Content Menu

● Introduction

● Understanding Powder Supply Systems

>> What is a Powder Supply System?

>> How Does It Differ from Traditional Methods?

● The Economic Advantages of Powder Supply Systems

>> Reduced Material Waste

>> Lower Labor and Maintenance Costs

>> Faster Production and Increased Throughput

>> Energy Efficiency

>> Bulk Purchasing and Inventory Management

● Operational Considerations

>> Initial Investment and Payback Period

>> Training and Skill Requirements

>> Maintenance and Reliability

● Comparing In-House vs. Outsourced Powder Coating

>> In-House Powder Coating

>> Outsourcing Powder Coating

>> Decision Factors

● Strategies for Maximizing Cost Savings

>> Optimize Powder Usage

>> Invest in Energy-Efficient Equipment

>> Streamline Inventory Management

>> Build Strong Supplier Relationships

>> Continuous Training and Process Improvement

● Case Study: Real-World Cost Savings

● Potential Challenges and How to Overcome Them

>> High Initial Investment

>> Training and Change Management

>> Maintenance and Downtime

>> Supplier Dependence

● The Environmental Perspective

● Is Our Powder Supply System the Best Option?

● Frequently Asked Questions

Introduction

In the competitive world of industrial finishing, cost efficiency is a decisive factor for business sustainability and growth. Among the various finishing solutions, powder coating has emerged as a preferred method for many manufacturers due to its durability, environmental benefits, and, most importantly, its potential for significant cost savings. But is our powder supply system truly the best option for maximizing cost efficiency? This article explores the economic advantages, operational considerations, and strategic factors that determine whether a powder supply system delivers optimal cost savings for your business.

Understanding Powder Supply Systems

What is a Powder Supply System?

