Content Menu

● Understanding Powder Coating and the Role of Automation

● What is Swinger Automation in Powder Coating?

>> Key Features of Swinger Automation Systems

● How Swinger Automation Enhances Efficiency

>> Optimized Spray Patterns for Uniform Coating

>> Improved Transfer Efficiency

>> Faster Coating Cycles with Reduced Labor

● How Swinger Automation Boosts Accuracy

>> Precision Control Over Coating Parameters

>> Enhanced Recess and Contour Coverage

>> Integration with Sensor and Scan Technologies

● Additional Benefits of Swinger Automation in Powder Coating

>> Simplified Maintenance and Reduced Downtime

>> Flexibility for Different Powders and Products

>> Environmental and Cost Advantages

● Best Practices for Implementing Swinger Automation

● Frequently Asked Questions (FAQs)

Powder coating is a widely used finishing process known for its durability, aesthetic finish, and environmental benefits over traditional liquid paint. In modern manufacturing, automation plays a crucial role in enhancing the efficiency and accuracy of powder coating operations. Among various automation technologies, the use of swinger automation systems stands out for its ability to improve powder application performance significantly. This article explores how swinger automation boosts powder coating efficiency and accuracy through precise control, dynamic motion, and optimized powder usage.

Understanding Powder Coating and the Role of Automation

Powder coating involves applying dry powder electrostatically to a substrate and then curing it under heat to form a uniform protective finish. The process demands careful control over powder deposition to ensure consistent thickness, coverage, and finish quality. Manual application can be inconsistent, leading to overspray, uneven coating, and material waste.

Automation introduces mecanismos such as robotic arms, automatic spray guns, and motion control systems to improve repeatability, precision, and throughput. One such mechanism is swinger automation, which dynamically positions the spray gun in optimal trajectories to enhance coating uniformity and reduce waste.

What is Swinger Automation in Powder Coating?

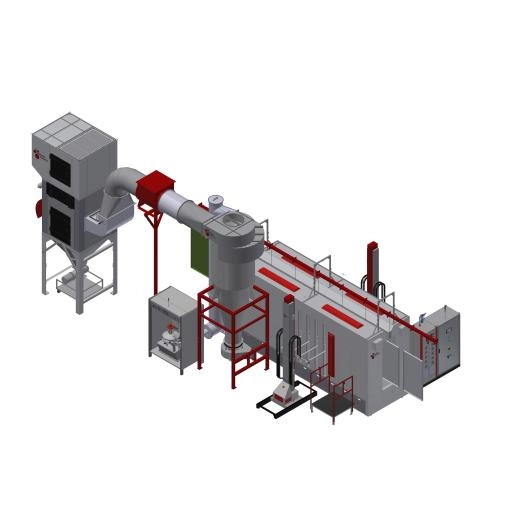

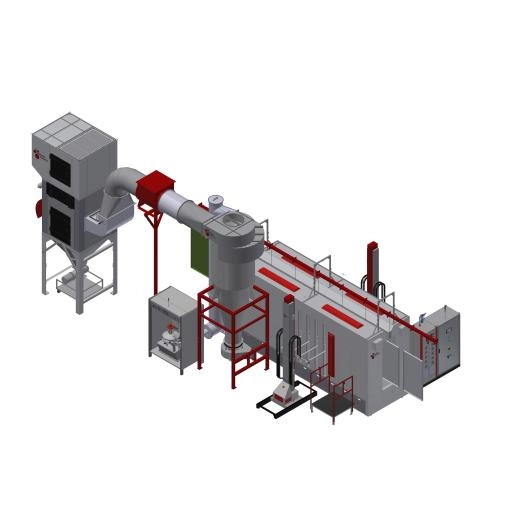

Swinger automation refers to the use of mechanically controlled swinging or oscillating gun movers that apply powder coating by moving back and forth in programmed arcs or strokes. Unlike fixed spray guns or linear motion systems, swinger systems enable the coating gun to dynamically adjust its position relative to the part surface, maintaining an optimal spray angle and distance throughout the coating process.

Key Features of Swinger Automation Systems

- Dynamic Gun Movement: Swinger systems create an oscillating motion, adjusting speed, stroke length, and angle for precise coating application.

- Programmable Control: Operators can customize swing parameters based on part geometry, powder type, and desired coating thickness.

- Improved Coverage: The swinging action enhances penetration into difficult recesses and complex shapes.

- Reduced Overspray: Maintaining the proper spray distance and angle reduces powder waste and improves transfer efficiency.

- Integration with Robotics: Swingers can be combined with robots or automated conveyors for seamless production.

How Swinger Automation Enhances Efficiency

Efficiency in powder coating relates to reducing cycle time, minimizing powder waste, and optimizing energy usage. Swinger automation offers several advantages that directly contribute to these goals.

