Content Menu

● Understanding Powder Coating and Swinger Systems

● Large Scale Production: Characteristics and Requirements

>> The Scale and Nature of Large Scale Production

>> Key Features of Swinger Systems for Large Scale

>> Advantages of Large Scale Swinger Systems

>> Challenges in Large Scale Production

● Small Scale Production: Characteristics and Needs

>> Understanding Small Scale Powder Coating

>> Overview of Swinger Systems for Small Scale

>> Advantages of Small Scale Systems

>> Challenges in Small Scale Production

● Comparing System Types: Batch vs Conveying for Powder Coating

● Selecting the Right Swinger Powder Coating System for Your Business

>> Factors to Consider

>> Cost Considerations

>> Future Scalability

● Emerging Trends in Swinger Powder Coating Systems

● Commonly Asked Questions

Powder coating is a versatile, efficient, and eco-friendly finishing process widely used across industries to protect and beautify metal and other surfaces. When it comes to implementing powder coating in production, the choice of equipment and system layout can vary significantly depending on whether the operation is large scale or small scale. Swinger powder coating systems, incorporating either batch or conveying setups, offer solutions tailored to these different production needs. This article explores the distinctions, advantages, challenges, and considerations of using Swinger powder coating systems for large-scale versus small-scale production, providing practical insights for businesses to select the right approach.

Understanding Powder Coating and Swinger Systems

Powder coating involves applying a dry powder electrostatically to a part, which is then cured under heat to form a durable skin. Swinger powder coating systems refer to automated or semi-automated systems designed to handle parts efficiently, including swing arm mechanisms for part positioning and coating application. This design allows for flexibility and adaptability to various part sizes and quantities.

Large Scale Production: Characteristics and Requirements

The Scale and Nature of Large Scale Production

Large scale powder coating production typically involves coating thousands or even millions of parts annually. Such operations demand high throughput, consistent quality, and automation to minimize labor costs.

Key Features of Swinger Systems for Large Scale

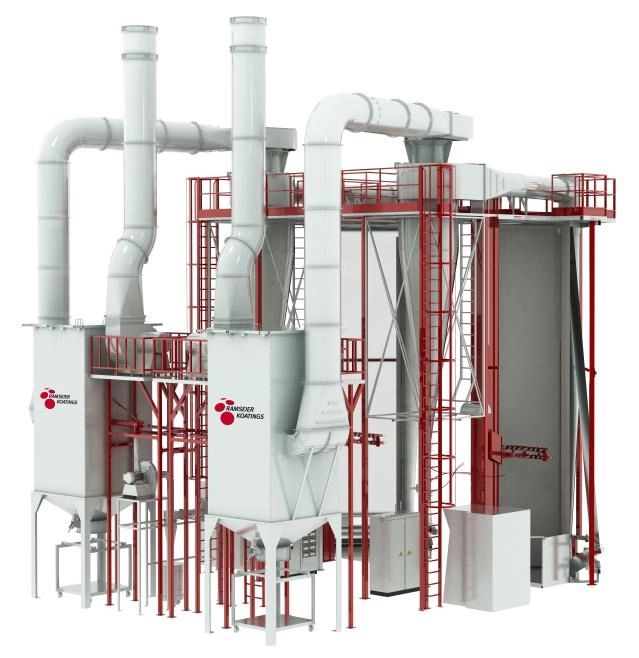

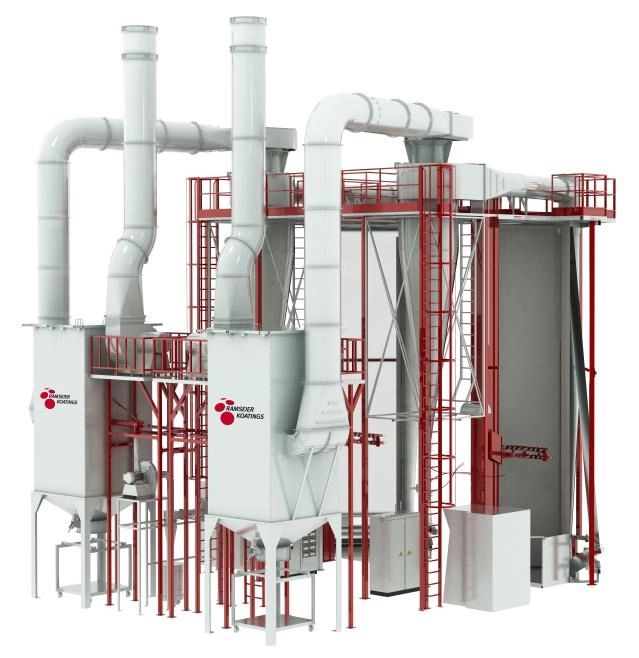

- Automated Conveying Systems: In large scale, swinger powder coating systems often incorporate automated conveyor lines to move parts through pretreatment, coating, and curing stages efficiently.

