Content Menu

● What is Swinger Powder Coating System?

>> Understanding Powder Coating Technology

>> The Swinger System Advantage

● Components and Operation of Swinger Powder Coating Systems

>> Key Elements of the System

>> How Swinger Systems Improve Efficiency

● Benefits of Swinger Powder Coating Systems

>> Superior Coating Quality and Durability

>> Environmental and Health Advantages

>> Cost Efficiency and Waste Reduction

>> Versatility in Applications

● Applications of Swinger Powder Coating Systems

>> Playground and Recreational Equipment

>> Automotive and Aerospace Components

>> Architectural and Industrial Equipment

● Future Trends and Innovations in Swinger Powder Coating Systems

>> Integration with Industry 4.0

>> Advanced Powder Formulations

>> Sustainable and Energy-Efficient Designs

● Frequently Asked Questions About Swinger Powder Coating Systems

Powder coating technology has radically transformed surface finishing over recent decades, offering a more durable, environmentally friendly, and aesthetically versatile alternative to conventional liquid paints. Among the various advanced systems available, Swinger powder coating systems have emerged as a pioneer, driving efficiency and superior performance in industrial and commercial surface finishing. This article explores the innovations, operational mechanisms, benefits, and future trends of Swinger powder coating systems, offering a comprehensive view of why they represent the future of efficient surface finishing.

What is Swinger Powder Coating System?

Understanding Powder Coating Technology

Powder coating is a dry finishing process where fine powder particles are applied electrostatically to a surface and then cured under heat to form a solid, durable, and uniform coating. Unlike liquid paints, powder coatings do not use solvents and are composed of thermoplastic or thermoset polymer particles that melt and fuse during the curing process. This method results in coatings with excellent resistance to corrosion, UV rays, scratches, and environmental wear.

