Content Menu

● Understanding Automated Powder Coating Systems

>> What Is Automated Powder Coating?

>> Benefits of Automation Over Manual Systems

● Key Components of Automated Powder Coating Solutions

>> Conveyor Systems

>> Automated Powder Spray Booths

>> Pretreatment and Washing Systems

>> Curing Ovens

>> Control and Monitoring Systems

● Selecting the Right Automated Powder Coating System for Your Production

>> Factors to Consider

>> Popular System Classes and Solutions

● Installation, Operation, and Maintenance Best Practices

>> Installation Considerations

>> Operating an Automated Powder Coating Line

>> Maintenance Tips

● Challenges and Limitations of Automated Powder Coating

● Frequently Asked Questions (FAQs)

Powder coating is a widely used finishing process that delivers durable, attractive, and corrosion-resistant coatings on metal and other substrates. For high-volume production environments, automation of powder coating processes has become essential to meet growing demands for speed, quality, and efficiency. Automated powder coating solutions combine advanced technology, conveyor systems, and precise application methods to maximize throughput while minimizing labor, waste, and errors. This article explores the best automated powder coating solutions tailored for high-volume production, detailing their features, benefits, and considerations for businesses operating in various industries.

Understanding Automated Powder Coating Systems

What Is Automated Powder Coating?