- High Capacity: Equipment designed for continuous operation with high output capabilities.

- Consistency and Speed: Automation ensures consistent coating thickness and color quality at rapid cycle times.

- Multistage Pretreatment: Essential for large volumes to maintain adhesion and durability.

- Energy Efficiency: Large operations focus on reducing operational costs, so energy-efficient curing ovens and recovery systems are integrated.

- Space Requirements: Such systems require considerable floor space for conveyors, ovens, and control rooms.

Advantages of Large Scale Swinger Systems

- Increased Throughput: Automated systems coat more parts with less downtime.

- Reduced Labor Costs: Automation decreases manual intervention.

- Superior Quality Control: Automated controls maintain uniform coating.

- Scalable Production: Can handle increased demand without significant downtime.

- Sustainability: Large operations often adopt environmentally friendly technologies due to regulations and cost savings.

Challenges in Large Scale Production

- High Initial Investment: Automated swinger systems with conveyors and ovens require substantial capital.

- Complex Maintenance: Sophisticated equipment demands skilled technicians.

- Space Intensive: Large facilities are necessary, increasing real estate costs.

- Changeover Time: Switching between part types or colors can be time-consuming.

Small Scale Production: Characteristics and Needs

Understanding Small Scale Powder Coating

Small scale production generally involves lower volume batches, custom jobs, or parts of varying sizes, often produced on demand or for niche markets.

Overview of Swinger Systems for Small Scale

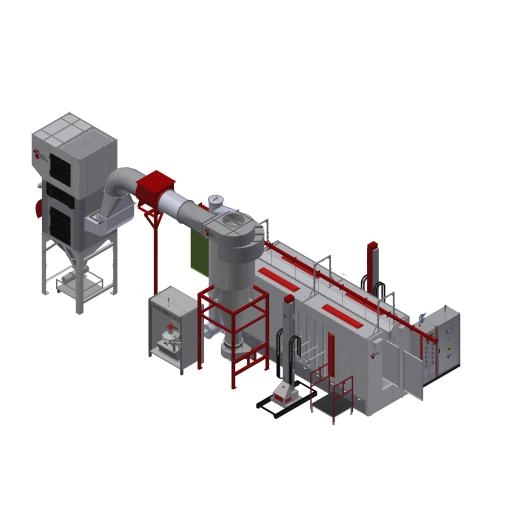

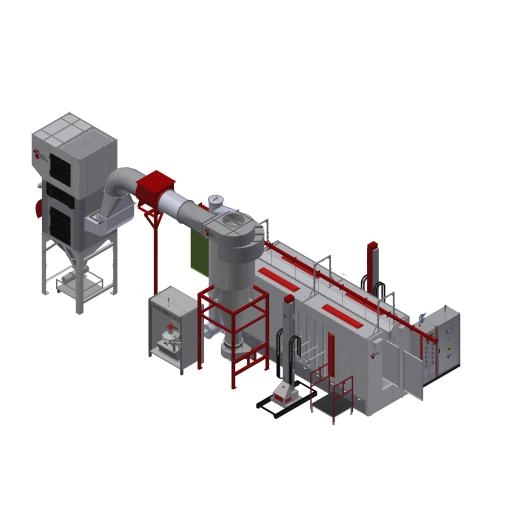

- Batch Systems: Swinger powder coating for small scale often relies on batch or manual systems where parts are coated in lots and moved manually or with small mechanized racks.

- Flexibility: Equipment must handle a wide range of part sizes and shapes efficiently.

- Compact Footprint: Limited space environments require compact and mobile systems.

- Cost-Effective: Initial investment and operating costs must align with lower production volumes.

- Manual or Semi-Automated: Often requires labor input for loading/unloading and quality checks.

- Simplified Pretreatment Options: Smaller pretreatment lines, often dip tanks or small steam units, are used.

Advantages of Small Scale Systems

- Lower Capital Costs: Batch swinger systems are more affordable.

- Flexibility to Change Jobs Quickly: Easier to switch color or finish.

- Ideal for Custom Work: Accommodates complex or varying parts.

- Smaller Space Requirements: Fits in smaller workshops or production floors.

- Easier Maintenance: Simpler systems with fewer components.

Challenges in Small Scale Production

- Labor Intensive: Manual handling increases labor needs.

- Lower Throughput: Not suitable for high volume demand.

- Inconsistent Quality: More operator-dependent variability.

- Longer Cycle Times: Batch processing can take more time per job.

