Content Menu

● Understanding Powder Coating

>> The Basics of Powder Coating Chemistry

● What is Swinger Powder Coating?

>> How Swinger Systems Differ from Traditional Methods

● Enhancing Coating Quality: The Scientific Principles

>> Controlled Particle Size and Distribution

> Optimal Electrostatic Charging

> Even and Accurate Film Thickness

> Superior Curing Process

Benefits of Swinger Powder Coating

>> Enhanced Durability and Corrosion Resistance

> Improved Aesthetic Quality

> Environmental and Cost Efficiency

Testing and Quality Assurance of Swinger Coated Products

● Applications of Swinger Powder Coating

● Challenges and Considerations in Swinger Powder Coating

● Frequently Asked Questions (FAQs)

Powder coating is a widely adopted finishing technique used to protect and beautify metal surfaces in various industries. Among the innovative solutions is the Swinger powder coating system, which has gained attention for its superior coating quality compared to traditional methods. This article delves into the science behind Swinger powder coating, explaining how it improves coating durability, appearance, and efficiency.

Understanding Powder Coating

Powder coating involves applying a dry, powdery substance composed of finely ground particles of pigment and resin to a metal surface. This powder is then cured under heat, forming a hard, durable layer that serves as both decoration and protection. The technology offers significant advantages over liquid paint, such as environmental friendliness, reduced waste, and longer-lasting finishes.

The Basics of Powder Coating Chemistry

The powder coating process applies an electrostatically charged powder to a grounded metal piece. When the coated piece passes through a curing oven, the powder melts, flows, and chemically reacts (cross-links) into a continuous coating. The resulting finish is tough, resistant to scratching, corrosion, and fading, making it ideal for outdoor and high-use applications.

What is Swinger Powder Coating?

