Content Menu

● Understanding Powder Supply Systems

>> What Is a Powder Supply System?

>> Importance of Advanced Powder Supply Systems

● Features of the Best Powder Supply Systems in the Market

>> Precision and Automation

>> Closed and Controlled Environments

>> Safety and Environmental Controls

>> Versatility and Customization

● How Our Powder Supply System Compares

>> Precision and Efficiency

>> Controlled Environment and Safety

>> Customization and Integration

>> Sustainability and Waste Reduction

>> Maintenance and Longevity

● Advantages of Our Powder Supply System

● Industry Applications

● Frequently Asked Questions

In modern manufacturing and industrial processes, powder supply systems play a crucial role in ensuring efficiency, safety, and product quality. As industries evolve, so do the technologies and methods used in powder handling, transfer, and dispensing. This article explores how our powder supply system stands in comparison to the best systems available in the market today, highlighting key features, innovations, and benefits.

Understanding Powder Supply Systems

What Is a Powder Supply System?

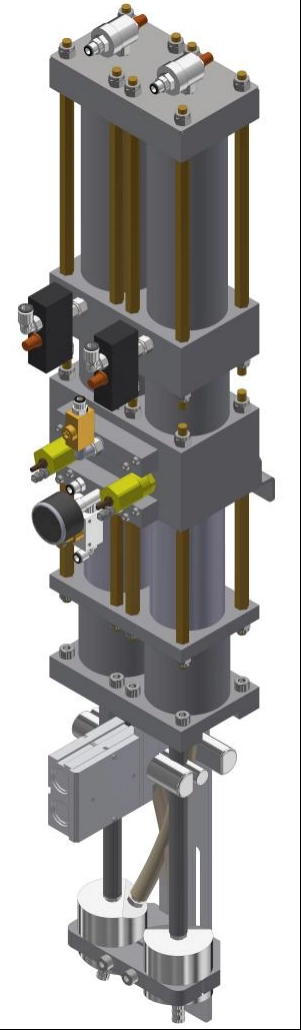

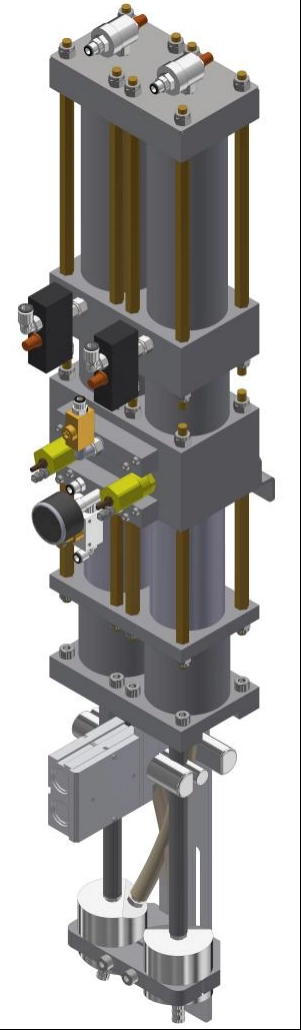

A powder supply system is an integrated setup designed to handle, transfer, and dispense powder materials in various industrial applications. These systems are engineered to minimize spillage, dust generation, and contamination while ensuring precise delivery of powders for manufacturing processes such as additive manufacturing, pharmaceuticals, food production, and chemical processing.

Importance of Advanced Powder Supply Systems

Efficient powder supply systems contribute to operational excellence by reducing waste, improving worker safety, maintaining product integrity, and enhancing overall productivity. They also support environmental sustainability by limiting dust pollution and resource depletion.

Features of the Best Powder Supply Systems in the Market

Precision and Automation

Top-tier powder supply systems incorporate advanced automation features that allow for precise weighing, dispensing, and packaging of powders. For example, some systems use integrated scales with digital readouts and automated conveyor belts to achieve high measurement accuracy and reduce manual intervention. Bluetooth-enabled controls and companion apps enable remote operation and storage of powder settings, enhancing user convenience and repeatability.

Closed and Controlled Environments

To safeguard powder quality, leading systems operate within closed environments with controlled atmospheres, often using inert gases to prevent oxidation and contamination. Vacuum exhaust filtering systems and airlocks actively maintain cleanliness and prevent cross-contamination during powder handling and packaging.

Safety and Environmental Controls

Safety is paramount in powder handling due to the risks of dust explosions, exposure to hazardous materials, and slip hazards from spillage. The best systems feature fugitive dust collection, humidity and oxygen monitoring, and robust construction materials such as 316L stainless steel to ensure durability and safety compliance.

