Content Menu

● Understanding Powder Coating and Its Process

>> What is Powder Coating?

>> Key Advantages of Powder Coating

>> Components of a Powder Coating Booth

● What is a Reciprocator?

>> Definition and Purpose

>> Types of Reciprocators

● How Reciprocators Enhance Efficiency

>> Improved Powder Application Uniformity

>> Increased Throughput Speed

>> Reduced Powder Waste

>> Lower Labor Costs and Consistency

>> Enhanced Worker Safety

● Integration of Reciprocators in Modern Powder Coating Booths

>> Automation and Control Systems

>> Synchronization with Conveyor Systems

>> Compatibility with Multi-Gun Systems

● Case Study: Reciprocators in Automotive Coating Booths

● Maintenance and Troubleshooting

>> Regular Lubrication and Inspection

>> Calibration and Programming Checks

>> Addressing Common Issues

● Future Trends for Reciprocators in Powder Coating

>> Smart Reciprocators

>> Adaptive Motion Algorithms

>> Energy Efficiency Improvements

● Summary

● Related Questions and Answers

Powder coating has become a popular finishing process in many industries due to its durability, environmental friendliness, and aesthetic benefits. As demand for higher throughput and consistent quality grows, modern powder coating booths increasingly rely on advanced automation and technology. One key component that dramatically improves the efficiency and performance of powder coating systems is the reciprocator. This article explores how reciprocators function, their benefits, and how they integrate into modern powder coating booths to enhance operational efficiency and finish quality.

Understanding Powder Coating and Its Process

Before delving into the advantages of reciprocators, it is important to understand the basics of powder coating.

What is Powder Coating?

Powder coating is a finishing process where dry powder particles are electrostatically charged and sprayed onto a grounded metal surface. The coated item is then cured in an oven where the powder melts and forms a uniform protective and decorative film.

Key Advantages of Powder Coating

- Durability: Superior resistance to scratches, corrosion, and chemicals.

- Environmental Impact: Contains no solvents, minimizing volatile organic compounds (VOC) emissions.

- Finish Variety: Wide color range and textures available.

- Uniform Coverage: Achieves a better finish on complex shapes compared to liquid paints.

