Content Menu

● Introduction

● What Are Automatic Spray Booth Systems?

>> H2: Definition and Functionality

>> H3: Core Components of Automatic Spray Booth Systems

● Types of Automatic Spray Booth Systems

>> H2: Overview of Common Booth Types

>> H3: Synchronous Automatic Spray Booth Systems

>> H3: Non-Synchronous Systems

>> H3: Single Station Systems

>> H3: Continuous Systems

● Why Choose Professional Automatic Spray Booth Systems Makers?

>> H2: Expertise in Custom OEM Solutions

>> H2: Ensuring Optimal Spray Environment

>> H3: Avoiding Common Design Pitfalls

● Benefits of Automatic Spray Booth Systems

>> H2: Improved Quality and Consistency

>> H2: Enhanced Production Efficiency

>> H2: Cost Reduction and Resource Optimization

>> H2: Safety and Environmental Compliance

● Technological Innovations in Automatic Spray Booth Systems

>> H2: Integration of AI and Sensors

>> H2: Advanced Paint Overspray Management

>> H3: Smart Booth Interfaces

● Applications of Automatic Spray Booth Systems

>> H2: Industry Use Cases

>> H3: OEM Manufacturing for Global Brands

● How to Select the Right Automatic Spray Booth Systems Maker

>> H2: Key Considerations

>> H3: Collaboration and Consultation

● Frequently Asked Questions (FAQs)

Introduction

As one of the premier automatic spray booth systems makers based in China, we specialize in manufacturing, designing, and supplying advanced automatic spray booth systems. Serving global brand owners, wholesalers, and manufacturers, we provide OEM services tailored to diverse production needs. This article explores the critical aspects of automatic spray booth systems, their types, benefits, and how partnering with professional automatic spray booth systems makers can transform your production line.

What Are Automatic Spray Booth Systems?

H2: Definition and Functionality

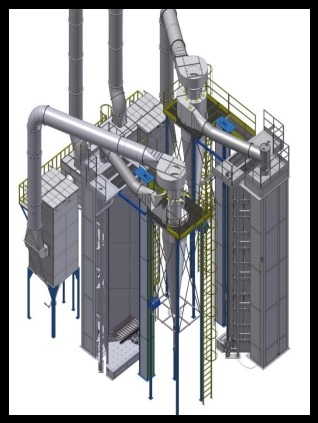

Automatic spray booth systems are engineered enclosures equipped with automated spraying technology designed for efficient, high-quality coating applications. These systems integrate robotic spray applicators, ventilation, filtration, and control units to ensure consistent finishes while maintaining safety and environmental standards.

H3: Core Components of Automatic Spray Booth Systems

- Robotic or automated spray guns

- Conveyor or part handling systems

- Airflow and ventilation units

- Filtration and paint overspray management

- Control and monitoring software

Types of Automatic Spray Booth Systems

H2: Overview of Common Booth Types

H3: Synchronous Automatic Spray Booth Systems

Ideal for repetitive, high-volume production lines, synchronous systems ensure uniform coating application with minimal downtime.

H3: Non-Synchronous Systems

These offer flexibility for varied production demands, allowing adjustments without halting the entire line.

H3: Single Station Systems

Often the most affordable and practical, these systems suit smaller operations and can be semi-automated or fully automated.

H3: Continuous Systems

Designed for extremely high-volume production, continuous systems use conveyors to maintain steady throughput.

Why Choose Professional Automatic Spray Booth Systems Makers?

H2: Expertise in Custom OEM Solutions

Professional automatic spray booth systems makers understand the nuances of production requirements, enabling them to design and manufacture booths that optimize spray quality, efficiency, and safety. They provide tailored OEM services to meet the unique needs of global brands and wholesalers.

H2: Ensuring Optimal Spray Environment

The perfect spray booth must balance several design objectives:

- Correct booth size for efficiency

- Airflow design that effectively manages overspray

- Compliance with safety and environmental regulations

- Cost-effective operation and maintenance

H3: Avoiding Common Design Pitfalls

Many costly mistakes stem from assumptions about airflow, filter selection, and booth sizing. Experienced makers apply advanced engineering and technology to prevent these errors, ensuring long-term operational success[1].

Benefits of Automatic Spray Booth Systems

H2: Improved Quality and Consistency

Automation eliminates variations caused by manual spraying, delivering uniform coatings that meet stringent quality standards.

H2: Enhanced Production Efficiency

Integration with conveyors and robotic spray arms accelerates production rates and reduces cycle times.