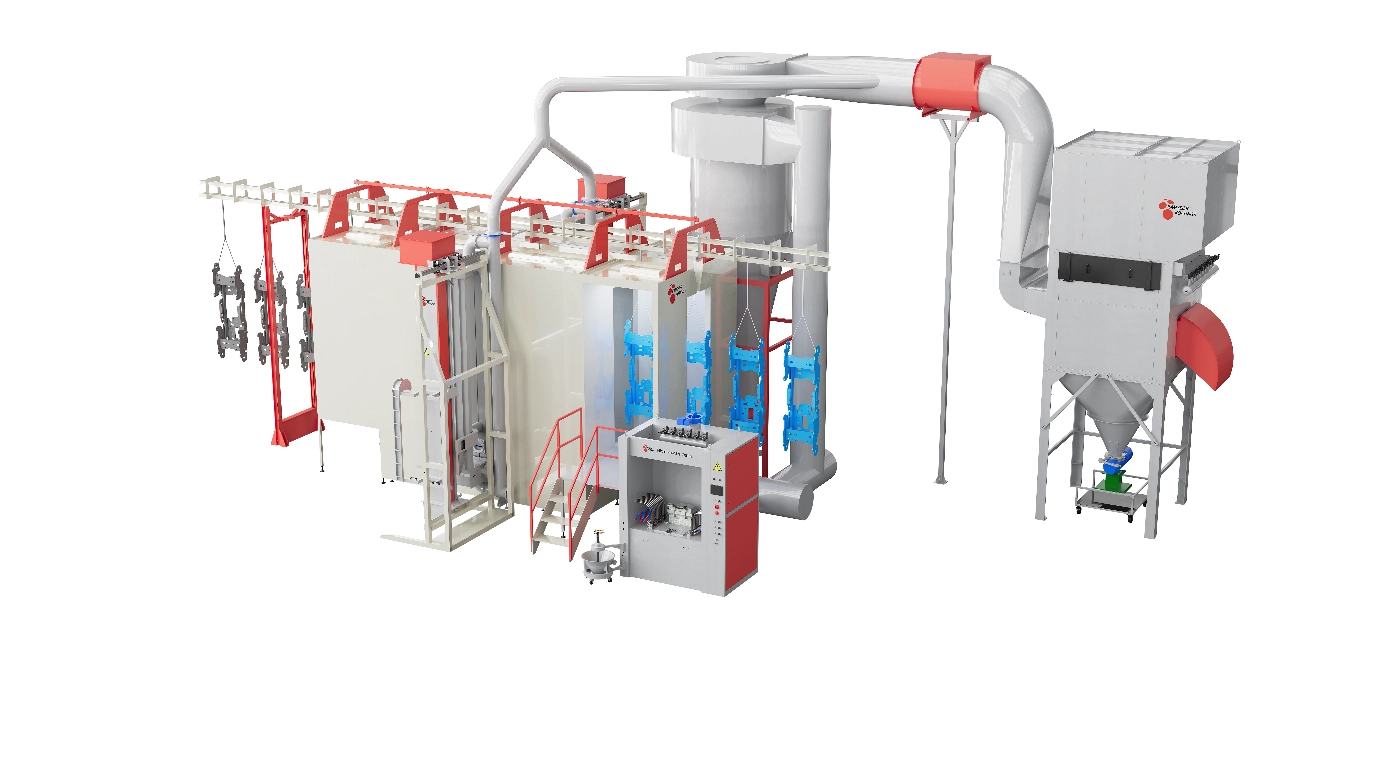

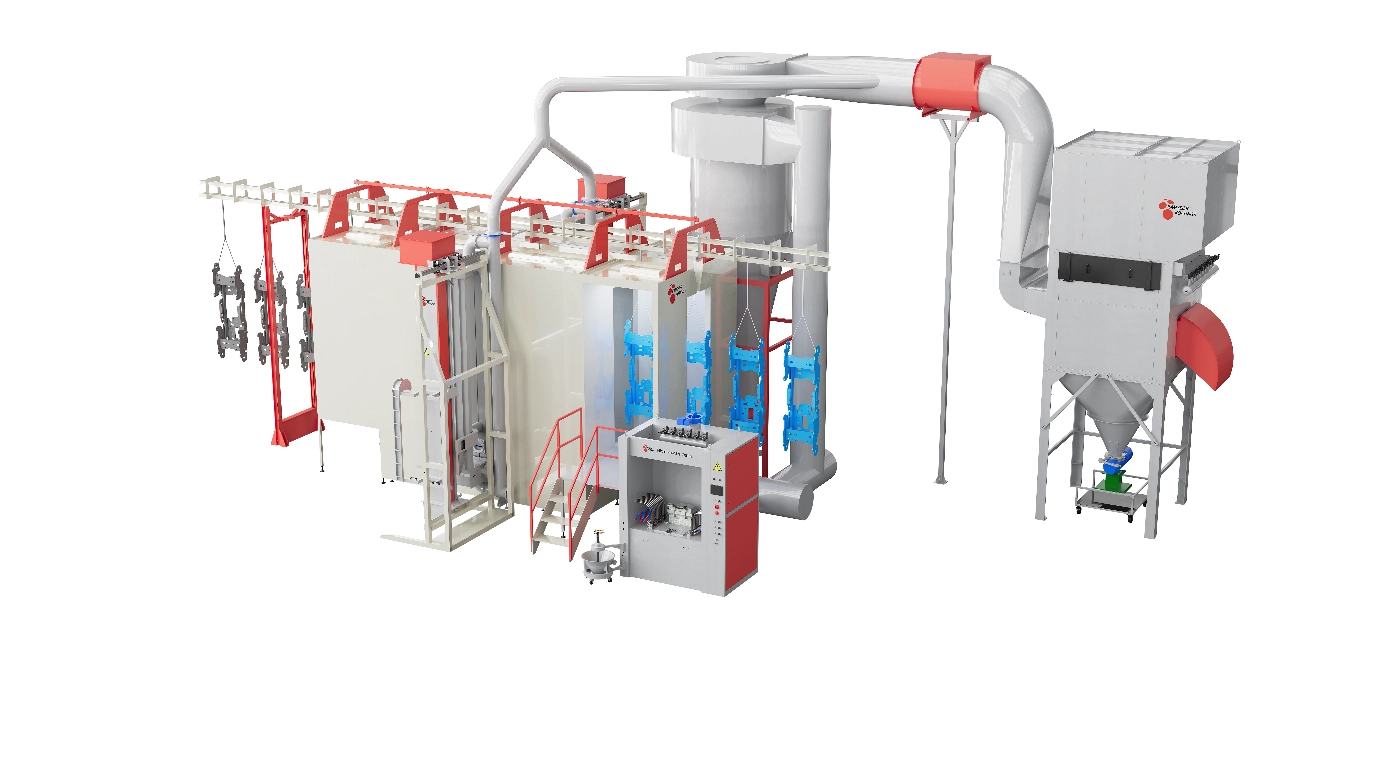

Automated powder coating systems typically involve machinery that applies powder coatings on parts without manual spraying for each item. These systems include several integrated components such as:

