Content Menu

● Understanding Powder Coating

>> What is Manual Powder Coating?

>> What is Automated Powder Coating?

● Comparing Automation and Manual Powder Coating

>> Cost Considerations

>> Efficiency and Productivity

>> Quality and Consistency

>> Flexibility and Customization

● Environmental and Safety Considerations

>> Environmental Impact

>> Worker Safety

● When Should You Choose Manual Powder Coating?

● When Is Automation the Better Choice?

● Steps to Transition from Manual to Automated Coating

>> Evaluate Current Processes

>> Invest in Training and Technology

>> Implement Gradually

>> Monitor and Optimize

● Conclusion

● Frequently Asked Questions (FAQs)

Powder coating is a widely used finishing process that enhances the durability and aesthetics of metal products. Choosing between automation and manual powder coating can significantly impact your business's efficiency, cost, and product quality. This article explores the key differences between automated and manual powder coating, helping you determine which method best suits your business needs.

Understanding Powder Coating

Powder coating involves applying a dry powder to a metal surface electrostatically and then curing it under heat to form a protective layer. It offers superior resistance to corrosion, chipping, and fading, making it popular in automotive, appliances, and construction industries.

What is Manual Powder Coating?

Manual powder coating refers to the process where operators apply the powder coating by hand using spray guns. This traditional method allows for high control over application, especially on complex or irregular shapes.

What is Automated Powder Coating?

