Content Menu

● Understanding Powder Hoppers and Their Function

>> What is a Powder Hopper?

>> Core Purpose of Powder Hoppers

>> Types of Powder Hoppers

● How Powder Hoppers Affect Coating Quality

>> Ensuring Consistent Powder Flow

>> Preventing Powder Clumping and Caking

>> Maintaining Optimal Powder Condition

● Key Design Features of Effective Powder Hoppers

>> Hopper Shape and Material

>> Air Pressure Regulation

>> Powder Agitation and Fluidization Systems

>> Ease of Cleaning and Maintenance

● Operational Best Practices for Powder Hopper Use

>> Regular Hopper Inspection

>> Optimizing Airflow and Pressure Settings

>> Managing Powder Quality Inside the Hopper

>> Coordinated Powder Feeding with Spray Operations

● Common Challenges in Powder Hopper Usage and Solutions

>> Challenge: Powder Bridging and Arching

>> Challenge: Powder Contamination

>> Challenge: Inconsistent Powder Feed

>> Challenge: Equipment Wear and Tear

● Future Innovations in Powder Hopper Technology

>> Smart Hopper Systems

>> Advanced Material Coatings

>> Powder Recycling and Sustainability Enhancements

● Conclusion

● Frequently Asked Questions (FAQ)

Achieving a smooth and even coating is essential in many industrial and manufacturing processes, especially when applying powder coatings on surfaces. The quality, efficiency, and consistency of the coating depend greatly on the equipment used, with powder hoppers playing a critical role in this operation. Powder hoppers serve as the reservoir and feeding mechanism to deliver powder consistently to the coating apparatus, directly impacting the overall coating performance.

This article explores the function and importance of powder hoppers in powder coating applications, discusses the design considerations, operational principles, and common challenges. We will delve into how powder hoppers contribute to high-quality coating finishes and optimize production processes for manufacturers.

Understanding Powder Hoppers and Their Function

What is a Powder Hopper?

