Content Menu

● Introduction

● What Is an Automatic Spray Booth Systems Factory?

>> Key Functions

● The Core Components of Automatic Spray Booth Systems

>> Airflow Management and Ventilation

>> Filtration Systems

>> Automation and Robotics

>> Safety and Environmental Controls

● Types of Automatic Spray Booth Systems

● Manufacturing Process in an Automatic Spray Booth Systems Factory

>> 1. Needs Assessment and Custom Design

>> 2. Component Fabrication

>> 3. System Assembly

>> 4. Installation and Commissioning

● Advantages of Partnering with an Automatic Spray Booth Systems Factory

>> Enhanced Production Efficiency

>> Superior Finish Quality

>> Resource and Cost Savings

>> Worker Safety and Environmental Compliance

>> Custom OEM Solutions

● Innovations in Automatic Spray Booth Systems

>> Smart Controls and IoT Integration

>> Energy-Efficient Designs

>> Advanced Filtration and Air Quality Management

● Applications Across Industries

● Frequently Asked Questions

>> 1. What are the main benefits of using an automatic spray booth system?

>> 2. How does an automatic spray booth system control overspray and emissions?

>> 3. Can automatic spray booth systems be customized for different industries?

>> 4. What is the difference between dry filter and water wash spray booths?

>> 5. What OEM services are available from an automatic spray booth systems factory?

● Citations:

