Content Menu

● Understanding Powder Coating and Its Importance

>> Advantages of Powder Coating Over Traditional Painting

● The Role of Smart Automation in Powder Coating

>> Key Technologies Driving Smart Powder Coating Automation

>>> Robotics and Automated Spray Systems

>>> Artificial Intelligence and Machine Learning

>>> Sensors and Real-Time Monitoring

>>> Internet of Things (IoT) and Connectivity

● Benefits of Smart Automation in Powder Coating

>> Increased Precision and Consistency

>> Higher Productivity and Efficiency

>> Reduced Environmental Impact

>> Enhanced Worker Safety

● Challenges and Considerations for Implementing Smart Automation

>> High Initial Investment

>> Integration with Existing Equipment

>> Cybersecurity Risks

>> Training and Skill Development

● The Future Landscape of Powder Coating

>> Fully Autonomous Powder Coating Lines

>> Advanced Materials and Coatings

>> Predictive Maintenance and Digital Twins

>> Sustainable and Energy-Efficient Processes

● Frequently Asked Questions (FAQ)

Powder coating is a well-established finishing process known for its durability, environmental friendliness, and cost-effectiveness. As industries advance into the era of Industry 4.0, powder coating is undergoing a significant transformation driven by smart automation technologies. These innovations are enhancing productivity, improving quality control, and making the process more sustainable and efficient. This article explores the future of powder coating through the lens of smart automation technologies, highlighting key advancements, benefits, and challenges, and providing a comprehensive outlook on what lies ahead for manufacturers and suppliers alike.

