Content Menu

● Introduction

● What Are Custom Automatic Spray Booth Systems?

>> Key Features

● Why Choose Custom Automatic Spray Booth Systems?

>> Enhanced Productivity and Consistency

>> Safety and Environmental Compliance

>> Cost Savings and Resource Efficiency

● Types of Custom Automatic Spray Booth Systems

>> Synchronous Systems

>> Non-Synchronous Systems

>> Single Station Systems

>> Continuous Systems

● Core Components and Customization Options

>> Programmable Controllers

>> Robotic Arms

>> Advanced Ventilation and Filtration

>> Real-Time Monitoring and Diagnostics

● The Customization Process: From Design to Installation

>> Needs Assessment

>> Engineering and Prototyping

>> Manufacturing and Quality Control

>> Installation and Training

● Maintenance and Longevity

● Industry Applications

● Case Studies: Real-World Success with Custom Automatic Spray Booth Systems

● Frequently Asked Questions about Custom Automatic Spray Booth Systems

● Conclusion

● Citations:

Introduction

In today's competitive manufacturing landscape, *Custom Automatic Spray Booth Systems* have emerged as a game-changing solution for businesses seeking efficiency, quality, and safety in their finishing processes. As a leading Chinese OEM manufacturer and supplier, we specialize in designing, producing, and wholesaling tailor-made automatic spray booth systems for international brands, wholesalers, and manufacturers. This comprehensive guide explores the technical, operational, and economic advantages of custom automatic spray booth systems, offering insights for businesses aiming to elevate their production capabilities.

---

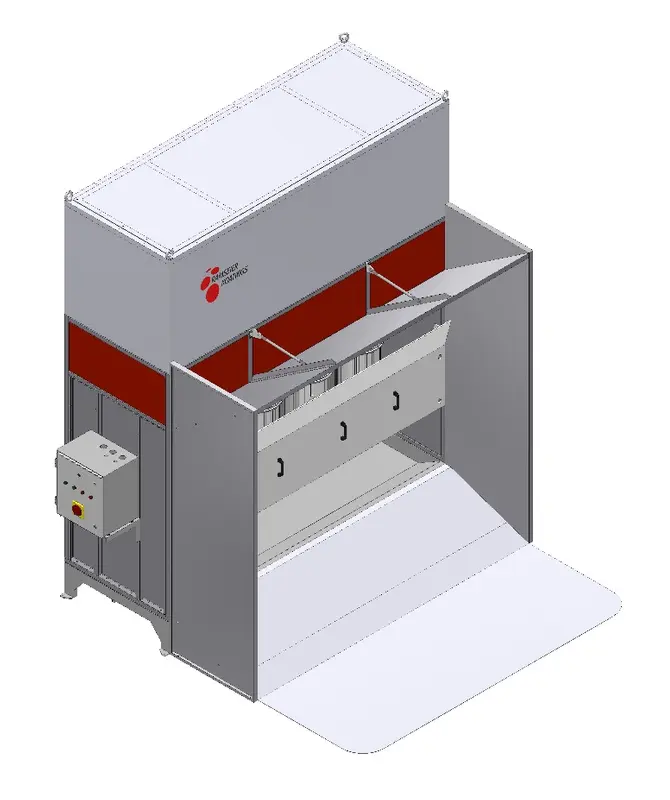

What Are Custom Automatic Spray Booth Systems?

Custom automatic spray booth systems are advanced, engineered enclosures designed to automate the application of paints and coatings on various products. Unlike standard models, these systems are tailored to the unique requirements of each client, ensuring optimal integration with specific production lines, product dimensions, and finishing standards[3][7][9].

Key Features

- Automated paint application using robotic arms or programmable controllers

- Customizable airflow and filtration for superior finish quality

- Advanced safety and environmental controls

- Integration with existing production infrastructure

---

Why Choose Custom Automatic Spray Booth Systems?

Enhanced Productivity and Consistency

Automated spray booth systems deliver precise, repeatable results, eliminating human error and ensuring uniform coating across every product. This consistency is especially critical for high-volume, repetitive production lines where quality cannot be compromised[1][6].

Safety and Environmental Compliance

Custom automatic spray booth systems are engineered to minimize worker exposure to hazardous fumes and chemicals. Integrated ventilation and filtration systems ensure a clean, safe working environment and help businesses comply with stringent OSHA, NFPA, and EPA regulations[2][6][9].

