Content Menu

● Understanding Powder Coating and Its Challenges

● How Automation Boosts Powder Coating Line Efficiency

>> High-Speed and Consistent Production

>> Robotic and Automatic Spray Systems

>> Integrated Powder Recovery Systems

>> Intelligent Monitoring and Control

>> Energy Efficiency and Process Optimization

● Key Benefits of Automation in Powder Coating Lines

● Implementing Automation: Technologies and Components

>> Robotic Spray Arms

>> Programmable Logic Controllers (PLC) and Central Control Systems

>> Sensor Arrays for Quality and Safety

>> Powder Handling and Recovery Units

>> Intelligent Software and IoT Integration

● Case Examples of Automation Impact

● Challenges and Considerations

● Frequently Asked Questions (FAQ)

In today's manufacturing environment, automation is revolutionizing powder coating production lines by drastically improving efficiency, quality, and cost-effectiveness. Through precise robotic application, real-time monitoring, integrated process control, and waste reduction, automated powder coating lines deliver faster throughput and superior finishes while minimizing labor and material costs.

Understanding Powder Coating and Its Challenges

Powder coating is a dry finishing process that applies a fine powder to metal or other surfaces, which is then cured under heat to form a durable, protective, and aesthetically pleasing layer. Traditionally, powder coating involved manual labor-intensive spraying, which presented several challenges:

- Inconsistent coating thickness and quality due to human error

- Slow production speeds limited by manual operation

- High powder waste because of overspray and inefficient recovery

- Energy inefficiencies in curing processes

- Labor costs and safety risks from prolonged exposure to powder and solvents

Automation addresses these challenges by incorporating advanced technologies and intelligent systems to streamline and standardize the coating process.

How Automation Boosts Powder Coating Line Efficiency

High-Speed and Consistent Production

Automated powder coating lines typically achieve production speeds ranging from 3 to 5 meters per minute, depending on product complexity and finish requirements. Unlike manual spray lines that require pauses and adjustments, automated systems operate continuously, delivering consistent film thickness and surface finish quality without fatigue or variation.

Robotic and Automatic Spray Systems

Robotic arms and automated spray guns ensure uniform application of powder coatings with optimized spraying angles, pressure, and distances. This precision reduces defects and rework. Automated systems can:

- Dynamically adjust spray parameters based on the shape and size of parts

- Use programmed paths or sensors for exact gun placement

- Maintain electrostatic charge settings precisely to avoid overcharging issues like surface "orange peel" defects

Such control translates directly to consistent, better-quality coatings and reduced material waste.