Understanding Powder Coating and Its Importance

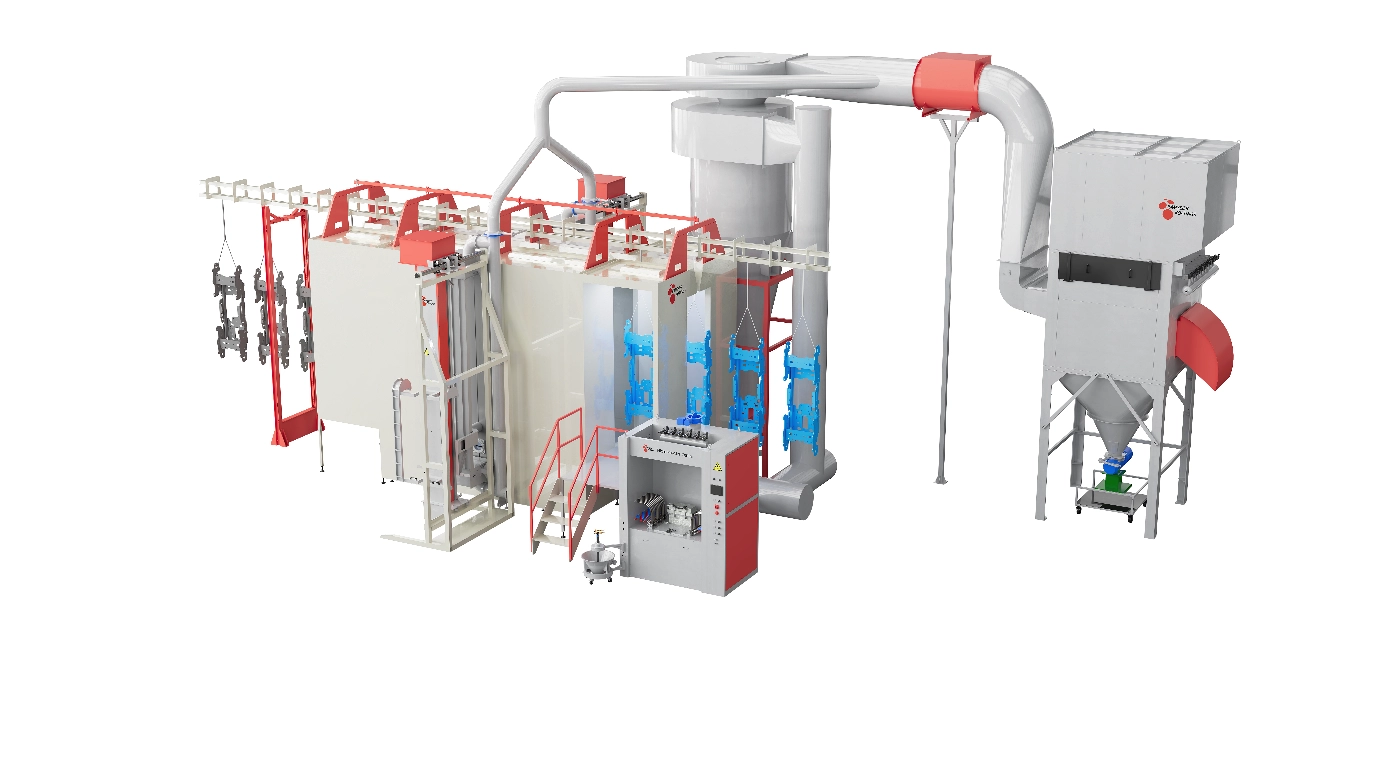

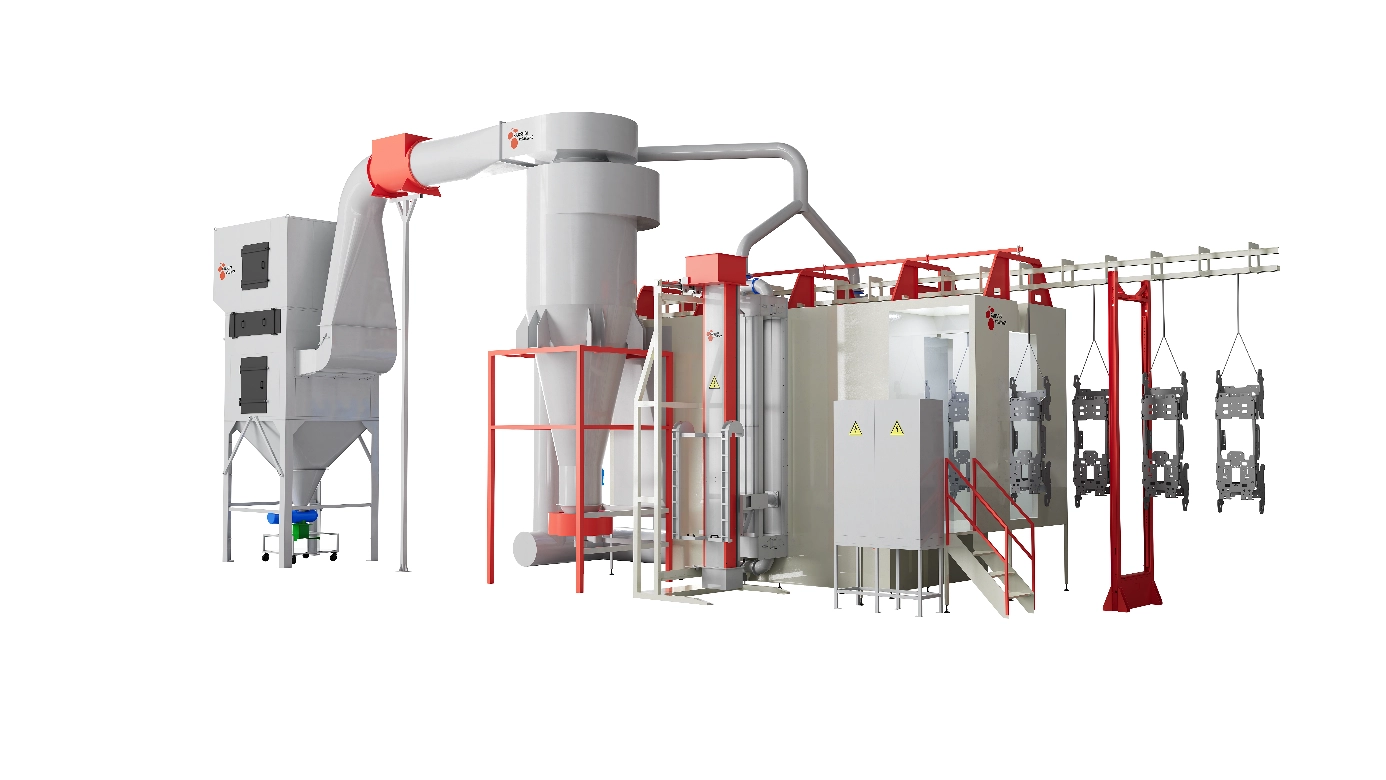

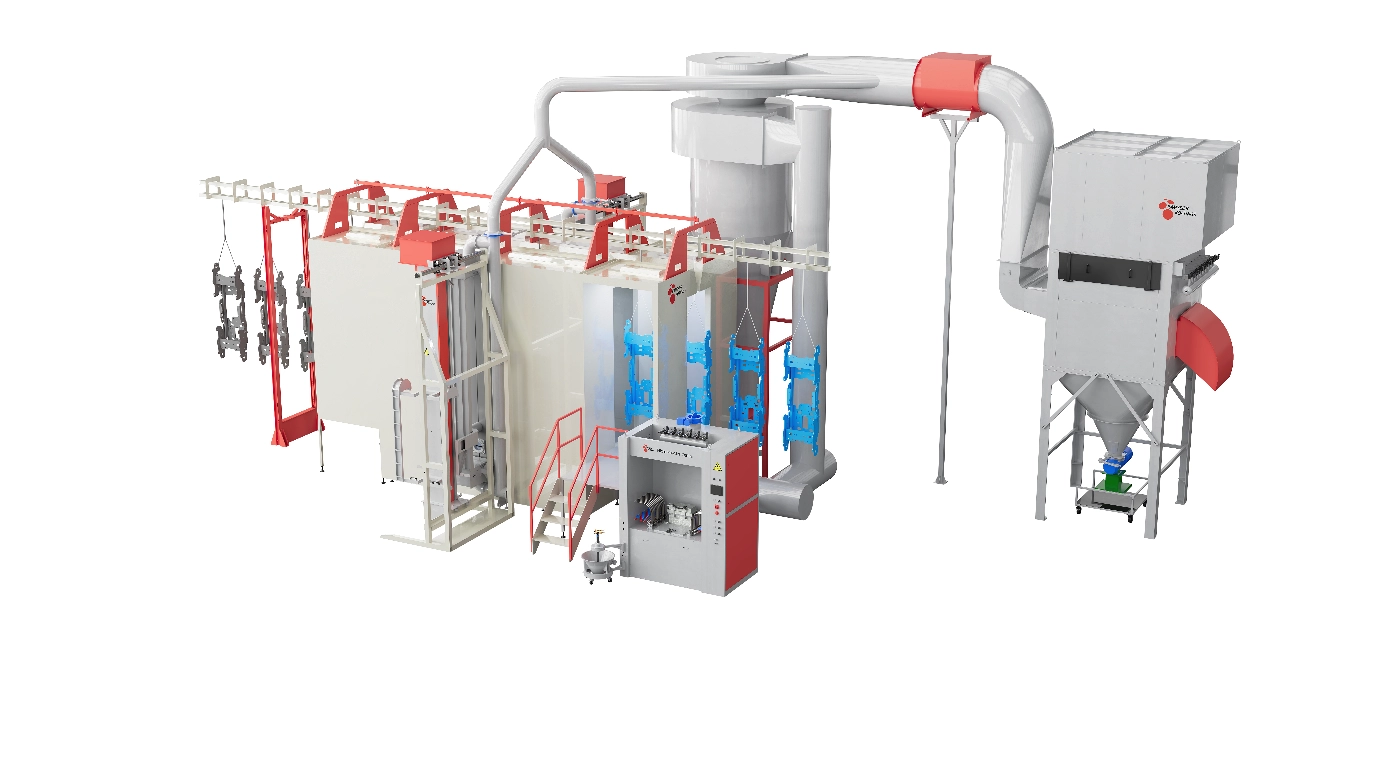

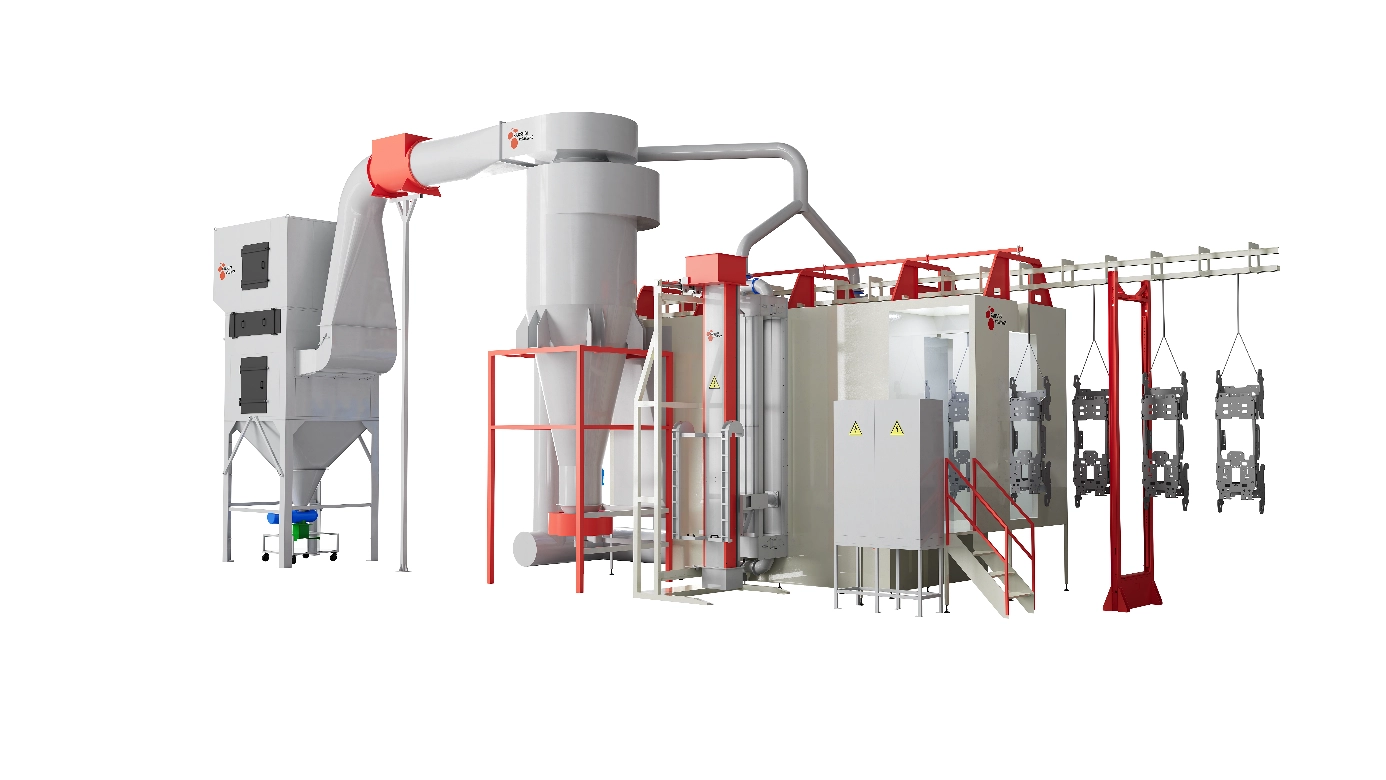

Powder coating involves applying a dry powder to a metal or other conductive surface, which is subsequently cured under heat to form a tough, protective layer. This coating technique is widely used across automotive, aerospace, appliances, construction, and furniture industries, providing corrosion resistance, aesthetic appeal, and environmental advantages over traditional liquid painting.

Advantages of Powder Coating Over Traditional Painting

- Environmentally friendly, with minimal volatile organic compounds (VOCs)

- Superior durability and resistance to wear and corrosion

- Efficient material usage with little overspray waste

- Wide range of finishes and colors

Despite these benefits, conventional powder coating methods have limitations like manual operation dependency, inconsistent application, and labor intensity. The integration of smart automation is designed to overcome these limitations and usher a new era in powder coating technology.

The Role of Smart Automation in Powder Coating

Smart automation refers to the use of advanced technologies like robotics, artificial intelligence (AI), machine learning, sensors, and the Internet of Things (IoT) to automate and optimize manufacturing processes. In powder coating, these technologies enable precise control, real-time monitoring, and adaptive processing, improving overall efficiency and product quality.

