Content Menu

● Understanding Powder Hoppers and Their Importance

>> What Are Powder Hoppers?

>> Why Maintenance and Cleaning Matter

● Best Practices for Maintaining Powder Hoppers

>> Regular Inspection and Monitoring

>> Scheduled Preventive Maintenance

>> Monitoring Powder Characteristics

● Best Practices for Cleaning Powder Hoppers

>> Preparing for Cleaning

>> Choosing the Right Cleaning Method

>>> Dry Cleaning Methods

>>> Wet Cleaning Methods

>> Cleaning Procedures

>> Post-Cleaning Inspection

● Safety Considerations in Hopper Maintenance and Cleaning

>> Dust Explosion Prevention

>> Personal Protective Equipment (PPE)

>> Safe Lockout-Tagout Procedures

● Troubleshooting Common Problems

>> Powder Build-up and Bridging

>> Corrosion and Surface Damage

>> Sensor Malfunction

>> Leakage and Contamination

● Advanced Maintenance Tips for Longevity

>> Using Liners and Coatings

>> Automation and Remote Monitoring

>> Staff Training and Documentation

● Conclusion

● Frequently Asked Questions (FAQs)

Powder hoppers are essential components in many industrial processes, especially in pharmaceutical, chemical, food, and powder coating industries. Proper maintenance and cleaning of powder hoppers ensure operational efficiency, prevent contamination, extend equipment life, and promote workplace safety. Given their crucial role in handling fine powders, powders' properties like flowability, moisture sensitivity, and contamination risk require specialized attention during maintenance and cleaning procedures.

This comprehensive article will cover the best practices for maintaining and cleaning powder hoppers, including detailed guidelines on inspection, cleaning methods, safety protocols, and troubleshooting common problems. By following these recommendations, operators and maintenance personnel can optimize hopper performance and minimize downtime.

Understanding Powder Hoppers and Their Importance

What Are Powder Hoppers?

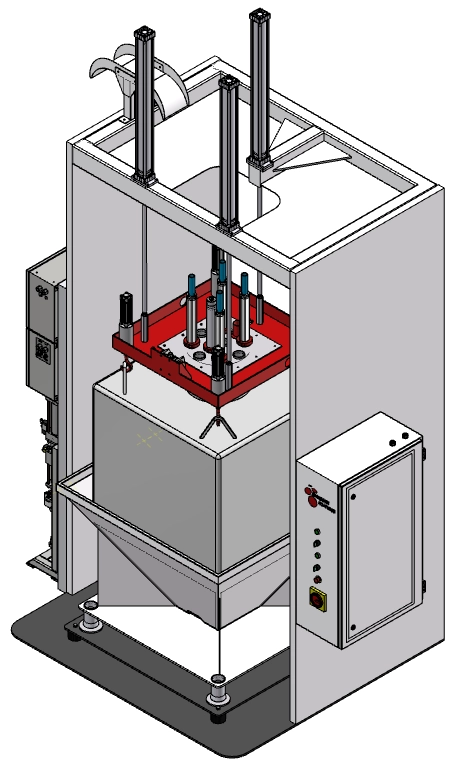

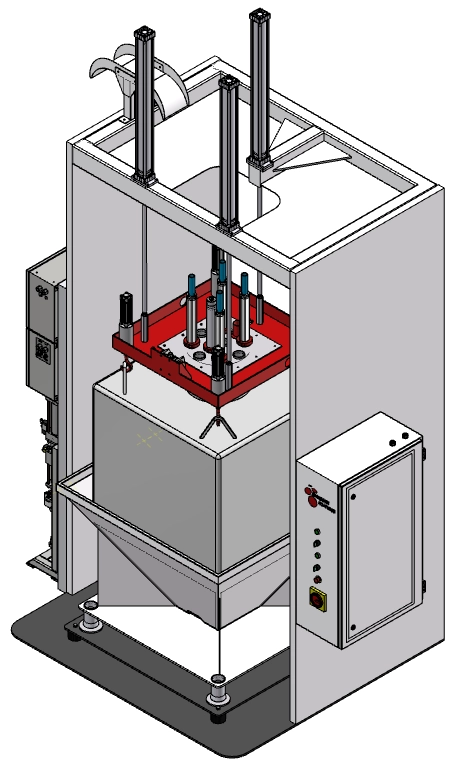

Powder hoppers are storage vessels or containers designed to hold and feed bulk powders into processing equipment. They regulate the flow of powders, ensuring consistent delivery rates during manufacturing or packaging operations. Hopper designs typically consider powder properties, flow characteristics, and the intended application.

Why Maintenance and Cleaning Matter

Regular maintenance and cleaning of hoppers prevent issues such as powder build-up, contamination, clogging, and equipment degradation. Without proper attention, these issues can lead to product quality problems, production delays, increased operating costs, and even safety hazards.

Best Practices for Maintaining Powder Hoppers

Regular Inspection and Monitoring

Routine inspections are the foundation of effective hopper maintenance.

- Visual Inspection: Check for signs of wear, corrosion, dents, or cracks on hopper walls and discharge outlets. Damaged surfaces may affect powder flow and contaminate the batch.

- Seal and Gasket Condition: Examine seals and gaskets for wear or brittleness to prevent leaks or contamination.

- Structural Integrity: Inspect supporting frames and mounting points for stability.

- Sensor and Instrumentation Check: Ensure flow meters, level sensors, and temperature gauges are functioning correctly.