The Swinger System Advantage

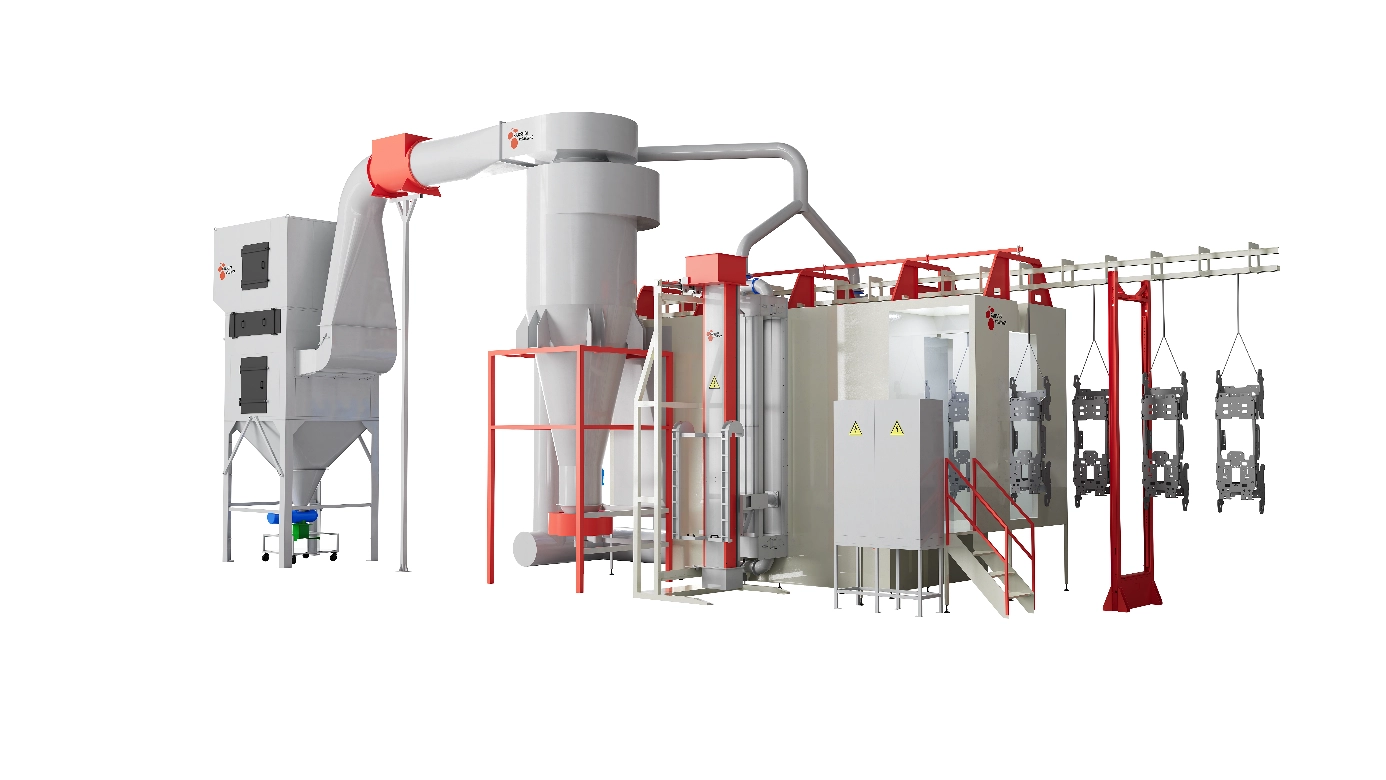

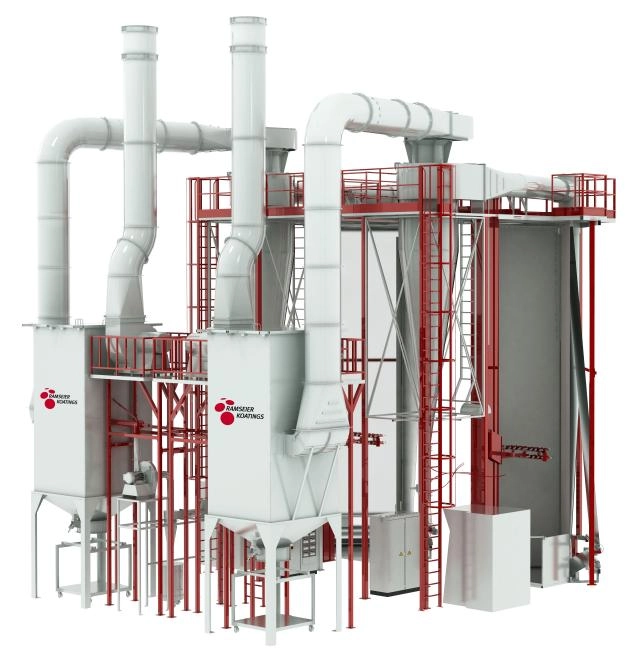

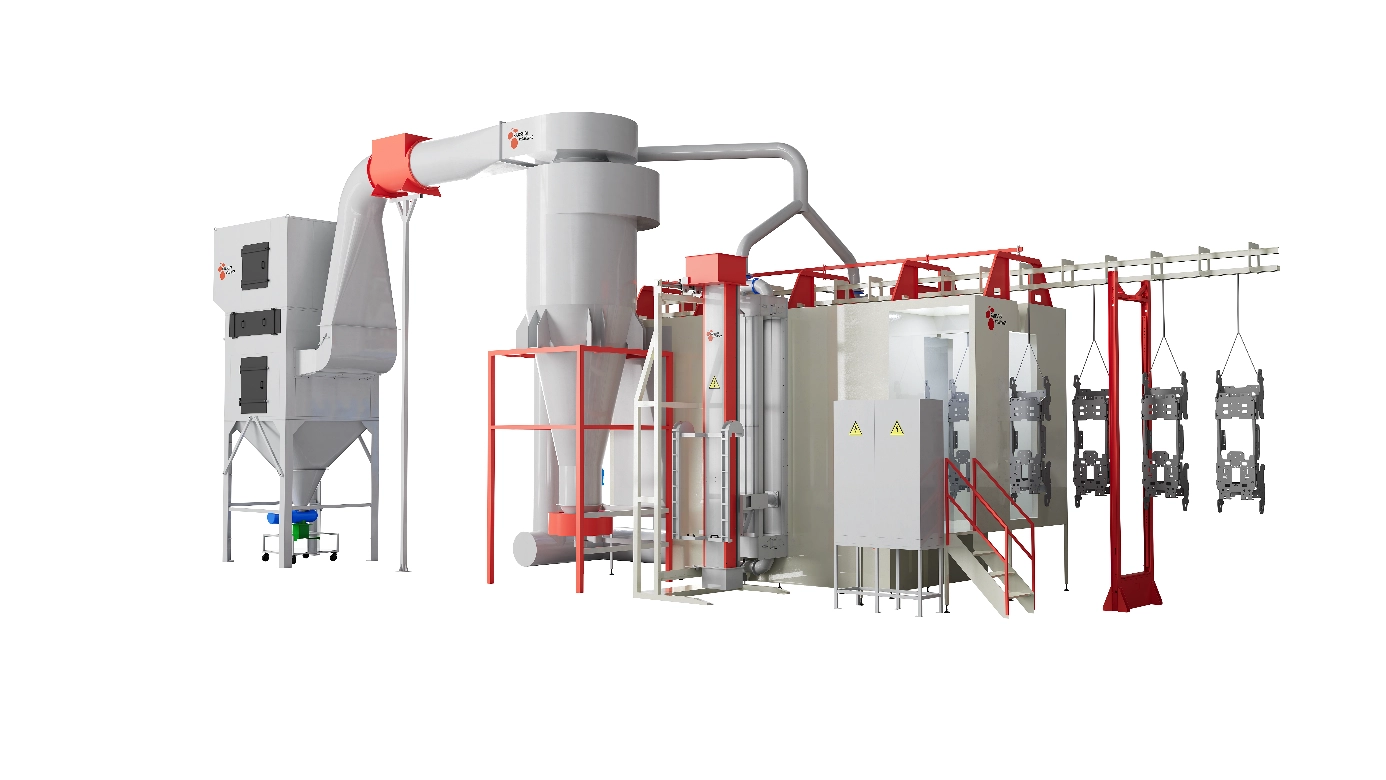

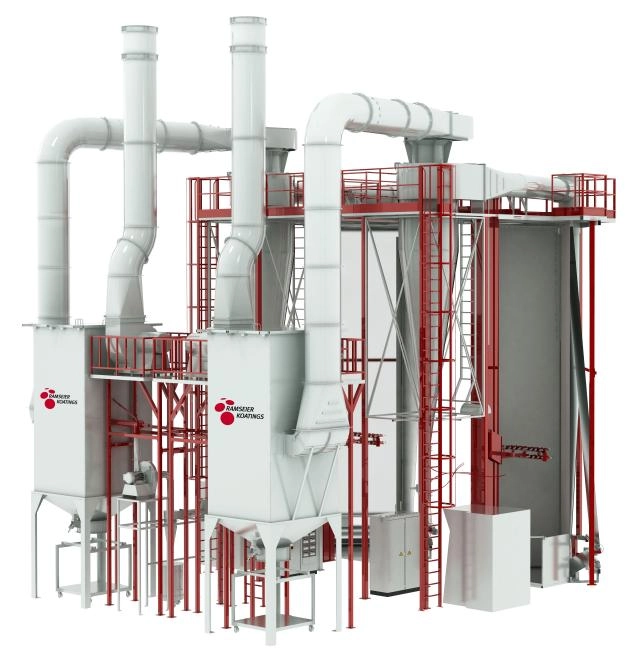

Swinger powder coating systems refer to a category of automated or semi-automated powder application technologies that use swinging or oscillating guns and optimized delivery systems to apply powder coatings efficiently. This mechanism enhances uniformity and coverage on complex shapes and large surfaces, reducing overspray waste and improving transfer efficiency.

Components and Operation of Swinger Powder Coating Systems

Key Elements of the System

Swinger powder coating systems generally include several critical components working in harmony:

- Pretreatment Station: This includes cleaning, degreasing, and sometimes phosphating of the substrate surface to optimize adhesion of the powder coating.

- Powder Application Guns: Electrostatic spray guns that charge powder particles so they adhere evenly to the substrate.

- Swinging Mechanism: A mechanical arm or multiple arms that oscillate the application guns methodically to ensure even coverage on all surfaces.

- Powder Recovery Units: These capture and recycle overspray powder, minimizing waste and creating a more sustainable process.

- Curing Oven: The coated parts are heated in an oven to cure the powder coating, creating a solid and durable finish.

How Swinger Systems Improve Efficiency

