Content Menu

● Understanding Automation in Powder Coating Lines

>> What Is Automation in Powder Coating?

>> Benefits of Automation in Powder Coating

● Planning for Automation Implementation

>> Assess Your Current Process

>> Define Clear Objectives

>> Budgeting and Return on Investment (ROI)

● Choosing the Right Automation Equipment

>> Automated Powder Application Systems

>> Conveyors and Material Handling

>> Curing Ovens and Quality Control

● Integration and Installation

>> System Compatibility and Communication

>> Phased Installation Approach

>> Staff Training and Change Management

● Optimizing Automated Powder Coating Lines

>> Regular Maintenance and Troubleshooting

>> Monitoring and Data Analytics

>> Flexibility for Product Variations

● Common Challenges & How to Address Them

>> Initial High Costs

>> Integration Complexity

>> Workforce Adaptation

>> Maintaining Quality Standards

● Future Trends in Powder Coating Automation

● FAQ

Automation has become a transformative force in the manufacturing sector, particularly in powder coating lines where precision, efficiency, and consistency are essential. Implementing automation can lead to significant improvements in production speed, product quality, and operational safety. However, to maximize these benefits, companies must follow best practices that ensure smooth integration, optimal performance, and long-term success.

This article provides a comprehensive guide for manufacturers looking to introduce automation to their powder coating lines, detailing strategies, essential considerations, and practical tips.

Understanding Automation in Powder Coating Lines

What Is Automation in Powder Coating?