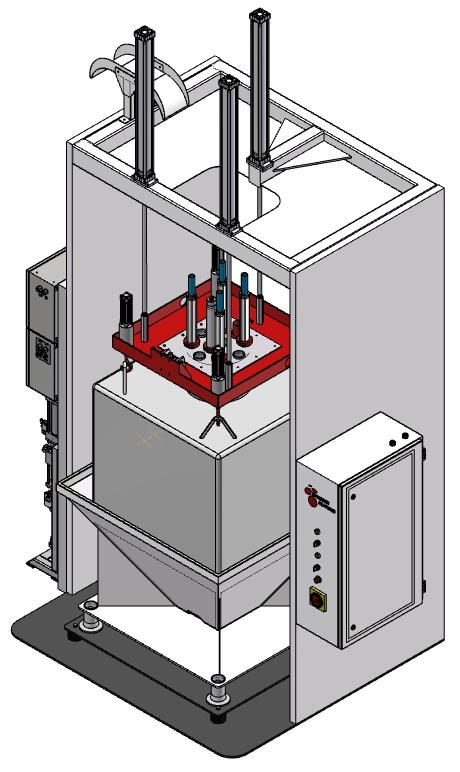

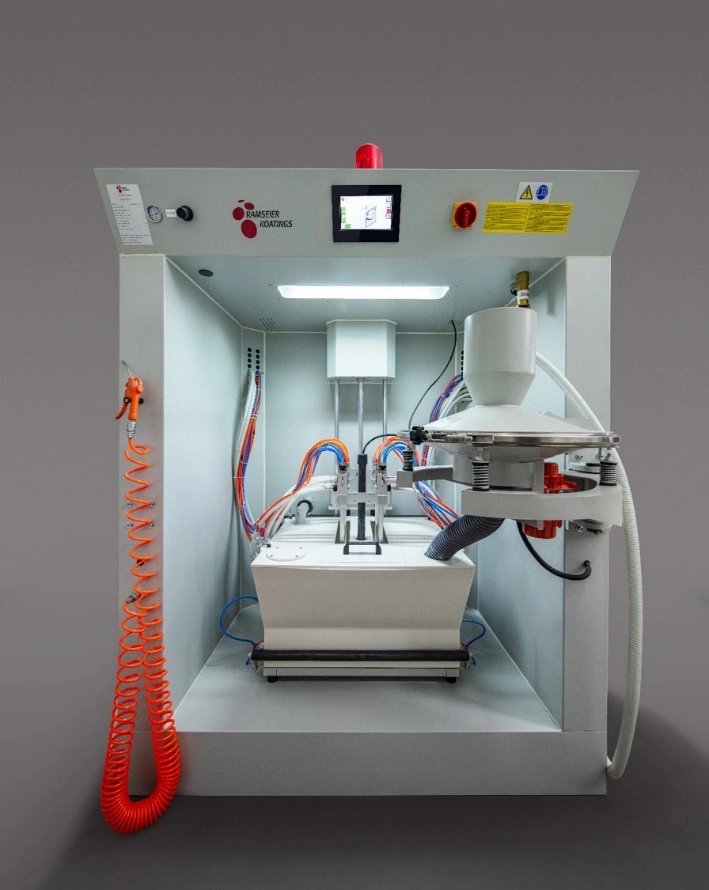

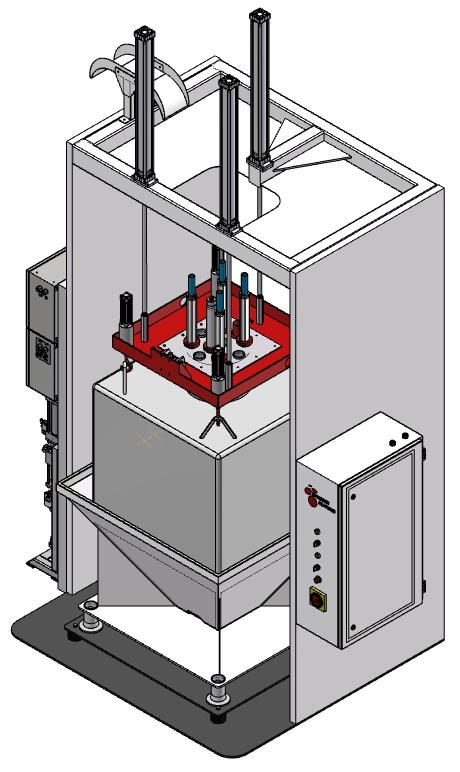

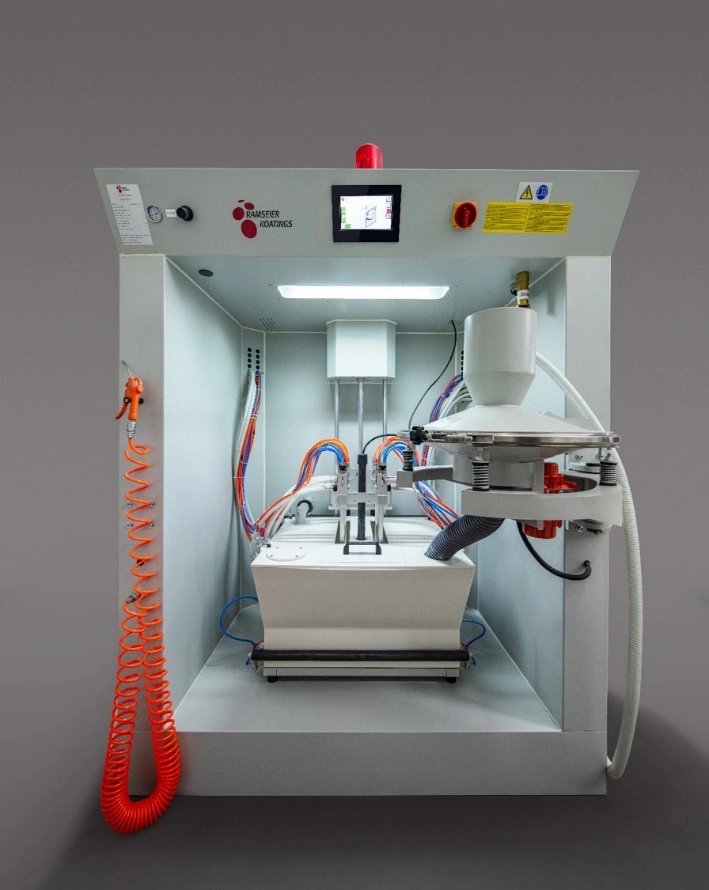

Automation in powder coating involves using robotic arms and conveyor systems to apply the powder. Robots are pre-programmed to cover products efficiently, ensuring uniform coating and reducing human error.

Comparing Automation and Manual Powder Coating

Choosing between these methods depends on several factors including production volume, product complexity, budget, and desired quality.

