Content Menu

● Understanding Vacuum-Based Powder Supply Systems

>> What Are Vacuum-Based Systems?

>> Key Advantages of Vacuum Conveying

>> Typical Applications and Performance

● Our Powder Supply System: Features and Benefits

>> System Design and Operation

>> Advantages Over Vacuum-Based Systems

>> Safety and Environmental Considerations

>> Maintenance and Ease of Use

>> Cost Efficiency

● Comparative Analysis: Our System vs. Vacuum-Based Systems

● When to Choose Our Powder Supply System

● When Vacuum-Based Systems Are Preferable

● Frequently Asked Questions

● Citations:

Powder handling and supply systems are critical components in many industries, including pharmaceuticals, chemicals, food processing, and manufacturing. Efficient and safe powder transfer can significantly impact product quality, operational safety, and production costs. Among the various powder supply technologies, vacuum-based systems have gained prominence due to their enclosed, dust-free operation and safety advantages. This article explores how our powder supply system compares to vacuum-based systems by examining key factors such as design, operation, safety, efficiency, maintenance, and cost.

Understanding Vacuum-Based Powder Supply Systems

What Are Vacuum-Based Systems?

Vacuum-based powder supply systems use negative pressure or suction to move powders from one location to another through enclosed pipelines. The core principle is similar to that of a domestic vacuum cleaner, where powders are entrained in an air stream and transported under vacuum conditions. These systems typically include vacuum generators, receivers, filters, and control units to manage powder flow and containment.

Key Advantages of Vacuum Conveying

- Dust Control and Safety: Vacuum conveying systems excel in minimizing dust exposure by enclosing the powder transfer process. This containment reduces the risk of combustible dust explosions and prevents product loss due to spills. Importantly, leaks in vacuum systems tend to draw air inward, preventing powder escape into the environment, which is a significant safety advantage over positive-pressure systems.

- Product Integrity: Vacuum systems can transport powders gently, reducing segregation and damage, which is essential for fragile or sensitive materials such as coated tablets.

- Flexibility and Integration: Many vacuum conveyors are modular and compact, allowing easy integration with existing production lines and flexible deployment across different processes.

- Energy Efficiency and Durability: Modern vacuum systems often use energy-efficient vacuum generation technologies and are constructed with durable materials, offering long service life and reduced operational costs.

- Regulatory Compliance: Vacuum systems often meet stringent industry standards and certifications, including FDA and ATEX, ensuring compliance with safety and hygiene requirements.

Typical Applications and Performance

Vacuum-based powder systems are suitable for handling a wide range of materials, including fine powders, granules, tablets, and pellets. Conveying rates can vary widely, with dilute-phase vacuum systems capable of moving up to 25,000 pounds per hour over distances less than 300 feet. Line diameters and configurations can be tailored to specific application needs, from small-scale "up-and-in" transfers to bulk material handling from large containers like silos or railcars.

Our Powder Supply System: Features and Benefits

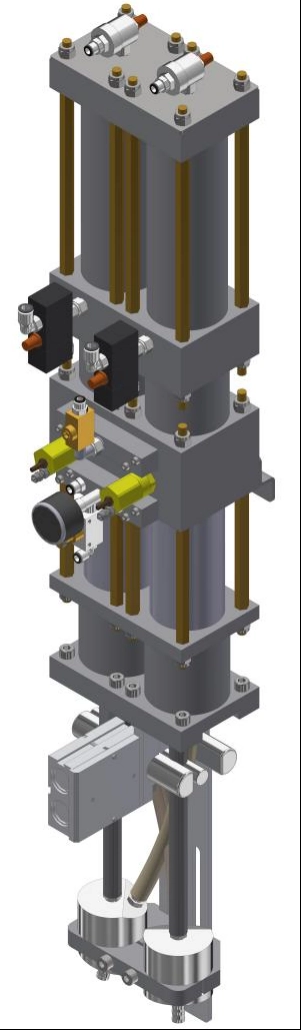

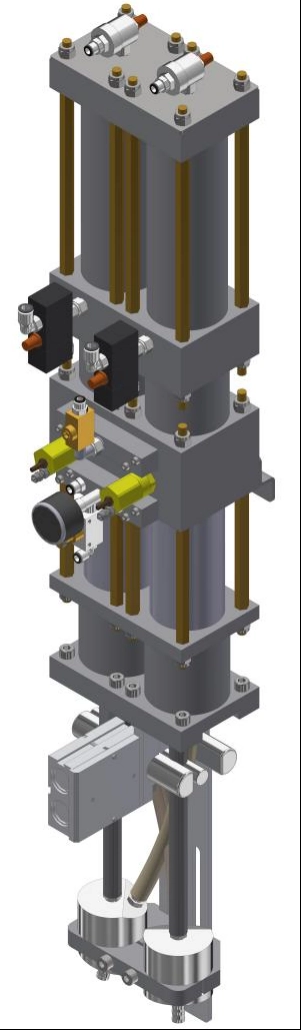

System Design and Operation

Our powder supply system is designed to provide reliable, automated powder transfer with a focus on speed, accuracy, and minimal manual intervention. It integrates advanced feeding mechanisms and control technologies to ensure consistent powder flow and precise dosing.