The swinging motion combined with precise gun control allows the powder to be deposited remarkably evenly and efficiently. Complex and irregular parts, which are typically challenging to coat uniformly, benefit tremendously from this approach. Additionally, automated movement reduces human error and speeds up production cycles.

Benefits of Swinger Powder Coating Systems

Superior Coating Quality and Durability

Swinger powder coating systems provide thick yet consistent film builds, which offer exceptional protection against corrosion, UV degradation, scratching, and impact. These coatings maintain gloss and color vibrancy for extended periods, making them ideal for outdoor equipment and industrial machinery.

Environmental and Health Advantages

Since powder coatings contain no solvents, their application does not release volatile organic compounds (VOCs) into the atmosphere. This makes Swinger systems environmentally safer and compliant with increasingly stringent environmental regulations. Furthermore, minimal powder waste due to the precise application reduces overall material consumption.

Cost Efficiency and Waste Reduction

By maximizing powder transfer efficiency and recycling overspray, Swinger systems reduce material costs and waste disposal needs. Faster cycle times and automated spraying reduce labor costs and increase throughput, making these systems economically attractive for manufacturers aiming to scale production.

Versatility in Applications

Swinger powder coating systems can be tailored to different powder formulations and substrate materials, including metals, plastics, and composites. They are widely used in industries ranging from automotive and recreational equipment to architectural fixtures and electronics.