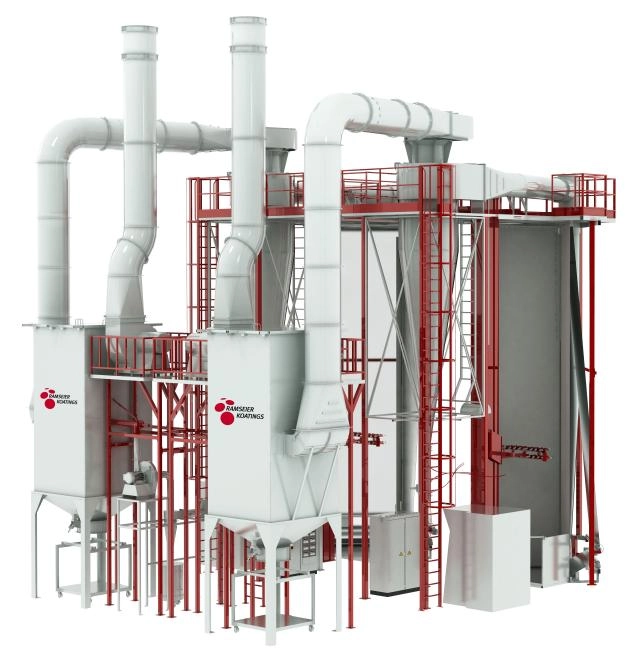

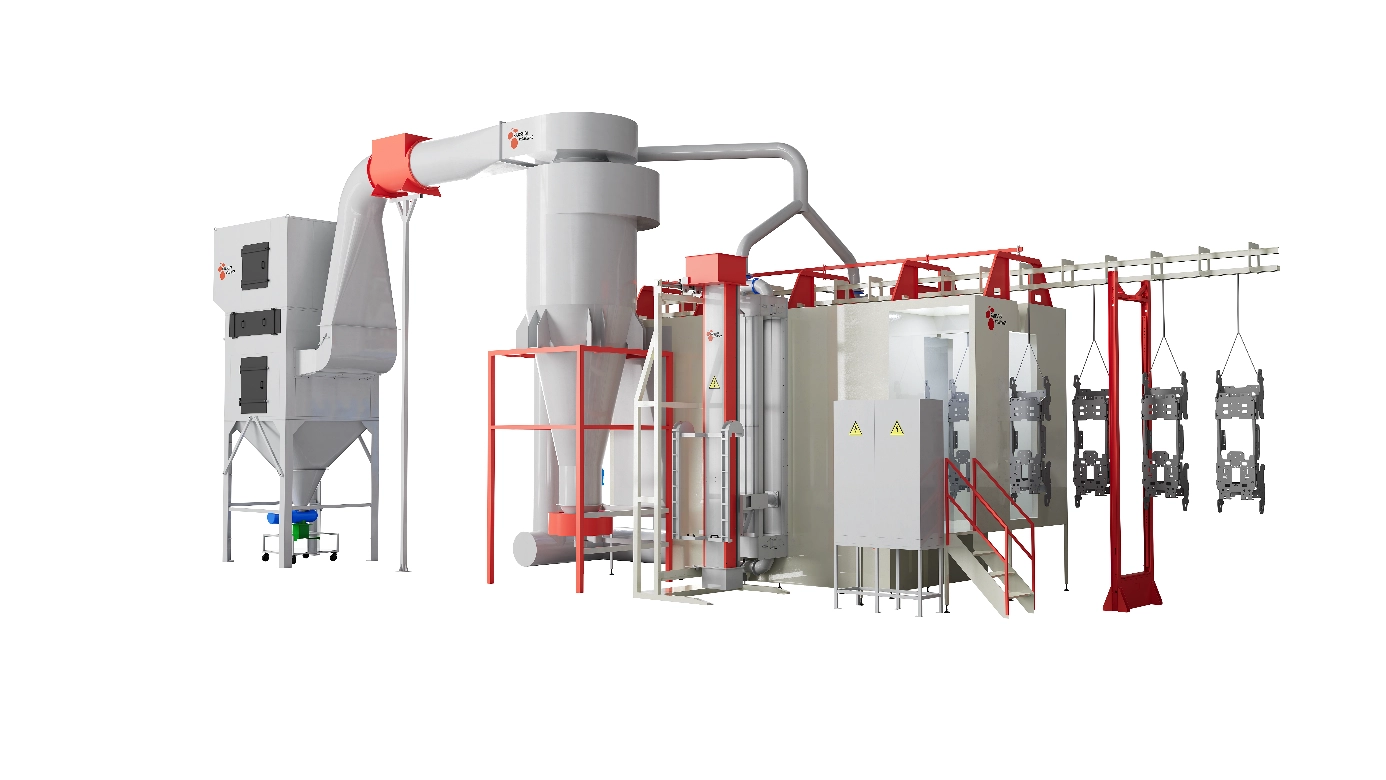

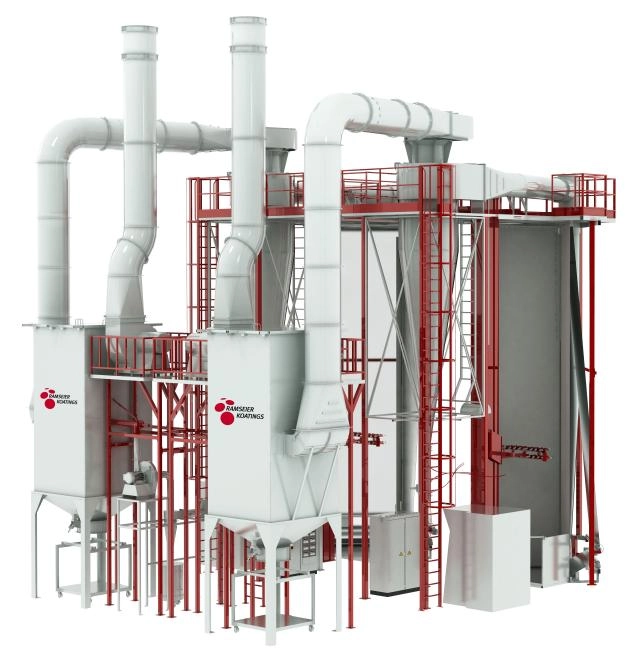

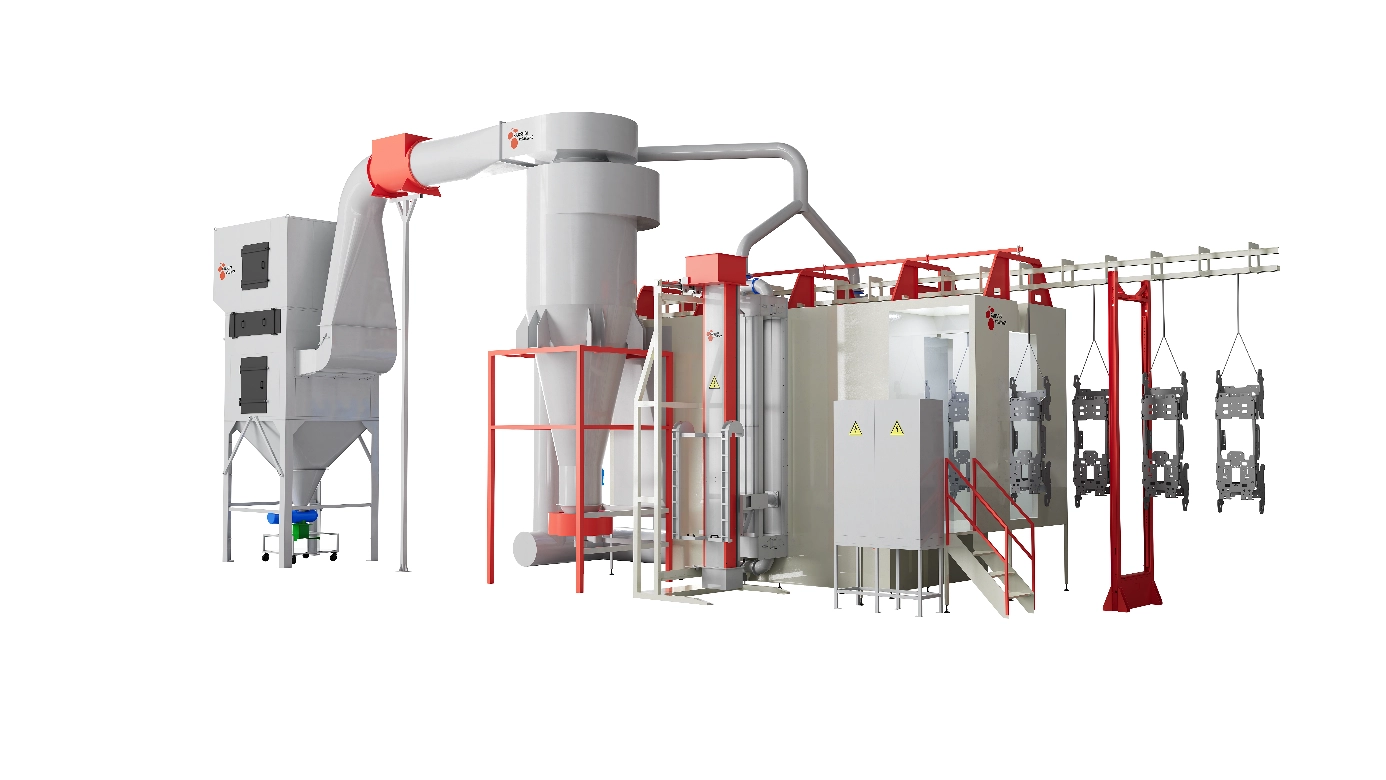

Automation in powder coating involves deploying machinery, controls, and software to perform coating tasks with minimal human intervention. This can include automated spray guns, conveyors, curing ovens, and robotic arms that handle objects for coating and curing. The goal is to reduce manual labor, increase repeatability, eliminate human error, and achieve uniform coating thickness and finish.

Benefits of Automation in Powder Coating

Automating a powder coating line offers numerous advantages:

- Improved Consistency: Automated systems apply powder uniformly, resulting in a high-quality finish every time.

- Increased Throughput: Automation accelerates processes such as coating application and curing, boosting production rates.

- Reduced Waste: Precise powder application minimizes overspray, lowering material costs and environmental impact.

- Enhanced Safety: Reducing manual handling of powder and exposure to chemicals decreases workplace hazards.

- Cost Savings: Though the initial investment may be high, automation reduces labor costs and scrap rates in the long run.

Planning for Automation Implementation

Assess Your Current Process

Before adding automation, thoroughly evaluate the existing coating line. Identify bottlenecks, repetitive manual tasks, and quality variability points. Document current production volumes, cycle times, defect rates, and labor usage to create a baseline for measuring improvements.

Define Clear Objectives

Clearly outline goals for automation implementation. Examples include:

- Reducing cycle time by X%

- Increasing throughput to meet demand

- Achieving uniform coating thickness within defined tolerances

- Lowering powder consumption and waste

- Enhancing safety compliance

Clear objectives will guide decisions about which automation technologies to invest in and which processes to prioritize.

Budgeting and Return on Investment (ROI)

Determine a realistic budget that covers equipment, installation, staff training, and ongoing maintenance. Consider not only upfront costs but also long-term savings from labor reduction and material efficiency. Calculate the expected ROI and payback period to justify the investment to stakeholders.