Cost Savings and Resource Efficiency

By optimizing paint usage and reducing overspray, these systems lower material costs and minimize waste. Automation also reduces labor expenses and the need for costly rework due to coating imperfections, translating into significant long-term savings[1][2][6].

---

Types of Custom Automatic Spray Booth Systems

Synchronous Systems

- Ideal for repetitive, high-volume production

- Operate in sync with the production line for maximum throughput[1]

Non-Synchronous Systems

- Offer greater flexibility and less downtime for adjustments

- Suitable for varied or batch production[1]

Single Station Systems

- Most affordable and practical for smaller operations

- Can be partially or fully automated[1]

Continuous Systems

- Designed for extremely high-volume operations

- Booths remain in constant motion to match production speed[1]

---

Core Components and Customization Options

Programmable Controllers

Allow for precise control of airflow, temperature, and paint application, ensuring optimal performance for different products and coatings[6].

Robotic Arms

Deliver consistent, high-quality finishes with minimal overspray and maximum repeatability, even on complex geometries[6].

Advanced Ventilation and Filtration

Custom automatic spray booth systems feature high-efficiency filters and controlled airflow to maintain a contaminant-free environment and protect both products and personnel[2][6].

Real-Time Monitoring and Diagnostics

Integrated sensors and analytics enable real-time tracking of booth performance, alerting operators to maintenance needs or system errors before they escalate[6].

---

The Customization Process: From Design to Installation

Needs Assessment

Every project begins with a thorough analysis of the client's production requirements, including product size, finish quality, throughput, and available space[3][7][9].

Engineering and Prototyping

Our engineers design a custom solution, selecting the optimal configuration, automation level, and safety features to match your workflow[3][9].

Manufacturing and Quality Control

All systems are fabricated using high-grade materials and undergo rigorous testing to ensure compliance with international standards and client specifications[9].

Installation and Training

We provide on-site installation, commissioning, and operator training to ensure seamless integration and maximum return on investment[3][9].

---

Maintenance and Longevity

Proper maintenance is essential to maximize the lifespan and performance of a custom automatic spray booth system. Key maintenance tasks include:

- Regular filter replacement and airflow checks

- Inspection and cleaning of motors, belts, and fans

- Monitoring system diagnostics for early detection of issues

- Establishing a customized maintenance schedule in collaboration with the booth manufacturer[5]

---

Industry Applications

Custom automatic spray booth systems are used across diverse industries, including:

- Automotive and truck manufacturing

- Aerospace and aviation

- Furniture and woodworking

- Heavy equipment and machinery

- Metal fabrication and electronics[3][7][9]

---

Case Studies: Real-World Success with Custom Automatic Spray Booth Systems

- Fender Music Instruments: Integrated a robotic paint spray system for consistent, high-quality finishes on musical instruments[3].

- Precision Body & Paint: Customized booth designed for efficient operation in cold climates, maintaining finish quality year-round[3].

- Walla Walla Foundry: Tailored solution for large-scale bronze casting, supporting unique artistic requirements[3].

---

Frequently Asked Questions about Custom Automatic Spray Booth Systems

Q1: What are the main advantages of custom automatic spray booth systems over standard models?

A1: Custom systems are designed to fit your specific production needs, maximizing efficiency, finish quality, and safety while minimizing waste and operational costs[1][3][7].

Q2: Can custom automatic spray booth systems be integrated into existing production lines?

A2: Yes, these systems are engineered for seamless integration with your current infrastructure, ensuring minimal disruption and optimal workflow[3][9].

Q3: How do automated spray booths improve workplace safety?

A3: Automation reduces worker exposure to hazardous fumes and chemicals, and advanced safety features like emergency shutoffs and real-time monitoring further enhance workplace safety[6][9].

Q4: What maintenance is required for custom automatic spray booth systems?

A4: Regular filter changes, airflow checks, and cleaning of mechanical parts are essential. Real-time diagnostics help identify maintenance needs early, and manufacturers often provide tailored maintenance schedules[5][6].

Q5: Are custom automatic spray booth systems suitable for small-scale manufacturers?

A5: Yes, single station and non-synchronous systems can be customized for smaller operations, offering affordability and flexibility without sacrificing quality[1][7][9].

