Content Menu

● Understanding Powder Usage Challenges in Manufacturing

>> Variability of Powder Properties

>> Handling and Dispensing Difficulties

>> Waste Generation Issues

>> Compliance and Quality Concerns

● What is Swinger's Smart Control System?

>> Core Components of the Smart Control System

● How Swinger's System Optimizes Powder Usage

>> Real-Time Monitoring and Feedback

>> Advanced Predictive Control

>> Minimizing Overfill and Underdose

>> Enhanced Flow Control Mechanisms

● Reducing Waste Through Intelligent Management

>> Precise Dosing Limits Scrap Production

>> Improved Batch Consistency Lowers Reprocessing

>> Automated Alerts and Maintenance Scheduling

>> Data Analytics for Continuous Improvement

● Applications Across Industries

>> Pharmaceutical Production

>> Metal Additive Manufacturing

>> Food and Beverage Processing

>> Chemical Manufacturing

● Benefits Beyond Waste Reduction

>> Cost Savings Through Material Efficiency

>> Enhanced Production Throughput

>> Compliance and Traceability

>> Sustainability and Corporate Responsibility

● Installation and Implementation Insights

>> Site Assessment and Customization

>> Training and Change Management

>> Integration with Legacy Systems

>> Ongoing Support and Upgrades

● Future Developments and Innovations

>> AI-Driven Process Optimization

>> Expanded Sensor Technologies

>> Cloud-Based Analytics and Remote Monitoring

>> Sustainable Packaging and Powder Recovery

● Frequently Asked Questions

>> 1. How does Swinger's Smart Control System handle powders with different properties?

>> 2. Can the system be installed on existing production lines?

>> 3. What are the primary cost savings associated with adopting the system?

>> 4. How does the system contribute to environmental sustainability?

>> 5. Is specialized training required to operate Swinger's system?

● Conclusion

In today's manufacturing landscape, efficiency and sustainability are paramount. The way raw materials are used, particularly powders in various industrial processes, directly impacts both cost efficiency and environmental footprint. Swinger's Smart Control System stands out as a groundbreaking technology that optimizes powder usage while significantly reducing waste. This article explores in depth how Swinger's system operates, its key features, applications, benefits, and future potential in transforming powder-based manufacturing.

Understanding Powder Usage Challenges in Manufacturing

Powder materials are fundamental in industries such as pharmaceuticals, metallurgy, ceramics, chemicals, and food processing. Despite their importance, controlling powder usage can be complex due to several inherent challenges.

Variability of Powder Properties

Powders differ in particle size, moisture content, flowability, and density. Variations in these properties lead to inconsistent volumes during weighing, dispensing, and further processing.

Handling and Dispensing Difficulties

Powders tend to compact, segregate, or dust during transport and handling. Dispensing systems without precision controls often result in overuse or spillage, increasing operational costs.

Waste Generation Issues

Excess powder dosage, poor mixture uniformity, and off-specification batches generate significant waste, often requiring reprocessing or disposal. This not only wastes raw material but also consumes additional energy and labor.

Compliance and Quality Concerns

Regulatory standards require exact powder dosages in pharmaceutical and food industries. Failure to maintain strict control impacts product quality and regulatory compliance.

What is Swinger's Smart Control System?

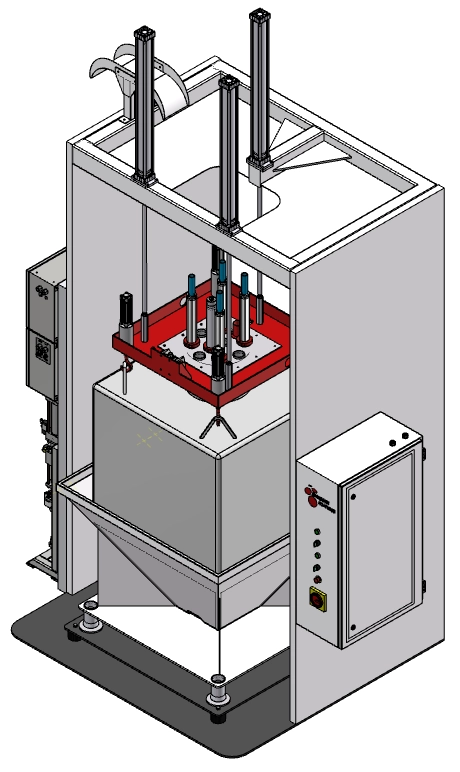

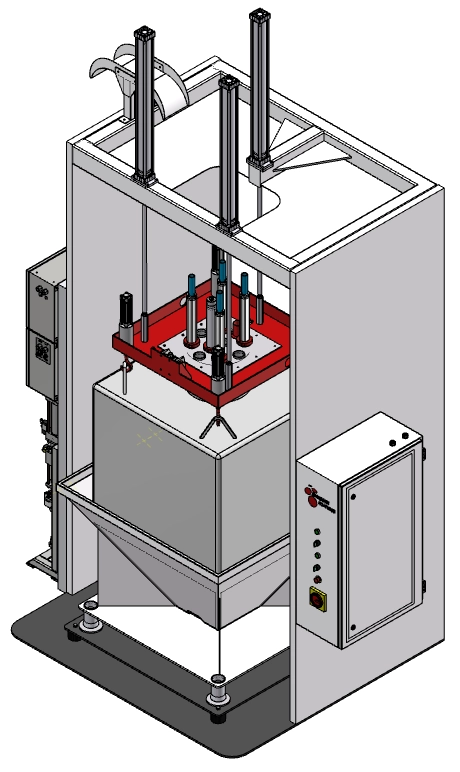

Swinger's Smart Control System is an intelligent, automated solution designed to address these challenges through advanced sensing, algorithmic control, and integration with production lines.

