Content Menu

● Understanding Powder Coating Operations

>> What is Powder Coating?

>> The Importance of Efficiency in Powder Coating

● The Role of Data in Powder Coating

>> Data Collection and Management

>> Real-Time Monitoring

● Data-Driven Decision Making

>> Analyzing Data for Insights

>> Predictive Analytics

● Enhancing ROI through Data-Driven Strategies

>> Reducing Waste

>> Improving Quality Control

>> Streamlining Operations

>> Enhancing Customer Satisfaction

● Case Studies: Success Stories in Data-Driven Powder Coating

>> Company A: Reducing Downtime

>> Company B: Minimizing Waste

>> Company C: Improving Quality

● Challenges in Implementing Data-Driven Decisions

>> Data Quality and Integrity

>> Resistance to Change

>> Technology Investment

● Future Trends in Data-Driven Powder Coating

>> Artificial Intelligence and Machine Learning

>> Advanced Analytics

>> Sustainability Initiatives

● Conclusion

>> Frequently Asked Questions

In the competitive landscape of manufacturing, particularly in powder coating operations, the ability to make informed, data-driven decisions is crucial for enhancing efficiency and maximizing return on investment (ROI). This article explores how leveraging data analytics can transform powder coating processes, leading to improved operational performance, reduced costs, and increased profitability.

Understanding Powder Coating Operations

What is Powder Coating?

