Content Menu

● Understanding Powder Coating Automation

>> What is Powder Coating?

>> The Role of Automation in Powder Coating

● Benefits of Powder Coating Automation

>> Increased Production Efficiency

>> Consistent Quality Control

>> Cost Savings

>> Flexibility and Scalability

● Key Components of Powder Coating Automation

>> Automated Spray Booths

>> Conveyor Systems

>> Curing Ovens

>> Robotic Systems

● Strategies for Implementing Powder Coating Automation

>> Assess Your Current Production Process

>> Set Clear Goals

>> Invest in the Right Technology

>> Train Your Workforce

>> Monitor and Optimize

● Challenges of Powder Coating Automation

>> Initial Investment Costs

>> Integration with Existing Systems

>> Maintenance and Upkeep

● Future Trends in Powder Coating Automation

>> Smart Automation

>> Sustainable Practices

>> Customization and Personalization

● Conclusion

>> Frequently Asked Questions

In today's competitive manufacturing landscape, scaling production efficiently is crucial for businesses looking to thrive. One of the most effective ways to achieve this is through powder coating automation. This article explores how to scale your production with powder coating automation, discussing the benefits, key components, and strategies for successful implementation.

Understanding Powder Coating Automation

What is Powder Coating?

Powder coating is a finishing process that applies a dry powder to a surface, which is then cured under heat to form a hard, durable finish. This method is widely used in various industries, including automotive, furniture, and appliances, due to its superior finish quality and environmental benefits.

The Role of Automation in Powder Coating

Automation in powder coating involves using advanced machinery and robotic systems to streamline the coating process. This technology enhances productivity, reduces labor costs, and improves the consistency and quality of the finish. By automating repetitive tasks, manufacturers can focus on more complex operations, ultimately leading to increased output and efficiency.

Benefits of Powder Coating Automation

Increased Production Efficiency

One of the primary advantages of automating powder coating processes is the significant increase in production efficiency. Automated systems can operate continuously, reducing downtime associated with manual labor. This allows manufacturers to meet higher demand without compromising quality.

Consistent Quality Control

Automated powder coating systems ensure uniform application of the coating material, which is critical for maintaining product quality. With precise control over application parameters, manufacturers can achieve consistent thickness and finish, reducing the likelihood of defects and rework.

Cost Savings

While the initial investment in automation technology can be substantial, the long-term savings are significant. Automated systems reduce labor costs, minimize material waste, and enhance energy efficiency. Over time, these savings can offset the initial costs and lead to higher profit margins.

Flexibility and Scalability

Automated powder coating systems are designed to be flexible and scalable. As production needs change, manufacturers can easily adjust their systems to accommodate different product sizes and types. This adaptability is essential for businesses looking to expand their offerings or respond to market changes.

Key Components of Powder Coating Automation

Automated Spray Booths

Automated spray booths are essential for efficient powder application. These booths are equipped with advanced spray guns that can be programmed to apply the powder evenly across various surfaces. The automation of this process not only speeds up production but also ensures a high-quality finish.

Conveyor Systems

Conveyor systems play a crucial role in automating the powder coating process. They transport items through different stages of the coating process, including pre-treatment, powder application, and curing. This continuous movement reduces manual handling and increases throughput.

Curing Ovens

Curing ovens are vital for the powder coating process, as they provide the heat necessary to cure the powder and create a durable finish. Automated curing ovens can be programmed to optimize temperature and time settings, ensuring consistent results across batches.