---

Conclusion

Custom automatic spray booth systems represent the pinnacle of efficiency, safety, and quality in modern manufacturing. By partnering with an experienced OEM supplier, businesses can unlock tailored solutions that drive productivity, reduce costs, and ensure compliance with global standards. Whether you're an international brand, wholesaler, or manufacturer, investing in a custom automatic spray booth system is a strategic move toward sustainable growth and operational excellence.

---

Citations:

[1] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[2] https://www.hppneumatics.com/spray-booth-benefits/

[3] https://www.spraysystems.com/custom-solutions/

[4] https://marathonspraybooths.com/faq/

[5] https://www.spraysystems.com/spray-paint-booth-repairs-and-maintenance/

[6] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[7] https://www.paint-booths.com/FAQS.html

[8] https://globalfinishing.com/2011/02/24/paint-booth-faqs-part-1/

[9] https://kaycospraybooths.com/faqs/

[10] https://www.hppneumatics.com/spray-booths/

[11] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[12] https://www.ramseierkoatings.com/news/Automated-Spray-Booth-Technology.html

[13] https://www.spraysystems.com/compliance-checklist/

[14] https://gsbindustries.com/products/custom-paint-booths/

[15] https://gsbindustries.com/products/paint-booths/

[16] https://www.spraysystems.com/nfpa-33-a-guide-to-fire-safety-compliance-for-paint-spray-booths/

[17] https://pfsspraybooths.com/custom-paint-booth-tailored-solutions-for-your-unique-needs

[18] https://www.autobodytoolmart.com/category/auto-paint-booth-accessories/a

[19] https://www.ramseierkoatings.com/what-is-the-best-automatic-spray-booth-system-for-small-scale-production.html

[20] https://www.pcimag.com/articles/110723-four-key-components-of-robotic-paint-booth-design-for-automakers

[21] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[22] https://www.godnfinishing.com/Products/automatic-spray-paint-booth/

[23] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[24] https://www.rohnerspraybooths.com/blog/benefits-of-custom-paint-booth

[25] https://www.sprayline.com

[26] https://marathonspraybooths.com

[27] https://istsurface.com/equipment/spray-equipment/paint-spray-booths/

[28] https://gsbindustries.com/paint-booth-design-and-functionality/

[29] https://relyonusa.com/the-perks-of-using-a-custom-commercial-paint-booth/

[30] https://productionsystems-usa.com

[31] https://www.rohnerspraybooths.com

[32] https://globalfinishing.com/2019/09/26/custom-paint-booths-what-to-look-for-beyond-the-equipment-specs-price/

[33] https://globalfinishing.com/2018/01/25/automotive-paint-booth-options-designed-improve-performance-efficiency/

[34] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[35] https://www.codinter.com/en/spray-booths-a-complete-guide/

[36] https://www.spraysystems.com/faq/

[37] https://pfsspraybooths.com/common-spray-booth-mistakes-and-how-to-avoid-them

[38] https://pfsspraybooths.com/importance-of-regular-maintenance-for-spray-paint-booths

[39] https://www.purchasing.com/automotive/spray-paint-booths/purchasing-guide/index.html

[40] https://www.accudraftpaintbooths.com/faqs/

[41] https://globalfinishing.com/2011/03/31/paint-booth-faqs-part-ii/

[42] https://rttsolutions.com/wp-content/uploads/2020/09/Spray-Booth-Manual-2020.pdf

[43] https://360zolutions.com/need-spraybooth-questions-to-answer/

[44] https://www.paint-booths.com/blog/top-10-things-to-think-about-before-ordering-your-paint-booth/

[45] https://rttsolutions.com/faq/

[46] https://www.spraysystems.com

[47] https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/paint-line-automation/automated-paint-systems.html

[48] https://360zolutions.com/products/liquid-painting/spraybooths/

[49] https://www.rohnerspraybooths.com/paint-booths/

[50] https://www.spraysystems.com/news-blog/

[51] https://magnaflux.com/Magnaflux/Blog/FPI-Customized-Solutions-for-Unique-Needs

[52] https://giffininc.com/products-systems/spraybooths/

[53] https://spraytech.com

[54] https://sprayboothsnw.com/faqs

[55] https://www.duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers

[56] https://www.youtube.com/watch?v=IQodfZvcX7Y

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.