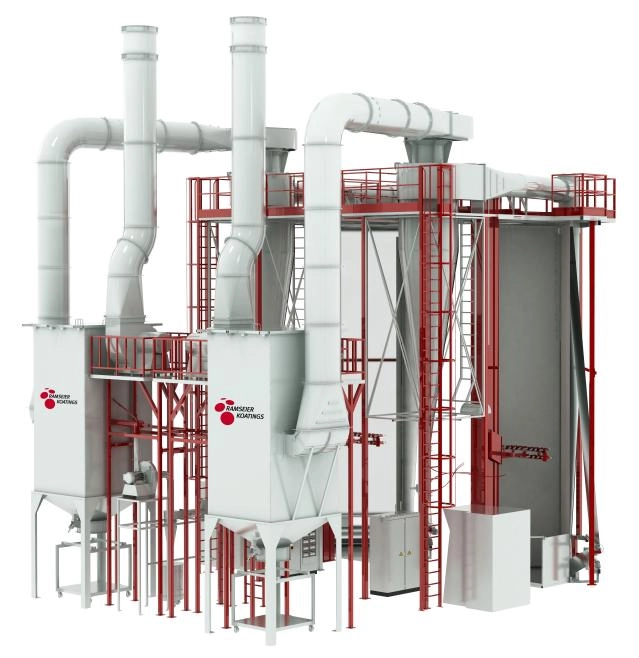

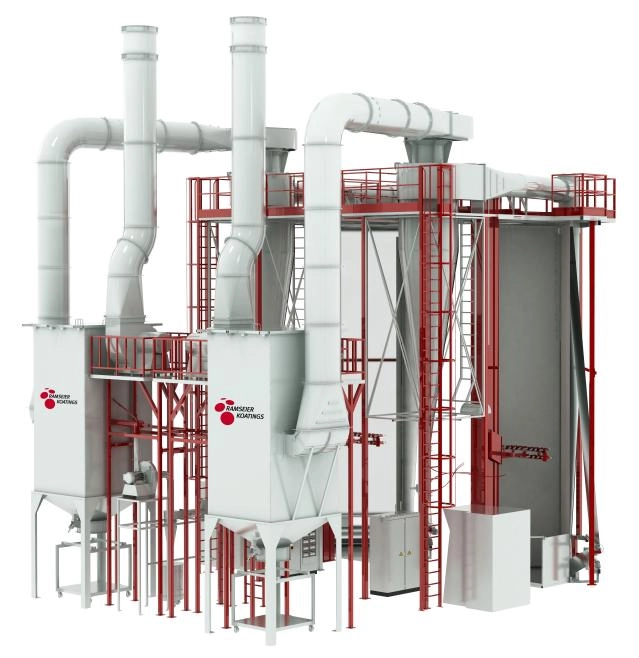

Introduction

In today's fast-paced manufacturing world, the demand for high-quality, efficient, and environmentally friendly coating solutions is greater than ever. As a leading China-based wholesale manufacturer and supplier of spray booth systems, we understand the importance of advanced automation and tailored OEM services for international partners. This article delves deep into the workings, advantages, and innovations of an Automatic Spray Booth Systems Factory, highlighting why these systems are the backbone of modern coating industries.

---

What Is an Automatic Spray Booth Systems Factory?

An Automatic Spray Booth Systems Factory is a specialized facility focused on the design, production, and assembly of automated spray booth solutions. These factories combine engineering expertise, advanced manufacturing techniques, and strict quality controls to produce systems that deliver consistent, high-quality finishes across various industries, including automotive, aerospace, furniture, electronics, and more[1][5].

Key Functions

- Design and Engineering: Customizing booth systems for specific client needs, including airflow, filtration, and automation requirements[2][4].

- Manufacturing: Utilizing modular panels, precision components, and advanced robotics for scalable production[4].

- Assembly and Testing: Ensuring each booth meets international safety and quality standards.

- OEM Services: Providing branding, customization, and integration support for international wholesalers and manufacturers.

---

The Core Components of Automatic Spray Booth Systems

Airflow Management and Ventilation

Efficient airflow is crucial for achieving flawless finishes and maintaining a safe working environment. Automatic spray booth systems use engineered airflow patterns—such as laminar, cross-draft, or downdraft—to control overspray and volatile organic compounds (VOCs)[2][6]. Proper ventilation removes hazardous fumes and maintains optimal temperature and humidity for paint application[2].

Filtration Systems

Modern automatic spray booths integrate multi-stage filtration systems, including intake and exhaust filters, to ensure clean air supply and effective removal of paint particles[2][4]. These may include:

- Dry Filters: Capture solid particles in the air[4].

- Water Curtain or Water Wash Systems: Use water films to trap paint particles and fumes, especially in high-volume or water-based paint applications[4][5].

- Activated Carbon Filters: Absorb VOCs and odors.

Automation and Robotics

Automation is the hallmark of advanced spray booth factories. Robotic arms and programmable controllers ensure precise, consistent application of coatings, reducing human error and increasing throughput[3]. Automated systems can handle repetitive tasks, adjust spray patterns, and monitor environmental conditions in real-time.

Safety and Environmental Controls

Automatic spray booth systems prioritize worker safety and environmental compliance. Features include explosion-proof lighting, fire suppression systems, and advanced emission controls to meet global standards[1][5].

---

Types of Automatic Spray Booth Systems

| Type of System | Description | Best For |

| Synchronous | Fast, consistent, minimal intervention; ideal for high-volume production | Automotive, mass manufacturing |

| Non-Synchronous | Flexible, compartmentalized, less downtime for adjustments | Custom jobs, mixed production |

| Single Station | Partial to full automation, affordable, practical for smaller batches | Small factories, workshops |

| Continuous | Constant motion, high capacity, higher installation and operating costs | Large-scale, 24/7 operations |

---

Manufacturing Process in an Automatic Spray Booth Systems Factory

1. Needs Assessment and Custom Design

The process begins with understanding the client's production goals, space constraints, and regulatory requirements. Engineers then design a system tailored to these needs, using CAD modeling and airflow simulations[4].

2. Component Fabrication

Key components—such as panels, filters, fans, and robotic arms—are manufactured using high-grade materials. Modular construction allows for easy assembly and scalability[4].

3. System Assembly

Technicians assemble the booth, integrating ventilation, filtration, automation, and safety features. Each system undergoes rigorous quality checks and functional testing to ensure reliability.