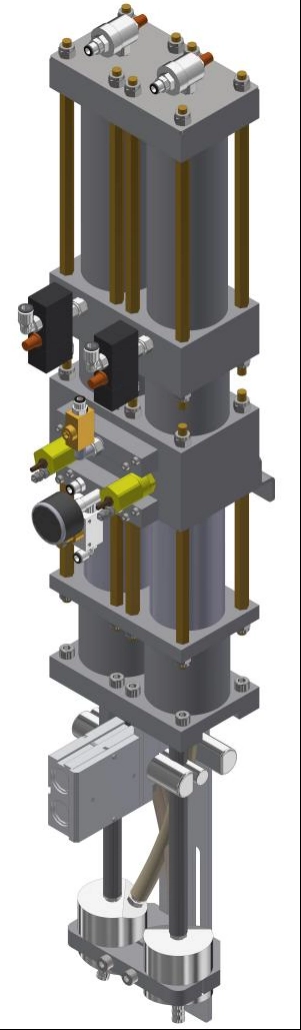

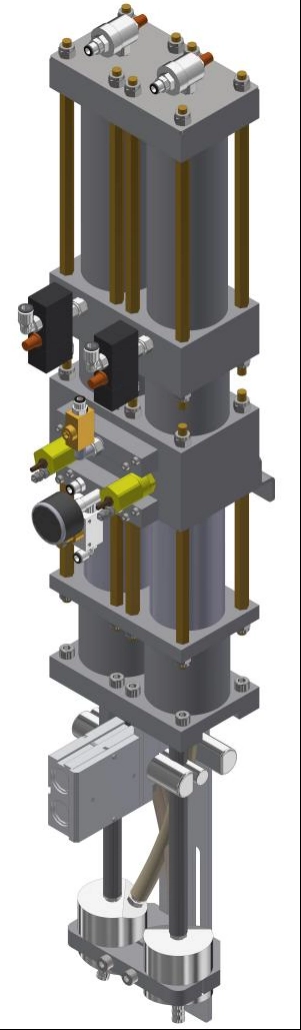

Robotic Systems

Robotic systems are increasingly used in powder coating applications to enhance precision and efficiency. These robots can be programmed to handle complex shapes and sizes, ensuring that every part receives the same level of coating quality.

Strategies for Implementing Powder Coating Automation

Assess Your Current Production Process

Before implementing automation, it is essential to evaluate your current production process. Identify bottlenecks, inefficiencies, and areas where automation could provide the most significant benefits. This assessment will help you determine the best approach to scaling your production.

Set Clear Goals

Establish clear goals for your automation project. These goals should align with your overall business objectives and focus on improving efficiency, reducing costs, and enhancing product quality. Having specific targets will guide your implementation strategy and help measure success.

Invest in the Right Technology

Choosing the right technology is critical for successful automation. Research various systems and equipment available in the market, considering factors such as compatibility with existing processes, scalability, and ease of use. Investing in high-quality equipment will pay off in the long run.

Train Your Workforce

While automation reduces the need for manual labor, it is essential to train your workforce to operate and maintain the new systems effectively. Providing comprehensive training will ensure that your team can maximize the benefits of automation and maintain high production standards.

Monitor and Optimize

Once your automated powder coating system is in place, continuously monitor its performance. Collect data on production rates, quality control, and operational efficiency. Use this information to identify areas for improvement and optimize your processes further.

Challenges of Powder Coating Automation

Initial Investment Costs

The upfront costs of implementing an automated powder coating system can be significant. However, businesses should view this as a long-term investment that will yield substantial returns through increased efficiency and reduced operational costs.

Integration with Existing Systems

Integrating new automated systems with existing production lines can pose challenges. It is crucial to ensure compatibility and minimize disruptions during the transition. Working with experienced automation providers can help facilitate a smoother integration process.

Maintenance and Upkeep

Automated systems require regular maintenance to ensure optimal performance. Establishing a maintenance schedule and training staff on proper upkeep will help prevent downtime and extend the lifespan of your equipment.

Future Trends in Powder Coating Automation

Smart Automation

The future of powder coating automation lies in smart technology. Integrating IoT (Internet of Things) devices and AI (Artificial Intelligence) into powder coating systems will enable real-time monitoring and data analysis, leading to even greater efficiencies and quality control.

Sustainable Practices

As environmental concerns grow, the powder coating industry is moving towards more sustainable practices. Automated systems can help reduce waste and energy consumption, aligning with the increasing demand for eco-friendly manufacturing processes.

Customization and Personalization

With advancements in automation technology, manufacturers can offer more customization options to their customers. Automated systems can easily adapt to different product specifications, allowing for personalized finishes without sacrificing efficiency.

Conclusion

Scaling your production with powder coating automation is not just a trend; it is a necessity for manufacturers looking to remain competitive in today's market. By investing in automated systems, businesses can enhance efficiency, improve quality, and reduce costs. As technology continues to evolve, those who embrace automation will be well-positioned to meet the demands of the future.

Frequently Asked Questions

1. What are the main benefits of powder coating automation?

- The main benefits include increased production efficiency, consistent quality control, cost savings, and flexibility in production.

2. How do automated spray booths work?

- Automated spray booths use advanced spray guns that can be programmed to apply powder evenly across surfaces, enhancing speed and quality.

3. What should I consider before implementing automation?

- Assess your current production process, set clear goals, invest in the right technology, and train your workforce.

4. What are the challenges of powder coating automation?

- Challenges include initial investment costs, integration with existing systems, and the need for regular maintenance.

5. What future trends should I be aware of in powder coating automation?

- Future trends include smart automation, sustainable practices, and increased customization options.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.