- Conveyor lines to move parts continuously through the coating process

- Automated spray booths with programmable guns that apply powder precisely

- Washers and pretreatment units to prepare surfaces

- Dry-off and curing ovens to finish the coating process

- Control systems that manage operations and monitor quality

Such systems are designed to handle large batches or continuous streams of parts efficiently, offering consistency and repeatability essential in high-volume production.[1][3][9]

Benefits of Automation Over Manual Systems

Compared to manual powder coating, automation offers significant advantages:

- Higher Throughput: Automated lines continuously coat parts faster than manual labor.

- Consistent Quality: Programmable guns provide uniform powder application for consistent coverage.

- Reduced Labor Costs: Less human intervention means savings on labor and fewer operator errors.

- Improved Efficiency: Fast color changes and minimal downtime enhance productivity.

- Waste Reduction: Controlled application minimizes powder overspray and cleanup.[3][7][1]

These benefits make automated systems ideal for industries like automotive, heavy machinery, appliances, and metal fabrication where volume and quality are critical.

Key Components of Automated Powder Coating Solutions

Conveyor Systems

The conveyor system is the backbone of automation, transporting parts through each process step. Options include:

- Chain-on-edge conveyors: Ideal for hanging parts securely in complex shapes.

- Overhead conveyors: Enable efficient movement in confined spaces.

- Roller conveyors: Suitable for flat or palletized items.

Well-designed conveyors improve line speed, reduce manual handling, and maintain order through the powder coating cycle.[9][10]

Automated Powder Spray Booths

Spray booths utilize robotic or fixed automatic guns that can be programmed for targeted coverage, including complex contours. Features include:

- Dynamic contouring: Guns adjust position to evenly coat irregular shapes.

- Multi-gun setups: Increase coverage area and speed.

- Reclamation systems: Capture overspray to reuse powder, reducing waste.

- Fast color change technology: Enables quick powder switching without dismantling equipment.[5][1]

These features help maintain coating precision and reduce cycle times for high-volume runs.

Pretreatment and Washing Systems

Successful coating depends heavily on surface preparation. Automated systems often integrate:

- Multi-stage washers: Typically 3- to 5-stage cleaning, including degreasing, rinsing, and phosphate coating.

- Single-stage washers: More energy- and resource-efficient options for less demanding applications.

- Dry-off ovens: Remove moisture before coating.

Pretreatment reduces defects and improves coating adhesion, which is critical for durable finishes in mass production.[3][9]

Curing Ovens

After powder application, curing ovens bake the coating to achieve full chemical and mechanical properties. Automated lines feature:

- Continuous ovens: Allow parts to pass through on conveyors for consistent heat exposure.

- Modular designs: Customizable length and temperature zones.

- Energy-efficient models: Reduce operational costs.

Proper curing ensures optimal finish hardness and longevity.[5][3]

Control and Monitoring Systems

Modern automated powder coating solutions come equipped with sophisticated control units that:

- Program spray parameters: Adjusting powder flow, gun speed, and pattern.

- Monitor line speed and part tracking: Ensuring accuracy in coating and curing.

- Integrate with management software platforms: For data analytics, maintenance scheduling, and inventory control.

Such controls minimize errors and support quality assurance in demanding production environments.[7][5]

Selecting the Right Automated Powder Coating System for Your Production

Factors to Consider

Choosing the best system depends on several variables:

- Production volume and speed requirements

- Part size, shape, and material

- Desired finish quality and coating thickness

- Available floor space and infrastructure

- Budget constraints and ROI expectations

- Level of automation desired (fully automatic vs. semi-automatic)

Balancing these factors will guide decisions on system components, automation level, and customization needs.[10][5]

Popular System Classes and Solutions

- Entry-Level Systems: Ideal for moderate volume with basic automation and manual loading/unloading.

