Content Menu

● Introduction

● Understanding Lean Manufacturing

>> What is Lean Manufacturing?

>> Importance of Lean in Powder Coating

● The Role of Data Management Systems

>> What is a Data Management System?

>> Key Features of Data Management Systems

● How Data Management Systems Support Lean Manufacturing

>> Enhancing Visibility and Control

>> Reducing Waste

>> Facilitating Continuous Improvement

>> Supporting Predictive Maintenance

>> Enhancing Employee Engagement

● Case Studies: Successful Implementations

>> Case Study 1: Streamlining Operations

>> Case Study 2: Reducing Waste

>> Case Study 3: Improving Quality Control

● Challenges and Considerations

>> Implementation Challenges

>> Choosing the Right System

● Future Trends in Data Management and Lean Manufacturing

>> Industry 4.0 and Smart Manufacturing

>> Sustainability and Environmental Impact

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary benefit of using a data management system in powder coating?

>> 2. How does a data management system help reduce waste?

>> 3. What role does predictive maintenance play in lean manufacturing?

>> 4. How can employees benefit from a data management system?

>> 5. What should manufacturers consider when choosing a data management system?

Introduction

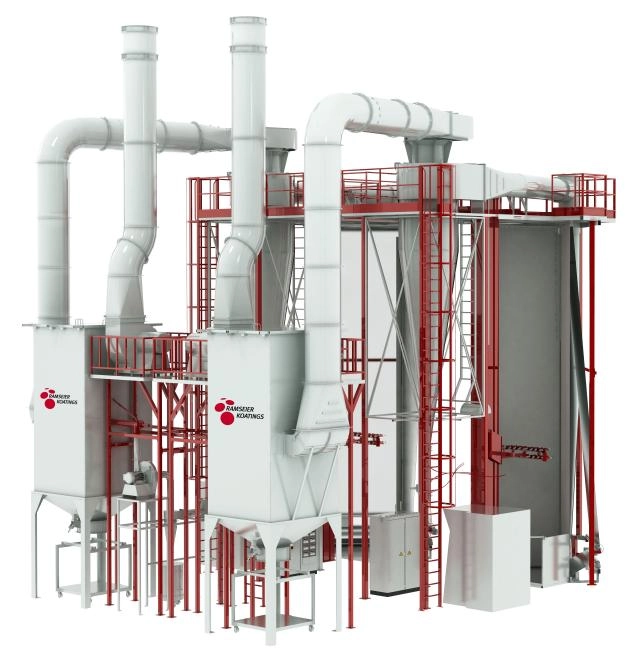

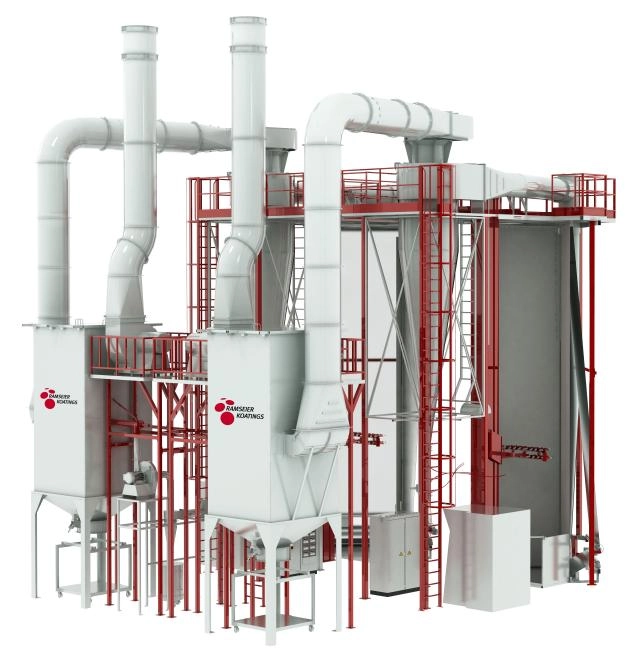

In the competitive landscape of manufacturing, lean principles have become essential for optimizing processes and reducing waste. The powder coating industry, known for its efficiency and quality demands, is increasingly adopting data management systems to enhance lean manufacturing practices. This article explores how these systems support lean methodologies, improve operational efficiency, and contribute to overall business success.

Understanding Lean Manufacturing

What is Lean Manufacturing?

Lean manufacturing is a systematic approach to identifying and eliminating waste through continuous improvement. It focuses on maximizing customer value while minimizing resources. The core principles of lean manufacturing include:

- Value Identification: Understanding what the customer values.

- Value Stream Mapping: Analyzing the flow of materials and information.

- Creating Flow: Ensuring smooth production processes.

- Establishing Pull: Producing only what is needed when it is needed.

- Pursuing Perfection: Continuously improving processes.

Importance of Lean in Powder Coating

In powder coating, lean manufacturing is crucial due to the need for high-quality finishes and efficient production cycles. The industry faces challenges such as material waste, equipment downtime, and quality control issues. Implementing lean principles helps manufacturers streamline operations, reduce costs, and enhance product quality.

The Role of Data Management Systems

What is a Data Management System?

A data management system (DMS) is a software solution designed to collect, store, and analyze data from various sources within a manufacturing environment. In the context of powder coating, a DMS integrates with production equipment, quality control systems, and inventory management to provide real-time insights into operations.

