Content Menu

● Understanding the Role of a Powder Coating Reciprocator

● Key Features to Look for in a High-Performance Powder Coating Reciprocator

>> Precision and Repeatability

>>> Importance of Accurate Positioning

>>> Programmable Motion Profiles

>> Durability and Build Quality

>>> Robust Materials and Components

>>> Maintenance Accessibility

>> Speed and Adjustment Range

>>> Wide Speed Range for Various Applications

>>> Adjustable Stroke Length

>> Integration and Compatibility

>>> Seamless Integration with Existing Systems

>>> Modular and Scalable Designs

>> User-Friendly Interface and Controls

>>> Intuitive Control Panels and Software

>>> Remote Monitoring and Diagnostics

>> Safety Features

>>> Emergency Stop Functions

>>> Protective Enclosures and Shields

>> Energy Efficiency

>>> Low Power Consumption Motors

>>> Standby and Sleep Modes

>> Cost vs. Return on Investment (ROI)

>>> Initial Investment Considerations

>>> Impact on Powder Usage and Production Efficiency

● Frequently Asked Questions (FAQs)

● Summary

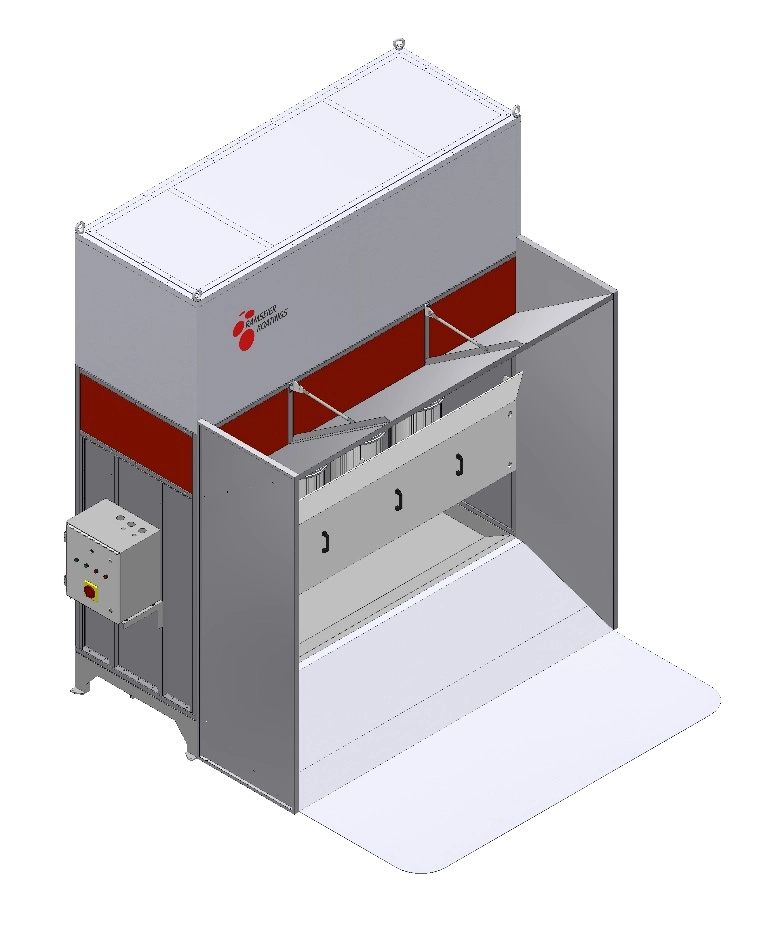

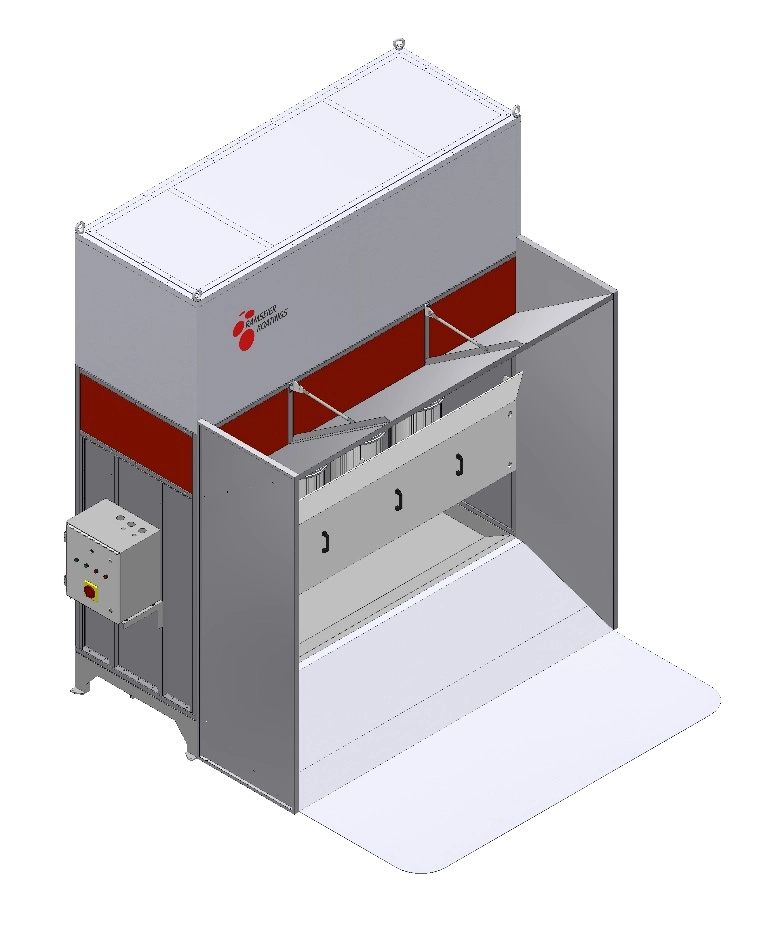

Powder coating has become an essential finishing process across various industries due to its durability, environmental friendliness, and aesthetic appeal. Among the many components required for an efficient powder coating system, the reciprocator plays a crucial role in ensuring even, consistent coating application. Investing in a high-performance powder coating reciprocator can significantly enhance production quality and efficiency. This article will explore the top features to look for when choosing a powder coating reciprocator, helping you make an informed decision for your business needs.

Understanding the Role of a Powder Coating Reciprocator

Before diving into the features, it's important to understand what a powder coating reciprocator does and why it is critical.

A powder coating reciprocator is a device that moves the powder spray gun in a controlled, back-and-forth motion. This reciprocating action helps ensure an even powder coating on the objects being finished, improving coverage and reducing waste. The reciprocator's consistency and precision affect the overall quality of the coating, the efficiency of powder usage, and the speed of the production process.