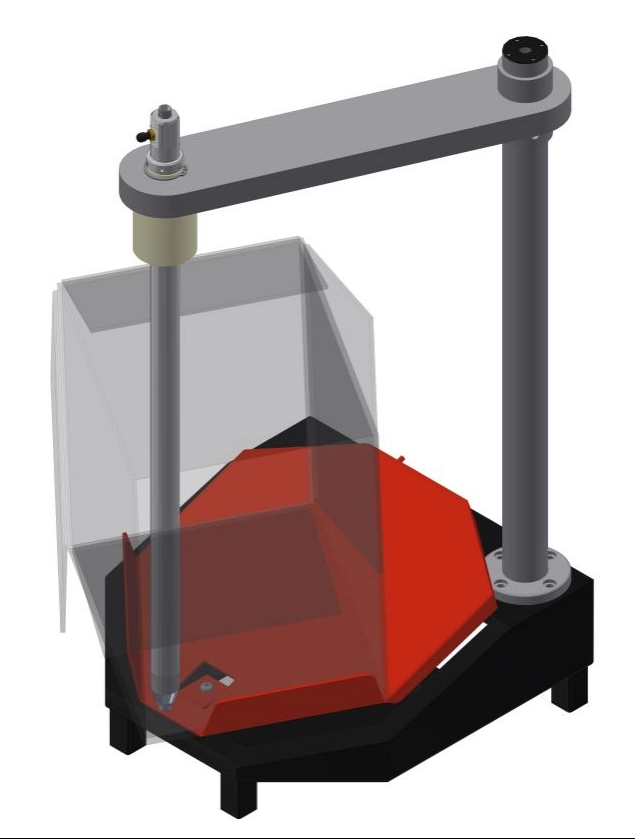

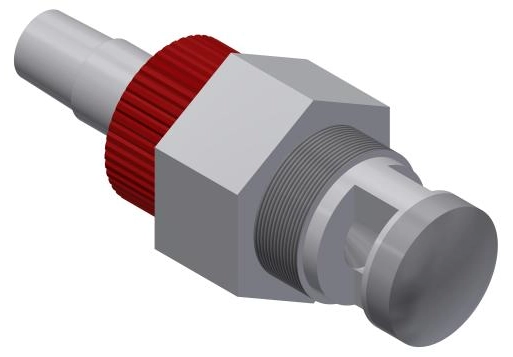

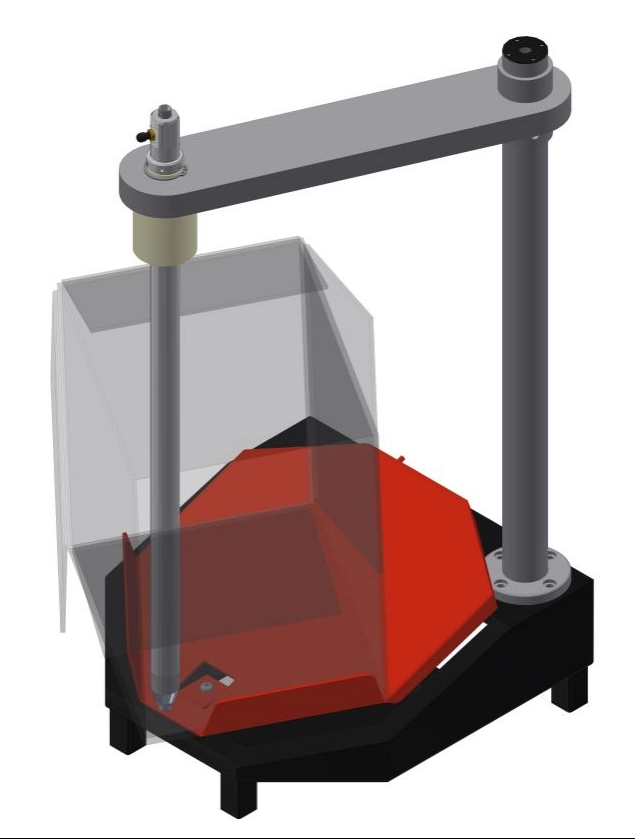

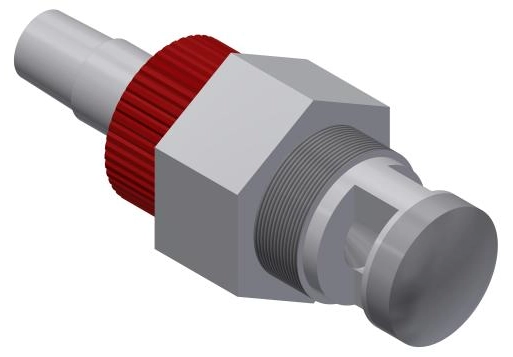

A powder supply system is an integrated setup designed to deliver powder coating materials efficiently from storage to application equipment. It typically includes storage silos or hoppers, feeding mechanisms, transfer lines, and control units that ensure a consistent, contamination-free supply of powder to the coating booth.

How Does It Differ from Traditional Methods?

Traditional finishing methods, such as liquid painting, often involve manual mixing, frequent cleaning, and higher waste due to overspray and evaporation. In contrast, modern powder supply systems are engineered to minimize waste, automate material delivery, and reduce labor requirements, making them inherently more cost-effective and environmentally friendly.

The Economic Advantages of Powder Supply Systems

Reduced Material Waste

One of the primary sources of cost savings in powder coating comes from its efficient use of materials. Unlike liquid coatings, powder coatings adhere more effectively to surfaces, resulting in less overspray and waste. Advanced powder supply systems further enhance this efficiency by providing precise control over powder flow, ensuring that only the necessary amount is used for each application. This not only reduces material costs but also minimizes the expense of waste disposal.

Lower Labor and Maintenance Costs

Powder supply systems are designed for automation and ease of use. Automated feeding and transfer mechanisms reduce the need for manual intervention, allowing operators to focus on quality control and process optimization. Additionally, these systems require less frequent cleaning and maintenance compared to liquid coating setups, which often involve messy solvents and time-consuming equipment washdowns. The reduction in labor and maintenance translates directly into lower operational costs.