Comparing System Types: Batch vs Conveying for Powder Coating

Both batch and conveying Swinger systems have their place depending on production scale.

| Feature | Batch Systems (Small Scale) | Conveying Systems (Large Scale) |

| Throughput | Low to moderate, suitable for small batches | High throughput, continuous production |

| Flexibility | Very flexible, good for diverse part sizes and custom jobs | Less flexible, best for uniform parts |

| Initial Investment | Lower capital expenditure | High initial cost |

| Space Requirements | Compact footprint | Requires larger facility space |

| Labor Requirement | Higher manual labor | Lower labor due to automation |

| Maintenance Complexity | Simpler, easier to maintain | More complex and technical |

Selecting the Right Swinger Powder Coating System for Your Business

Factors to Consider

1. Production Volume and Frequency: High volumes favor conveying systems, while smaller, varied orders suit batch systems.

2. Part Dimensions and Complexity: Large or unusual parts may require batch swinger setups.

3. Budget Constraints: Assess upfront cost, operational expenses, and ROI.

4. Facility Space: Larger setups need spacious accommodations.

5. Labor Availability: Consider workforce skills and costs.

6. Quality and Finish Requirements: Automated large scale systems often provide tighter control.

7. Environmental Regulations: Larger plants must adhere to stricter eco-standards.

Cost Considerations

Budgeting should factor in equipment, installation, training, maintenance, and materials. Leasing options may help small businesses manage costs.

Future Scalability

Evaluate if your system can expand with your business growth or adapt to changing product lines.

Emerging Trends in Swinger Powder Coating Systems

- Integration of Robotics: For higher precision and reduced labor.

- Smart Controls and IoT: Real-time monitoring for quality assurance.

- Energy-Saving Technologies: Improved ovens and powder reclaim systems.

- Modular Designs: Allow easier upgrades and rearrangements.

- Eco-Friendly Pretreatment: Steam units and low-waste dip tanks.

Commonly Asked Questions

1. What is the main difference between Swinger batch and conveying powder coating systems?

Batch systems coat parts in smaller, manual or semi-automated lots and are more flexible in handling varied sizes; conveying systems automate part movement for continuous large-scale production with higher throughput.

2. Can a small business afford a large-scale Swinger system?

Generally, no. Large-scale systems require significant investment and space, making them less practical for small operations with lower volumes.

3. How do pretreatment methods differ for large and small scale powder coating?

Large scale usually uses multistage dip tank systems for consistent cleaning at high volumes; small scale may use steam units or smaller dip tanks for more manageable batch sizes.

4. Is automation always better for powder coating?

It depends on production volume and budget. Automation improves throughput and consistency but requires higher upfront costs and maintenance.

5. How does powder reclaim work in large scale systems?

Large scale systems often include powder recovery units that capture excess powder for reuse, reducing waste and operating costs.

[1] https://pacpowder.com/news/why-choose-commercial-powder-coating-for-large-scale-projects-and-high-volume-production-runs/

[2] https://ia800600.us.archive.org/5/items/ittushu-2470/%E6%B8%85%E5%8D%8E%E5%A4%A7%E5%AD%A6%E5%9B%BE%E4%B9%A6%E9%A6%86-%E6%88%98%E7%96%AB%E7%89%88/H_%E8%AF%AD%E8%A8%80%E3%80%81%E6%96%87%E5%AD%97/12133_%E5%9B%BD%E9%99%85%E4%BA%A4%E6%B5%81%E8%8B%B1%E8%AF%AD%E9%98%85%E8%AF%BB%E8%BF%9B%E9%98%B6%E6%95%99%E7%A8%8B_text.pdf

[3] https://powderx.com/powder-coating-pretreatment-methods/

[4] https://www.scribd.com/document/648139562/%E9%AB%98%E7%BA%A7%E8%8B%B1%E8%AF%AD1-%E7%AC%AC3%E7%89%88-%E5%AD%A6%E4%B9%A0%E6%8C%87%E5%8D%97

[5] https://www.linkedin.com/pulse/pros-cons-batch-system-vs-automated-powder-03lnc

[6] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[7] https://productionsystems-usa.com/comparing-batch-vs-conveying-powder-coating-systems/

[8] https://huggingface.co/facebook/xm_transformer_unity_hk-en/commit/e37fd5ab9c6faf7a9547972cf6dace1c144c49c8.diff?file=en_zh_spm.dict

[9] https://insights.made-in-china.com/Powder-Coating-Equipment-101-How-to-Choose-the-Right-Solution-for-Your-Needs_SAUajwBWXxHg.html

[10] https://raw.githubusercontent.com/hermitdave/FrequencyWords/master/content/2016/zh/zh_50k.txt

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.