Applications of Swinger Powder Coating Systems

Playground and Recreational Equipment

Powder coatings applied by Swinger systems provide playground equipment with durable, vibrant, and weather-resistant finishes. Advanced multi-layer coating options, including zinc-rich primers and super durable polyester powders, ensure long service life even in harsh coastal environments.

Automotive and Aerospace Components

The automotive industry benefits from Swinger systems for high-quality finishes on chassis, rims, and engine parts, where resistance to corrosion and wear is critical. In aerospace, lightweight and wear-resistant powder coatings improve component performance and lifespan.

Architectural and Industrial Equipment

Architectural metals, such as aluminum extrusions and steel structures, achieve superior aesthetics and protection. Industrial equipment subjected to corrosive and abrasive conditions also relies on Swinger powder coatings for extended durability and reduced maintenance.

Future Trends and Innovations in Swinger Powder Coating Systems

Integration with Industry 4.0

Increasingly, Swinger powder coating systems are being integrated with smart manufacturing technologies such as IoT sensors, AI-driven quality control, and automated process adjustments. These innovations allow real-time monitoring and optimization, ensuring consistent coating quality and operational efficiency.

Advanced Powder Formulations

Research and development in powder chemistry continue to enhance powder coating properties, including faster curing times, improved flexibility, enhanced UV resistance, and environmentally friendly bio-based powders. Swinger systems are evolving to accommodate these next-generation powders for superior finishes.

Sustainable and Energy-Efficient Designs

New Swinger system models focus on energy conservation through better oven insulation, optimized airflow, and lower temperature curing processes. These improvements reduce the environmental footprint and operating costs.

Frequently Asked Questions About Swinger Powder Coating Systems

1. What makes Swinger powder coating systems more efficient than traditional spray methods?

Swinger systems use a swinging or oscillating arm mechanism to apply powder evenly across surfaces, minimizing overspray and waste while providing consistent coverage, especially on complex geometries.

2. Can Swinger powder coating systems be used on non-metal surfaces?

Yes, powder coatings can be applied to plastics, composites, and concrete, though specific pretreatment and powder formulations are required to ensure adhesion and durability.

3. How does the curing process work in Swinger powder coating systems?

After powder application, coated parts pass through a curing oven where heat causes the powder particles to melt, flow, and chemically bond, creating a tough, uniform film.

4. Are Swinger powder coating systems environmentally friendly?

Yes, they use powder materials that contain no solvents or VOCs, and their efficient powder recovery systems minimize waste, making them much greener than traditional solvent-based painting.

5. What industries benefit most from Swinger powder coating systems?

Industries such as automotive, aerospace, architectural construction, playground and recreational equipment manufacturing, and industrial machinery heavily benefit due to the system's durability, efficiency, and finish quality.

[1] https://www.pfonline.com/articles/powder-coatings-are-in-full-swing-at-the-playground

[2] https://www.scribd.com/document/674645326/%E6%9F%AF%E6%9E%97%E6%96%AF%E8%8B%B1%E8%AF%AD%E8%AF%AD%E6%B3%95%E7%B3%BB%E5%88%97-1-%E4%BB%8B%E8%AF%8D

[3] https://www.unitedfinishing.net/united-solutions/powder-coating-systems

[4] https://ia800600.us.archive.org/5/items/ittushu-2470/%E6%B8%85%E5%8D%8E%E5%A4%A7%E5%AD%A6%E5%9B%BE%E4%B9%A6%E9%A6%86-%E6%88%98%E7%96%AB%E7%89%88/H_%E8%AF%AD%E8%A8%80%E3%80%81%E6%96%87%E5%AD%97/12133_%E5%9B%BD%E9%99%85%E4%BA%A4%E6%B5%81%E8%8B%B1%E8%AF%AD%E9%98%85%E8%AF%BB%E8%BF%9B%E9%98%B6%E6%95%99%E7%A8%8B_text.pdf

[5] https://www.pfonline.com/topics/powder

[6] https://www.scribd.com/document/498929761/%E5%8F%8C%E8%89%B2%E8%A1%A8%E8%A7%A3%E8%8B%B1%E8%AF%AD%E8%AF%8D%E6%B1%87

[7] https://boneheadperformance.com/powder-coating/atv-and-motorcycle-powder-coating-prices/

[8] https://www.cs.cmu.edu/afs/cs.cmu.edu/project/cmt-40/Nice/Transfer/Chinese/xferlexicon.txt

[9] https://www.ramseierkoatings.com/how-to-choose-the-right-swinger-powder-coating-system-for-your-production-line.html

[10] https://github.com/busiyiworld/maimemo-export/blob/main/exported/translation/%E6%98%9F%E7%81%AB%E5%88%9D%E4%B8%AD%E8%8B%B1%E8%AF%AD%E8%AF%8D%E6%B1%871600%E8%AF%8D.csv

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.