Content Menu

● Understanding Powder Hoppers and Their Importance

● Key Features to Look for in a High-Quality Powder Hopper

>> 1. Durable and Appropriate Construction Materials

>>> Material Type

>>> Surface Finish and Coating

>> 2. Correct Hopper Geometry and Design

>>> Hopper Shape

>>> Outlet Design

>> 3. Efficient Flow Control Mechanisms

>>> Flow Aids

>>> Control Valves

>> 4. Easy Maintenance and Cleaning Features

>>> Access Points

>>> Cleaning Compatibility

>>> Dust Containment

>> 5. Accurate Volume and Level Indicators

>>> Level Sensors

>> 6. Safety Features and Compliance

>>> Explosion Protection

>>> Hazardous Area Compatibility

>> 7. Customization and Integration Capabilities

>>> Modular Design

>>> Automation Ready

>>> Size and Capacity Options

● Additional Benefits of Investing in a High-Quality Powder Hopper

● Common Challenges in Powder Handling and How Good Hoppers Solve Them

>> Powder Bridging and Rat-holing

>> Dust Emission Control

● How to Choose the Right Powder Hopper for Your Application

● Frequently Asked Questions (FAQs)

● Conclusion

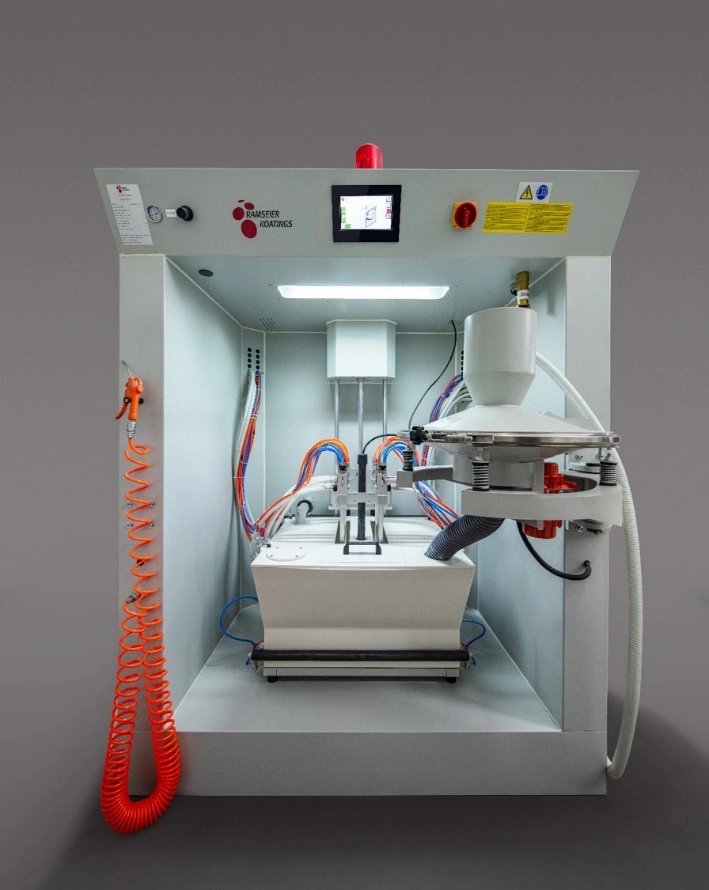

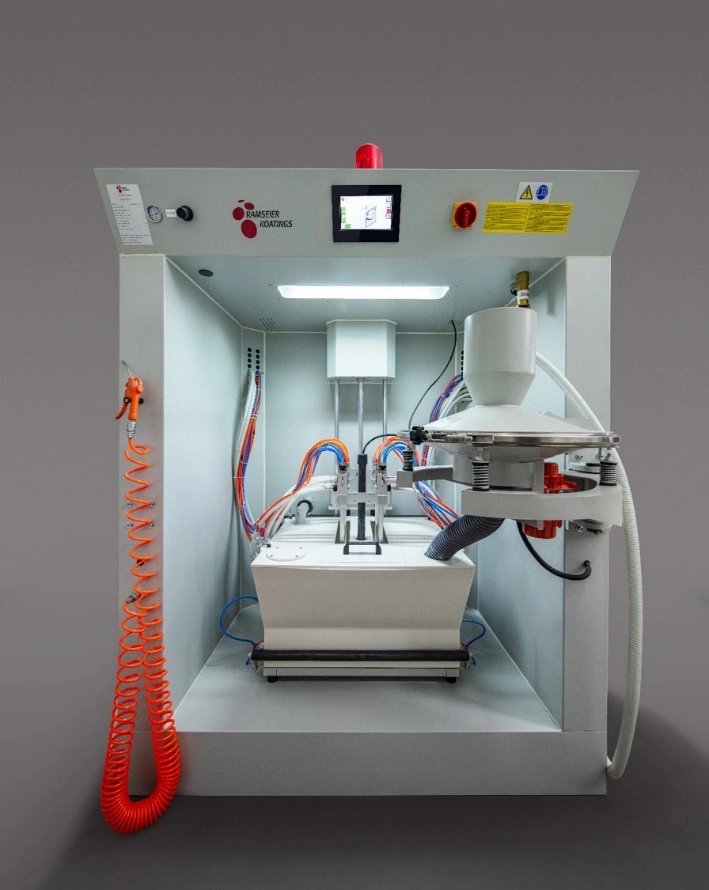

When dealing with powders in various industries such as pharmaceuticals, food processing, chemicals, or construction materials, having the right equipment to handle and dispense powders accurately and efficiently is crucial. One key piece of equipment in many powder handling systems is the powder hopper. A powder hopper stores and feeds powder materials to downstream processes, ensuring a smooth and controlled flow. Selecting a high-quality powder hopper can significantly improve productivity, reduce waste, and maintain product consistency.

This article will explain the top features to look for in a high-quality powder hopper, guiding you in choosing the best hopper for your specific needs. We will cover important characteristics such as material construction, design features, ease of maintenance, flow control, and safety elements.

Understanding Powder Hoppers and Their Importance

Before diving into features, it is important to understand what a powder hopper is and why it matters.

A powder hopper is a container designed to hold bulk powder materials temporarily and feed them into a processing system in a controlled manner. The right powder hopper prevents bridging and clogging, ensures consistent delivery, and protects powders from contamination.

Due to the nature of powders, these hoppers must be carefully designed to handle factors like powder cohesiveness, moisture sensitivity, and fine particle dust control. Without a proper hopper, plants may face frequent production stops, quality issues, and safety hazards.