Cost Considerations

Manual powder coating requires less upfront investment but higher labor costs over time.

- Manual Coating Costs

- Low initial setup cost

- Higher labor and training expenses

- More powder waste due to human error

- Automated Coating Costs

- High capital investment in robotic systems

- Lower labor costs

- Reduced powder waste and energy savings

Efficiency and Productivity

Automation shines in high-volume production environments.

- Manual Efficiency

- Slower process due to human application

- More frequent breaks and human limitations

- Suitable for small batches or customized work

- Automation Efficiency

- Continuous operation with minimal downtime

- Faster coating speeds

- Ideal for large-scale, repetitive production runs

Quality and Consistency

Consistency is vital for brand reputation and product performance.

- Manual Quality

- Skilled operators can achieve excellent results

- Greater variability due to human factors

- Potential for heavier or uneven coats

- Automated Quality

- High repeatability and uniform thickness control

- Better adhesion and finish consistency

- Reduced defects and rework

Flexibility and Customization

Different projects may demand different approaches.

- Manual Flexibility

- Easier to adapt to new or customized designs

- Handles complex shapes and spots more precisely

- Suitable for low-volume or prototype runs

- Automated Flexibility

- Limited by robot programming and fixture design

- Better suited for standard, repetitive items

- Changeovers can be time-consuming and costly

Environmental and Safety Considerations

Both methods have environmental impacts but automation can offer greener advantages.

Environmental Impact

- Manual powder coating often leads to excess overspray and powder waste.

- Automated systems optimize powder usage and minimize airborne particles.

- Energy consumption is typically higher in manual setups due to inefficiencies.

Worker Safety

- Manual coating exposes workers to powder inhalation and repetitive strain injuries.

- Automation reduces direct human exposure to potentially hazardous powders.

- Compliance with workplace safety regulations is easier with automation.

When Should You Choose Manual Powder Coating?

Manual powder coating is ideal for businesses with:

- Small to medium production volumes

- High mix, low volume orders or custom designs

- Limited capital for automated systems

- Requirement for detailed work on complex or irregular parts

Manual application offers control and adaptability without significant upfront investment.

When Is Automation the Better Choice?

Automated powder coating suits businesses that:

- Produce large volumes of consistent products

- Seek to reduce labor costs and increase throughput

- Prioritize uniform quality and minimal waste

- Have capital available for technological investment

Automation can offer a competitive edge in scale and repeatability.

Steps to Transition from Manual to Automated Coating

For companies considering automation, a planned approach is essential.

Evaluate Current Processes

Analyze your production volume, product types, and quality requirements.

Invest in Training and Technology

Choose the right robots and software, and train your workforce to operate and maintain the systems.

Implement Gradually

Start automation with a pilot line before full facility rollout.

Monitor and Optimize

Continuously track performance and adjust to maximize efficiency and quality.

Conclusion

Choosing between automation vs manual powder coating depends on your business scale, product demands, budget, and long-term goals. Manual coating excels in flexibility and lower initial costs but faces limitations in speed and consistency. Automation, though costly upfront, delivers superior efficiency, quality, and environmental benefits for high-volume production. By carefully assessing your operations and future plans, you can select the most suitable powder coating method to enhance your product finish and business growth.

Frequently Asked Questions (FAQs)

Q1: How much does it cost to set up an automated powder coating system?

A1: Setup costs vary widely depending on system size and complexity but typically range from tens of thousands to several hundred thousand dollars.

Q2: Can manual powder coating produce the same quality as automated systems?

A2: Skilled operators can achieve high-quality finishes, but consistency and repeatability are generally better with automation.

Q3: Is manual powder coating safer for workers?

A3: No, automation tends to reduce workers' exposure to hazardous powders and repetitive tasks, improving safety.

Q4: How does powder waste compare between manual and automated coating?

A4: Automated systems optimize powder usage and have significantly less waste compared to manual spray, which often produces more overspray.

Q5: Can automated systems handle complex shapes and small batches?

A5: Automated systems are less flexible and usually better for large batches of standard shapes, whereas manual coating is more adaptable for complex or small runs.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.