Content Menu

● Understanding Your Swinger Powder Coating Equipment

● Routine Maintenance Practices

>> Daily Maintenance

>> Weekly Maintenance

>> Monthly Maintenance

● Best Cleaning Techniques

>> Cleaning the Spray Gun Properly

>> Maintaining the Powder Hopper

>> Keeping Air Supply Clean and Dry

● Troubleshooting Common Issues

>> Powder Buildup and Clogging

>> Inconsistent Spray Patterns

>> Equipment Downtime

● Proper Storage and Handling Practices

>> Storing Powder Materials

>> Equipment Storage When Not in Use

● Operator Training and Safety Considerations

>> Continuous Training

>> Safety Protocols

● Advanced Maintenance Tips

>> Use of Diagnostic Tools

>> Parts Replacement and Upgrades

● Environmental and Regulatory Compliance

● Frequently Asked Questions

● Conclusion

Maintaining your Swinger powder coating equipment is crucial for ensuring high-quality finishes, reducing downtime, and extending the life of your machinery. Powder coating is a popular and eco-friendly finishing process widely used in various industries for its durability and aesthetic appeal. However, to get the best performance from your equipment, routine maintenance and proper care are essential. This comprehensive guide outlines the best practices for maintaining your Swinger powder coating equipment, covering all critical aspects from cleaning and inspection to troubleshooting and storage.