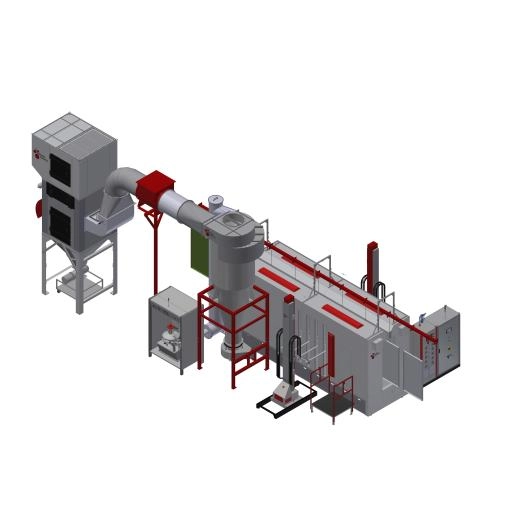

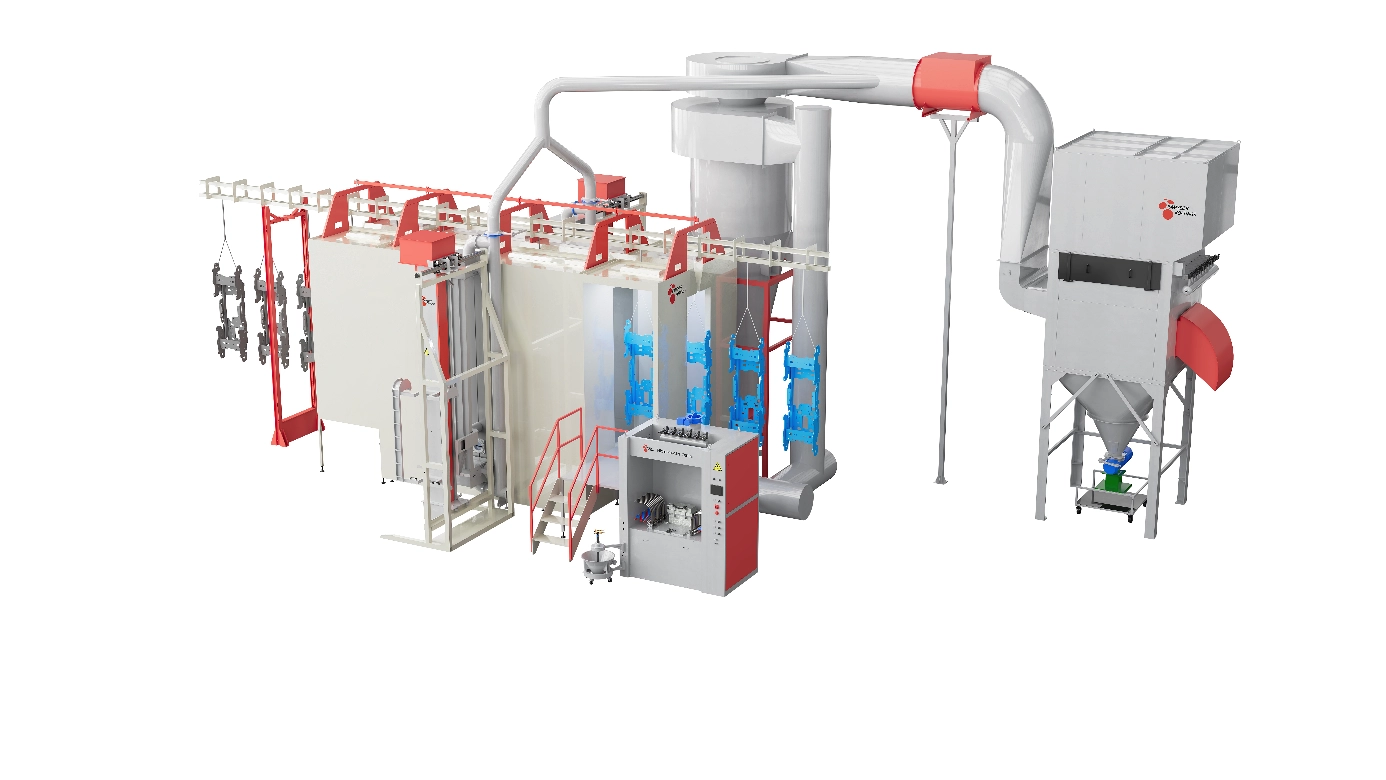

Powder coating is a finishing process that applies a dry powder to a surface, which is then cured under heat to form a hard, durable finish. This method is widely used in various industries, including automotive, appliances, and furniture, due to its superior finish quality and environmental benefits compared to traditional liquid coatings.

The Importance of Efficiency in Powder Coating

Efficiency in powder coating operations is paramount. Factors such as material waste, energy consumption, and labor costs directly impact profitability. Therefore, manufacturers are increasingly turning to data-driven strategies to optimize these processes.

The Role of Data in Powder Coating

Data Collection and Management

Data collection in powder coating operations involves gathering information from various sources, including production machinery, quality control systems, and inventory management. This data can include:

- Production rates: Tracking how many items are coated per hour.

- Material usage: Monitoring the amount of powder used versus the amount wasted.

- Quality metrics: Analyzing defect rates and rework instances.

Implementing a robust data management system allows manufacturers to centralize this information, making it accessible for analysis and decision-making.

Real-Time Monitoring

Real-time monitoring systems provide immediate insights into production processes. By utilizing sensors and IoT devices, manufacturers can track equipment performance, detect anomalies, and respond to issues before they escalate. This proactive approach minimizes downtime and enhances overall productivity.

Data-Driven Decision Making

Analyzing Data for Insights

Data analysis involves interpreting the collected data to identify trends, patterns, and areas for improvement. For instance, by analyzing production data, manufacturers can determine the optimal curing times and temperatures for different powder types, leading to better quality finishes and reduced energy consumption.

Predictive Analytics

Predictive analytics uses historical data to forecast future outcomes. In powder coating operations, this can mean predicting equipment failures or identifying potential quality issues before they occur. By anticipating these problems, manufacturers can schedule maintenance or adjust processes proactively, thus avoiding costly downtime.

Enhancing ROI through Data-Driven Strategies

Reducing Waste

One of the most significant benefits of data-driven decision-making is the reduction of waste. By analyzing material usage data, manufacturers can identify inefficiencies in the coating process, such as over-spraying or incorrect application techniques. Implementing changes based on these insights can lead to substantial cost savings.