Core Components of the Smart Control System

- Precision Sensors: Real-time measurement of powder flow rate, weight, humidity, and particle characteristics.

- Adaptive Algorithms: Machine learning-based algorithms analyze sensor data to adjust dispensing parameters dynamically.

- User Interface: Intuitive control panels and monitoring dashboards provide operators with actionable insights.

- Integration Modules: Compatibility with existing machinery and ERP systems facilitates seamless operation.

How Swinger's System Optimizes Powder Usage

Optimization begins with accurate measurement and precise control, minimizing excess or shortfall in powder quantities.

Real-Time Monitoring and Feedback

Sensors continuously measure powder dispensed and compare it against target parameters. Deviations trigger instantaneous adjustments, ensuring dosages remain within ideal limits.

Advanced Predictive Control

Using historical and ongoing data, Swinger's algorithms predict variations due to environmental factors or batch differences and proactively adjust dispensing speeds and volumes.

Minimizing Overfill and Underdose

The system prevents common issues like overfill that cause waste, and underdose that degrade product quality. This balance reduces scrap material and rework.

Enhanced Flow Control Mechanisms

Adjustable feeder speeds and vibration settings enhance powder flow consistency, reducing bridge formation and segregation inside hoppers.

Reducing Waste Through Intelligent Management

Waste reduction is a key benefit of Swinger's system, achieved via multiple pathways.

Precise Dosing Limits Scrap Production

By dispensing exactly the required amount, leftover powder that must be discarded or recycled is minimized.

Improved Batch Consistency Lowers Reprocessing

Fewer off-spec batches translate into reduced need to discard or reprocess powder, saving resources and time.

Automated Alerts and Maintenance Scheduling

The system notifies operators of abnormal equipment wear or powder shortages before they cause production errors.

Data Analytics for Continuous Improvement

Comprehensive data logs enable root cause analysis of past waste incidents and drive process enhancements over time.

Applications Across Industries

Swinger's Smart Control System is versatile and applicable in diverse powder-based manufacturing sectors.

Pharmaceutical Production

In tablet pressing or encapsulation, dosage accuracy is crucial. Swinger's system ensures compliant powder fills and uniformity, enhancing patient safety and reducing costly recalls.

Metal Additive Manufacturing

Metal powder usage optimization lowers material costs in 3D printing and reduces contamination risk, improving final part quality.

Food and Beverage Processing

Powders like flour, sugar, and cocoa benefit from minimized spillage and consistent blends, maintaining product taste and quality.

Chemical Manufacturing

Precise dosing of catalyst or reagent powders improves reaction efficiency while reducing hazardous waste generation.

Benefits Beyond Waste Reduction

The Smart Control System delivers operational advantages that extend beyond environmental impact.

Cost Savings Through Material Efficiency

Lower powder wastage translates directly to reduced raw material expenses, improving profit margins.

Enhanced Production Throughput

With fewer stoppages caused by dispensing errors or equipment jams, production lines operate more smoothly and efficiently.

Compliance and Traceability

Accurate records of powder usage fulfill regulatory documentation requirements and support quality audits.

Sustainability and Corporate Responsibility

Reducing powder waste aligns with corporate sustainability goals, appealing to environmentally conscious customers and investors.

Installation and Implementation Insights

Successfully adopting Swinger's technology involves strategic planning.

Site Assessment and Customization

Systems are tailored to the specific powder type, equipment configuration, and production scale.

Training and Change Management

Operators receive training on system use, troubleshooting, and interpreting analytics dashboards.

Integration with Legacy Systems

The control system interfaces with existing control units and ERP/MES systems for centralized management.

Ongoing Support and Upgrades

Swinger offers continuous software updates and remote diagnostics to maintain optimal performance.

Future Developments and Innovations

Swinger is actively developing enhancements to broaden capabilities.

AI-Driven Process Optimization

More sophisticated AI models will enable fully autonomous powder management with minimal human intervention.

Expanded Sensor Technologies

Next-generation sensors will detect powder chemical composition and contamination in real-time.

Cloud-Based Analytics and Remote Monitoring

Industry 4.0 integration will allow operators to oversee multiple sites and receive predictive maintenance alerts remotely.

Sustainable Packaging and Powder Recovery

Efforts to integrate powder recovery systems and eco-friendly handling solutions will further reduce environmental impact.

Frequently Asked Questions

1. How does Swinger's Smart Control System handle powders with different properties?

The system uses adaptive algorithms and adjustable hardware settings to accommodate variations in flowability, density, and humidity, ensuring consistent dosing across powder types.

2. Can the system be installed on existing production lines?

Yes, the system is designed for compatibility and modularity, enabling integration with most current equipment without extensive downtime.

3. What are the primary cost savings associated with adopting the system?

Savings arise mainly from reduced raw material waste, lower reprocessing needs, improved production efficiency, and compliance cost avoidance.

4. How does the system contribute to environmental sustainability?

By minimizing powder waste, reducing off-spec batches, and optimizing energy use via more efficient dispensing, the system lowers overall environmental footprint.

5. Is specialized training required to operate Swinger's system?

Yes, but Swinger provides comprehensive training programs focusing on operation, maintenance, and data interpretation to empower operators efficiently.

Conclusion

Swinger's Smart Control System represents a major advancement in powder management technology. By leveraging intelligent sensing, machine learning, and real-time control, it optimizes powder usage and dramatically reduces waste. Across multiple industries, this translates into cost savings, improved product quality, regulatory compliance, and enhanced sustainability metrics. As manufacturing continues evolving towards smarter and greener processes, Swinger's innovative solution is positioned to play a vital role in driving transformation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing companya

.

.