Content Menu

● What are Swinger Reciprocators?

>> Definition and Basic Functionality

>> Components of a Swinger Reciprocator

● How Swinger Reciprocators Enhance Coating Consistency

>> Understanding Coating Consistency

>> Swinging Motion vs. Linear Motion

>> Case Study: Metal Panel Coating

● How Swinger Reciprocators Improve Coating Speed

>> Maximizing Cycle Efficiency

>> Synchronization with Automated Systems

>> Energy Efficiency and Lower Maintenance

● Applications of Swinger Reciprocators in Industry

>> Automotive Painting

>> Electronics and Semiconductor Manufacturing

>> Packaging Industry

>> Furniture and Woodworking

● Technical Considerations for Implementing Swinger Reciprocators

>> Selection Criteria

>> Maintenance and Calibration

● Future Trends in Swinger Reciprocator Technology

>> Smart Controls and IoT Integration

>> Multi-Axis Swinging and Hybrid Motion

>> Environmentally Friendly Coating Solutions

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What makes swinger reciprocators different from conventional reciprocators?

>> 2. Can swinger reciprocators handle complex shapes effectively?

>> 3. Are swinger reciprocators compatible with robotic coating systems?

>> 4. How do swinger reciprocators improve overall process speed?

>> 5. What maintenance is required to keep swinger reciprocators operating optimally?

Coating operations are pivotal in numerous industrial processes, from automotive manufacturing to electronics and packaging. Achieving uniform, high-quality coating while maintaining operational efficiency is often a challenging balancing act. Enter swinger reciprocators — specialized mechanical systems designed to optimize coating application by enhancing consistency and speed.

This comprehensive article delves into the working principles, benefits, and applications of swinger reciprocators in coating processes. Through detailed explanations and technical insights, it aims to clarify how these devices revolutionize coating operations in various industries.

What are Swinger Reciprocators?

Definition and Basic Functionality

Swinger reciprocators are mechanical devices used to create controlled reciprocating motion — a back-and-forth movement — typically in spray coating systems. Unlike conventional linear reciprocators that move solely in one axis, swinger reciprocators pivot or swing around a fixed point, enabling a distinct pattern of movement that improves coverage.

Their name derives from this swinging motion, which allows coating equipment such as spray guns or nozzles to move uniformly across a substrate, ensuring an even layering of materials like paint, adhesives, or other coatings.

Components of a Swinger Reciprocator

A typical swinger reciprocator assembly consists of:

- Drive Motor: Powers the reciprocating action.

- Swivel Mechanism: Facilitates the swinging motion.

- Mounting Arm: Connects the coating device and provides spatial control.

- Control System: Manages movement speed, stroke length, and timing.

- Sensors (optional): Monitor position and adapt operations for precision.

Together, these components work harmoniously to produce a consistent application pattern that traditional linear reciprocators may not achieve.

How Swinger Reciprocators Enhance Coating Consistency

Understanding Coating Consistency

Coating consistency refers to the uniformity and quality of the applied coating layers. Variations in thickness, coverage, or texture can lead to defects, reduced product lifespan, and aesthetic issues. Maintaining consistent coating thickness is essential for both functional and cosmetic reasons.

Swinging Motion vs. Linear Motion

Conventional linear reciprocators move in a straight, repetitive path, resulting in potential overlaps or gaps due to acceleration/deceleration at stroke ends. In contrast, swinger reciprocators utilize a swinging motion that maintains a steadier velocity over the coated surface, reducing irregularities caused by speed changes.

- Reduced Stagnation Zones: The continuous swinging minimizes sudden stops and starts, preventing over-application in any single area.

- Improved Edge Coverage: The arc of the swing adapts more naturally to edges and contours, offering better coating on complex shapes.

- Even Spray Distribution: Swinging ensures the spray hits the target consistently at a controlled angle, avoiding streaks or splotches.

Case Study: Metal Panel Coating

In metal panel coating, uniform thickness ensures corrosion protection and appearance quality. Swinger reciprocators maintain a smooth, even film by oscillating the spray gun across the panel with precise timing, drastically reducing repaint and rework rates.

How Swinger Reciprocators Improve Coating Speed

Maximizing Cycle Efficiency

Speed in coating operations is not only about moving faster but also optimizing motion to reduce wasted time without compromising quality. Swinger reciprocators contribute by enabling:

- Higher Operational Speeds: The steady swinging motion allows faster coating without variation in layer thickness.

- Reduced Downtime: Fewer defects mean less time spent on quality control and reworking.

- Optimized Spray Patterns: Controlled oscillations lead to ideal spray overlaps, eliminating the need for slower, multiple passes.