Versatility and Customization

Market-leading powder supply systems offer modular designs that can be customized to specific industry needs. Options include automated lidding, bottle filling and indexing, drum dispensing, and compatibility with various container sizes. These systems can be retrofitted to existing production lines or designed as turnkey solutions.

How Our Powder Supply System Compares

Precision and Efficiency

Our powder supply system matches the highest standards by incorporating automated weighing and dispensing technologies that ensure consistent and accurate powder delivery. Like the best systems, it reduces manual handling, thereby minimizing human error and increasing throughput.

Controlled Environment and Safety

We prioritize powder integrity by utilizing a closed system with inert gas atmospheres and vacuum technology to transport powders. This approach aligns with industry leaders that prevent oxidation and contamination, ensuring product quality throughout the process. Our system also includes dust collection and environmental monitoring features to maintain workplace safety and regulatory compliance.

Customization and Integration

Our system is designed with flexibility in mind, capable of integrating with various powder containers, including big bags and drums. It supports automation options such as automated lid application and labeling, similar to top competitors. Additionally, it can be configured to meet specific customer requirements, providing a tailored solution for different industrial sectors.

Sustainability and Waste Reduction

By minimizing powder spillage and dust generation, our system supports sustainable manufacturing practices. Efficient powder transfer reduces waste and environmental impact, comparable to the best powder transfer systems that emphasize eco-friendly operations.

Maintenance and Longevity

Constructed with high-quality materials and precision engineering, our powder supply system offers durability and low maintenance needs. This ensures long-term reliability and cost-effectiveness, on par with leading systems designed for industrial robustness.

Advantages of Our Powder Supply System

- High Accuracy: Automated weighing and dispensing reduce variability.

- Safety Features: Vacuum exhaust filtration and inert atmospheres protect workers and product quality.

- Customizable: Modular design accommodates various container types and sizes.

- Automation Ready: Supports automated filling, lidding, and labeling.

- Sustainability: Reduces waste and dust pollution.

- Durability: Stainless steel construction with corrosion-resistant finishes.

Industry Applications

Our powder supply system is suitable for a broad range of industries, including:

- Additive Manufacturing (3D printing with metal powders)

- Pharmaceuticals (precise dosing and contamination control)

- Food Processing (hygienic powder handling)

- Chemical Manufacturing (safe transfer of reactive powders)

- Cosmetics and Personal Care (consistent blending and packaging)

Frequently Asked Questions

Q1: How does automation improve powder dispensing accuracy?

Automation reduces human error by precisely controlling powder flow and weight, resulting in consistent batch quality and less material waste.

Q2: What safety measures are included in modern powder supply systems?

Key safety features include vacuum dust collection, inert gas atmospheres to prevent oxidation, oxygen and humidity monitoring, and sealed environments to minimize exposure to hazardous powders.

Q3: Can powder supply systems handle different powder types and container sizes?

Yes, advanced systems offer modular designs and customizable feed mechanisms to accommodate various powders and container formats, including big bags, drums, and bottles.

Q4: How do powder supply systems contribute to environmental sustainability?

By minimizing spillage, dust emissions, and resource wastage, these systems reduce environmental pollution and support sustainable manufacturing practices.

Q5: What maintenance is required for powder supply systems?

Regular cleaning, inspection of seals and filters, and monitoring of environmental controls are necessary to maintain system performance and longevity.

[1] https://www.metal-am.com/custom-powder-systems-introduces-new-metal-powder-packaging-solution/

[2] https://www.loaddevelopment.com/best-electronic-powder-dispenser/

[3] https://macawberindia.in/key-benefits-powder-transfer-system-material-handling/

[4] https://www.multistation.com/wp-content/uploads/2017/12/psv-slm-solutions.pdf

[5] https://www.thomasnet.com/suppliers/usa/powder-handling-systems-95949376

[6] https://www.binks.co.jp/eng/ms/products/bigbag.html

[7] https://www.pcimag.com/articles/93532-evolution-of-the-powder-booth-and-reclaim-system

[8] https://www.biscuitpeople.com/magazine/post/1343-continuous-powder-supply-system-flour-dosing-and-feeding-system

[9] https://www.ddpsinc.com/powder-handling-systems

[10] https://www.cpecn.com/features/supply-meets-demand-with-continuous-powder-processing-system/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.