Faster Production and Increased Throughput

Efficiency gains from powder supply systems are not limited to material and labor savings. Automated systems enable faster changeovers between colors and finishes, reducing downtime and increasing overall production throughput. For businesses with high-volume or multi-color production lines, this can lead to substantial cost savings by maximizing equipment utilization and minimizing idle time.

Energy Efficiency

Modern powder supply systems often incorporate energy-efficient technologies, such as optimized air flow, advanced filtration, and programmable controls. These features help reduce energy consumption during both the application and curing processes. Lower energy usage not only cuts utility bills but also supports sustainability initiatives, which can be a selling point for environmentally conscious clients.

Bulk Purchasing and Inventory Management

A well-designed powder supply system facilitates bulk purchasing of powder materials, allowing businesses to negotiate better prices with suppliers and reduce per-unit costs. Efficient inventory management, enabled by automated tracking and storage solutions, further minimizes the risk of shortages, overstocking, or material degradation. This strategic approach to procurement and storage can result in significant long-term savings.

Operational Considerations

Initial Investment and Payback Period

While the long-term savings of a powder supply system are compelling, the initial investment can be substantial. Costs include not only the equipment itself but also installation, training, and potential facility modifications. However, many businesses find that the payback period is relatively short, especially when accounting for reduced waste, lower labor costs, and increased productivity.

Training and Skill Requirements

To fully realize the benefits of a powder supply system, operators and maintenance staff must be properly trained. Investing in regular training programs ensures that employees are up-to-date with the latest process innovations and best practices. Well-trained staff can improve efficiency, reduce errors, and extend equipment lifespan.

Maintenance and Reliability

Modern powder supply systems are engineered for reliability, but regular maintenance is still essential to prevent breakdowns and maintain consistent performance. Implementing a preventive maintenance schedule and using advanced monitoring tools can help avoid costly downtime and ensure that the system continues to deliver cost savings over time.

Comparing In-House vs. Outsourced Powder Coating

In-House Powder Coating

Bringing powder coating operations in-house offers several advantages, including greater control over quality, faster response times, and the ability to optimize processes for maximum efficiency. While the upfront investment is higher, long-term cost savings can be substantial due to reduced transportation costs, improved workflow integration, and direct oversight of material usage.

Outsourcing Powder Coating

For businesses with sporadic or low-volume production needs, outsourcing powder coating may be more cost-effective. Specialized providers offer expertise and scalability, allowing companies to pay only for the services they require without the burden of maintaining their own equipment. However, outsourcing can lead to longer lead times and less control over quality and scheduling.

Decision Factors

The choice between in-house and outsourced powder coating depends on production volume, quality requirements, available capital, and long-term business goals. For high-volume, quality-sensitive operations, an in-house powder supply system is often the best option for cost savings and operational control.

Strategies for Maximizing Cost Savings

Optimize Powder Usage

Implement strict inventory controls and monitor powder consumption closely. Use only as much powder as necessary for each job, and take advantage of bulk purchasing discounts offered by suppliers.

Invest in Energy-Efficient Equipment

Upgrade to energy-efficient ovens, lighting, and air handling systems to reduce utility costs. Regularly audit energy usage and implement conservation measures where possible.

Streamline Inventory Management

Use automated tracking systems to monitor powder levels, reduce overstocking, and minimize waste. Proper storage conditions help preserve powder quality and prevent losses due to contamination or environmental factors.

Build Strong Supplier Relationships

Negotiate long-term contracts with reliable suppliers to secure favorable pricing and ensure a steady supply of high-quality powder materials. Strong supplier relationships can lead to additional cost-saving opportunities over time.

Continuous Training and Process Improvement

Regularly train staff on best practices and new technologies. Encourage a culture of continuous improvement to identify and eliminate inefficiencies in the coating process.

Case Study: Real-World Cost Savings

A mid-sized manufacturing company implemented a modern powder supply system, investing in automated feeding, bulk storage, and advanced inventory management. Within the first year, the company reported:

- A 20% reduction in powder material costs due to bulk purchasing and reduced waste.

- A 15% decrease in labor expenses through automation and streamlined workflows.