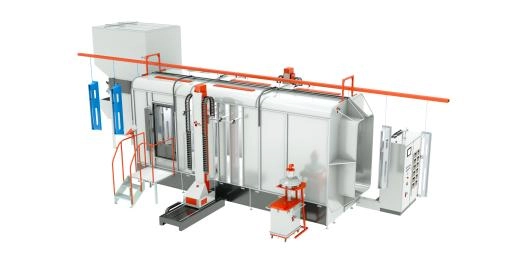

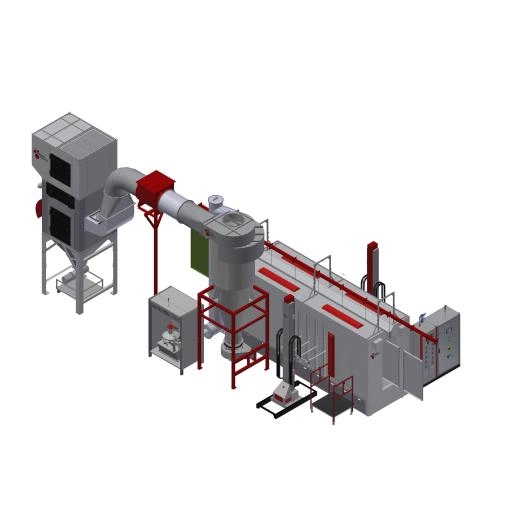

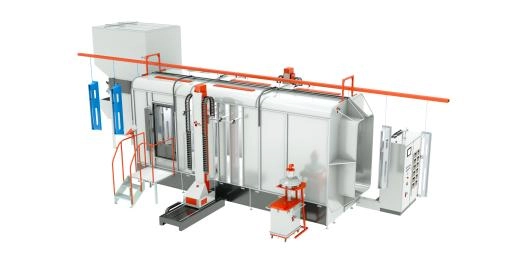

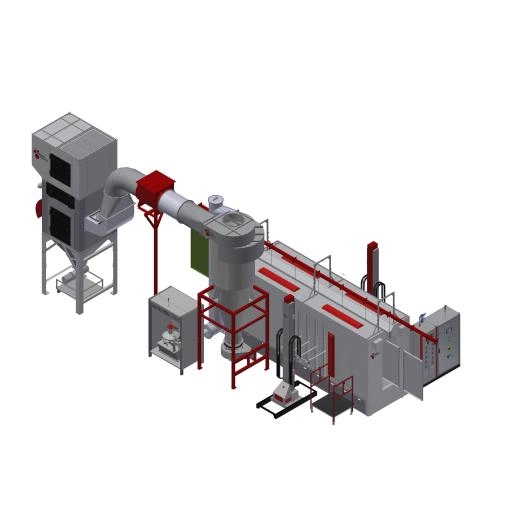

Swinger powder coating systems represent an advancement in the application and curing technology for powder coatings. Unlike traditional powder coating systems, which often rely on older generation equipment and methods, Swinger systems incorporate state-of-the-art application equipment designed for precision, efficiency, and optimal powder usage.

How Swinger Systems Differ from Traditional Methods

The Swinger system uses sophisticated spraying technology that ensures a more uniform application of powder particles. This uniformity is crucial for several reasons:

- It minimizes powder waste by targeting coating only where needed.

- It prevents issues such as uneven thickness, sagging, and bubbling.

- It allows for thinner yet durable coatings, saving material and cost.

Moreover, Swinger systems improve powder flow and coverage by finely controlling the electrostatic charge and spray pressure, resulting in better adhesion and consistent film thickness.

Enhancing Coating Quality: The Scientific Principles

Controlled Particle Size and Distribution

ne of the key scientific factors in Swinger powder coating is the precise control over powder particle size and distribution. Smaller, uniformly sized particles are easier to charge and apply evenly. Swinger systems use advanced powder feeders and spray guns that handle such powders with precision, leading to smoother, denser coatings that cure uniformly.

Optimal Electrostatic Charging

lectrostatic charging is fundamental to powder coating quality. Swinger technology incorporates high-efficiency charging systems that produce a stable and consistent electrical field, ensuring that powder particles adhere firmly to every surface area. This reduces overspray and recycling of powder, making the process more sustainable.

Even and Accurate Film Thickness

consistently applied layer of powder ensures that the final cured coating has an even film thickness, which is crucial for protective properties and aesthetic quality. The Swinger system's controls measure and adjust powder flow in real-time, preventing weak spots or excess build-up. This results in coatings that meet or exceed industry thickness standards, enhancing durability.

Superior Curing Process

fter application, the coating must undergo a curing process where the powder melts and chemically cross-links. Swinger systems often incorporate precise temperature control and heat distribution technology in curing ovens. This prevents undercuring or overcuring, both of which can degrade coating performance. Well-cured coatings exhibit excellent adhesion, hardness, and chemical resistance.

Benefits of Swinger Powder Coating

Enhanced Durability and Corrosion Resistance

winger powder coatings create a tougher, more resilient barrier against environmental stressors such as moisture, UV exposure, and chemical attack. This resistance prevents common coating failures like peeling, chalking, and rusting that occur with inferior coatings. The durability ensures longer maintenance cycles and lower lifecycle costs.

Improved Aesthetic Quality

niform particle distribution and electrostatic application result in smoother textures and richer, more vibrant colors. Swinger coatings can achieve smooth gloss, matte, or textured finishes free from defects like orange peel or runs. This superior finish quality elevates product appeal and value.

Environmental and Cost Efficiency

winger powder coating minimizes wasted powder and energy consumption during curing. The precise application means less recycling and overspray, reducing material usage and environmental impact. Additionally, quicker curing times translate into higher throughput and energy savings.

Testing and Quality Assurance of Swinger Coated Products

Ensuring the high quality of Swinger powder coating involves rigorous testing techniques:

- Solvent Cure Test: Checks chemical resistance by rubbing solvents on the cured coating to confirm full curing.