Scheduled Preventive Maintenance

Implement a scheduled preventive maintenance program that includes:

- Lubrication of moving parts such as valves, agitators, or vibrators.

- Tightening of fasteners and checking alignment.

- Calibration of sensors to maintain accurate monitoring.

- Replacement of worn-out components before failure.

Monitoring Powder Characteristics

Maintaining powder properties is critical. Monitor moisture levels, flowability, and particle size distribution regularly, since changes may indicate hopper issues or environmental problems like humidity intrusion.

Best Practices for Cleaning Powder Hoppers

Preparing for Cleaning

Before beginning cleaning procedures, follow these preparation steps:

- Shutdown Procedures: Ensure the hopper is isolated from the process with proper lockout-tagout (LOTO) procedures to prevent accidental startup.

- Empty the Hopper: Fully discharge all powder contents, using pneumatic or mechanical means if necessary.

- Safety Precautions: Provide personal protective equipment (PPE) for operators such as masks, gloves, and safety glasses due to dust exposure risks.

Choosing the Right Cleaning Method

The cleaning method depends on powder type, hopper material, hopper design, and contamination risk.

Dry Cleaning Methods

- Vacuum Cleaning: Industrial vacuum systems efficiently remove residual powders, especially useful with dry, non-toxic materials.

- Compressed Air: Blowing compressed air can dislodge powder particles from hard-to-reach areas but should be used cautiously to avoid dust dispersion.

- Brushes and Scrapers: Manual removal of stubborn powder residues with soft brushes or plastic scrapers.

Wet Cleaning Methods

- High-Pressure Washing: Using water with detergents to clean sticky or caked powders from hopper surfaces.

- Chemical Cleaning: Applying solvents or detergents compatible with hopper materials and powders to dissolve residues.

- Steam Cleaning: Effective for sterilization and removing oils or fats in food and pharmaceutical applications.

Cleaning Procedures

- Clean the interior surfaces thoroughly, paying attention to corners, seams, and discharge outlets where powders can accumulate.

- Rinse surfaces to remove any cleaning agents thoroughly to avoid contamination.

- Dry the hopper completely before reassembling or restarting operations, especially for powders sensitive to moisture.

Post-Cleaning Inspection

- Inspect surfaces after cleaning to confirm all residues are removed.

- Check seals, gaskets, and valves for integrity.

- Reassemble any removed components and verify proper installation.

Safety Considerations in Hopper Maintenance and Cleaning

Dust Explosion Prevention

Powders can create combustible dust clouds, posing an explosion risk during cleaning.

- Ensure adequate ventilation when working with dust.

- Avoid open flames or sparks near hopper cleaning areas.

- Use explosion-proof vacuum cleaners designed for combustible dust.

Personal Protective Equipment (PPE)

- Operators should wear appropriate PPE such as respirators, gloves, and eye protection.

- Training on safe handling and cleaning procedures is critical.

Safe Lockout-Tagout Procedures

Always isolate power sources and machinery prior to maintenance or cleaning to prevent accidental energization.

Troubleshooting Common Problems

Powder Build-up and Bridging

- Cause: Moisture, poor powder flowability, or hopper design defects.

- Solution: Use vibrators or air cannons to promote powder flow. Review hopper geometry to reduce stagnant zones.

Corrosion and Surface Damage

- Cause: Harsh cleaning agents or abrasive powders.

- Solution: Select compatible cleaning chemicals and consider surface coatings or liners.

Sensor Malfunction

- Cause: Dust deposits or mechanical damage.

- Solution: Regular sensor cleaning and calibration.

Leakage and Contamination

- Cause: Damaged seals or gaskets.

- Solution: Routine inspection and timely replacement of seals.

Advanced Maintenance Tips for Longevity

Using Liners and Coatings

Applying liners or surface coatings can reduce wear, facilitate cleaning, and improve powder flow.

Automation and Remote Monitoring

Integrate sensors for condition monitoring to predict maintenance needs, reducing manual inspection frequency and preventing failures.

Staff Training and Documentation

Ensure staff receive ongoing training on maintenance and cleaning protocols. Maintain detailed logs and checklists to track activities and identify trends.

Conclusion

Maintaining and cleaning powder hoppers are vital practices to uphold product quality, ensure safety, and enhance process efficiency. By implementing routine inspections, appropriate cleaning methods, robust safety procedures, and leveraging advanced technologies, industries can maximize hopper lifespan and operational reliability.

Frequently Asked Questions (FAQs)

1. How often should powder hoppers be cleaned?

The cleaning frequency depends on the type of powder, production schedule, and contamination risk, but a general rule is to clean after each batch or production shift to prevent buildup and cross-contamination.

2. What is the safest cleaning method for powder hoppers?

Vacuum cleaning using explosion-proof equipment combined with wet cleaning (when safe) is preferred. Avoid compressed air blowing unless proper containment is possible to reduce dust exposure.

3. Can chemical cleaning damage powder hoppers?

Yes, certain chemicals can corrode hopper surfaces or damage seals. Always select cleaning agents compatible with hopper materials and powders handled.

4. How can powder bridging be prevented inside hoppers?

Ensure hopper designs incorporate steep wall angles and use vibrators or aeration devices to keep powders flowing smoothly.

5. What PPE is essential during hopper maintenance and cleaning?

Respirators, gloves, eye protection, and protective clothing are necessary to guard against dust inhalation, chemical exposure, and physical injuries.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.