4. Installation and Commissioning

Upon delivery, the factory's technical team installs and calibrates the booth at the client's site, providing training and after-sales support.

---

Advantages of Partnering with an Automatic Spray Booth Systems Factory

Enhanced Production Efficiency

Automation reduces manual labor, speeds up production cycles, and minimizes downtime. Consistent spray application means fewer defects and less rework[3].

Superior Finish Quality

Controlled environments and precise automation deliver uniform coatings, critical for industries like automotive and electronics where quality is paramount[1][2].

Resource and Cost Savings

Automated systems optimize paint usage, reduce overspray, and lower energy consumption, translating to significant cost savings over time[3].

Worker Safety and Environmental Compliance

Advanced filtration and ventilation protect workers from hazardous fumes and ensure compliance with international emission standards[1][5].

Custom OEM Solutions

Factories offer OEM services, allowing international partners to brand, customize, and integrate spray booth systems seamlessly into their operations.

---

Innovations in Automatic Spray Booth Systems

Smart Controls and IoT Integration

Modern systems feature programmable logic controllers (PLCs), touch-screen interfaces, and remote monitoring capabilities. IoT sensors track performance metrics, predict maintenance needs, and enable real-time adjustments.

Energy-Efficient Designs

Energy recovery systems, LED lighting, and variable-speed fans help reduce power consumption and operational costs.

Advanced Filtration and Air Quality Management

Multi-stage filtration, water-based abatement, and HEPA filters ensure both product quality and environmental protection[5].

---

Applications Across Industries

Automatic spray booth systems are indispensable in:

- Automotive: For painting vehicles and parts with high consistency[1].

- Aerospace: For coating aircraft components under strict quality controls.

- Furniture and Woodworking: For finishing wood products with minimal overspray[4].

- Electronics: For dust-free coating of sensitive components[1].

- Metalworking and Plastics: For protective and decorative coatings on tools, machinery, and plastic parts[1][5].

---

Frequently Asked Questions

1. What are the main benefits of using an automatic spray booth system?

Automatic spray booth systems offer improved efficiency, consistent finish quality, lower operating costs, and enhanced worker safety by automating the coating process and ensuring controlled environmental conditions[3][5].

2. How does an automatic spray booth system control overspray and emissions?

These systems use engineered airflow patterns and multi-stage filtration (dry, water-based, or hybrid) to capture overspray and remove harmful fumes, ensuring compliance with environmental regulations[2][4][5].

3. Can automatic spray booth systems be customized for different industries?

Yes, automatic spray booth systems can be tailored to meet the specific needs of various industries, including automotive, aerospace, electronics, and woodworking, with options for different sizes, filtration methods, and automation levels[1][4].

4. What is the difference between dry filter and water wash spray booths?

Dry filter booths use replaceable filters to trap paint particles, while water wash booths use a water curtain or turbulence to capture particles and fumes—ideal for high-volume or water-based paint applications[4][5].

5. What OEM services are available from an automatic spray booth systems factory?

OEM services include branding, custom design, integration support, and after-sales service, allowing international partners to offer tailored solutions under their own brands.

---

Citations:

[1] https://www.codinter.com/en/spray-booths-a-complete-guide/

[2] https://www.linkedin.com/pulse/article-7-spray-booths-airflow-management-topcoat-ramon-perez-pmp-2razc

[3] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[4] https://www.diva-portal.org/smash/get/diva2:18241/fulltext01

[5] https://www.dbmtec.com/en/industrial-spray-booths/

[6] https://www.spraysystems.com/wp-content/uploads/2015-Presentation-Paper-Spray-Booth-Essentials.pdf

[7] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[8] https://airknowledge.gov/ILT/TOXC220/Current/CI/04TOXC220_Handout_Innovative_Spray_Booth_Technology.pdf

[9] https://www.ecotechsystems.net/services

[10] https://airblast.co.uk/resource-hub/blog/how-might-a-spray-booth-benefit-your-business/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.