Choosing the Right Automation Equipment

Automated Powder Application Systems

The core of any automated powder coating line is the application system. Choose among options such as robotic arms, reciprocating guns, or carousel systems based on:

- Part size and complexity

- Production volume and speed requirements

- Powder type and application technique (tribo, corona, or electrostatic spray)

Robotic systems offer high flexibility for complex geometries, while fixed systems are better suited for high-volume, simple parts.

Conveyors and Material Handling

Efficient material transport is critical to seamless automation. Select conveyor systems that match your product size, weight, and throughput goals. Options include:

- Chain conveyors for heavy loads

- Belt conveyors for lightweight and small parts

- Roller conveyors for rectangular or palletized products

Automated loading and unloading devices can further reduce manual intervention.

Curing Ovens and Quality Control

Automated ovens with precise temperature control ensure consistent curing results. Integration with sensors and feedback systems helps maintain quality standards and prevent under- or over-curing. Including automated inspection equipment such as optical scanners or coating thickness gauges supports real-time quality monitoring.

Integration and Installation

System Compatibility and Communication

Ensure all automation components communicate effectively via control systems. Use industry-standard protocols like PLC (programmable logic controller) programming or SCADA (supervisory control and data acquisition) for centralized control and data collection. Compatibility reduces downtime and simplifies troubleshooting.

Phased Installation Approach

Implement automation in phases to minimize disruption. For example, start by automating the powder application process, then gradually add conveyors, curing, and quality control systems. Validate each phase thoroughly before moving on to the next.

Staff Training and Change Management

Successful automation requires well-trained operators and maintenance personnel. Provide comprehensive training to build confidence and reduce errors. Communicate clearly about how automation benefits their work to overcome resistance and foster a smooth transition.

Optimizing Automated Powder Coating Lines

Regular Maintenance and Troubleshooting

Establish preventive maintenance schedules to keep robotic arms, spray guns, conveyors, and ovens in peak condition. Promptly address issues such as spray nozzle clogs, conveyor misalignments, or sensor failures to prevent production losses.

Monitoring and Data Analytics

Use automation software to collect data on production rates, powder usage, cycle times, and quality metrics. Analyze this data regularly to identify trends, anticipate failures, and refine processes for continuous improvement.

Flexibility for Product Variations

Design automation systems with flexibility to handle changes in part design, size, or volume. Modular robotic programming and adjustable conveyor settings can accommodate evolving production needs without costly retrofits.

Common Challenges & How to Address Them

Initial High Costs

Automation can require large upfront investment in equipment and infrastructure. Mitigate this by prioritizing automation for processes with the biggest ROI and exploring leasing or financing options.

Integration Complexity

Integrating diverse automation components can create technical challenges. Work with experienced system integrators and vendors who offer end-to-end solutions and post-installation support.

Workforce Adaptation

Operators may resist changes due to fear of job loss or new technology. Engage employees early in the process, provide thorough training, and focus on how automation enhances their roles.

Maintaining Quality Standards

Automated processes can sometimes produce defects if not properly calibrated. Use feedback loops, automated inspection, and regular quality audits to maintain standards.

Future Trends in Powder Coating Automation

- AI and Machine Learning: Advanced algorithms will enable predictive maintenance, adaptive spray control, and defect detection.

- IoT Integration: Connected sensors will provide real-time data across the entire production line for smarter decision-making.

- Sustainability Focus: Automation will increasingly emphasize energy efficiency, powder recycling, and waste reduction.

FAQ

Q1: How long does it typically take to implement automation in a powder coating line?

A1: Implementation timelines vary based on system complexity but generally range from several weeks to a few months for phased integrations.

Q2: Can automation systems handle different powder colors and types without reconfiguration?

A2: Modern systems often have quick-change modules and programmable settings to accommodate different powders with minimal downtime.

Q3: How does automation improve powder usage efficiency?

A3: Automated spray guns apply powder more precisely, reducing overspray and reclaiming excess powder for reuse.

Q4: What safety improvements come with automating powder coating?

A4: Automation reduces workers' exposure to powder particles, solvents, and moving machinery, improving workplace safety.

Q5: Is automation scalable for small and medium-sized coating operations?

A5: Yes, automation solutions can be modular and customizable to fit different production scales and budgets.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.