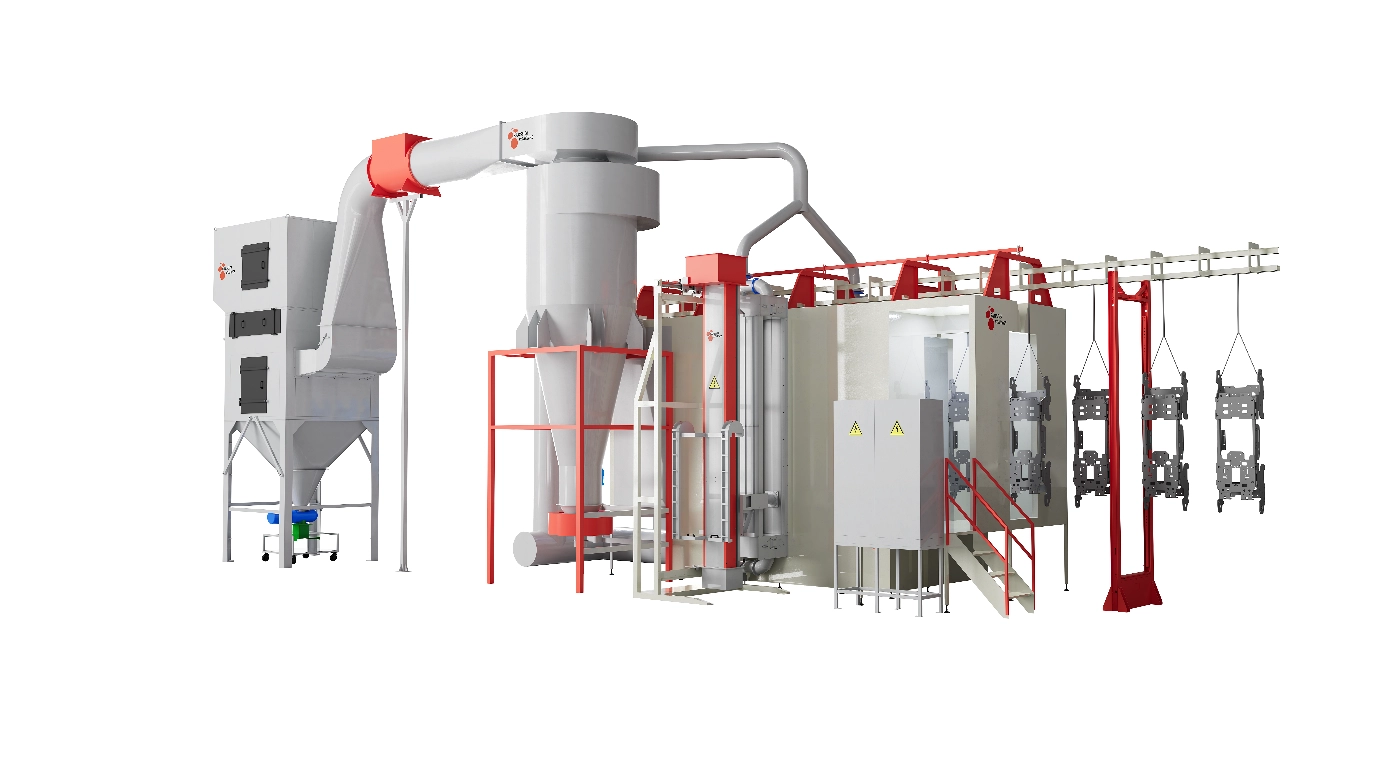

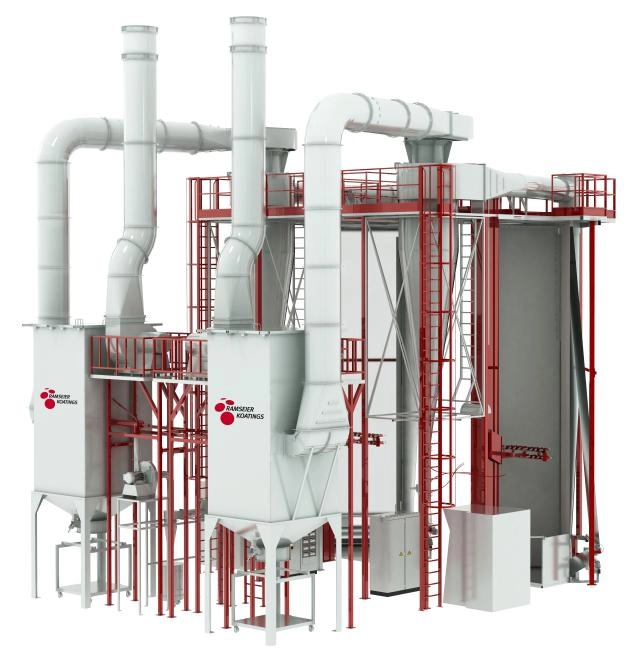

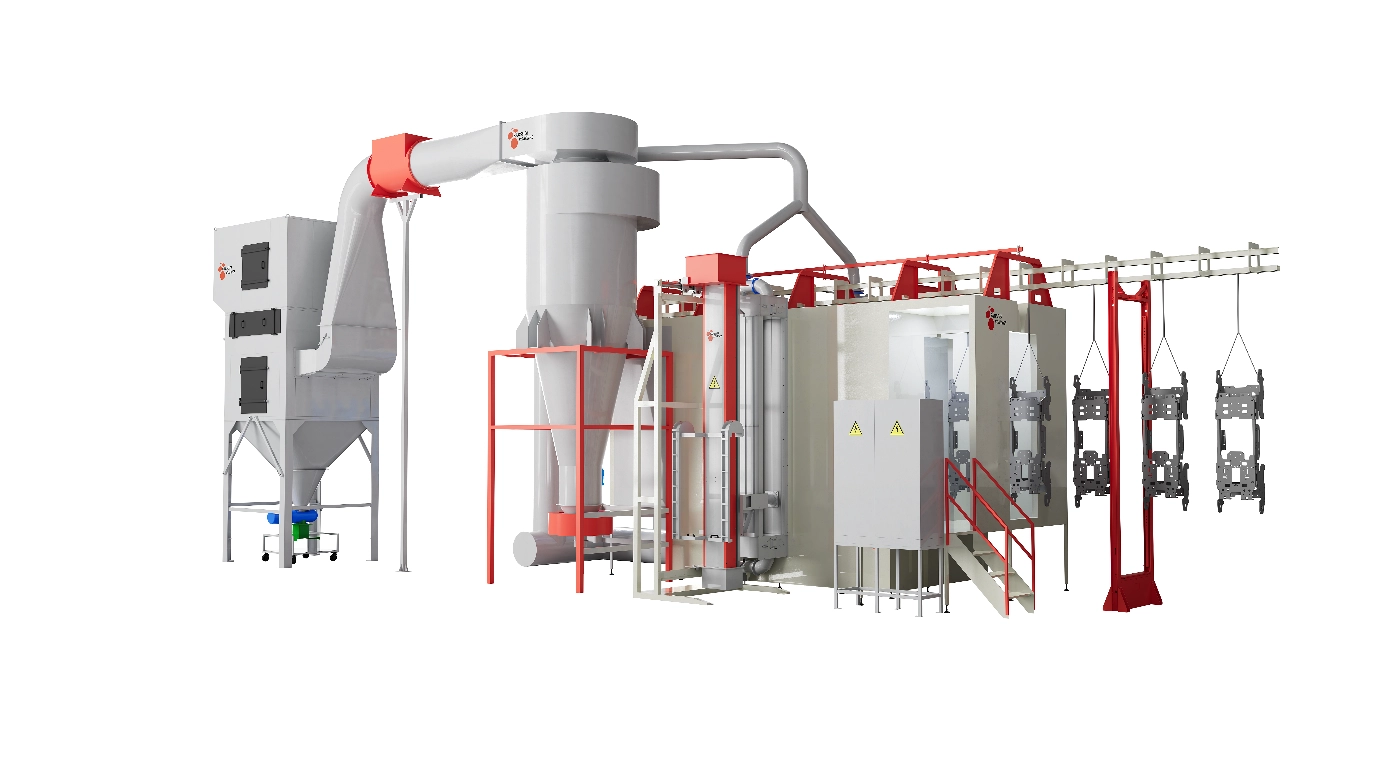

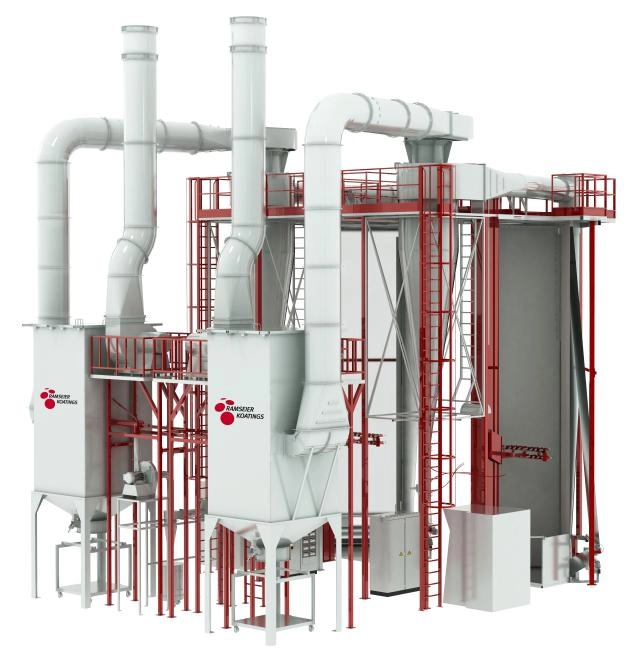

Integrated Powder Recovery Systems

Automation often includes powder recovery technology that collects overspray powder using negative pressure systems and recycles it back into the coating process. This feature can save approximately 15 to 35% of powder material, significantly cutting costs and environmental impact.

Intelligent Monitoring and Control

Advanced powder coating lines deploy sensors for real-time data collection on parameters such as powder flow rate, electrostatic charge, temperature, humidity, and curing oven conditions. Central processing units analyze this data to:

- Automatically adjust process variables for optimal performance

- Trigger alarms and corrective actions if any parameters deviate from preset standards

- Display operational data for operators to monitor line performance

Such automation enhances process stability, reduces downtime and rejects, and facilitates predictive maintenance.

Energy Efficiency and Process Optimization

Automated curing ovens precisely control temperature and curing times according to coating specifications, eliminating energy waste from overheating or under-curing. Some systems incorporate heat recovery to reuse excess thermal energy. These technological improvements lead to reduced operational costs and higher throughput.

