Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Do Vibrating Sieves Work?

● The Importance of Preventing Contamination

>> Risks of Contamination

>> The Role of Vibrating Sieves in Contamination Prevention

● Benefits of Using Vibrating Sieves

>> 1. Effective Removal of Contaminants

>> 2. Prevention of Cross-Contamination

>> 3. Enhanced Product Quality

>> 4. Increased Efficiency

>> 5. Easy Maintenance and Cleaning

● Applications of Vibrating Sieves in Various Industries

>> Food Industry

>> Pharmaceutical Industry

>> Chemical Manufacturing

>> Powder Coating

● Innovations in Vibrating Sieve Technology

>> Ultrasonic Sieving

>> Automated Systems

● Conclusion

>> Frequently Asked Questions

In the world of powder production, maintaining the purity and quality of materials is paramount. Contamination can lead to significant issues, including product recalls, safety hazards, and financial losses. One of the most effective tools in preventing contamination during powder processing is the vibrating sieve. This article explores how vibrating sieves work, their benefits, and their critical role in various industries.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

A vibrating sieve is a mechanical device that uses vibration to separate materials based on size and density. It consists of a screen or mesh that allows smaller particles to pass through while retaining larger ones. The vibration helps to keep the material moving, preventing clogs and ensuring a consistent flow.

How Do Vibrating Sieves Work?

Vibrating sieves operate by utilizing an out-of-balance motor that creates a vibration. This vibration causes the material on the screen to move in a controlled manner, allowing particles to be sorted effectively. The design of the sieve can vary, with different mesh sizes and configurations tailored to specific applications.

The Importance of Preventing Contamination

Risks of Contamination

Contamination in powder production can arise from various sources, including foreign particles, dust, and even cross-contamination between different batches. The risks associated with contamination include:

- Health Hazards: Contaminated powders can pose serious health risks, especially in food and pharmaceutical industries.

- Product Quality: Contaminants can affect the quality and performance of the final product, leading to customer dissatisfaction.

- Regulatory Compliance: Many industries are subject to strict regulations regarding product purity. Non-compliance can result in fines and legal issues.

The Role of Vibrating Sieves in Contamination Prevention

Vibrating sieves play a crucial role in mitigating these risks by ensuring that only clean, high-quality powders are processed. Here's how they contribute to contamination prevention:

Benefits of Using Vibrating Sieves

1. Effective Removal of Contaminants

Vibrating sieves are designed to remove foreign particles, such as stones, metal fragments, and other impurities. By using precise mesh screens, they ensure that only the finest, cleanest powders pass through. This is essential for maintaining product integrity and safety.

2. Prevention of Cross-Contamination

In industries where multiple products are processed, cross-contamination can be a significant concern. Vibrating sieves can be equipped with different mesh screens for different materials, preventing cross-contamination between product batches. This is particularly important for allergen-free or organic products, where even trace amounts of contaminants can be problematic.

3. Enhanced Product Quality

By effectively removing oversized particles and contaminants, manufacturers can ensure that only high-quality, uniform powders are used in production. This leads to better adhesion, smoother finishes, and overall improved durability of the final products.

4. Increased Efficiency

Vibrating sieves help maintain a consistent flow of materials, reducing downtime caused by blockages. This increased efficiency is particularly beneficial in high-volume production environments, where time is money.

5. Easy Maintenance and Cleaning

Modern vibrating sieves are designed with easy-to-clean surfaces and components. This reduces the risk of contamination and ensures that each batch meets health and safety standards. Regular cleaning and maintenance are essential for optimal performance and longevity of the equipment.

Applications of Vibrating Sieves in Various Industries

Food Industry

In food processing, vibrating sieves are used to ensure that powders such as flour, sugar, and spices are free from contaminants and meet quality standards. They help maintain the integrity of the product, ensuring that consumers receive safe and high-quality food items.

Pharmaceutical Industry

Within the pharmaceutical sector, vibrating sieves are crucial for ensuring that powders meet stringent size specifications, ultimately influencing drug efficacy. They help in removing impurities that could affect the performance of medications.

Chemical Manufacturing

In chemical manufacturing, vibrating sieves play a significant role in the separation of different chemical components. This is vital for production efficiency and ensuring that the final products are free from unwanted substances.