Key Features of Data Management Systems

1. Real-Time Monitoring: Continuous tracking of production parameters such as temperature, humidity, and powder application rates.

2. Data Analytics: Analyzing trends and patterns to identify inefficiencies and areas for improvement.

3. Integration Capabilities: Seamless connection with other systems like ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management).

4. Reporting Tools: Generating detailed reports for quality control, compliance, and performance evaluation.

5. User-Friendly Interfaces: Easy access to data for operators and management, facilitating informed decision-making.

How Data Management Systems Support Lean Manufacturing

Enhancing Visibility and Control

Data management systems provide manufacturers with real-time visibility into their operations. This transparency allows for better control over production processes, enabling quick responses to issues as they arise. For instance, if a machine shows signs of inefficiency, operators can address the problem immediately, reducing downtime and maintaining production flow.

Reducing Waste

One of the primary goals of lean manufacturing is to minimize waste. A DMS helps achieve this by:

- Tracking Material Usage: Monitoring powder consumption and identifying excess usage, which can lead to cost savings.

- Optimizing Inventory Levels: Ensuring that materials are available when needed without overstocking, thus reducing holding costs.

- Improving Quality Control: By analyzing data from quality checks, manufacturers can identify defects early and adjust processes to prevent rework and scrap.

Facilitating Continuous Improvement

Continuous improvement is a cornerstone of lean manufacturing. Data management systems support this by providing insights that drive process enhancements. For example, by analyzing production data, manufacturers can identify bottlenecks and implement changes to streamline workflows. This iterative process fosters a culture of improvement and innovation.

Supporting Predictive Maintenance

Predictive maintenance is a proactive approach that uses data analytics to predict equipment failures before they occur. By monitoring machine performance and analyzing historical data, manufacturers can schedule maintenance activities at optimal times, reducing unplanned downtime and extending equipment life.

Enhancing Employee Engagement

A data management system empowers employees by providing them with the information they need to perform their jobs effectively. When operators have access to real-time data, they can make informed decisions that contribute to lean practices. Additionally, involving employees in data analysis fosters a sense of ownership and accountability.

Case Studies: Successful Implementations

Case Study 1: Streamlining Operations

A leading powder coating manufacturer implemented a data management system to enhance its production efficiency. By integrating real-time monitoring and analytics, the company reduced its cycle time by 20%. The system provided insights into machine performance, allowing for timely maintenance and adjustments that improved overall throughput.

Case Study 2: Reducing Waste

Another manufacturer focused on minimizing material waste through a DMS. By tracking powder usage and application rates, the company identified areas where excess powder was being applied. Adjustments to the application process led to a 15% reduction in material costs, significantly impacting the bottom line.

Case Study 3: Improving Quality Control

A third case involved a manufacturer that struggled with quality inconsistencies. By implementing a data management system, the company was able to analyze quality metrics in real time. This led to the identification of specific process parameters that affected coating quality, resulting in a 30% decrease in defects.

Challenges and Considerations

Implementation Challenges

While the benefits of data management systems are clear, implementing these systems can pose challenges. Manufacturers must consider:

- Integration with Existing Systems: Ensuring that the DMS works seamlessly with current equipment and software.

- Training and Adoption: Providing adequate training for employees to effectively use the new system.

- Data Security: Protecting sensitive production data from cyber threats.

Choosing the Right System

Selecting the appropriate data management system is critical. Manufacturers should evaluate systems based on:

- Scalability: The ability to grow with the business.

- Customization: Flexibility to adapt to specific manufacturing processes.

- Support and Maintenance: Availability of technical support and system updates.

Future Trends in Data Management and Lean Manufacturing

Industry 4.0 and Smart Manufacturing

The advent of Industry 4.0 is transforming the manufacturing landscape. Data management systems are becoming increasingly sophisticated, incorporating technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning. These advancements enable even greater levels of automation, data analysis, and predictive capabilities.

Sustainability and Environmental Impact

As manufacturers face increasing pressure to adopt sustainable practices, data management systems will play a crucial role in tracking and reducing environmental impact. By optimizing resource usage and minimizing waste, these systems contribute to more sustainable manufacturing processes.

Conclusion

Data management systems are essential tools for supporting lean manufacturing in the powder coating industry. By enhancing visibility, reducing waste, facilitating continuous improvement, and supporting predictive maintenance, these systems empower manufacturers to operate more efficiently and effectively. As the industry continues to evolve, the integration of advanced technologies will further enhance the capabilities of data management systems, driving innovation and sustainability in powder coating.

Frequently Asked Questions

1. What is the primary benefit of using a data management system in powder coating?

The primary benefit is enhanced visibility and control over production processes, allowing for real-time monitoring and quick responses to issues.

2. How does a data management system help reduce waste?

It tracks material usage and optimizes inventory levels, ensuring that resources are used efficiently and minimizing excess.

3. What role does predictive maintenance play in lean manufacturing?

Predictive maintenance uses data analytics to anticipate equipment failures, allowing for timely maintenance and reducing unplanned downtime.

4. How can employees benefit from a data management system?

Employees gain access to real-time data, enabling them to make informed decisions and contribute to lean practices effectively.

5. What should manufacturers consider when choosing a data management system?

Manufacturers should evaluate scalability, customization options, and the availability of support and maintenance services.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.