H2: Cost Reduction and Resource Optimization

Higher transfer efficiency reduces paint waste and lowers material costs. Automated filter monitoring and maintenance alerts further cut operational expenses[2].

H2: Safety and Environmental Compliance

Automated systems minimize worker exposure to hazardous fumes and ensure proper ventilation and filtration, meeting global environmental standards.

Technological Innovations in Automatic Spray Booth Systems

H2: Integration of AI and Sensors

Modern automatic spray booth systems makers incorporate sensors and AI to monitor spray patterns and adjust parameters in real-time, optimizing finishes and reducing defects.

H2: Advanced Paint Overspray Management

Innovative filtration technologies, including dry filters and water wash systems, capture overspray effectively, reducing environmental impact[1].

H3: Smart Booth Interfaces

Some systems connect to Building Management Systems (BMS), enabling remote monitoring, automatic balancing of booth atmosphere, and predictive maintenance alerts[1].

Applications of Automatic Spray Booth Systems

H2: Industry Use Cases

- Automotive manufacturing for car bodies and parts

- Consumer electronics for precise component coating

- Furniture finishing for wood and metal products

- Industrial equipment protective coatings

H3: OEM Manufacturing for Global Brands

As automatic spray booth systems makers, we provide customized OEM manufacturing and design services to international clients, ensuring their production lines benefit from advanced, reliable spray booth technology.

How to Select the Right Automatic Spray Booth Systems Maker

H2: Key Considerations

- Experience and track record in OEM manufacturing

- Ability to customize designs to specific production needs

- Compliance with international safety and environmental standards

- After-sales support and training services

H3: Collaboration and Consultation

Engage with automatic spray booth systems makers early in the design process to align booth specifications with your production fundamentals and finishing requirements[1][2].

Frequently Asked Questions (FAQs)

1. What distinguishes automatic spray booth systems makers from regular manufacturers?

They specialize in designing and producing automated, integrated spray booth solutions tailored to high-volume and precision coating needs.

2. How can OEM services from automatic spray booth systems makers benefit my business?

OEM services provide customized booths that fit your production line perfectly, enhancing efficiency and product quality while reducing costs.

3. What are the main types of automatic spray booth systems available?

Synchronous, non-synchronous, single station, and continuous systems, each suited to different production volumes and flexibility needs.

4. How do automatic spray booth systems improve safety?

Automation reduces worker exposure to hazardous fumes and ensures proper ventilation and filtration, complying with safety regulations.

5. Can automatic spray booth systems be integrated with modern factory management technology?

Yes, many systems connect with Building Management Systems (BMS) for real-time monitoring, maintenance alerts, and operational optimization.

[1] https://www.spraysystems.com/wp-content/uploads/2015-Presentation-Paper-Spray-Booth-Essentials.pdf

[2] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[3] https://www.diva-portal.org/smash/get/diva2:18241/fulltext01

[4] https://www.spraysystems.com/safety-features/

[5] https://pfsspraybooths.com/why-auto-repair-shops-need-professional-spray-booths

[6] https://marathonspraybooths.com/faq/

[7] https://www.duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers

[8] https://www.pacgroup.co.uk/general/everything-you-need-to-know-about-spray-booths/

[9] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[10] https://www.emcinsurance.com/losscontrol/techsheet/spray-booth-safety-steps

[11] https://sprayboothsnw.com/faqs

[12] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[13] https://www.paint-booths.com/FAQS.html

[14] https://spraytech.com/f-a-q/

[15] https://www.spraysystems.com/faq/

[16] https://www.science.gov/topicpages/p/paint+spray+booth

[17] https://www.spraysystems.com/spray-paint-booth-filtration-water-wash-vs-dry-filter/

[18] https://patents.google.com/patent/WO1998017402A1/en

[19] https://colo2016.en.made-in-china.com/product/PFutnCrvCzkK/China-Automatic-Powder-Coating-Booth-System.html

[20] https://www.asminternational.org/tss/wp-content/uploads/sites/38/files/content/safety5.pdf

[21] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/why-you-should-automate-your-paint-booth.html

[22] https://www.truteksystems.co.in/blogDetail/Top-7-Benefits-of-Automated-Industrial-Painting-Systems

[23] https://alliedcleanrooms.com/paint-booths-types-and-benefits/

[24] https://www.spraysystems.com/industries/industrial-manufacturing/

[25] https://globalfinishing.com/2011/02/24/paint-booth-faqs-part-1/

[26] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-5-safety-regulations/

[27] https://www.ecotechsystems.net/about

[28] https://totalfinishingsolutions.com

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.