- Impact Test: Assesses adhesion and impact resistance by dropping a weighted ball on the coated surface and evaluating damage.

- Salt Spray Test: Measures corrosion resistance in a corrosive salt fog environment, ensuring minimal coating peelback.

- Film Thickness Test: Uses precise gauges to verify coating thickness consistency and adherence to specifications.

Each of these tests confirms whether the Swinger-coated products meet the stringent industry standards, guaranteeing performance and reliability.

Applications of Swinger Powder Coating

Swinger powder coating is utilized in various industries, including:

- Automotive components

- Industrial machinery

- Outdoor architectural metalwork

- Consumer appliances

- Aerospace parts

Its enhanced coating performance supports the demanding environments of these sectors, providing improved product lifespan and appearance.

Challenges and Considerations in Swinger Powder Coating

While Swinger systems enhance powder coating, correct process control is critical:

- Accurate temperature and timing in curing ovens are essential to avoid coating failures.

- Surface preparation must be meticulous to ensure proper adhesion.

- Operators need training to leverage the sophisticated equipment fully.

Despite these challenges, Swinger technology offers a reliable path to superior coating outcomes.

Frequently Asked Questions (FAQs)

Q1: What makes Swinger powder coating different from other powder coating systems?

A1: Swinger systems utilize advanced application equipment for precise powder spraying and electrostatic charging, resulting in better powder transfer efficiency, uniform coating thickness, and superior finish quality.

Q2: How does Swinger powder coating improve corrosion resistance?

A2: By ensuring an even, well-cured, and defect-free coating layer, Swinger powder coatings form a robust barrier that prevents moisture and corrosive elements from reaching the metal substrate.

Q3: Can Swinger powder coatings be applied to non-metal surfaces?

A3: While primarily designed for metals, some formulations adapted for Swinger systems can coat certain plastics and composites, though metal-based applications remain dominant.

Q4: Is Swinger powder coating environmentally friendly?

A4: Yes, the system minimizes overspray and waste and uses powder that contains no solvents, reducing volatile organic compound (VOC) emissions significantly.

Q5: How long does a Swinger powder coating last?

A5: Coatings applied via Swinger systems can last up to 20 years, depending on environmental conditions and maintenance, due to enhanced thickness control, curing, and adhesion quality.

[1] https://www.keystonekoating.com/blog/how-powder-coating-is-quality-tested/

[2] https://ia800600.us.archive.org/5/items/ittushu-2470/%E6%B8%85%E5%8D%8E%E5%A4%A7%E5%AD%A6%E5%9B%BE%E4%B9%A6%E9%A6%86-%E6%88%98%E7%96%AB%E7%89%88/H_%E8%AF%AD%E8%A8%80%E3%80%81%E6%96%87%E5%AD%97/12133_%E5%9B%BD%E9%99%85%E4%BA%A4%E6%B5%81%E8%8B%B1%E8%AF%AD%E9%98%85%E8%AF%BB%E8%BF%9B%E9%98%B6%E6%95%99%E7%A8%8B_text.pdf

[3] https://www.ametals.com/post/everything-you-should-know-about-powder-coating-finishes

[4] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[5] https://www.ramseierkoatings.com/swinger-vs-traditional-powder-coating-systems-which-one-fits-your-needs.html

[6] https://www.scribd.com/document/498929761/%E5%8F%8C%E8%89%B2%E8%A1%A8%E8%A7%A3%E8%8B%B1%E8%AF%AD%E8%AF%8D%E6%B1%87

[7] https://www.ramseierkoatings.com/what-makes-swinger-powder-coating-systems-stand-out-in-the-market.html

[8] https://huggingface.co/openbmb/VisCPM-Chat/raw/main/vocab.txt

[9] https://www.apriliaforum.com/forums/showthread.php?251751-Powdercoating-swingarm

[10] https://www.apriliaforum.com/forums/archive/index.php/t-53651.html

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.