- Mid-Range Systems: Incorporate multi-gun booths, automated conveyors, and integrated curing ovens.

- Premium Systems: Fully automated lines with robotic guns, continuous conveyors, fast color change, and advanced control software.

Some leading companies like Nordson, Wagner, and Powder-X offer modular systems tailored for specific industry needs with scalable options for growth.[1][3][5]

Installation, Operation, and Maintenance Best Practices

Installation Considerations

- Plan layout for smooth flow from wash to cure stations.

- Ensure adequate ventilation and powder recovery systems.

- Commission with expert support for programming and testing.

Operating an Automated Powder Coating Line

- Train operators thoroughly on control systems and safety.

- Monitor process parameters daily.

- Use quality powder materials compatible with the system.

Maintenance Tips

- Regularly clean spray guns and recoveries.

- Inspect conveyor chains and system components.

- Calibrate sensors and control units periodically to maintain consistency.[3][5]

Proper care extends equipment life and sustains high production quality.

Challenges and Limitations of Automated Powder Coating

While automated systems excel in efficiency and consistency, challenges include:

- High Initial Investment: Automation requires significant upfront capital.

- Complex Setup: Installation and tuning can be time-consuming.

- Space Requirements: Conveyor lines and ovens need substantial factory floor area.

- Limited Flexibility: Rapid design changes or small custom runs may be less efficient.

- Technical Expertise: Skilled staff needed for system management.[1][5]

Businesses must weigh these factors against production goals and volume scalability.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from automated powder coating systems?

A1: High-volume industries like automotive, appliance manufacturing, metal fabrication, and heavy machinery benefit due to their need for speed, consistency, and durable finishes.

Q2: How much can automation reduce labor costs in powder coating?

A2: Automation can significantly reduce labor costs by minimizing manual painting and handling, sometimes cutting related expenses by 30-50% depending on the scale.

Q3: Can automated powder coating systems handle complex shapes?

A3: Yes, with features like dynamic contouring and robotic guns that adjust to different angles, automated systems can coat intricate and irregular parts evenly.

Q4: What maintenance is required for automated powder coating lines?

A4: Regular cleaning of spray guns, conveyor inspection, sensor calibration, and routine preventative maintenance keep the system running smoothly and ensure quality control.

Q5: Are automated powder coating systems suitable for small production runs?

A5: Generally, no. These systems are optimized for high-volume production; small or custom runs might be better served by batch or manual systems due to setup times and cost efficiency.

[1] https://hmft.com/blogs/news/manual-vs-automatic-which-nordson-powder-coating-system-is-right-for-your-business

[2] https://huggingface.co/facebook/xm_transformer_unity_hk-en/commit/e37fd5ab9c6faf7a9547972cf6dace1c144c49c8.diff?file=en_zh_spm.dict

[3] https://www.powderx.com/automated-powder-coating-systems/

[4] https://www.scribd.com/document/813455547/%E8%8B%B1%E8%AF%AD%E8%AF%8D%E6%B1%87%E5%AD%A6%E5%AE%9E%E8%B7%B5

[5] https://www.wagner-group.com/us/industry/products/powder-coating/complete-systems/

[6] https://www.scribd.com/document/666776779/%E5%A6%82%E9%B1%BC%E5%BE%97%E6%B0%B4%E8%AE%B0%E5%8D%95%E8%AF%8D-%E4%B8%93%E4%B8%9A%E5%85%AB%E7%BA%A7%E8%AF%8D%E6%B1%87%E8%AF%AD%E5%A2%83%E8%AE%B0%E5%BF%86-%E8%8C%85%E9%A3%8E%E5%8D%8E-Z-Library

[7] https://reasonablechoice.net/en/blog/automation-of-powder-coating-application

[8] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[9] https://www.precisioncoatingtech.com/powder-coating-line/

[10] https://precisionconveyor.com/high-production-powder-coating-systems/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.