Components of a Powder Coating Booth

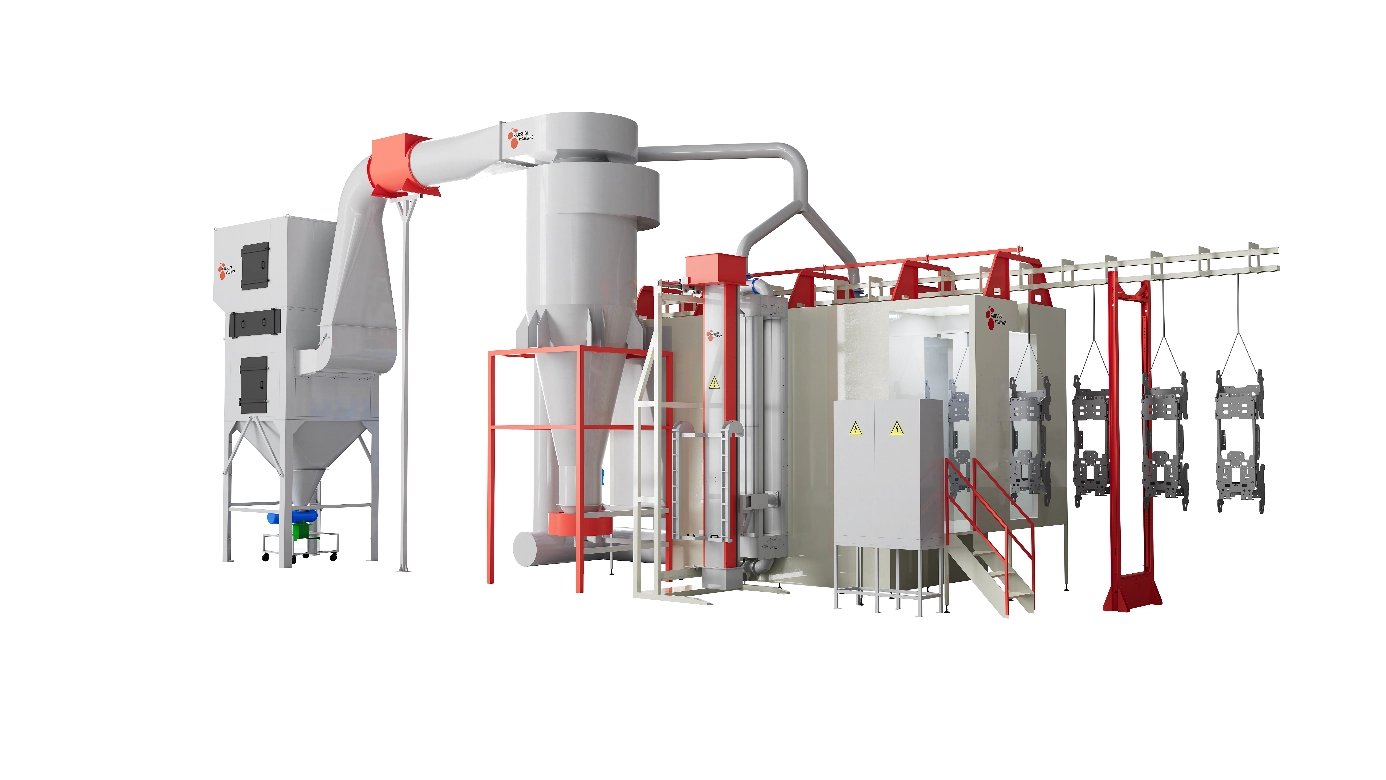

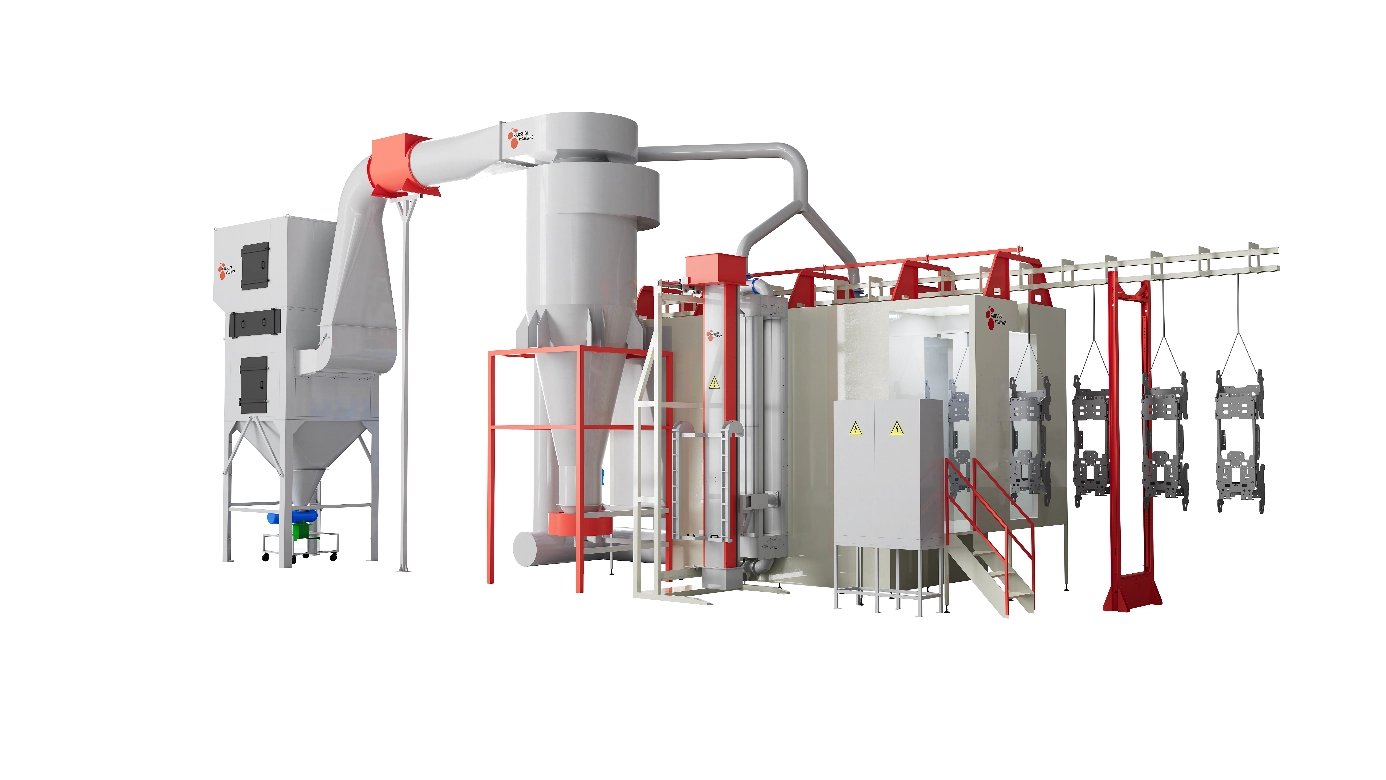

A typical powder coating booth includes:

- Spray guns: Where electrostatically charged powder is sprayed.

- Booth enclosure: Captures overspray and provides a controlled environment.

- Powder recovery system: Collects and reuses overspray powder.

- Reciprocator mechanism: Moves the spray guns in a programmed manner.

What is a Reciprocator?