Key Features to Look for in a High-Quality Powder Hopper

1. Durable and Appropriate Construction Materials

Material Type

The first and perhaps most critical feature is the material used to construct the hopper. Common materials include stainless steel, carbon steel, aluminum, and various plastics.

- Stainless Steel: Ideal for pharmaceutical and food processing applications due to its corrosion resistance, smooth finish, and ease of cleaning.

- Carbon Steel: Suitable for non-corrosive powders but may require special coatings to prevent rust.

- Plastics (Polyethylene, Polypropylene): Used mainly for lightweight, non-abrasive powders in low-temperature environments.

Make sure the material chosen matches your powder's chemical properties and the operating environment.

Surface Finish and Coating

A smooth interior surface finish minimizes powder buildup and facilitates easy cleaning. Some hoppers use food-grade or pharmaceutical-grade polished finishes to prevent contamination and ensure easy material flow. Additionally, coatings like epoxy or Teflon can reduce powder adhesion and corrosion.

2. Correct Hopper Geometry and Design

Hopper Shape

The shape of the hopper affects how powder flows inside it. The most common shapes include conical, wedge-shaped, and cylindrical hoppers with conical bottoms.

- Conical or Steep Sloped Bottoms: Encourage gravity flow and reduce bridging.

- Flat Bottoms with Agitators: Sometimes used when powders tend to bridge, supplemented with mechanical aids.

Selecting the right geometry helps prevent common powder flow problems like rat-holing (where material flows only through a channel) or arching (blocking at the outlet).

Outlet Design

The outlet size and shape influence flow rate and consistency. A tapered outlet is preferred as it minimizes clogging but allows controlled dispensing. Some high-quality hoppers have interchangeable outlet inserts or adjustable valves to optimize flow for different powders.

3. Efficient Flow Control Mechanisms

Managing the powder discharge rate is essential when integrating powder hoppers into production lines.

Flow Aids

High-quality hoppers often include built-in flow aids such as:

- Vibrators: Apply gentle vibration to loosen powder and prevent settling or arching.

- Air Fluidizing Pads: Use air pulses to keep powder moving and prevent clogging.

- Mechanical Agitators: Rotary or paddle agitators break up bridges and promote smooth flow.

Flow aids can be combined or customized depending on the powder characteristics.

Control Valves

Integrated control valves or gates allow operators to start, stop, or adjust powder flow precisely. Pneumatic or motorized valves offer automation options for improved consistency and reduced manual intervention.