Key Features to Look for in a High-Performance Powder Coating Reciprocator

Precision and Repeatability

Importance of Accurate Positioning

One of the most important features of a powder coating reciprocator is its ability to position the spray gun accurately and repeatedly. Precise positioning ensures uniform application of the powder and reduces the likelihood of overspray or uneven thickness. Reciprocators that use advanced motion control systems, such as servo motors or stepper motors, often provide better precision and smoother movements compared to basic pneumatic or mechanical models.

Programmable Motion Profiles

High-performance reciprocators usually come with programmable motion profiles, allowing users to customize the speed, stroke length, dwell time, and acceleration/deceleration patterns. This flexibility helps operators optimize the coating process for different part shapes and sizes, thereby improving efficiency and finish quality.

Durability and Build Quality

Robust Materials and Components

The reciprocator must withstand demanding production environments, including exposure to powders, dust, and varying temperatures. High-quality materials such as stainless steel, anodized aluminum, or reinforced polymers ensure the reciprocator maintains its integrity and accuracy over extended use. Components like sealed bearings and countersunk fasteners also contribute to durability by resisting wear and corrosion.

Maintenance Accessibility

A well-designed reciprocator enables easy maintenance with accessible parts and modular construction. This minimizes downtime and maintenance costs, allowing operators to quickly replace worn components or conduct routine inspections without disassembling the entire unit.

Speed and Adjustment Range

Wide Speed Range for Various Applications

Different coating jobs require different spray gun speeds to achieve optimal coverage. A high-performance reciprocator offers a wide speed range, typically adjustable from a few centimeters per second to several meters per second. Variable speed control allows operators to tailor the reciprocating motion to delicate small parts or larger, more robust items.

