Content Menu

● Introduction

● What is an Automatic Spray Booth System?

>> Key Components of Automatic Spray Booth Systems

● Advantages of Partnering with an Automatic Spray Booth Systems Provider

>> Enhanced Productivity and Efficiency

>> Superior Finish Quality

>> Environmental and Safety Benefits

>> Customization and Flexibility

● Our OEM Services for Global Brands

● Industry Applications of Automatic Spray Booth Systems

>> Automotive Industry

>> Aerospace and Industrial Equipment

>> Woodworking and Furniture

>> Powder Coating and Blasting

● Technical Innovations in Automatic Spray Booth Systems

>> Single-Arm Reciprocator Technology

>> Pressurized Cabins with Advanced Ventilation

>> Energy-Efficient Heating and Curing Systems

● Choosing the Right Automatic Spray Booth Systems Provider

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In the modern manufacturing landscape, achieving high-quality finishes efficiently is paramount. As a leading Chinese manufacturer, wholesaler, and supplier specializing in automatic spray paint booths, we provide OEM services to global brands, wholesalers, and producers. This comprehensive guide explores the critical role of an Automatic Spray Booth Systems Provider in enhancing productivity, safety, and finish quality across industries.

What is an Automatic Spray Booth System?

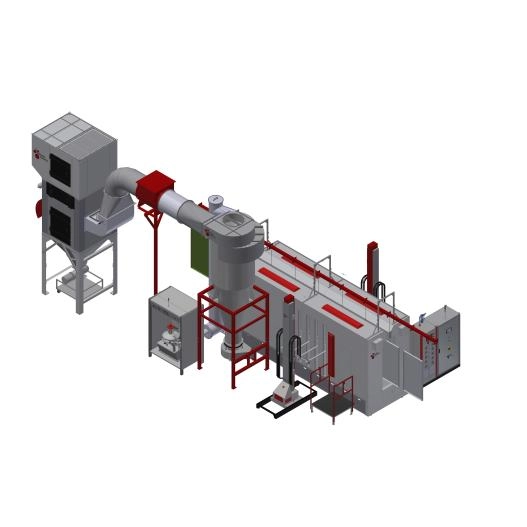

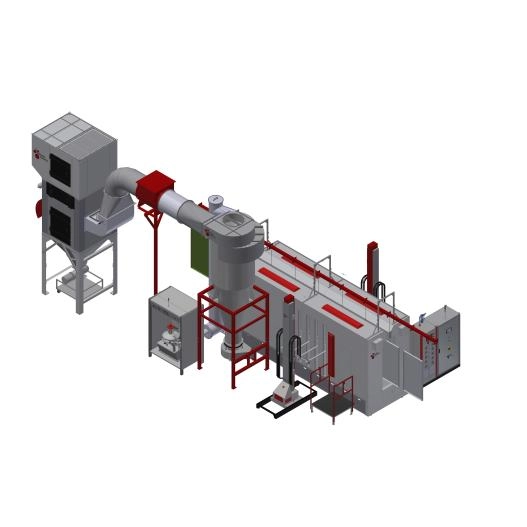

An Automatic Spray Booth System is a technologically advanced enclosure designed to automate the painting or coating process. Unlike manual spray booths, these systems integrate robotics, precision controls, and ventilation to deliver consistent, high-quality finishes while minimizing waste and environmental impact.

Key Components of Automatic Spray Booth Systems

- Spray Guns and Reciprocators: Automated arms equipped with spray guns ensure uniform paint application.

- Pressurized Cabin: Maintains optimal airflow to reduce overspray and contamination.

- Ventilation and Filtration: Advanced exhaust and filtration systems remove harmful fumes and particles.

- Control Systems: Programmable logic controllers (PLCs) manage spray patterns, speed, and curing cycles.

Advantages of Partnering with an Automatic Spray Booth Systems Provider

Enhanced Productivity and Efficiency

Automatic spray booths significantly increase throughput by enabling continuous, precise painting operations without manual intervention. This reduces labor costs and turnaround times, crucial for high-volume manufacturers.

Superior Finish Quality

The precision and repeatability of automatic systems ensure uniform coating thickness and smooth finishes, reducing rework and customer complaints.