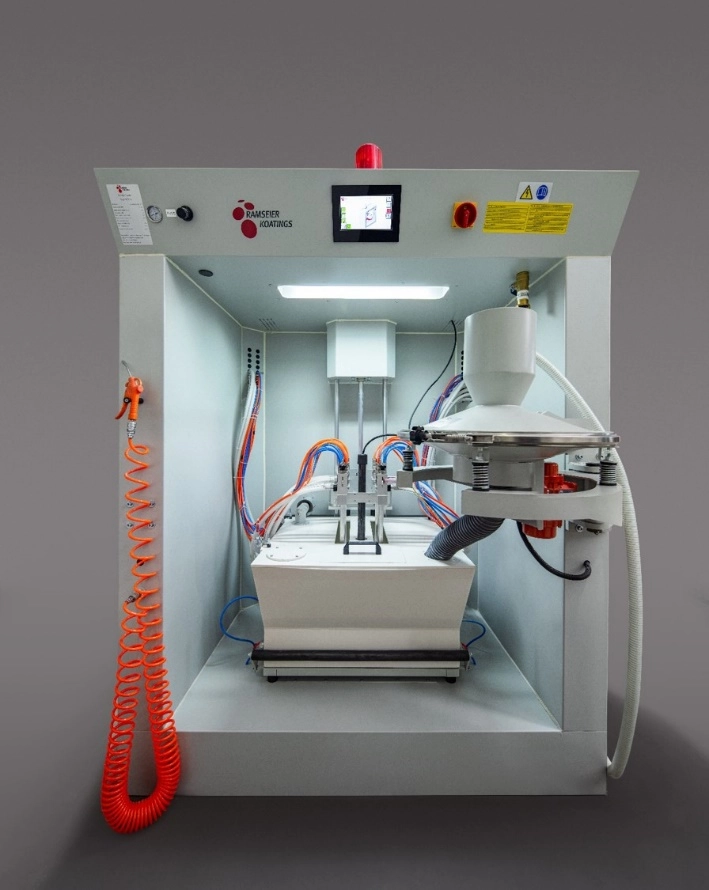

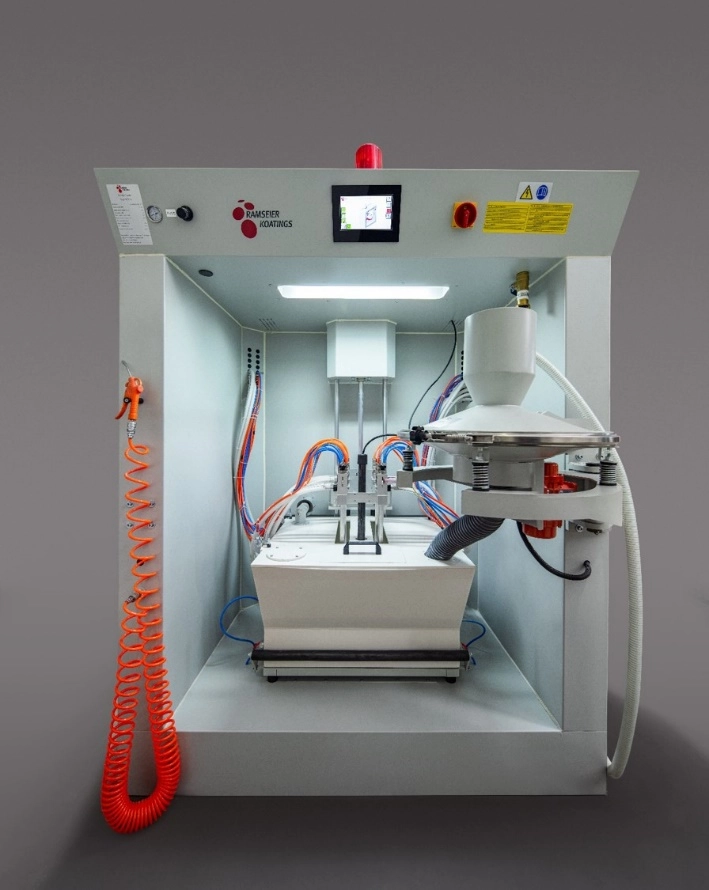

Powder Coating

In powder coating applications, vibrating sieves are used to ensure that the powder is free from contaminants and is of uniform particle size. This is essential for achieving a smooth and even finish on coated products.

Innovations in Vibrating Sieve Technology

Ultrasonic Sieving

Recent advancements in vibrating sieve technology include the integration of ultrasonic systems. These systems apply ultrasonic vibrations to the screen surface, breaking down surface tension and preventing mesh clogging. This innovation enhances the efficiency of the sieving process, particularly for challenging materials.

Automated Systems

Automation in vibrating sieve systems allows for real-time monitoring and adjustments. This ensures optimal performance and reduces the need for manual intervention, further minimizing the risk of contamination.

Conclusion

Vibrating sieves are indispensable tools in powder production, playing a critical role in preventing contamination and ensuring product quality. Their ability to effectively remove impurities, prevent cross-contamination, and enhance efficiency makes them essential in various industries, including food, pharmaceuticals, and chemicals. As technology continues to evolve, vibrating sieves will likely become even more efficient and effective, further safeguarding the integrity of powder production processes.

Frequently Asked Questions

1. What types of contaminants can vibrating sieves remove?

- Vibrating sieves can remove foreign particles such as stones, metal fragments, and other impurities that may contaminate powders.

2. How do vibrating sieves prevent cross-contamination?

- By using different mesh screens for different materials, vibrating sieves can prevent cross-contamination between product batches.

3. What industries benefit from using vibrating sieves?

- Industries such as food processing, pharmaceuticals, and chemical manufacturing benefit significantly from the use of vibrating sieves.

4. How often should vibrating sieves be cleaned?

- Regular cleaning is essential to prevent contamination and ensure optimal performance. The frequency depends on the volume of production and the type of materials processed.

5. What innovations are being made in vibrating sieve technology?

- Innovations include ultrasonic sieving systems and automated monitoring, which enhance the efficiency and effectiveness of the sieving process.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.