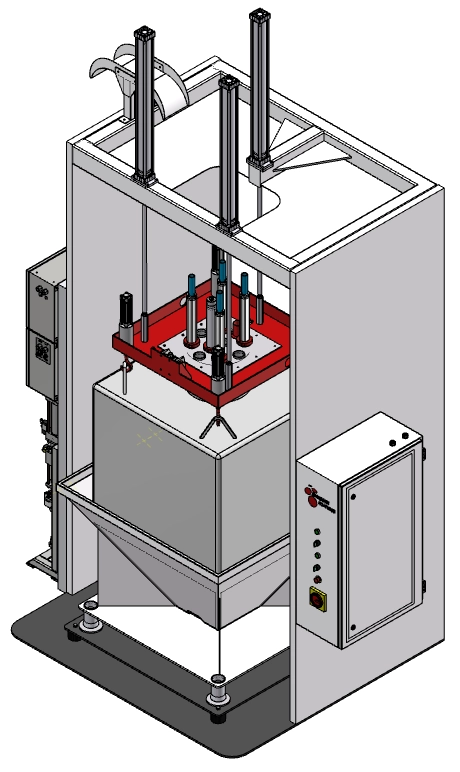

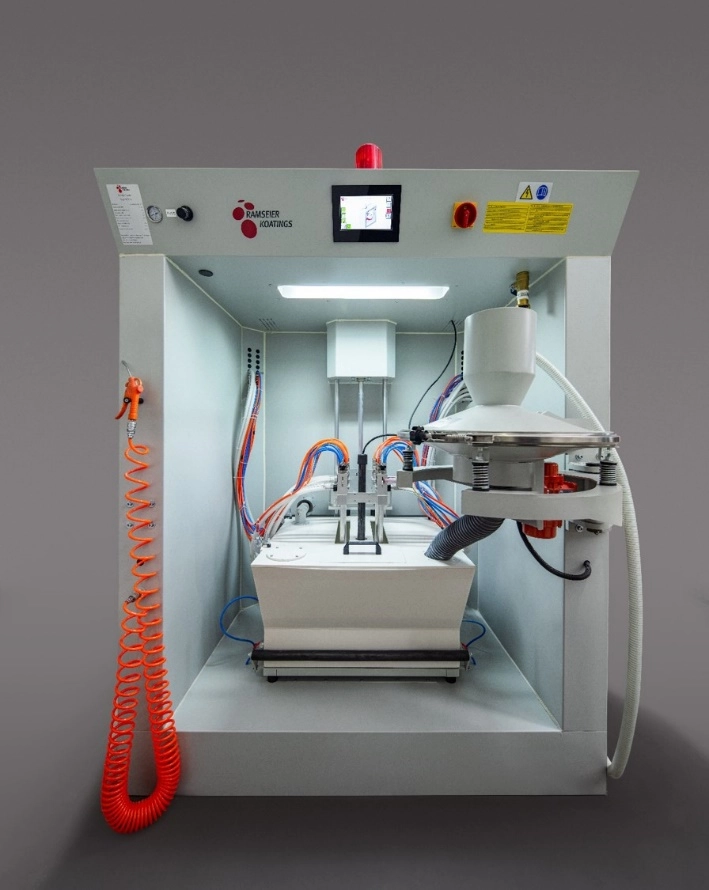

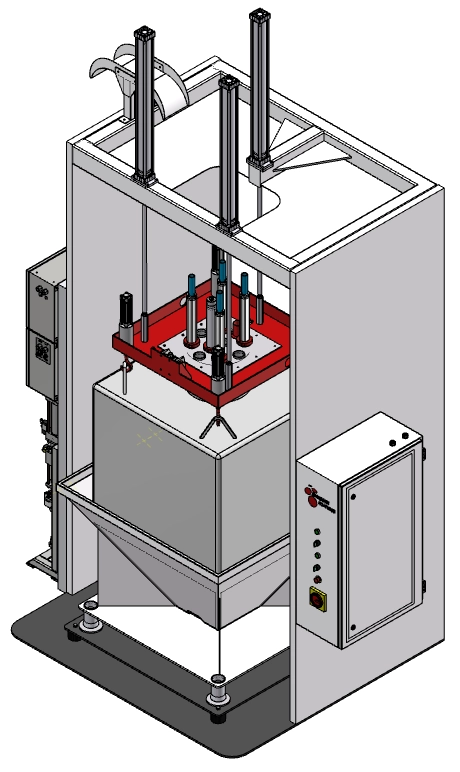

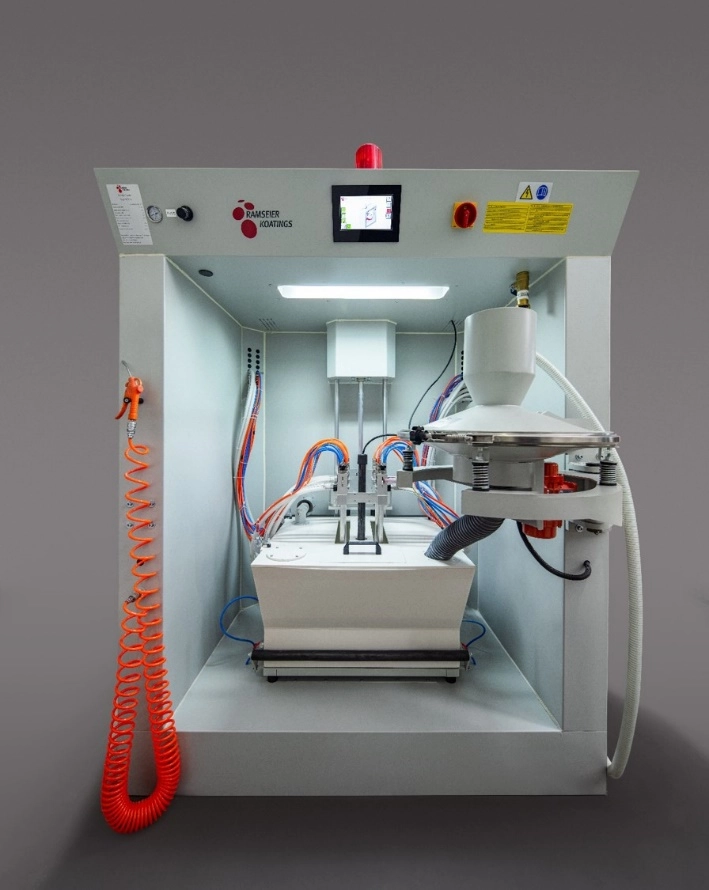

Understanding Your Swinger Powder Coating Equipment

Before diving into maintenance routines, it's important to understand the components and operation of your powder coating system. Swinger powder coating equipment typically includes the powder hopper, spray gun, pumping system, recovery unit, and curing oven. Each plays a vital role in the coating process, and their upkeep directly impacts the quality and efficiency of your production.

Routine Maintenance Practices

Daily Maintenance

Maintaining your equipment daily will prevent buildup and ensure smooth operation.

- Clean the Spray Gun: After each use, thoroughly clean the spray gun to remove any residual powder that may clog nozzles and affect spray consistency.

- Check Powder Hopper: Make sure the hopper is free of contaminants and moisture that could cause powder clumps or uneven coating.

- Inspect Air Filters: Clean or replace air filters to maintain proper airflow and prevent contamination entering the system.

- Wipe Down Surfaces: Clean external surfaces of the equipment to avoid powder accumulation that can affect electronic components.

Weekly Maintenance

In addition to daily checks, more in-depth weekly maintenance helps uphold system performance.

- Inspect Nozzles and Electrodes: Look for wear or damage and replace parts if necessary to ensure optimal powder flow and charging.

- Check Hose Connections: Tighten or replace any loose or worn hoses to prevent leaks or pressure drops.

- Lubricate Moving Parts: Apply suitable lubricants to mechanical parts as recommended in the manufacturer's manual.

- Test Powder Flow: Run a test spray to verify consistent powder delivery and adjust settings if needed.

Monthly Maintenance

Monthly maintenance includes detailed system checks that require more time but significantly enhance reliability.

