Content Menu

● Increased Production Efficiency and Speed

>> Continuous Operation and Reduced Downtime

>> Higher Throughput in Limited Space

● Superior Coating Quality and Consistency

>> Precision in Powder Application

>> Controlled Curing Process

● Cost Reductions Through Labor and Material Savings

>> Lower Labor Costs

>> Efficient Powder Usage

● Enhanced Safety and Workplace Conditions

>> Reduced Manual Handling

>> Environmental Controls

● Scalability and Flexibility for Production Needs

>> Easy Integration with Existing Lines

>> Quick Color and Job Changeovers

● Environmental Sustainability

>> Reduced Waste and Energy Consumption

>> Compliance with Environmental Standards

● Frequently Asked Questions

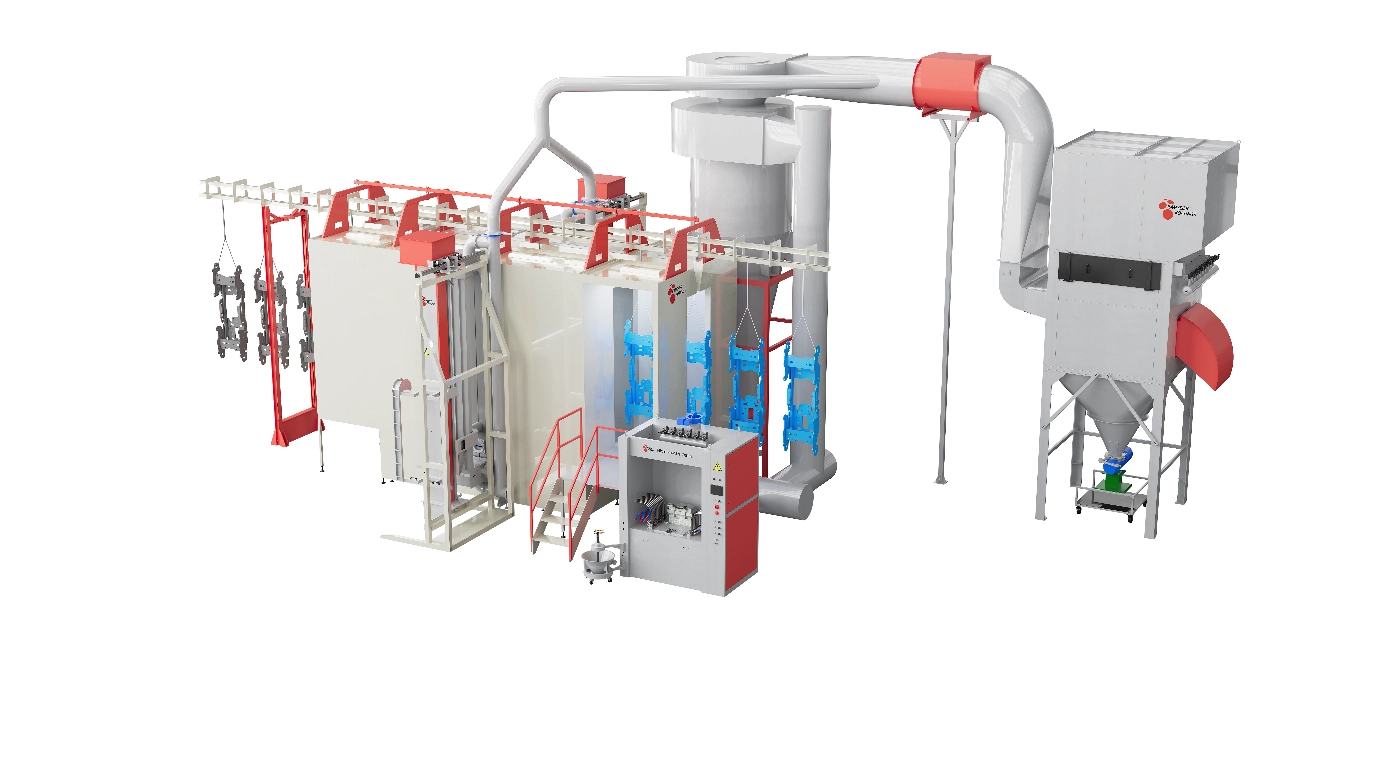

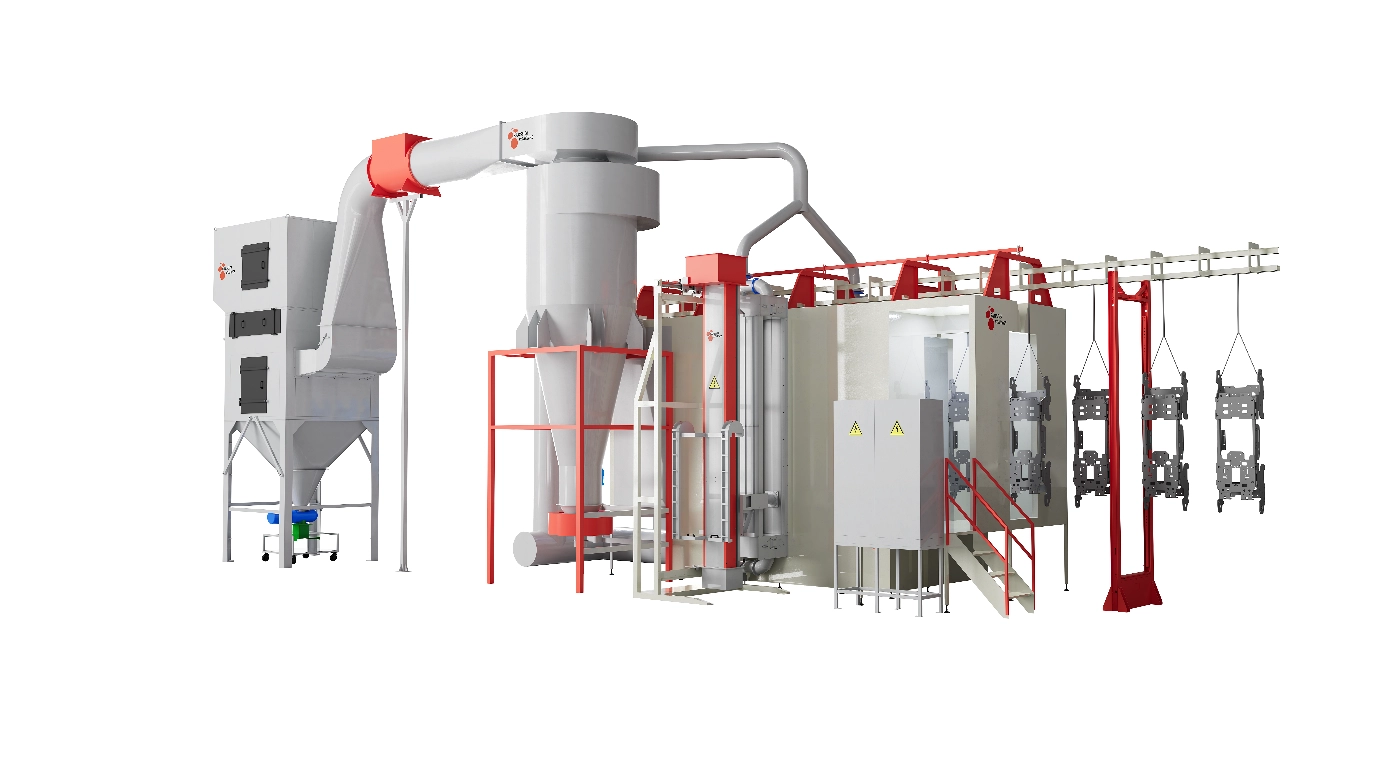

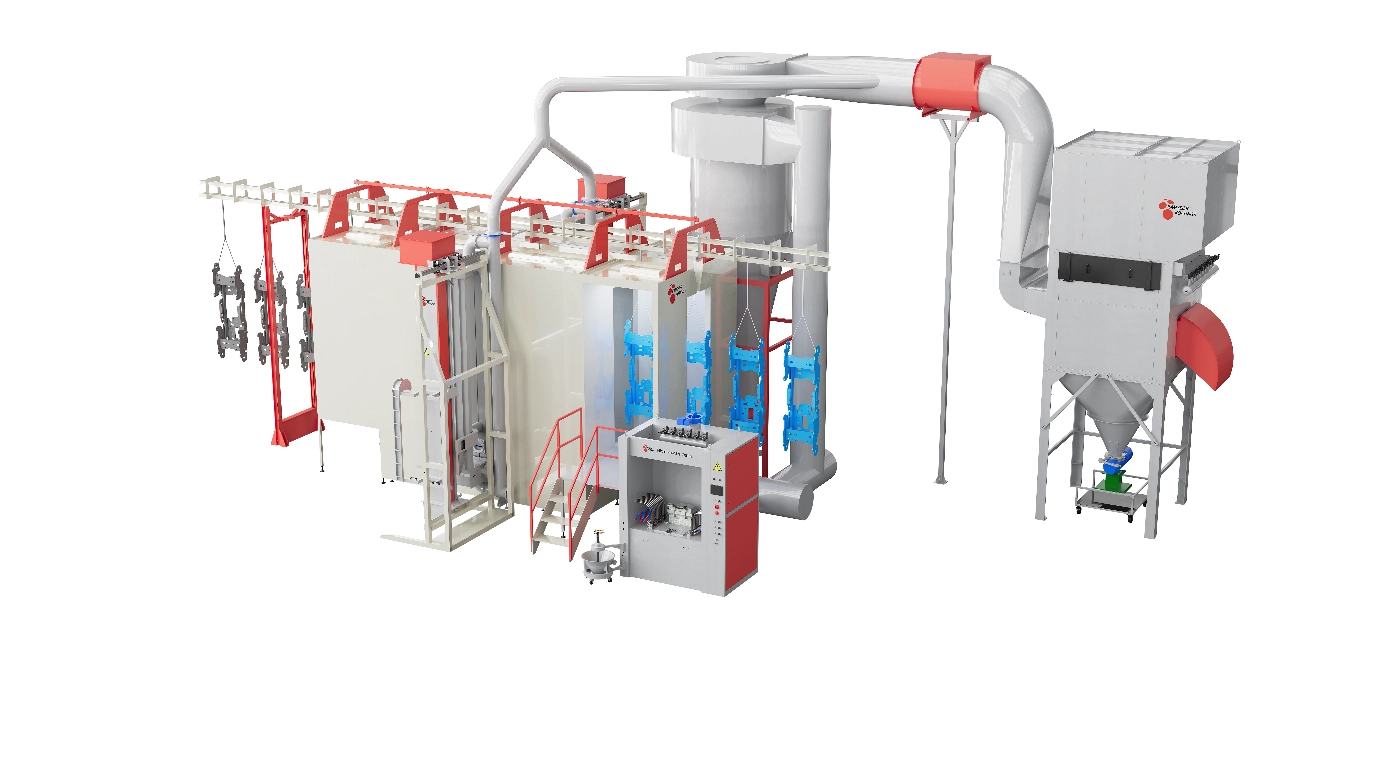

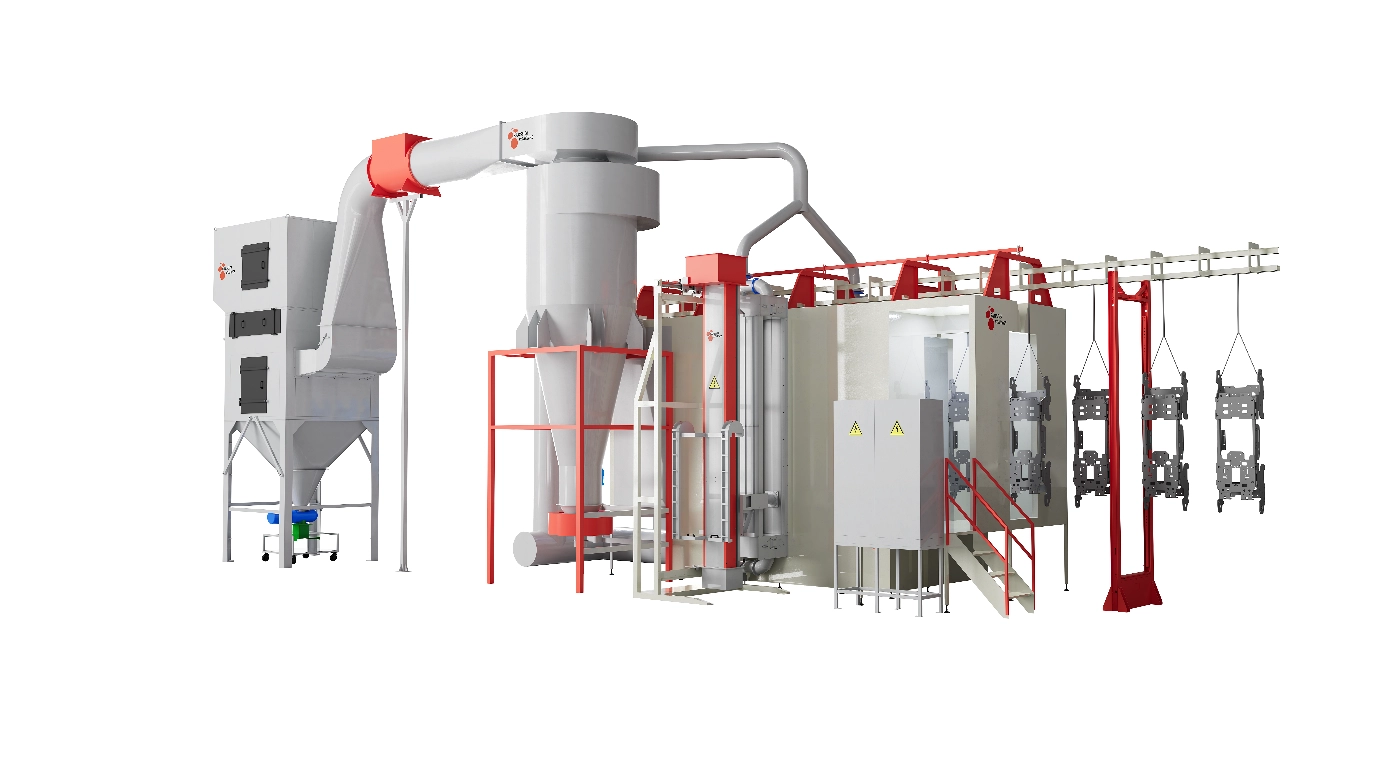

In modern manufacturing and finishing industries, fully automated powder coating systems have revolutionized the way metal parts and products are coated. These systems integrate advanced robotics, precision