- A 10% improvement in operational efficiency, resulting in higher throughput and fewer production delays.

- Lower energy bills thanks to energy-efficient equipment and optimized process controls.

These results demonstrate the tangible benefits of adopting a state-of-the-art powder supply system for cost savings and operational excellence.

Potential Challenges and How to Overcome Them

High Initial Investment

Mitigate the impact of upfront costs by seeking financing options, grants, or phased implementation plans. Calculate the expected payback period to justify the investment to stakeholders.

Training and Change Management

Address resistance to change by involving employees in the decision-making process and highlighting the long-term benefits of the new system. Provide comprehensive training and ongoing support.

Maintenance and Downtime

Implement a preventive maintenance program and use predictive analytics to identify potential issues before they lead to costly breakdowns. Keep critical spare parts in stock to minimize downtime.

Supplier Dependence

Diversify your supplier base to reduce the risk of supply chain disruptions. Establish contingency plans to ensure continuity of operations in case of supplier issues.

The Environmental Perspective

Powder coating is widely recognized for its environmental benefits compared to traditional liquid coatings. It produces minimal volatile organic compounds (VOCs), generates less hazardous waste, and allows for the recycling of overspray powder. These advantages not only reduce regulatory compliance costs but also enhance the company's reputation among environmentally conscious customers.

Is Our Powder Supply System the Best Option?

Based on the evidence, a modern powder supply system offers substantial cost savings through reduced material waste, lower labor and maintenance costs, increased production efficiency, and energy savings. While the initial investment is higher, the long-term benefits often outweigh the costs, especially for businesses with high-volume or quality-sensitive production needs.

However, the best option for cost savings depends on individual business circumstances, including production volume, available capital, and strategic priorities. Companies should conduct a thorough cost-benefit analysis, considering both direct and indirect savings, before making a decision.

Frequently Asked Questions

1. How much can a powder supply system reduce material costs?

A modern powder supply system can reduce powder material costs by 15-25% through bulk purchasing, precise application, and minimized waste.

2. What are the main operational expenses in powder coating?

Key expenses include powder materials, energy consumption, labor, equipment maintenance, inventory management, and supplier relationships.

3. Is powder coating more energy-efficient than liquid coating?

Yes, powder coating generally uses less energy, especially when paired with energy-efficient ovens and automated systems, leading to lower utility bills.

4. Can small businesses benefit from a powder supply system?

While the initial investment may be high, small businesses with consistent production can benefit from long-term savings; those with sporadic needs may prefer outsourcing.

5. What role does staff training play in cost savings?

Regular training improves process efficiency, reduces errors, and extends equipment lifespan, all contributing to overall cost savings.

6. How can companies ensure a steady supply of powder materials?

Building strong supplier relationships and negotiating long-term contracts help ensure a reliable supply and favorable pricing.

7. What are the environmental benefits of powder coating?

Powder coating produces minimal VOCs, generates less hazardous waste, and allows for recycling, reducing compliance costs and supporting sustainability goals.

[1] https://hmft.com/blogs/news/the-cost-savings-of-using-powder-coating-equipment-over-traditional-liquid-coating-methods

[2] https://www.afusa.net/cost-saving-tips-for-powder-coating/

[3] https://totalfinishingsupplies.com/blogs/blog/powder-coating-in-house-vs-outsourcing-weighing-the-pros-and-cons

[4] https://www.powdercoatingonline.com/cost-reduction-solutions-for-powder-coating-companies/

[5] https://businessplan-templates.com/blogs/running-costs/powder-coating

[6] https://www.cnblogs.com/luohenyueji/p/16990846.html

[7] https://www.ramseierkoatings.com/what-makes-our-powder-supply-system-better-than-traditional-methods.html

[8] https://blog.csdn.net/qq_41552508/article/details/129793125

[9] https://www.sohu.com/a/546373052_121155311

[10] https://huggingface.co/datasets/Mxode/Firefly-Rephrased-Multiturn-300K/viewer

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.