- Calibrate Equipment: Check and adjust the settings on the spray gun, pumps, and recovery system to maintain accuracy.

- Clean Recovery Unit: Remove collected powder properly, and clean filters and cyclone separators to maintain suction efficiency.

- Inspect Electrical Components: Look for loose connections, frayed wires, or component overheating to avoid electrical failures.

- Review Software/Firmware Updates: Update any control software or firmware to ensure your system runs with the latest improvements and security patches.

Best Cleaning Techniques

Cleaning the Spray Gun Properly

The spray gun is one of the most critical parts of the system. When cleaning:

- Disassemble Components: Carefully dismantle the nozzle, electrodes, and other removable parts.

- Use Appropriate Cleaning Tools: Employ brushes and compressed air to remove powder residue without damaging delicate parts.

- Avoid Harsh Chemicals: Use manufacturer-approved solvents or cleaning agents to prevent corrosion or degradation.

Maintaining the Powder Hopper

- Prevent Moisture Exposure: Always use desiccants or dehumidifiers to keep the powder dry.

- Regular Powder Rotation: Avoid powder aging or hardening by rotating stock regularly and not mixing old and new powders.

Keeping Air Supply Clean and Dry

- Install Proper Air Dryers: Use refrigerated or desiccant air dryers to remove moisture from the compressed air.

- Routine Air Filter Replacement: Ensure that clean and dry air enters the system to reduce contamination risk.

Troubleshooting Common Issues

Powder Buildup and Clogging

- Cause: Powder moisture, static discharge issues, or dirty parts can cause powder to accumulate.

- Solution: Increase cleaning frequency, improve air drying, and check grounding connections on the gun and booth.

Inconsistent Spray Patterns

- Cause: Worn nozzles, faulty electrodes, or improper settings can disturb spray quality.

- Solution: Replace damaged parts, recalibrate the system, and verify electrical functionality.

Equipment Downtime

- Cause: Lack of routine maintenance or ignoring minor faults can lead to failures.

- Solution: Implement a strict maintenance schedule and train operators to recognize early warning signs.

Proper Storage and Handling Practices

Storing Powder Materials

- Keep Powder in Sealed Containers: Protect powders from moisture and dust contamination.

- Control Storage Temperature: Maintain stable temperatures to avoid powder degradation.

Equipment Storage When Not in Use

- Cover Equipment: Use dust covers to safeguard the machinery.

- Disconnect Power Supply: Prevent electrical hazards or unintended operation.

- Conduct Pre-Storage Cleaning: Ensure equipment is free of powder residues before storing.

Operator Training and Safety Considerations

Continuous Training

- Train operators regularly on equipment use and maintenance procedures.

- Promote awareness about signs of equipment malfunction.

Safety Protocols

- Use personal protective equipment (PPE) such as masks and gloves to prevent inhaling powder.

- Ensure proper ventilation in the work area.

- Follow manufacturer safety guidelines closely.

Advanced Maintenance Tips

Use of Diagnostic Tools

- Apply diagnostic software or tools offered by Swinger to monitor system health.

- Analyze data trends to predict and prevent equipment failures.

Parts Replacement and Upgrades

- Replace worn parts promptly using manufacturer-certified components.

- Consider system upgrades that enhance efficiency or ease of maintenance.

Environmental and Regulatory Compliance

- Properly dispose of waste powders and cleaning solvents.

- Maintain records of maintenance and inspections for regulatory audits.

- Stay informed on changing environmental regulations affecting powder coating operations.

Frequently Asked Questions

Q1: How often should I clean the spray gun on my Swinger powder coating equipment?

*A1: It is recommended to clean the spray gun after every use to prevent buildup and clogging.*

Q2: What is the best way to prevent moisture from affecting powder coating quality?

*A2: Keeping powders in sealed containers and using air dryers in the compressed air system helps prevent moisture exposure.*

Q3: How can I tell if the nozzles or electrodes need replacing?

*A3: Signs include inconsistent spray patterns, powder buildup, or physical damage during inspection.*

Q4: What safety measures are necessary while operating Swinger powder coating equipment?

*A4: Operators should wear PPE, maintain proper ventilation, and follow manufacturer safety instructions.*

Q5: How does regular maintenance reduce equipment downtime?

*A5: Timely cleaning and inspections help identify potential issues before they cause failures, ensuring continuous operation.*

Conclusion

Maintaining your Swinger powder coating equipment diligently will enhance the quality of your coatings, minimize repair costs, and maximize equipment life. By implementing daily, weekly, and monthly maintenance practices, properly cleaning equipment, addressing common issues promptly, and following safety and storage guidelines, you ensure optimal performance of your powder coating system. Continuous operator training and staying current with environmental and regulatory requirements bolster your operational efficiency further. Prioritizing maintenance enables you to reap the full benefits of your Swinger equipment in your powder coating operations.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.