control, and continuous process flow to enhance productivity, quality, and safety. The following article will detail the top benefits of fully automated powder coating systems, providing an in-depth understanding of why many businesses are transitioning from manual or semi-automated methods to fully automated solutions.

Increased Production Efficiency and Speed

One of the most significant advantages of fully automated powder coating systems is the dramatic increase in production efficiency. Automated systems operate continuously, often 24/7, without the fatigue or distractions that human operators face. This allows for faster throughput and shorter lead times.

Continuous Operation and Reduced Downtime

Unlike manual processes that require frequent pauses for employee breaks or adjustments, automated powder coating lines run seamlessly. Integrating spraying, conveying, and curing within a single automated workflow minimizes downtime. The production cycle time for each piece becomes consistent, enabling stable and predictable output.

Higher Throughput in Limited Space

Automation often includes robotic arms and smart conveyors that optimize space utilization. As a result, more parts can be processed simultaneously or in rapid succession, increasing the volume of coated items without needing significant floor space expansion.

Superior Coating Quality and Consistency

Quality consistency is crucial in powder coating to ensure durability, appearance, and performance. Fully automated systems excel in controlling parameters that affect the coating's quality and uniformity.

Precision in Powder Application

Robotic sprayers and computerized controls provide uniform powder deposition across every surface of the parts. This precision prevents common human errors such as uneven thickness or missed spots, leading to a smoother, more attractive finish.

Controlled Curing Process

Fully automated powder coating lines include ovens and curing chambers with integrated temperature and time controls, ensuring the coating cures properly. This control guarantees the powder melts and bonds exactly as required, maximizing the coating's protective properties.

Cost Reductions Through Labor and Material Savings

While the initial investment in a fully automated system may be higher than manual equipment, long-term cost savings are substantial.

Lower Labor Costs

Automation decreases the dependency on skilled labor for applying and monitoring coatings. With fewer operators needed on the line, labor expenses reduce dramatically, and employees can be reassigned to other value-added activities.

Efficient Powder Usage

Automated systems optimize powder consumption by applying the exact amount required for each part, reducing overspray and waste. Many systems include powder recovery units that capture and reuse excess powder, further enhancing material efficiency and cost-effectiveness.

Enhanced Safety and Workplace Conditions

Fully automated powder coating systems improve worker safety by minimizing human exposure to powder particles and hazardous environments.

Reduced Manual Handling

Automation reduces the need for workers to manually handle parts in the spraying area, decreasing the risk of injuries and exposure to inhaling powder or fumes.