Advantages Over Vacuum-Based Systems

- High-Speed Filling and Supply: Our system is optimized for rapid powder filling and supply, which can improve throughput in high-volume production environments.

- Automated and Fully Controlled: Featuring automated controls and sensors, our system reduces operator involvement and the risk of human error, enhancing process consistency.

- Adaptability to Various Powder Types: Designed to handle powders with different bulk densities and flow characteristics, our system can be customized for specific material requirements.

- Minimized Cross-Contamination: With enclosed transfer paths and quick cleaning capabilities, our system supports hygienic operation and reduces the risk of cross-contamination.

Safety and Environmental Considerations

While vacuum systems inherently reduce dust escape, our system incorporates robust dust control measures, including sealed transfer points and dust extraction units, to maintain a clean and safe working environment. Additionally, we implement features that prevent powder spillage and exposure during supply operations.

Maintenance and Ease of Use

Our powder supply system is engineered for straightforward maintenance with accessible components and automated cleaning cycles. This design minimizes downtime and reduces the learning curve for operators, contributing to overall productivity.

Cost Efficiency

By balancing automation, speed, and maintenance needs, our system offers competitive operational costs. It eliminates frequent container changes and manual scooping, which reduces labor expenses and material waste.

Comparative Analysis: Our System vs. Vacuum-Based Systems

| Feature | Our Powder Supply System | Vacuum-Based Systems |

| Dust Control | Enclosed transfer with dust extraction units | Superior dust containment with inward leak design |

| Product Handling | Suitable for various powders, fast filling | Gentle transport, protects fragile materials |

| Throughput | High-speed filling optimized for production | High throughput possible; up to 25,000 lb/hr |

| System Complexity | Automated, integrated controls | Modular, flexible but may require complex setup |

| Energy Consumption | Efficient but depends on mechanical components | Often energy-efficient with advanced vacuum tech |

| Maintenance | Easy access, automated cleaning | Minimal maintenance, durable construction |

| Safety | Robust dust control, sealed design | Preferred by NFPA for dust explosion risk mitigation |

| Installation Flexibility | Customizable, easy integration | Modular and mobile options available |

| Cost | Competitive for high-volume, automated processes | Initial investment can be high; cost-effective long-term |

When to Choose Our Powder Supply System

- When high-speed powder filling and supply are critical to production efficiency.

- When handling powders with varying bulk densities requiring adaptable feeding mechanisms.

- When automation and reduced manual intervention are priorities.

- When ease of maintenance and quick cleaning are essential to minimize downtime.

- When cost-effective operation with reliable dust control is needed.

When Vacuum-Based Systems Are Preferable

- When maximum dust containment and explosion risk reduction are paramount.

- When transporting fragile or sensitive powders requiring gentle handling.

- When modularity and flexibility for varying production layouts are needed.

- When compliance with strict regulatory standards for hygiene and safety is required.

- When conveying powders over short to moderate distances with high throughput.

Frequently Asked Questions

Q1: How do vacuum-based systems prevent dust explosions?

Vacuum systems maintain negative pressure, so any leaks draw air inward, preventing powder from escaping and accumulating in the environment, which reduces explosion risk.

Q2: Can our powder supply system handle fragile powders without damage?

Yes, our system is designed to handle a range of powders carefully, though vacuum systems may offer gentler transport for extremely delicate materials.

Q3: What maintenance is required for vacuum-based powder systems?

Vacuum systems typically require minimal maintenance due to durable construction but need regular filter cleaning and vacuum generator checks.

Q4: Are vacuum-based systems energy efficient?

Modern vacuum conveyors use energy-efficient vacuum generation technologies, such as ejector-driven COAX® systems, reducing energy consumption.

Q5: How flexible are vacuum-based systems in production lines?

They are highly flexible, with modular designs and mobile frames allowing easy integration and layout modifications.

---

Citations:

[1] https://www.ptonline.com/articles/10-things-to-know-when-specifying-vacuum-conveying-systems-for-powders

[2] https://www.piab.com/en-us/vacuum-conveyors-for-bulk-powders-granules-and-small-parts

[3] https://www.powderbulksolids.com/pneumatic-conveying/contained-powder-transfer-vacuum-based-pneumatic-conveying

[4] https://insights.globalspec.com/article/23680/vacuums-suck-they-re-great-for-powder-handling

[5] https://broendum.com/en/insight-into-the-technical-aspects-of-vacuum-cleaners/

[6] https://shop.machinemfg.com/advantages-and-disadvantages-of-powder-metallurgy/

[7] https://patents.google.com/patent/CN201946686U/zh

[8] https://www.columbiacoatings.com/insandity-powder-vacuum.aspx

[9] https://www.alphaprecisionpm.com/blog/advantages-and-disadvantages-of-powder-metallurgy

[10] https://patents.google.com/patent/CN108452917B/zh

[11] https://powdermetallurgy.com/advantages-and-disadvantages-of-powder-metallurgy/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.