Environmental and Safety Benefits

Equipped with advanced filtration and exhaust systems, these booths minimize volatile organic compound (VOC) emissions and protect workers from hazardous fumes, aligning with global environmental regulations.

Customization and Flexibility

As an Automatic Spray Booth Systems Provider, we offer tailored solutions to meet diverse industry requirements—from automotive and aerospace to woodworking and powder coating.

Our OEM Services for Global Brands

We specialize in providing OEM manufacturing and design services for international automatic spray booth brands, wholesalers, and producers. Our factory capabilities include:

- Custom design and engineering based on client specifications.

- High-quality manufacturing with strict quality control.

- Efficient production and timely delivery.

- After-sales support including installation guidance and staff training.

This partnership model enables foreign brands to leverage our manufacturing expertise while maintaining their market identity.

Industry Applications of Automatic Spray Booth Systems

Automotive Industry

Automatic spray booths are essential for automotive refinishing and manufacturing, delivering flawless paint jobs on cars, trucks, and parts with high speed and consistency.

Aerospace and Industrial Equipment

Precision finishing is critical in aerospace and heavy equipment manufacturing. Automated systems ensure compliance with stringent quality standards.

Woodworking and Furniture

Specialized booths cater to the unique needs of woodworkers, providing dust-free environments and optimal paint application for fine finishes.

Powder Coating and Blasting

Automatic booths designed for powder coating and abrasive blasting improve efficiency and safety in these demanding processes.

Technical Innovations in Automatic Spray Booth Systems

Single-Arm Reciprocator Technology

Mounted on linear precision guides with brushless motors, this technology ensures smooth and accurate spray movements, reducing paint waste.

Pressurized Cabins with Advanced Ventilation

Pressurization minimizes overspray and contamination, while customizable exhaust systems (dry or wet) maintain air quality and comply with environmental standards.

Energy-Efficient Heating and Curing Systems

Modern booths incorporate air makeup and curing heat systems that optimize drying times and energy consumption, boosting production capacity.

Choosing the Right Automatic Spray Booth Systems Provider

When selecting a provider, consider:

- Experience and industry expertise.

- Customization capabilities.

- Compliance with safety and environmental standards.

- Quality of components and manufacturing.

- After-sales service and technical support.

Our company excels in all these areas, ensuring clients receive reliable, cutting-edge spray booth systems tailored to their needs.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from automatic spray booth systems?

A1: Automotive, aerospace, woodworking, powder coating, and industrial equipment sectors benefit greatly due to the need for high-quality, efficient finishing processes.

Q2: How does an automatic spray booth improve environmental safety?

A2: By incorporating advanced filtration and exhaust systems, automatic spray booths reduce VOC emissions and protect workers from harmful fumes.

Q3: Can automatic spray booths be customized for specific production needs?

A3: Yes, providers offer tailored designs including booth size, airflow type, spray technology, and curing systems to meet unique client requirements.

Q4: What is OEM service in the context of automatic spray booth systems?

A4: OEM service involves manufacturing spray booths for other brands, allowing them to market the products under their own brand name while leveraging the manufacturer's expertise.

Q5: How does automation affect the quality of paint finishes?

A5: Automation ensures consistent spray patterns and thickness, reducing defects and improving overall finish quality.

Conclusion

As a premier Automatic Spray Booth Systems Provider, our expertise in design, manufacturing, and OEM services positions us as a trusted partner for international brands seeking advanced, reliable spray booth solutions. Our commitment to quality, innovation, and customer satisfaction ensures that clients achieve superior finishing results with enhanced efficiency and safety.

[1] https://www.spraysystems.com

[2] https://marathonspraybooths.com

[3] https://www.paint-booths.com/category/automotive-paint-booths.html

[4] https://www.godnfinishing.com/Products/automatic-spray-paint-booth/

[5] https://www.blowtherm-usa.com

[6] https://www.shanghai.gov.cn/cmsres/e7/e774040988e9444baacf08669b7d8d12/f5f974250770014900e73d0e682c5abc.xlsx

[7] https://www.rohnerspraybooths.com

[8] https://gxq.cq.gov.cn/zwgk_202/jczwgkbzml/jycyly/ggjyfwzxhd/ggjyfwzxhd/qtxxgk/202502/P020250228387467959728.xlsx

[9] http://www.iden.cn/home/newDesign.SupplyChain

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.