Key Technologies Driving Smart Powder Coating Automation

Robotics and Automated Spray Systems

Robots equipped with intelligent spray guns can deliver consistent powder layers with high precision, minimizing human error and material waste. These systems use programmed paths and adaptive controls to handle complex shapes and varying surface textures.

Artificial Intelligence and Machine Learning

AI algorithms analyze data from sensors to fine-tune coating parameters such as powder flow rate, spray distance, and curing time, ensuring optimal adhesion and finish appearance. Machine learning models improve over time by learning from past production results to prevent defects.

Sensors and Real-Time Monitoring

Advanced sensors track environmental conditions like temperature, humidity, and electrostatic charge, which significantly affect powder coating quality. Real-time data helps operators and machines make immediate adjustments, maintaining consistent output.

Internet of Things (IoT) and Connectivity

IoT platforms connect powder coating equipment with enterprise systems, enabling remote supervision, predictive maintenance, and detailed analytics. This connectivity provides transparency across the production line and supports data-driven decision-making.

Benefits of Smart Automation in Powder Coating

Increased Precision and Consistency

Automated control ensures uniform powder application, reducing rework and scrap rates. Smart systems produce predictable, high-quality finishes that meet stringent industry standards.

Higher Productivity and Efficiency

Robotic spraying and automated material handling speed up the coating process and allow for continuous operation. Combined with AI-driven scheduling and maintenance, these advances minimize downtime and boost throughput.

Reduced Environmental Impact

Smart automation optimizes powder usage and reduces overspray wastage, lowering material costs and environmental footprint. Real-time monitoring helps maintain eco-friendly process parameters.

Enhanced Worker Safety

Automation minimizes workers' exposure to hazardous chemicals and reduces manual handling risks, creating a safer workplace environment.

Challenges and Considerations for Implementing Smart Automation

Despite its advantages, adopting smart automation in powder coating requires overcoming certain challenges:

High Initial Investment

Robotic systems and smart sensors require significant capital outlay, which can be a barrier for small-to-medium enterprises.

Integration with Existing Equipment

Retrofitting smart technologies into legacy powder coating lines demands compatibility assessments and technical expertise.

Cybersecurity Risks

Connectivity exposes equipment to potential cyber threats, necessitating robust security protocols.

Training and Skill Development

Workers need training to operate and maintain advanced systems, requiring investment in workforce development.

The Future Landscape of Powder Coating

Looking forward, powder coating will continue evolving with deeper integration of smart technologies. Emerging trends likely to shape the future include:

Fully Autonomous Powder Coating Lines

Future systems may operate with minimal human intervention, using AI-driven decision-making to optimize operations from powder delivery to curing.

Advanced Materials and Coatings

Smart automation will facilitate application of next-generation powders with enhanced properties such as self-healing, anti-microbial, or conductive coatings.

Predictive Maintenance and Digital Twins

Digital twins—virtual replicas of physical systems—will enable simulations and predictive analytics to preempt equipment failures and optimize line performance.

Sustainable and Energy-Efficient Processes

Integration of renewable energy and waste recycling systems with smart controls will promote greener powder coating operations.

Frequently Asked Questions (FAQ)

Q1: How does automation improve powder coating quality?

Automation uses precise robotic arms and sensors that ensure uniform powder application and curing conditions, reducing defects and improving finish consistency.

Q2: Can small manufacturers afford smart powder coating technologies?

Initial costs are high, but scalable solutions and leasing options are increasingly available, making smart automation more accessible to smaller operations.

Q3: What role does AI play in powder coating?

AI analyzes process data to optimize parameters in real time, prevent defects, and learn from production history to continuously improve coating quality.

Q4: How do IoT devices benefit powder coating plants?

IoT enables remote monitoring, predictive maintenance, and data analytics, increasing uptime and operational transparency.

Q5: Are there any safety concerns with automated powder coating?

Automation reduces human exposure to hazardous powders and chemicals, enhancing workplace safety, but machinery operation protocols must still be followed to avoid accidents.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.