why Choose Us as Your Automatic Spray Booth Systems Company?

H2: Comprehensive OEM and ODM Services

We offer end-to-end solutions from design, manufacturing, assembly, to after-sales support, tailored to the specific needs of automatic spray booth systems companies worldwide.

H2: Commitment to Quality and Innovation

Our factory employs advanced production techniques and rigorous quality control to deliver reliable, high-performance spray booth systems that enhance your manufacturing capabilities.

H2: Global Reach and Support

With extensive experience serving international clients, we provide timely delivery, technical training, and responsive customer service to ensure your success.

Frequently Asked Questions (FAQs)

1. What are the main benefits of using an automatic spray booth system?

Automatic spray booths improve coating consistency, increase production speed, reduce paint waste, and enhance worker safety.

2. Can automatic spray booth systems be customized for different industries?

Yes, these systems are highly adaptable and can be tailored to meet specific requirements in automotive, electronics, furniture, and other sectors.

3. How does automation reduce operational costs in spray booths?

Automation minimizes labor, reduces paint waste through higher transfer efficiency, and lowers the risk of defects, cutting overall production expenses.

4. What environmental features do automatic spray booth systems include?

They incorporate advanced ventilation, filtration, and paint abatement technologies to control emissions and comply with environmental regulations.

5. Do you provide OEM services for international automatic spray booth systems companies?

Yes, we specialize in OEM manufacturing, offering customized design and production services to global partners.

[1] https://www.dbmtec.com/en/industrial-spray-booths/

[2] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[3] https://www.cxhuarui.com/The-Benefits-of-Using-an-Automatic-Spray-Booth-in-Manufacturing-id45271556.html

[4] https://www.diva-portal.org/smash/get/diva2:18241/fulltext01

[5] https://www.codinter.com/en/spray-booths-a-complete-guide/

[6] https://airknowledge.gov/ILT/TOXC220/Current/CI/04TOXC220_Handout_Innovative_Spray_Booth_Technology.pdf

[7] https://www.fenderbender.com/home/article/33035666/latest-paint-booths-expand-capabilities-improve-efficiency

[8] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[9] https://totalfinishingsolutions.com

[10] https://paint-booth.en.made-in-china.com

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.