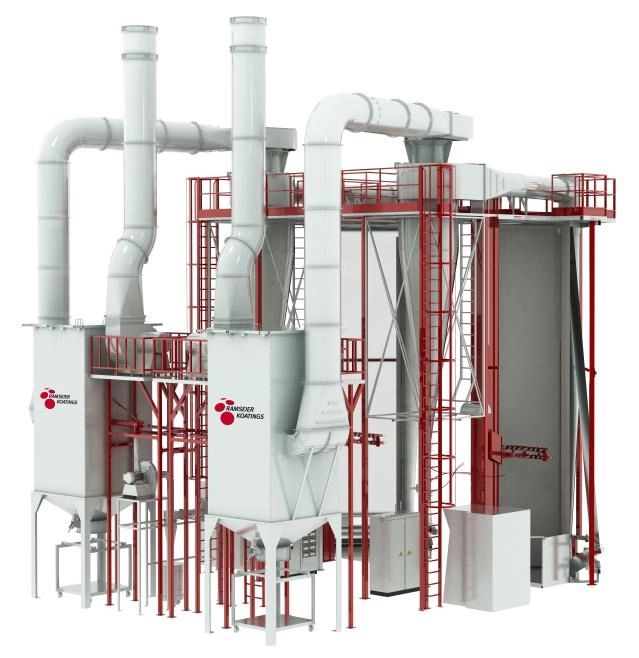

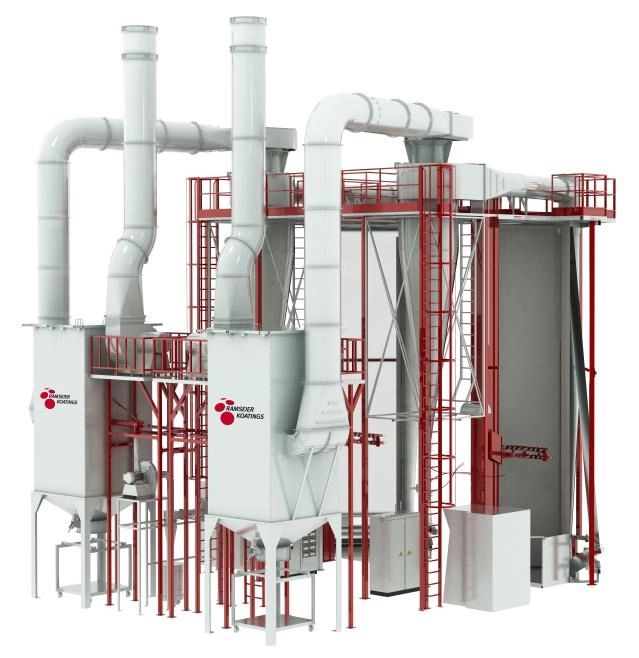

Synchronization with Automated Systems

Modern swinger reciprocators can be integrated into automated coating lines. Their programmable control allows synchronization with conveyor belts, robotic arms, and drying stations, streamlining production flow and minimizing bottlenecks.

Energy Efficiency and Lower Maintenance

Because swinger reciprocators move smoothly and avoid harsh stops, they place less mechanical stress on motors and joints. This leads to:

- Reduced wear and tear, lowering maintenance intervals.

- Energy savings, as motors run at more consistent loads.

- Enhanced longevity of the coating equipment, indirectly improving throughput over time.