Key Benefits of Automation in Powder Coating Lines

| Benefit | Description |

| Increased Production Speed | Continuous automated operation improves throughput compared to manual coating |

| Consistent Coating Quality | Robots and sensors ensure uniform powder application and curing |

| Labor Cost Reduction | Automation reduces manpower needs and associated expenses |

| Material Waste Minimization | Powder recovery systems recycle overspray, saving raw materials |

| Improved Workplace Safety | Reduced human exposure to powders and hazardous environments |

| Energy Efficiency | Optimized curing and heat recovery lower energy consumption |

| Data-Driven Process Control | Real-time sensor monitoring enables quick adjustments and predictive maintenance |

Implementing Automation: Technologies and Components

Robotic Spray Arms

These programmable robots perform coating with high repeatability. They navigate complex geometries on automotive parts, appliances, or construction elements, applying the right powder amount in the right spots.

Programmable Logic Controllers (PLC) and Central Control Systems

PLCs coordinate all equipment on the line—from pre-treatment to curing ovens—ensuring synchronization and smooth workflow. They collect sensor data, execute control algorithms, and interface with human-machine interfaces (HMI) for operator oversight.

Sensor Arrays for Quality and Safety

Sensors measure critical process parameters such as:

- Powder dust concentration

- Electrostatic charge levels

- Temperature and humidity

- Conveyor speed and positioning

- Volatile organic compounds or combustible gas levels

This multi-sensor approach safeguards production quality and personnel health.

Powder Handling and Recovery Units

Automated conveyors, fluidized beds, and recovery hoppers move, apply, and reclaim powder with minimal spillage. Efficient filtration and recycling mechanisms reduce raw material costs.

Intelligent Software and IoT Integration

Modern lines may integrate IoT connectivity for remote monitoring, cloud data analysis, and integration with manufacturing execution systems (MES). The software supports decision-making, ongoing process optimization, and digital traceability.

Case Examples of Automation Impact

- Automotive Industry: Lines coating wheels and chassis components run at optimized speeds near 4-5 meters per minute with robotic arms ensuring flawless finishes and minimal rejects.

- Consumer Appliances: Smaller parts lines achieve high throughput through continuous automated spraying and curing with minimal labor input.

- Construction Materials: Coating of aluminum profiles uses moderate line speeds with precise powder application supplying weather-resistant, durable finishes.

Challenges and Considerations

While automation offers many advantages, companies must consider:

- Initial capital investment for robotic and control systems

- Integration complexity with existing line equipment

- Skilled workforce needed to program, maintain, and troubleshoot automated systems

- Customization requirements for different coating powders or product types

However, the return on investment is often rapid due to labor savings, reduced material waste, higher throughput, and lower defect rates.

Frequently Asked Questions (FAQ)

Q1: How much powder savings can automation provide?

A1: Automated powder coating lines with recovery systems can reduce powder consumption by 15 to 35%, equivalent to saving 20 to 50 grams per square meter of coated surface.

Q2: Does automation reduce labor costs significantly?

A2: Yes, automation reduces manual intervention drastically, cutting labor costs and reducing operational errors and fatigue-related issues.

Q3: Can automated systems handle complex part geometries?

A3: Yes, robotic spray arms with programmable paths and sensor inputs precisely adapt to complex shapes for uniform coating.

Q4: Is energy consumption lower with automated curing?

A4: Automated ovens optimize temperature and curing time, reducing energy waste and sometimes incorporating heat recovery systems for further savings.

Q5: How does real-time monitoring improve production?

A5: Sensors and control systems enable immediate adjustments, preventing defects, minimizing downtime, and supporting preventive maintenance for stable production.

[1] https://www.coatinglinekt.com/news/how-fast-is-the-production-speed-of-an-automatic-powder-coating-line/

[2] https://patents.google.com/patent/CN109189036A/zh

[3] https://www.hinahcoatingline.com/news/automatic-powder-coating-machine-how-does-it-enhance-production-efficiency

[4] https://patents.google.com/patent/CN112452618A/zh

[5] https://www.rohnerspraybooths.com/blog/integrating-automation-into-your-finishing-process

[6] https://patents.google.com/patent/CN114328826B/zh

[7] https://www.fabtechexpo.com/news/automation-powder-coating-production

[8] https://patents.google.com/patent/CN1955979A/zh

[9] https://reasonablechoice.net/en/blog/automation-of-powder-coating-application

[10] https://blog.csdn.net/2401_84911273/article/details/138954445

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.