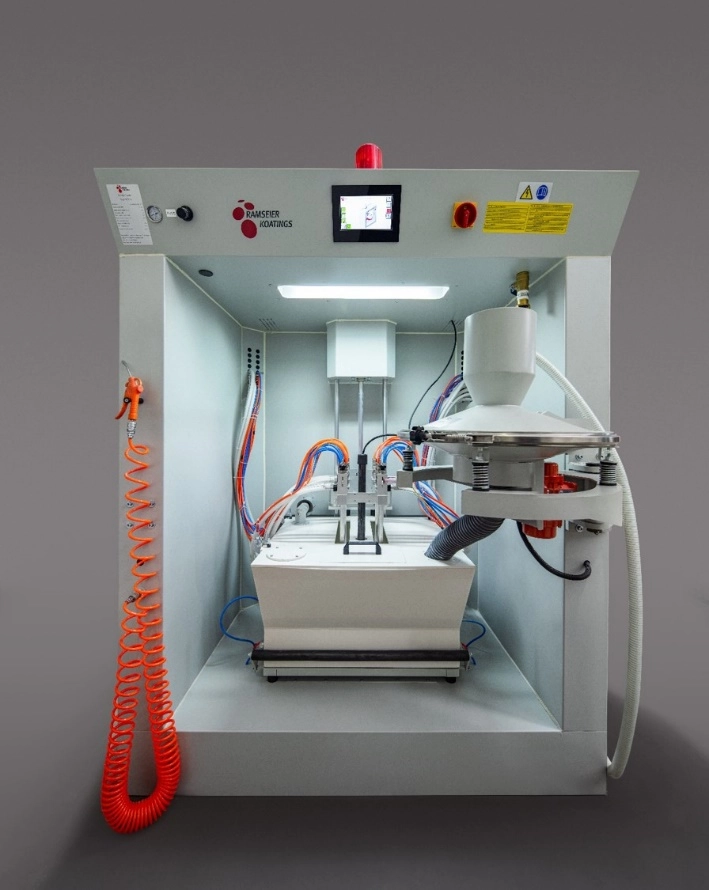

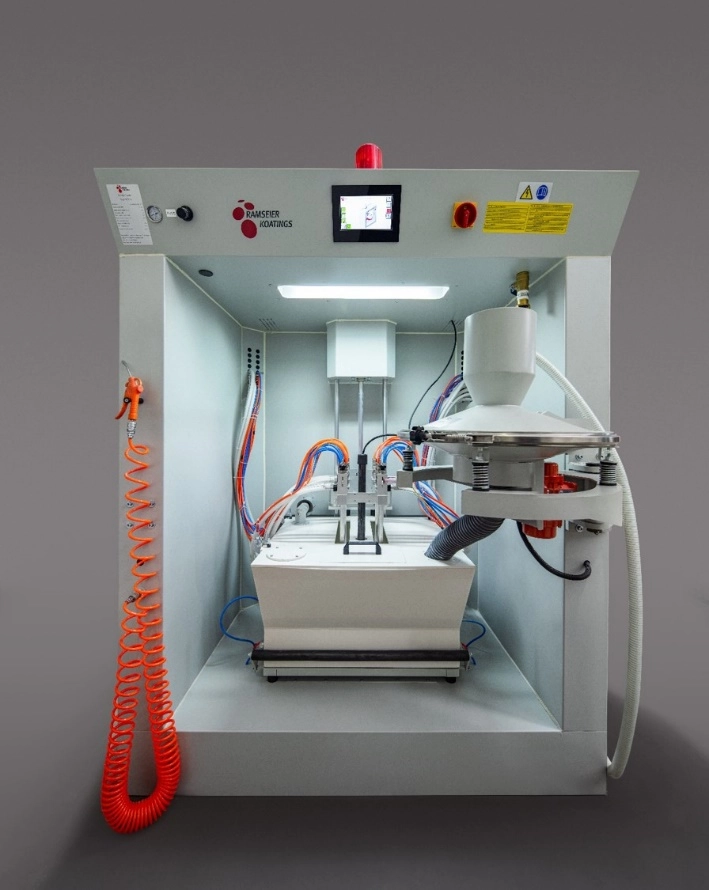

A powder hopper is a container or vessel designed to store, hold, and supply powder materials for surface coating processes. Typically made of stainless steel or other corrosion-resistant materials, powder hoppers ensure the stable supply of powder to the coating equipment, such as spray guns or electrostatic applicators.

Core Purpose of Powder Hoppers

The primary function of a powder hopper is to act as a buffer system that prevents interruptions in the coating process by providing a continuous and controlled flow of powder. By maintaining a consistent powder level and pressure inside the hopper, the system supports uniform application and reduces the risk of coating defects caused by irregular powder supply.

Types of Powder Hoppers

Powder hoppers come in various designs depending on the powder coating system and operational needs:

- Gravity-fed hoppers: Rely on gravity to feed powder into the spray guns.

- Pressurized hoppers: Use compressed air or vacuum to transfer powder under controlled pressure.

- Fluidized hoppers: Incorporate air fluidization to keep powder particles suspended and flowing smoothly.

- Vibratory hoppers: Use vibration to prevent powder clumping and ensure steady flow.

Each type offers unique advantages in different manufacturing environments and powder characteristics.

How Powder Hoppers Affect Coating Quality

Ensuring Consistent Powder Flow

Smooth and even coating largely depends on a stable powder feed rate. Powder hoppers regulate this by controlling the powder's movement into the spray equipment. Features like air pressure controls, agitators, and flow channels within the hopper minimize interruptions and fluctuations in the powder's movement, which can otherwise lead to uneven deposition and surface imperfections.

Preventing Powder Clumping and Caking

Powder particles are prone to clumping due to moisture, static charge, or particle size variations. Powder hoppers with fluidization or vibration mechanisms help keep the powder free-flowing by breaking clumps and evenly distributing the powder. This results in a homogenous powder stream and, consequently, a uniform coating.

Maintaining Optimal Powder Condition

Powder hoppers also protect the coating powder from environmental effects such as humidity and contamination. Many hoppers are equipped with seals and inert gas purging capabilities to maintain powder quality. Good powder condition ensures predictable electrostatic properties, which are critical for smooth powder attraction and layering on the substrate.

Key Design Features of Effective Powder Hoppers

Hopper Shape and Material

The geometric design of a powder hopper affects powder flow dynamics. Conical or funnel-shaped hoppers promote gravity-assisted flow, reducing powder stagnation zones. Materials like anti-static stainless steel prevent powder adhesion and reduce charge buildup.