Environmental Controls

Integrated filtration and ventilation systems in automated lines capture airborne particles and maintain cleaner air quality within the workspace, meeting occupational health standards and environmental regulations.

Scalability and Flexibility for Production Needs

Automated powder coating systems are often modular, allowing manufacturers to scale operations as demand grows.

Easy Integration with Existing Lines

These systems can be integrated with upstream and downstream processes such as parts washing, drying, and packaging, promoting seamless production flow and reducing handling time.

Quick Color and Job Changeovers

Some automated systems incorporate fast color change technology, enabling producers to switch between jobs with minimal downtime. This flexibility supports smaller batch sizes and diversified product lines without sacrificing efficiency.

Environmental Sustainability

With increasing emphasis on environmentally friendly manufacturing, automated powder coating systems offer advantages that help companies reduce their ecological footprint.

Reduced Waste and Energy Consumption

Precise application reduces powder waste, and automation optimizes curing temperature and duration to conserve energy. Additionally, some systems are designed to reclaim and recycle powder overspray.

Compliance with Environmental Standards

By integrating dust collection and filtration systems, automated lines reduce emissions and particulate release. This makes it easier for manufacturers to comply with stringent environmental regulations.

Frequently Asked Questions

Q1: How much productivity improvement can be expected with automation?

A1: Fully automated powder coating lines can significantly increase productivity by enabling continuous operation and faster processing, often doubling output compared to manual methods.

Q2: Is the quality of the coating better with automated systems?

A2: Yes. Automation provides precise control over powder application and curing, resulting in uniform and durable coatings exceeding manual consistency.

Q3: What are the typical cost savings associated with fully automated powder coating systems?

A3: Labor costs reduce due to less manual intervention, and material costs decrease through optimized powder usage and recovery. Over time, energy savings and reduced rework also contribute to cost efficiency.

Q4: Can fully automated powder coating systems handle small and large production volumes?

A4: Absolutely. Many systems are modular and scalable, supporting small batch production with quick changeovers as well as large, continuous production runs.

Q5: How do automated systems improve workplace safety?

A5: By minimizing manual handling and including dust filtration, automated lines reduce worker exposure to powders, lower injury risks, and maintain healthier working environments.

[1] https://www.ltcoatingline.com/resources/4-benefits-of-an-automated-powder-coating-system.html

[2] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[3] https://thestuffofsuccess.com/2023/02/14/how-automated-powder-coating-systems-can-benefit-your-business/

[4] https://mdx.mdict.org/%E6%8C%89%E8%AF%8D%E5%85%B8%E8%AF%AD%E7%A7%8D%E6%9D%A5%E5%88%86%E7%B1%BB/%E8%8B%B1%E8%AF%AD/%E8%8B%B1%E8%AF%AD%E4%B8%93%E4%B8%9A%E8%AF%8D%E5%85%B8/%5B%E8%8B%B1-%E6%B1%89%5D/%5B%E8%8B%B1-%E6%B1%89%5D%206%E4%B8%87%E5%A4%9A%E4%B8%AA%E5%8F%A5%E5%AD%90%E9%A3%9E%E8%B7%836.0%E5%8F%A5%E5%BA%93%E5%AF%BC%E5%87%BA%EF%BC%88%E9%99%84%E6%BA%90%E6%96%87%E4%BB%B6%EF%BC%89/%5B%E8%8B%B1-%E6%B1%89%5D%206%E4%B8%87%E5%A4%9A%E4%B8%AA%E5%8F%A5%E5%AD%90%E9%A3%9E%E8%B7%836.0%E5%8F%A5%E5%BA%93%E5%AF%BC%E5%87%BA%EF%BC%88%E9%99%84%E6%BA%90%E6%96%87%E4%BB%B6%EF%BC%89.txt

[5] https://m.coatinglinekt.com/news/what-are-the-advantages-of-a-fully-automated-powder-coating-system/

[6] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[7] https://www.hinahcoatingline.com/news/why-choose-automated-powder-coating-line

[8] https://huggingface.co/luomingshuang/icefall_asr_tal-csasr_pruned_transducer_stateless5/resolve/9f6047e33ffd8b19abf2a62301edae758d1da763/data/lang_char/words.txt

[9] https://blog.isa.org/4-benefits-of-an-automated-powder-coating-system

[10] https://www.wagner-group.com/us/industry/products/powder-coating/complete-systems/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.