Adjustable Stroke Length

Similarly, the ability to adjust the stroke length is critical when coating parts of varying sizes and shapes. Some reciprocators feature quick-change stroke settings or infinite adjustment capabilities, allowing rapid adaptation to different production runs without extensive downtime or recalibration.

Integration and Compatibility

Seamless Integration with Existing Systems

A good reciprocator should easily integrate with your existing powder coating setup, including spray booths, powder feeders, and control systems. Compatibility with industry-standard control interfaces (such as PLC or CAN bus) simplifies installation and reduces startup time.

Modular and Scalable Designs

Many high-performance reciprocators offer modular designs that allow for scalability. Whether you need a single-axis reciprocator for a small operation or a multi-axis system for complex parts, modularity ensures the reciprocator grows with your business needs.

User-Friendly Interface and Controls

Intuitive Control Panels and Software

Operators benefit from reciprocators that feature clear, user-friendly control panels or software interfaces. Touchscreen controls, color displays, and menu-based navigation simplify programming and monitoring. The ability to save and recall presets reduces setup time between jobs.

Remote Monitoring and Diagnostics

Advanced reciprocators provide remote monitoring and diagnostics capabilities. This enables maintenance teams to track performance in real-time, diagnose issues early, and perform predictive maintenance, enhancing overall equipment uptime.

Safety Features

Emergency Stop Functions

Safety is paramount in any industrial setting. High-quality reciprocators include emergency stop buttons and safety interlocks that immediately halt operation to protect operators and equipment.

Protective Enclosures and Shields

In environments where moving parts pose a risk, protective covers and shields help prevent accidental contact. Additionally, dust and powder containment shields contribute to cleaner, safer workspaces.

Energy Efficiency

Low Power Consumption Motors

Energy costs can add substantially to operational expenses over time. Choosing a reciprocator that incorporates energy-efficient motors and optimized motion profiles reduces power consumption without compromising performance.

Standby and Sleep Modes

Some reciprocators feature standby or sleep modes for periods of inactivity, lowering energy usage during downtime while allowing rapid restarts.

Cost vs. Return on Investment (ROI)

Initial Investment Considerations

While high-performance powder coating reciprocators may command a higher upfront cost, their advantages in precision, durability, and adaptability generally lead to cost savings over time.

Impact on Powder Usage and Production Efficiency

Improved coating uniformity reduces powder waste and rework—significant factors contributing to operational costs. Faster cycle times and reduced downtime further improve ROI.

Frequently Asked Questions (FAQs)

Q1: What is the ideal speed range for a powder coating reciprocator?

A1: The ideal speed range varies with the application, but most high-performance reciprocators offer adjustable speeds from around 10 cm/s to over 100 cm/s to accommodate different part sizes and coating requirements.

Q2: Can a reciprocator handle complex-shaped parts?

A2: Yes. Reciprocators with programmable motion profiles and multi-axis capabilities can be adapted to handle complex geometries, ensuring uniform coverage even on difficult parts.

Q3: How often should powder coating reciprocators be maintained?

A3: Maintenance frequency depends on usage intensity and environment but typically includes monthly inspections and lubrication of moving parts, with more comprehensive servicing annually or as needed.

Q4: Are reciprocators compatible with all types of powder coating guns?

A4: Most reciprocators are designed to be compatible with standard powder coating guns. However, it is always advisable to check compatibility or use adapter fixtures if needed.

Q5: How does a reciprocator improve powder efficiency?

A5: By ensuring consistent, even motion and correct speed, reciprocators reduce overspray and powder buildup in undesired areas, thus minimizing powder waste and lowering material costs.

Summary

Selecting a high-performance powder coating reciprocator requires careful consideration of several critical features. Precision and repeatability ensure even application of coating, while durability and ease of maintenance guarantee long-term reliable operation. Adjustable speed and stroke length allow the system to be versatile for different parts, and integration capabilities ensure seamless operation in existing setups. User-friendly controls and safety features protect the operators, and energy-efficient designs contribute to lower operating costs. Although the initial investment may be significant, the return on investment through enhanced productivity and reduced waste makes a quality reciprocator a valuable asset in any powder coating operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.