Applications of Swinger Reciprocators in Industry

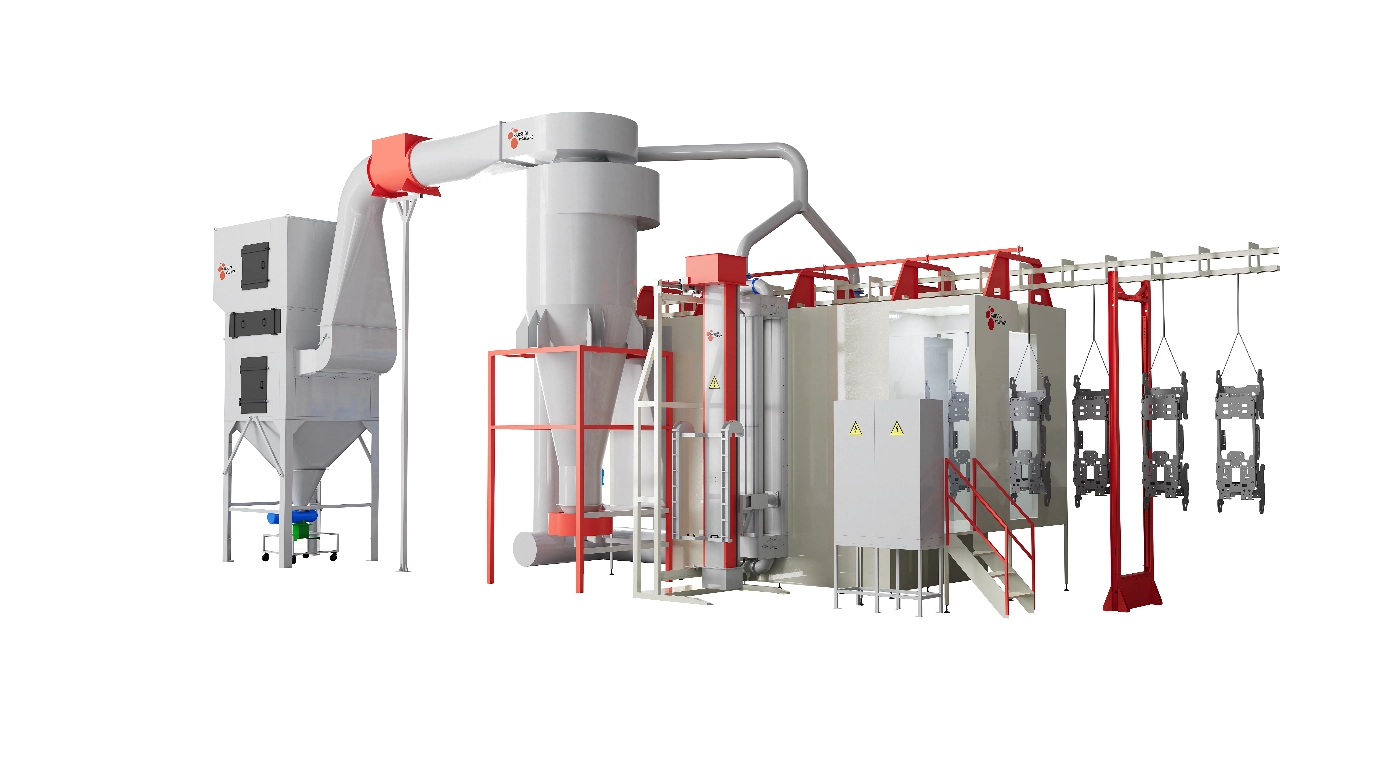

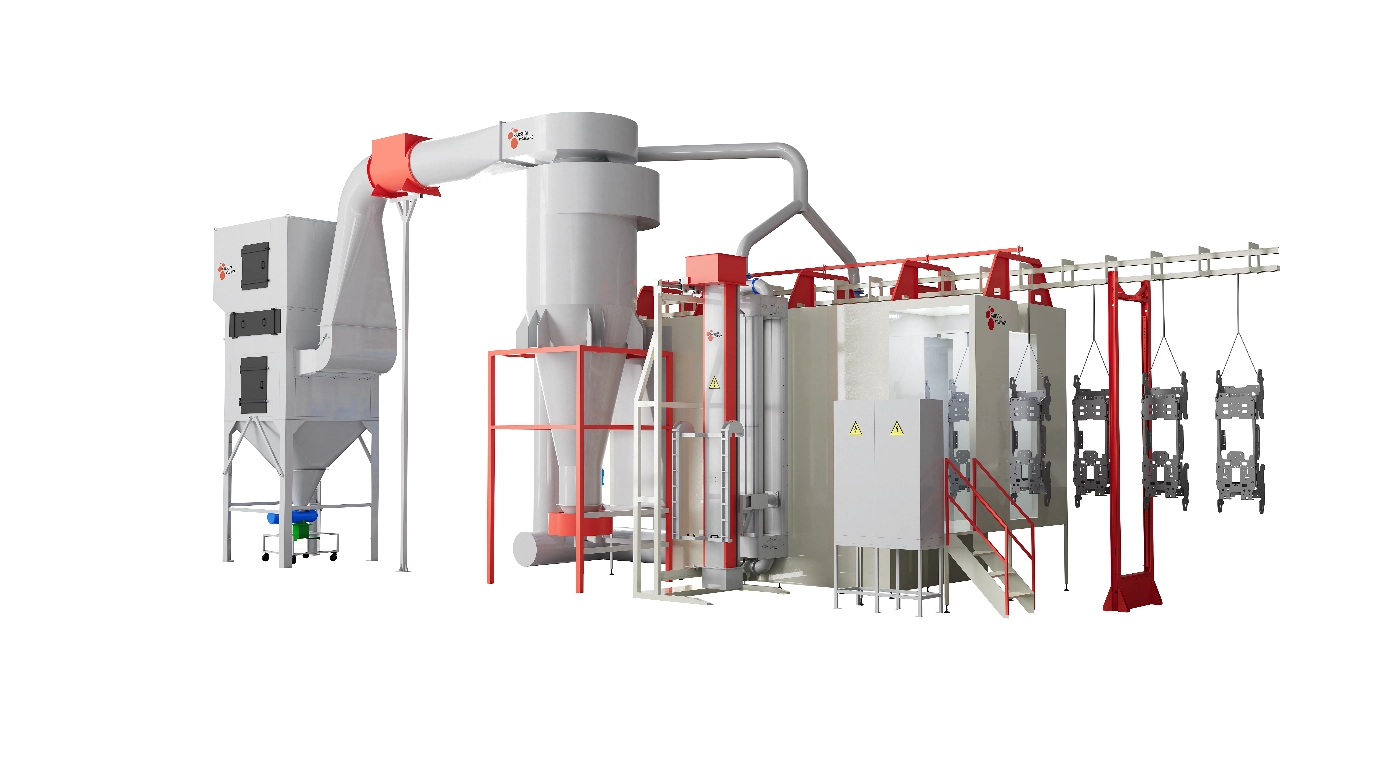

Automotive Painting

In automotive assembly lines, swinger reciprocators are indispensable for painting car bodies and parts. Swinging motion facilitates even coating over curves and recesses, ensuring a high-quality finish while meeting stringent throughput targets.

Electronics and Semiconductor Manufacturing

Protective coating on delicate electronic components requires high precision. Swinger reciprocators deliver this precision by enabling gentle, consistent spray coverage, preventing defects linked to uneven layers.

Packaging Industry

In food and pharmaceutical packaging, coatings protect contents and provide barrier qualities. Swinger reciprocators help maintain rapid operation speeds while preventing contamination with uniform, controlled coatings.

Furniture and Woodworking

Swinger reciprocators are used in lacquer and varnish applications, producing smooth finishes on wood surfaces efficiently and consistently, accentuating natural grain without blotches or streaks.

Technical Considerations for Implementing Swinger Reciprocators

Selection Criteria

Selecting the right swinger reciprocator depends on:

- Substrate size and shape: Larger or more complex shapes may require longer strokes or multiple axes.

- Type of coating material: Viscosity and spray characteristics impact motion parameters.

- Application speed requirements: Balancing speed and quality controls.

- Integration with existing equipment: Compatibility with control systems and mechanical mounts.

Maintenance and Calibration

Regular calibration ensures the swinging motion remains precise. Maintenance includes:

- Lubrication of pivot points

- Inspection of motor function

- Checking control systems for responsiveness

- Replacement of worn parts before failure

Proper upkeep maximizes coating quality and reliability.

Future Trends in Swinger Reciprocator Technology

Smart Controls and IoT Integration

Advanced control systems embedded with IoT (Internet of Things) enable:

- Real-time monitoring of coating performance

- Predictive maintenance alerts

- Adaptive motion adjustments based on sensor feedback

These improvements lead to even higher precision and operational efficiency.

Multi-Axis Swinging and Hybrid Motion