Air Pressure Regulation

Controlled air pressure in pressurized or fluidized hoppers ensures that powder is propelled consistently towards the spray gun. Adjusting pressure settings optimizes powder delivery according to the coating requirements and powder type.

Powder Agitation and Fluidization Systems

Integrated agitators or fluidizing pads counter powder settling and bridging. Air pulsation or vibration mechanisms maintain powder looseness, crucial for uniform coating application.

Ease of Cleaning and Maintenance

Efficient powder hoppers are designed for easy disassembly, cleaning, and powder changeover. This reduces downtime and prevents cross-contamination, maintaining coating quality standards.

Operational Best Practices for Powder Hopper Use

Regular Hopper Inspection

Routine checks for wear, residue buildup, or damage help prevent disruptions. Worn seals or damaged liners can lead to powder leakage and inconsistent feed.

Optimizing Airflow and Pressure Settings

Matching air pressure and flow rates to powder properties prevents powder over-spray or insufficient deposition, aiding in a flawless coating layer.

Managing Powder Quality Inside the Hopper

Keeping the powder dry and free from contaminants via dehumidification or inert gas purging extends powder usability and coating consistency.

Coordinated Powder Feeding with Spray Operations

Synchronizing hopper powder feed with the spray gun's operation ensures balanced powder delivery, minimizing wastage and achieving the optimal coating thickness.

Common Challenges in Powder Hopper Usage and Solutions

Challenge: Powder Bridging and Arching

Bridging occurs when powder forms blockages inside the hopper, interrupting the flow. To address this:

- Use fluidization or vibration to dislodge clumps.

- Ensure hopper geometry supports consistent flow.

- Adjust powder particle size distribution.

Challenge: Powder Contamination

Contaminants affect powder charge and adhesion properties:

- Maintain clean hopper interiors.

- Use sealed hopper designs.

- Control environmental humidity.

Challenge: Inconsistent Powder Feed

Caused by pressure fluctuations or uneven powder distribution:

- Calibrate air pressure controls regularly.

- Employ automated monitoring systems.

- Maintain powder fluidity inside the hopper.

Challenge: Equipment Wear and Tear

Continuous use can degrade hopper parts:

- Schedule preventive maintenance.

- Replace worn components promptly.

- Use abrasion-resistant materials for high-wear zones.

Future Innovations in Powder Hopper Technology

Smart Hopper Systems

Integration of sensors and IoT technology enables real-time monitoring of powder levels, flow rates, and quality metrics. Automated adjustments maintain ideal feeding conditions, reducing manual interventions and improving coating reliability.

Advanced Material Coatings

Developments in non-stick and anti-static materials for hopper interiors reduce powder adherence and static buildup, enhancing powder flow and minimizing hopper cleaning frequency.

Powder Recycling and Sustainability Enhancements

Innovative hopper designs allow for easy powder reclamation and reuse, aligning with eco-friendly manufacturing goals and reducing material costs.

Conclusion

Powder hoppers are indispensable components in powder coating processes that significantly influence the quality and consistency of the final coating. Through controlled powder storage, flow regulation, and protection of powder properties, hoppers ensure smooth and even layers on coated surfaces, helping manufacturers achieve impeccable finishes and reduce operational inefficiencies. Proper selection, maintenance, and operation of powder hoppers, coupled with the adoption of emerging technologies, will continue to enhance coating performance across industries.

Frequently Asked Questions (FAQ)

Q1: Why is powder hopper design important for coating quality?

A1: The design affects powder flow dynamics. Proper shape and agitation mechanisms prevent blockages and ensure consistent powder delivery, which is crucial for uniform coating.

Q2: How does powder fluidization improve hopper performance?

A2: Fluidization uses air to keep powder particles suspended and free-flowing, preventing clumps and maintaining uniform feeding to the spray gun.

Q3: What are common causes of powder hopper malfunctions?

A3: Powder bridging, contamination, inconsistent pressure, and equipment wear are typical causes that interrupt smooth coating operations.

Q4: How can operators maintain powder quality inside the hopper?

A4: Using sealed hoppers, dehumidifiers, and inert gases helps protect powder from moisture and contamination, preserving coating characteristics.

Q5: Can powder hoppers handle different types of powders?

A5: Yes, with adjustable features like air pressure regulation and varying agitation methods, hoppers can be optimized for different powder materials and particle sizes.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.