Improving Quality Control

Data-driven quality control measures ensure that products meet the required standards before they leave the production line. By integrating quality metrics into the data management system, manufacturers can quickly identify defects and implement corrective actions, reducing the rate of returns and enhancing customer satisfaction.

Streamlining Operations

Data analytics can help streamline operations by optimizing workflow and resource allocation. For example, analyzing production schedules can reveal bottlenecks in the process, allowing managers to adjust staffing or equipment usage to improve throughput.

Enhancing Customer Satisfaction

By improving product quality and reducing lead times, data-driven decisions can significantly enhance customer satisfaction. Satisfied customers are more likely to return and recommend the business, leading to increased sales and profitability.

Case Studies: Success Stories in Data-Driven Powder Coating

Company A: Reducing Downtime

Company A implemented a real-time monitoring system that tracked equipment performance. By analyzing this data, they identified a recurring issue with one of their curing ovens. Predictive maintenance alerts allowed them to address the problem before it caused significant downtime, resulting in a 20% increase in production efficiency.

Company B: Minimizing Waste

Company B focused on reducing material waste by analyzing powder usage data. They discovered that certain application techniques led to excessive overspray. By training staff on more efficient application methods, they reduced powder waste by 30%, significantly lowering material costs.

Company C: Improving Quality

Company C integrated quality control metrics into their data management system. By analyzing defect rates, they identified a correlation between specific powder types and higher defect rates. Switching to a different supplier for those powders improved their first-pass yield by 15%, enhancing overall product quality.

Challenges in Implementing Data-Driven Decisions

Data Quality and Integrity

One of the primary challenges in data-driven decision-making is ensuring the quality and integrity of the data collected. Inaccurate or incomplete data can lead to misguided decisions. Therefore, manufacturers must prioritize data accuracy at the source and implement regular audits of their data management systems.

Resistance to Change

Implementing data-driven strategies often requires a cultural shift within the organization. Employees may resist changes to established processes. To overcome this, management should provide training and demonstrate the benefits of data-driven decision-making to gain buy-in from staff.

Technology Investment

Investing in the necessary technology for data collection and analysis can be a barrier for some manufacturers. However, the long-term ROI from improved efficiency and reduced costs typically outweighs the initial investment.

Future Trends in Data-Driven Powder Coating

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into powder coating operations is set to revolutionize the industry. These technologies can analyze vast amounts of data to identify patterns and make recommendations for process improvements, further enhancing efficiency and quality.

Advanced Analytics

As data analytics tools become more sophisticated, manufacturers will be able to leverage advanced analytics to gain deeper insights into their operations. This will enable more precise forecasting and optimization, driving even greater ROI.

Sustainability Initiatives

With increasing pressure to adopt sustainable practices, data-driven decision-making will play a crucial role in helping manufacturers reduce their environmental impact. By analyzing energy consumption and waste generation, companies can implement strategies to minimize their carbon footprint while maintaining profitability.

Conclusion

Data-driven decision-making is no longer a luxury but a necessity for powder coating operations aiming to boost ROI. By harnessing the power of data analytics, manufacturers can reduce waste, improve quality, streamline operations, and enhance customer satisfaction. As technology continues to evolve, those who embrace data-driven strategies will be well-positioned to thrive in an increasingly competitive market.

Frequently Asked Questions

1. What is the primary benefit of data-driven decision-making in powder coating?

- The primary benefit is improved efficiency, leading to reduced costs and increased profitability.

2. How can predictive analytics help in powder coating operations?

- Predictive analytics can forecast equipment failures and quality issues, allowing for proactive maintenance and adjustments.

3. What challenges do manufacturers face when implementing data-driven strategies?

- Challenges include ensuring data quality, overcoming resistance to change, and making necessary technology investments.

4. How does real-time monitoring improve production efficiency?

- Real-time monitoring allows for immediate insights into production processes, enabling quick responses to issues and minimizing downtime.

5. What future trends should powder coating manufacturers watch for?

- Key trends include the integration of AI and ML, advanced analytics, and sustainability initiatives.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.