Research is ongoing into combining swinging motion with linear and rotational movements, creating hybrid reciprocators capable of coating highly complex 3D surfaces with minimal manual intervention.

Environmentally Friendly Coating Solutions

Swinger reciprocators facilitate efficient use of coating materials, reducing overspray and waste, supporting sustainable manufacturing practices.

Conclusion

Swinger reciprocators represent a transformative technology in coating operations, delivering superior consistency and enhanced speed. By employing a controlled swinging motion, they ensure uniform layer application, reduce defects, and boost production throughput. Their adaptability across multiple industries—from automotive to electronics—demonstrates their broad utility.

Investing in modern swinger reciprocators with advanced control systems and maintenance regimes can lead to improved product quality, cost savings, and sustainable manufacturing practices. For companies aiming to optimize their coating processes, swinger reciprocators provide a compelling solution that marries technology and efficiency.

Frequently Asked Questions (FAQs)

1. What makes swinger reciprocators different from conventional reciprocators?

Swinger reciprocators use a pivoting, swinging motion rather than a straight back-and-forth linear movement. This results in more even coating coverage and consistent speed across the substrate.

2. Can swinger reciprocators handle complex shapes effectively?

Yes, their swinging arc can adapt to various surface contours and edges, providing smooth coating on complex geometries that linear systems struggle with.

3. Are swinger reciprocators compatible with robotic coating systems?

Absolutely. They can be integrated with robotic arms and automated assembly lines, offering programmable motion control for synchronized, high-speed coating.

4. How do swinger reciprocators improve overall process speed?

They maintain a consistent spraying velocity, reduce rework by enhancing coating uniformity, and eliminate inefficiencies like stops and starts, enabling faster throughput.

5. What maintenance is required to keep swinger reciprocators operating optimally?

Regular lubrication, inspection of mechanical and electrical components, calibration of motion, and prompt replacement of worn parts are essential for peak performance.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing companya

.

.