Definition and Purpose

A reciprocator is a mechanical device designed to move the powder spray guns back and forth in a linear or oscillatory motion. It ensures consistent and even powder application by controlling the speed, stroke length, and timing of the spray guns.

Types of Reciprocators

- Linear Reciprocators: Move spray guns along a straight line, commonly used for long or flat parts.

- Orbital or Circular Reciprocators: Move guns along a circular or elliptical path for complex shapes.

- Custom Programmable Reciprocators: Allow precise motion control tailored to part geometry.

How Reciprocators Enhance Efficiency

Improved Powder Application Uniformity

By steadily moving the spray guns, reciprocators prevent powder buildup and lead to a much more uniform coating thickness across the part. Manual operators or static spray guns often miss spots or create excessive powder buildup.

Increased Throughput Speed

Reciprocators are capable of moving at optimized speeds without fatigue or variability, enabling faster coating cycles. This increases the number of parts processed per hour without compromising quality.

Reduced Powder Waste

An even powder layer reduces the chance of overspray and powder rebound, reducing material waste. Reciprocators help focus powder where needed and avoid excessive application, saving costly powder material.

Lower Labor Costs and Consistency

Automation with reciprocators decreases dependence on manual spraying, reducing labor costs and variability between operators, leading to consistent finish quality.

Enhanced Worker Safety

By limiting manual spraying, workers are less exposed to powder inhalation and repetitious motions, improving occupational safety conditions.

Integration of Reciprocators in Modern Powder Coating Booths

Automation and Control Systems

Modern reciprocators are integrated with PLCs (Programmable Logic Controllers), sensors, and software systems that offer automated control over movement speed, stroke length, and coordination with spray gun triggering. This allows for fine tuning of parameters for different part geometries and coating requirements.

Synchronization with Conveyor Systems

Reciprocators work in tandem with conveyor systems to ensure spray guns move consistently as parts travel through the booth, optimizing cycle time and ensuring even coverage on all surfaces.

Compatibility with Multi-Gun Systems

Some coating lines employ multiple reciprocators simultaneously or use multi-gun reciprocators to coat large parts efficiently. This modular setup provides scalability and flexibility.

Case Study: Reciprocators in Automotive Coating Booths

Automotive parts such as wheels, chassis components, and body panels require extremely uniform powder coatings to meet quality standards. Reciprocators enable high-volume throughput with minimal defect rates in paint thickness. Integration with automated line controls also reduces downtime and addresses complex geometries with precise motion paths.

Maintenance and Troubleshooting

Regular Lubrication and Inspection

Reciprocator components such as bearings, guide rails, and motors require regular maintenance to prevent mechanical failure and ensure smooth operation.

Calibration and Programming Checks

Ensuring the motion parameters are correctly programmed for specific parts is important to avoid uneven coating or powder waste.

Addressing Common Issues

- Inconsistent Stroke Length: May cause uneven coating; often resolved by recalibrating sensors.

- Motor Jamming or Noise: Usually due to lack of lubrication or mechanical wear.

- Misalignment: Causes overlapping or gaps in powder coverage; requires realignment of the reciprocator assembly.

Future Trends for Reciprocators in Powder Coating

Smart Reciprocators

IoT-enabled reciprocators that communicate real-time performance data to maintenance teams can reduce downtime and optimize parameters dynamically.

Adaptive Motion Algorithms

Using AI-based vision systems to adapt reciprocator motion in real time to complex part shapes and surface variations is a promising direction.

Energy Efficiency Improvements

Reducing power consumption through regenerative braking and high-efficiency motors will further enhance operational savings.

Summary

Reciprocators play a crucial role in modern powder coating booths by improving coating uniformity, increasing throughput, reducing waste, lowering labor costs, and enhancing worker safety. Their integration with automated controls and conveyors enables high precision and efficient processing of complex geometries. Maintenance is key to keeping reciprocators running smoothly. Future technology advancements point towards smarter and more adaptive reciprocators, driving even greater efficiencies in powder coating processes.

Related Questions and Answers

Q1: What is the main function of a reciprocator in powder coating?

A1: The main function is to move spray guns back and forth in a controlled manner to achieve uniform powder application over the parts being coated.

Q2: How do reciprocators help reduce powder waste?

A2: They provide consistent and even powder coverage, reducing overspray and rebound powder, which minimizes waste.

Q3: Can reciprocators be used for parts with complex shapes?

A3: Yes, especially programmable and orbital reciprocators can be customized for coating complex geometries effectively.

Q4: What maintenance is required for reciprocators?

A4: Regular lubrication, inspection of mechanical parts, calibration of motion parameters, and timely troubleshooting of any mechanical or motor issues.

Q5: How do reciprocators improve worker safety?

A5: By automating the spray gun movement, they reduce workers' exposure to powder inhalation and minimize repetitive manual motions.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.