Optimized Spray Patterns for Uniform Coating

Swinger systems are designed to produce effective and consistent spray patterns by controlling the gun's position precisely. This ensures the powder is applied in a uniform layer without over- or under-coating. The oscillatory movement allows the powder plume to cover a broader surface area evenly, reducing the need for multiple passes and speeding up the process.

Improved Transfer Efficiency

Transfer efficiency measures how much powder adheres to the part versus powder lost as overspray. Swinger automation maintains ideal distances and angles continuously, resulting in higher transfer efficiency. By reducing wasted powder, manufacturers save on material costs and limits environmental impact.

Faster Coating Cycles with Reduced Labor

Automated swinger gun movers allow higher strokes per minute compared to manual methods. The speedy and repeatable motion shortens cycle times while consistent application reduces rework. This automation reduces the dependence on skilled operators for hand-held spraying, lowering labor costs and variability.

How Swinger Automation Boosts Accuracy

Accuracy in powder coating refers to the precise control of coating thickness and coverage, ensuring product quality and meeting tight specifications.

Precision Control Over Coating Parameters

Swinger automation systems typically include sophisticated controls that fine-tune powder flow, electrostatic charge, gun speed, and stroke frequency. This precise regulation allows coating thicknesses to be kept within tight tolerances, sometimes adjustable with micrometer-level accuracy.

Enhanced Recess and Contour Coverage

Complex parts with recesses and contours often experience uneven coating. Swinging motions can dynamically adjust gun position to maintain perpendicular angles to surfaces, improving powder penetration into these difficult areas. As a result, coating quality improves without compromising efficiency.

Integration with Sensor and Scan Technologies

Modern swinger systems can be integrated with sensors and part-scanning technologies to adapt movement patterns in real time. This allows the system to compensate for part variances or fixtures, ensuring consistent application across batches.

Additional Benefits of Swinger Automation in Powder Coating

Simplified Maintenance and Reduced Downtime

Swinger systems are engineered for durability, minimizing wear from moving elements. Their precise motion limits excess powder buildup on gun components, reducing the frequency of cleaning and maintenance. Automated purge cycles can be integrated to facilitate quick and clean color changes.

Flexibility for Different Powders and Products

The programmability of swinger systems allows easy adjustment for various powder types, such as metallic, textured, or specialty finishes. This flexibility supports multi-product lines without extensive retooling or downtime.

Environmental and Cost Advantages

Higher transfer efficiency means less powder consumption and less airborne powder emission. This leads to lower operating costs and improved compliance with environmental regulations regarding waste and worker safety.

Best Practices for Implementing Swinger Automation

For manufacturers looking to leverage swinger automation, some best practices include:

- Conducting detailed part analysis to program optimal swing parameters.

- Integrating with powder management systems for smooth material handling.

- Ensuring regular calibration of electrostatic and spray controls.

- Training operators on system adjustments to handle varying production needs.

- Investing in system diagnostics and monitoring for proactive maintenance.

Frequently Asked Questions (FAQs)

Q1: What types of parts benefit most from swinger automation?

A1: Parts with complex shapes, deep recesses, or large surface areas benefit the most because swinger motion improves coverage and uniformity.

Q2: How does swinger automation compare to robotic powder coating systems?

A2: Swinger automation can be standalone or combined with robots. It offers efficient, cost-effective motion control, especially for medium complexity parts and dedicated lines, whereas robotic systems provide more flexibility for highly varied products.

Q3: Can swinger systems handle multiple colors and frequent color changes?

A3: Yes, advanced swinger systems incorporate automatic cleaning and purge functions that enable fast, contamination-free color changes supporting flexible production.

Q4: What maintenance is required for swinger automation equipment?

A4: Regular cleaning of powder paths, inspection of moving parts, and calibration of control systems are essential, but overall maintenance is simplified due to optimized motion and durable design.

Q5: How much powder savings can be expected with swinger automation?

A5: Savings vary but typical benefits include 10-20% reduction in powder usage due to increased transfer efficiency and reduced overspray.

[1] https://www.youtube.com/watch?v=h_srhalzcmI

[2] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[3] https://reasonablechoice.net/en/blog/automation-of-powder-coating-application

[4] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[5] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating/automatic-powder-coating

[6] https://www.fabtechexpo.com/news/automation-powder-coating-production

[7] https://www.ramseierkoatings.com/advantages-of-using-swinger-technology-in-automated-powder-coating-lines.html

[8] https://www.ramseierkoatings.com/swinger-vs-traditional-powder-coating-systems-which-one-fits-your-needs.html

[9] ftp://ftp.txdot.gov/pub/txdot-info/cmd/txctesttxdotgov/plansonlinetest/plans/SL-CNSTR/2023/02%20FEB/02%20Proposals/Williamson_001508451_Proposal.pdf

[10] https://cdn.mscdirect.com/global/images/ProductDataSheet/pds_sku_1156350_productbrochure_unclassified.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.