4. Easy Maintenance and Cleaning Features

Powder hoppers used in industries with strict hygiene requirements must be simple to clean and maintain.

Access Points

Look for hoppers with large inspection ports or removable sections. This facilitates rapid cleaning and inspection, reducing downtime.

Cleaning Compatibility

Materials and finishes should withstand cleaning chemicals and methods like CIP (clean-in-place) or SIP (sterilize-in-place) if applicable. Smooth internal surfaces reduce powder residues and microbial growth sites.

Dust Containment

A high-quality hopper includes dust-tight seals and filters to contain powder dust during filling and discharge, protecting workers and equipment.

5. Accurate Volume and Level Indicators

Knowing how much powder is in the hopper at any time prevents interruptions and batch errors.

Level Sensors

Modern hoppers come equipped with various level sensors such as:

- Ultrasonic sensors: Detect powder surface without contact.

- Capacitive or radar sensors: Provide continuous volume measurements.

- Mechanical level indicators: Float or rod mechanisms for visual feedback.

Choosing the right sensor depends on the powder's physical properties and environment.

6. Safety Features and Compliance

Handling powders can involve dust explosion risks, inhalation hazards, or contamination.

Explosion Protection

For combustible powders, hoppers should comply with safety standards (like ATEX or NFPA). Features may include:

- Pressure relief vents.

- Explosion suppression or isolation systems.

- Grounding and bonding to prevent static electricity buildup.

Hazardous Area Compatibility

If used in hazardous zones, equipment must be certified for safe operation and incorporate anti-static materials.

7. Customization and Integration Capabilities

A one-size-fits-all hopper rarely meets every application need.

Modular Design

Some manufacturers offer modular hopper systems where components like outlet valves, agitators, or sensors can be swapped or added.

Automation Ready

High-quality powder hoppers integrate easily with automated control systems (PLCs or SCADA), allowing remote operation and data collection.

Size and Capacity Options

Choose from a range of hopper volumes that fit your production scale, with options for expansion as requirements grow.

Additional Benefits of Investing in a High-Quality Powder Hopper

- Improved product consistency: Smooth, uninterrupted powder flow ensures uniform mixing, packaging, or processing.

- Reduced downtime: Reliable operation reduces delays caused by clogs or maintenance.

- Enhanced worker safety: Dust containment and explosion protection reduce health hazards.

- Cost savings: Minimizing powder waste and cleaning time lowers operational expenses.

Common Challenges in Powder Handling and How Good Hoppers Solve Them

Powder Bridging and Rat-holing

Bridging happens when powder forms a stable arch blocking flow; rat-holing is when only powder in a flow channel moves. High-quality hoppers designed with proper slope angles, flow aids, and outlet geometry prevent these problems.

Dust Emission Control

Powders generate dust that can dirty equipment, harm workers, and contaminate products. Dust-tight seals and vent filters in powder hoppers reduce emissions significantly.

How to Choose the Right Powder Hopper for Your Application

- Identify powder characteristics: Particle size, flowability, moisture sensitivity.

- Determine required capacity: Match hopper volume with batch sizes or continuous throughput.

- Consider environmental conditions: Temperature, humidity, cleanliness standards.

- Evaluate maintenance support and warranty: Reliable customer service and robust equipment design.

- Consult with suppliers: Share application details to get custom recommendations.

Frequently Asked Questions (FAQs)

Q1: What materials are best for powder hoppers used in the pharmaceutical industry?

A1: Stainless steel is preferred due to its corrosion resistance, sanitary finish, and compliance with hygiene standards.

Q2: How can I prevent powder bridging in my hopper?

A2: Use properly designed hopper sloping, flow aids like vibrators or agitators, and ensure the outlet diameter is adequate for your powder's flow characteristics.

Q3: Are powder hoppers explosion-proof?

A3: Some powder hoppers are designed to meet explosion protection standards with features like pressure relief vents and grounding, suitable for combustible powders.

Q4: Can powder hoppers be integrated with automation systems?

A4: Yes, many high-quality hoppers offer compatibility with control systems like PLCs for automated flow control and monitoring.

Q5: How often should powder hoppers be cleaned?

A5: Frequency depends on powder type and production requirements but should occur regularly to prevent contamination and build-up, facilitated by hopper design features like easy access panels.

Conclusion

Selecting a high-quality powder hopper involves careful consideration of materials, design, flow control, maintenance, safety, and integration capabilities. A well-chosen hopper ensures efficient powder handling, improved product quality, and safer operations. By examining the features outlined above, you can find a hopper that optimally fits your process needs, enhancing productivity and reliability.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.